Abstract

In this research, we systematically investigated equiatomic CoCrFeNi and CoCrFeMnNi high-entropy alloys (HEAs). Both of these HEA systems are single-phase, face-centered-cubic (FCC) structures. Specifically, we examined the tensile response in as-cast quaternary CoCrFeNi and quinary CoCrFeMnNi HEAs at room temperature. Compared to CoCrFeNi HEA, the elongation of CoCrFeMnNi HEA was 14% lower, but the yield strength and ultimate tensile strength were increased by 17% and 6%, respectively. The direct real-time evolution of structural defects during uniaxial straining was acquired via in situ neutron-diffraction measurements. The dominant microstructures underlying plastic deformation mechanisms at each deformation stage in as-cast CoCrFeNi and CoCrFeMnNi HEAs were revealed using the Convolutional Multiple Whole Profile (CMWP) software for peak-profile fitting. The possible mechanisms are reported.

1. Introduction

High-entropy alloys (HEAs), an intriguing new class of equiatomic solid-solution alloys, have attracted interest for their promising engineering applications as structural materials [1,2,3,4]. Comprehensive studies have been devoted to achieving excellent combinations of high strength and good ductility and determining the microstructural-evolution-driven deformation responses in single-phase, face-centered-cubic (FCC) HEAs under uniaxial loading [5,6,7,8,9,10,11,12,13,14]. The desired mechanical properties of a good strength–ductility balance in the HEAs may be tailored via tuning their elemental compositions [15,16].

The mechanical properties of FCC materials are strongly microstructure-sensitive in terms of the dislocation activities, whereby the interactions of dislocations with other defects and the dislocations strongly influence the accumulation of tensile damage under monotonic loading. Therefore, it is important to explore the real-time development of structural defects governing the deformation behavior during strain accumulation under tensile loading, which can be achieved via in situ neutron-diffraction measurements.

The most popular FCC HEA, the Cantor alloy CoCrFeMnNi, not only exhibits good mechanical performance but also high fatigue resistance [5,10,11,17,18,19,20]. The as-cast microstructure of the HEAs enhances fatigue resistance [21,22]. Specifically, the as-cast dendritic structure is beneficial to tensile-overload-driven deformation twinning, and thus enhances fatigue resistance in CoCrFeMnNi HEAs [22]. However, investigations of tensile-loading-governed microstructural defects in as-cast CoCrFeMnNi alloys are lacking. Furthermore, there is a need to gain better understanding of the reciprocal relationships between elemental composition, microstructural evolution, testing conditions, and tensile performance. The objective of the present study was to investigate the tensile properties and the corresponding microstructural evolution in as-cast quinary CoCrFeMnNi and quaternary CoCrFeNi HEAs. In situ neutron-diffraction measurements were performed to examine the direct real-time microstructural evolution governing tensile-deformation mechanisms during uniaxial straining.

2. Materials and Methods

The equiatomic concentrated solid-solution alloys CoCrFeNi and CoCrFeMnNi were studied in the present work. The as-cast CoCrFeNi and CoCrFeMnNi HEAs were vacuum-arc-melted from equal molar compositions with the purities of elemental powders higher than 99.9 wt % under a high-purity argon atmosphere. After arc-melting, the ingots were heated to 1273 K for 6 h for homogenization. The as-cast CoCrFeNi and CoCrFeMnNi HEAs revealed dendritic structures with grain sizes around 1034 and 995 µm, respectively, as shown in Figure S1 in the Supplementary Information.

The in situ neutron-diffraction measurements were carried out during tensile tests at the TAKUMI beamline in the Materials and Life Science Experimental Facilities at J-PARC, Japan. The loading direction was 45° with respect to the neutron beam, associated with two detector banks located at ±90° concurrently recording diffraction vector patterns in both the loading and transverse directions. For the tensile test, cylindrical dog-bone-shaped specimens with a gauge length of 30 mm and a diameter of 6 mm were prepared. Quaternary and quinary samples were step-loaded in the elastic regime, followed by a continuous loading at a nominal strain rate of 5 × 10−5/s in the plastic regime. In situ neutron-diffraction patterns were recorded at several specific strain values at which the two specimens were held. The in situ neutron-diffraction profiles were analyzed using the general structure analysis system (GSAS) [23] for single-peak fitting and Convolutional Multiple Whole Profile (CMWP) software [24,25] for determining the tensile deformation mechanisms, following the previously reported protocols [15,22,26]. We followed our earlier protocol for the procedures for in situ neutron-diffraction experiments during the tensile test and a complete data analysis process [15]. In addition, the neutron-diffraction peaks demonstrated a single FCC phase in both quaternary and quinary HEAs before and after tensile deformation; therefore, the influence of phase transformation on the deformation mechanism was ignored in the present study [27,28,29].

3. Results

3.1. Tensile Properties

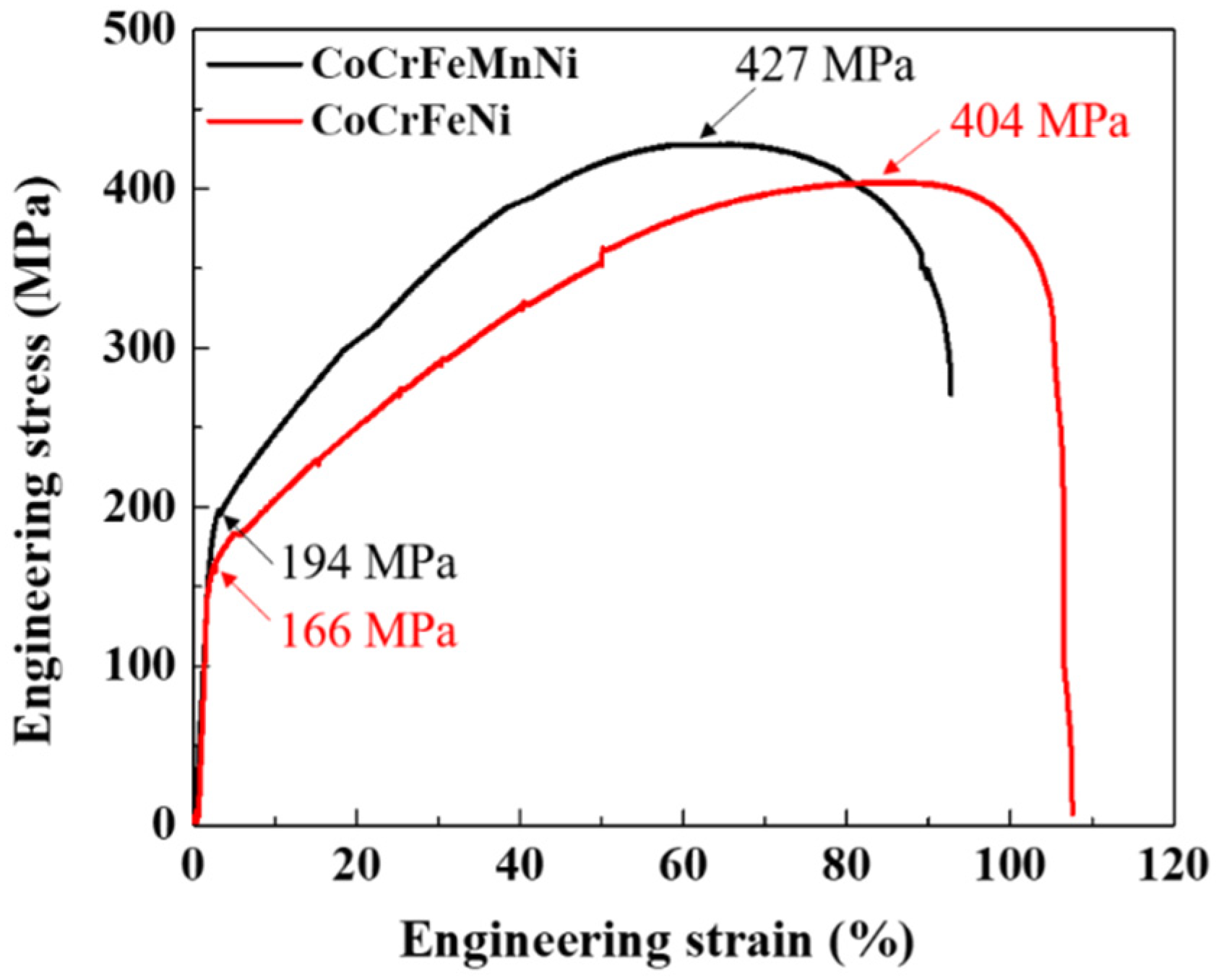

Figure 1 describes the uniaxial tensile engineering stress–strain (S-S) curves of both CoCrFeNi and CoCrFeMnNi HEAs. The macroscopic yielding point of the CoCrFeMnNi HEA started at a stress of 194 MPa, which was a remarkable 17% increase compared to that of the CoCrFeNi HEA. The ultimate tensile strength (UTS) of the CoCrFeMnNi HEA was 427 MPa, which was greater than the 404 MPa of the CoCrFeNi HEA. The elongations to failure of the CoCrFeNi and CoCrFeMnNi HEAs were 107% and 92%, respectively. Although the addition of Mn decreased ductility by 14%, it significantly enhanced the yield stress (YS) and UTS of the alloy. This suggested a hardening behavior in the CoCrFeMnNi HEA. The addition of Mn achieved a good balance between high tensile strength and ductility, which is an outstanding characteristic for wide and practical applications of HEAs. Since the strain rates were similar in the as-cast quaternary and quinary alloys, their tensile properties are presumably related to the element composition and the evolution of different structural defects at each deformation stage. In this work, we focused on the elastic deformation and plastic deformation stages within the UTS.

Figure 1.

Engineering stress–strain (S-S) curves of the CoCrFeNi and CoCrFeMnNi alloys.

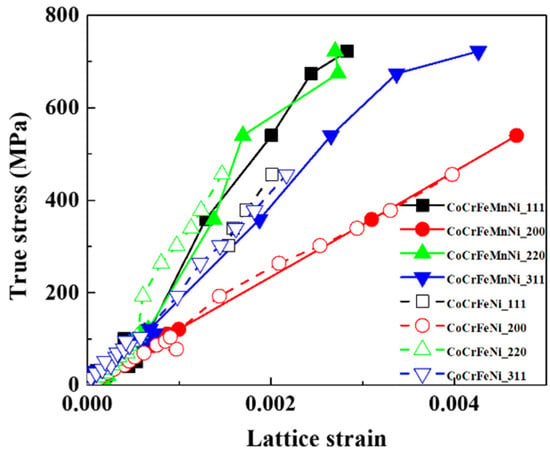

3.2. Lattice Strain Evolution

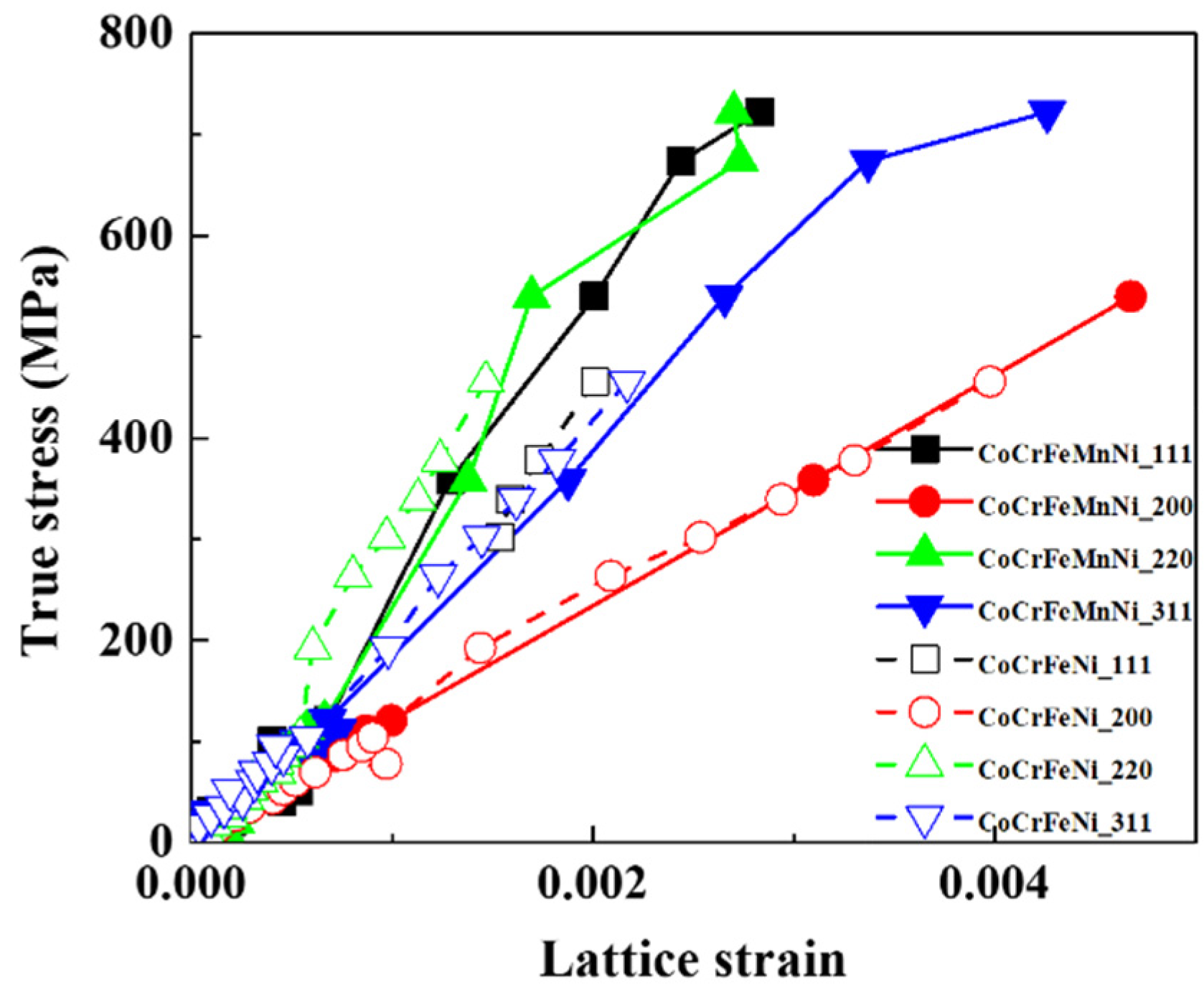

Figure 2 presents the lattice strain evolution of different grain orientations of {311}, {220}, {200}, and {111} with respect to the applied stress along the axial loading direction in the two HEAs. Similar trends in all grain orientations were observed for both HEAs, which increased linearly during macroscopic elastic deformation within the yielding region. The elastic constant of each orientation was determined from its slope. Among all the orientations, the {200} grain had the lowest elastic modulus and was the easiest-deforming lattice plane in both quaternary and quinary alloys, which has similarly been observed in other FCC polycrystalline metallic systems [30,31]. Beyond the macroscopic yield stress, all grain orientations in both HEAs significantly deviated from the original linear slopes and continuously increased with applied stress. Among all grains, the {220} and {111} orientations revealed smaller strain increases, whereas the {200} grain exhibited a larger increase in elastic strain than the initial linear increase for each orientation in both HEAs. This implies load sharing from the {220} and {111} to the {200} grain families. With increasing the applied stress above the UTS in the CoCrFeMnNi HEA, there were obvious shifts in all grains toward much higher strain values at which they bore more loading at large deformation.

Figure 2.

Lattice strain evolution with respect to true stress along the axial loading direction in the CoCrFeNi and CoCrFeMnNi HEAs.

3.3. Microstructural Evolutions during Tensile Straining

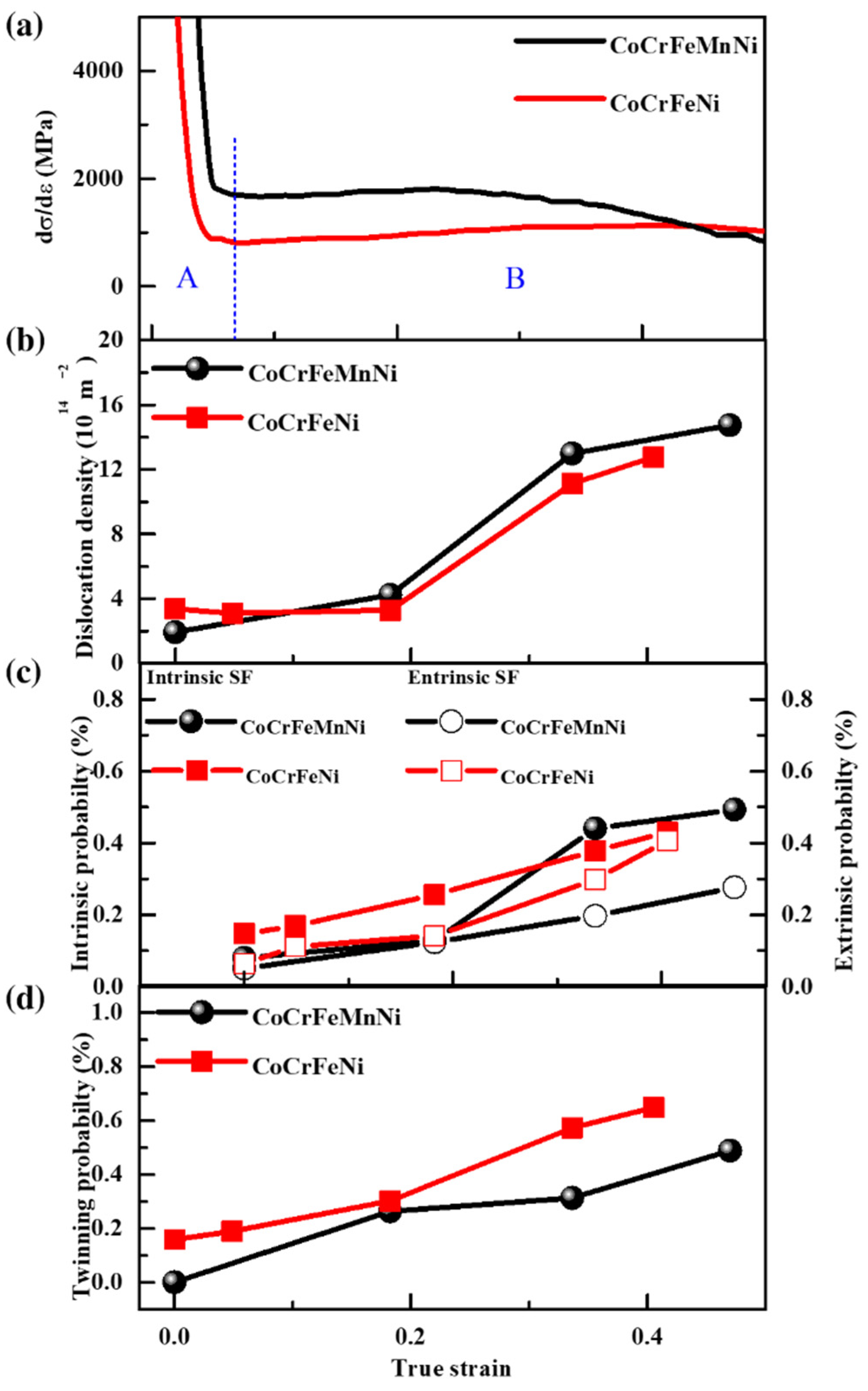

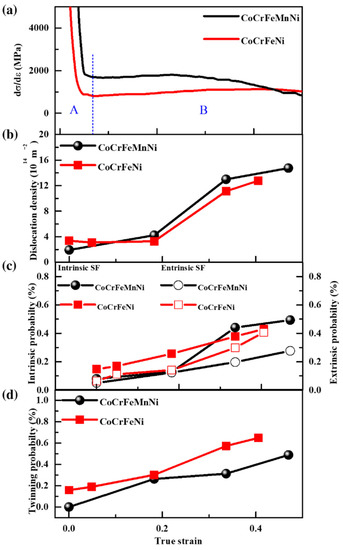

Figure 3a depicts the multi-stage work-hardening behaviors with respect to the macroscopic true strain in the CoCrFeNi and CoCrFeMnNi HEAs. We mainly focused on major deformation stages A and B. In regime A, there was a continuous decline in the work hardening rate around a true strain of 0.07 for both CoCrFeNi and CoCrFeMnNi HEAs, representing the dominant deformation of dislocation activities in this region. However, their major differences in deformation mechanisms were identified during the plastic regime B, which was the most important deformation stage in determining the overall tensile performance of the two HEAs. A larger strain hardening was observed in the CoCrFeMnNi HEA, which thus enhanced the tensile strength of the quinary alloy. The work-hardening rate in the CoCrFeMnNi HEA reached a steady state up to a strain of around 0.25 and then gradually decreased, similar to that in the fine-grained CoCrFeMnNi HEA [15]. Compared to the CoCrFeMnNi HEA, the strain-hardening rate of the CoCrFeNi HEA increased gradually before approaching a steady state at a strain of 0.3 and long-remained in a steady state up to a strain larger than 0.5. A similar tendency of the strain hardening rate at this stage was also observed in the quaternary alloy [8]. Such a long steady state of twinning-activated deformation appears close to failure, postpones necking, and significantly enhances the ductility of the CoCrFeNi HEA. The real-time evolution of the microstructural defects during tensile deformation was explored using CMWP analysis.

Figure 3.

(a) Work-hardening rate, (b) dislocation density, (c) formation probabilities of intrinsic and extrinsic stacking faults (SFs), and (d) formation probability of twins as a function of macroscopic true strain along the axial loading direction in CoCrFeNi and CoCrFeMnNi HEAs.

CMWP was employed to quantitatively determine different kinds of structural defects governing the dominant behavior at each deformation regime during straining in both quaternary and quinary alloys. The dynamic evolution of dislocation density, stacking faults (SF), and twinning analyzed by CMWP fitting procedures was related to the variation in peak shape and peak width broadening of the diffraction profiles. The SF and twinning formation probabilities were directly determined based on the shifts and breadths of the sum of symmetrical and asymmetrical Lorentzian-function-based sub-profiles, given by fifth-order polynomials of the planar fault density [32,33]. The type of sub-profiles follows the specific selection rule for the hkl indices of the Bragg reflections [32]. The dislocation density is related to the Fourier coefficient of the strain profile as follows [8,24,33,34]:

where b is the absolute value of the Burgers vector, g is the absolute value of the diffraction vector, C is the dislocation contrast factor, ρ is the dislocation density, L is the variable of the Fourier transform, f is the Wilkens’ function, and Re* is the cut-off radius of the dislocations.

Figure 3 presents the development of dislocation density, the formation probability of twinning, and intrinsic and extrinsic SF as a function of true strain along the axial loading direction. In Figure 3b, the dislocation density generally increases with increasing strain for both HEAs, but a higher dislocation density is shown by the CoCrFeMnNi than the CoCrFeNi HEA during tensile loading. In the first deformation stage, at a low strain below 0.2, the dislocation density gradually increased in the quinary alloy, whereas it remained almost unchanged in the quaternary alloy. Both HEAs displayed a strong rise in dislocation density at an intermediate strain of 0.2–0.4, which is in accordance with previous work [8,15]. Accompanying the evolution of dislocation density, the increased tendency of formation probability of other defects such as intrinsic and extrinsic SFs and twins with increasing strain was similar in the two HEAs (Figure 3c,d). The formation probabilities of intrinsic and extrinsic SFs and twins at intermediate strain were almost two times higher than those below a strain of 0.2 in both HEAs. In Figure 3c, the formation probabilities of intrinsic and extrinsic SFs in the CoCrFeNi HEA are slightly higher than those in the CoCrFeMnNi HEA at a low strain; however, their evolution was different at an intermediate strain. The formation probability of intrinsic SFs in the CoCrFeMnNi HEA was higher than that in the CoCrFeNi HEA, whereas the formation probability of extrinsic SFs in the CoCrFeMnNi HEA was lower than that in the CoCrFeNi HEA. In Figure 3d, the CoCrFeNi HEA displays a much higher formation probability of twinning at both low and intermediate strains compared to the CoCrFeMnNi HEA. The much higher formation probability of deformation twins, obtained by the CMWP analysis, coupled with a longer steady state of strain hardening in stage B produced better elongation in the CoCrFeNi than in the CoCrFeMnNi HEA. In contrast with the as-cast CoCrFeNi and CoCrFeMnNi HEAs in the present study, a fine-grained CoCrFeMnNi HEA of 17 µm exhibited improvements in both strength and ductility compared to a fine-grained CoCrFeNi HEA of 39 µm at a strain rate of 1 × 10−4, which was attributed to the deformation-twinning-induced complex multiple-stage strain-hardening behavior in CoCrFeMnNi HEA [12].

4. Discussion

Table 1 summarizes the tensile properties of CoCrFeNi and CoCrFeMnNi HEAs with different grain sizes and strain rates at room temperature. Various factors, such as the number of solid-solution elements, elemental composition, grain size, and strain rate, simultaneously govern the microstructural-development-driven tensile deformation mechanisms and thus the tensile properties of HEAs. The larger number of alloying elements is beneficial in overcoming the strength–ductility trade-off, and it has a major impact on the fracture strain but not on the yield strength of equimolar solid-solution alloys [9,12]. Compared to the number of alloying elements, the alloying composition has a much more significant impact on the tensile performances of HEAs [9,15,16,35].

Table 1.

Summary of the tensile properties of CoCrFeNi and CoCrFeMnNi HEAs with different grain sizes and strain rates at room temperature.

A higher strain rate and grain refinement were found to have positive effects on the tensile properties of HEAs. While no significant effects of quasi-static strain rates on tensile properties were reported in either fine-grained CoCrFeNi or CoCrFeMnNi HEA [13], higher quasi-static strain-rate-promoted stacking faults enhanced the UTS and elongation in coarse-grained CoCrFeNi HEA [14]. The dominant microstructures of dislocation slips at quasi-static strain rates together with deformation twins at dynamic strain rates determine tensile deformation behaviors in both fine-grained CoCrFeNi and CoCrFeMnNi HEAs [13], whereas deformation-induced planar slip at lower strain together with induced stacking faults at higher strain were found in fine-grained CoCrFeNi HEA [14]. However, despite being strained at different strain rates, the tensile deformation mechanisms in the CoCrFeMnNi HEAs with similar fine-grain sizes were driven by the dislocation plasticity at lower strains and twinning at higher strains close to fracture [15,17]. Meanwhile, yield strength increased but fracture strain decreased when decreasing the grain size from coarse- to ultrafine-grained in CoCrFeMnNi HEAs, whose deformations were dominated by planar dislocation glide, stacking faults, and, finally, by the cell structures at higher strains [11]. In general, it can be suggested that compared to the number of solid-solution elements and strain rates, the alloying composition and grain size play a more crucial role in the tensile strength and ductility of HEAs. While a planar dislocation slip-dominated microstructure was found at lower true strains, the predominant microstructure of different structural defects such as stacking faults, dislocation substructure, and deformation twins was different at higher true strains in the HEAs.

Compared to the previously reported CoCrFeNi HEAs [8,9,12,13,14], the ductility of the as-cast CoCrFeNi HEA was much more striking, with almost two times higher elongation to failure. The as-cast CoCrFeNi HEA revealed a UTS comparable to that of the coarse-grained CoCrFeNi HEA (200–300 µm) [14] but lower YS and UST than those reported for a fine-grained CoCrFeNi HEA (22–39 µm) [12,13]. Similarly, the as-cast CoCrFeMnNi HEA revealed a better ductility but lower YS and UTS in comparison to the previously reported CoCrFeMnNi HEAs [5,11,12,13,15,17]. At the same tensile strain rate, the as-cast CoCrFeMnNi alloy showed a decrease of 20% in YS and 31% in UTS but a compensation of 44% in strain to failure compared to our previously reported fine-grained CoCrFeMnNi HEA (18 µm) [15]. Compared to the CoCrNi medium-entropy alloy [6,7], the yield strengths of the as-cast CoCrFeNi and CoCrFeMnNi HEAs were not particularly high; however, the tensile ductility of the as-cast HEAs significantly increased. The as-cast CoCrFeNi and CoCrFeMnNi HEAs revealed excellent ductility associated with a moderate tensile strength. Our findings suggest that the striking enhancement in ductility in the as-cast CoCrFeNi and CoCrFeMnNi HEAs was presumably not directly related to the number of alloying elements or alloying composition but to the dendritic microstructure of the HEAs. Higher strain-activated stacking faults and deformation twins were conducive to better elongation to fracture in the as-cast CoCrFeNi and CoCrFeMnNi HEAs.

5. Conclusions

Compared to the completely recrystallized microstructures of HEAs, as-cast CoCrFeNi and CoCrFeMnNi HEAs exhibited a much higher tensile ductility. The as-cast CoCrFeMnNi HEA revealed a higher tensile strength but at the cost of lower ductility compared to the as-cast CoCrFeNi HEA. A larger strain hardening demonstrated the improved tensile strength of the CoCrFeMnNi HEA, whereas a longer steady state of twinning formation explained the enhanced ductility of the CoCrFeNi HEA. Plastic deformation governed by dislocation slips at low true strain as well as intrinsic and extrinsic SFs and deformation twins at high strain were obtained in both HEAs. The as-cast microstructure-promoted stacking faults and deformation twins may be favorable for high ductility in HEAs.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/cryst12020157/s1, Figure S1: OM micrographs of the CoCrFeNi (a) and CoCrFeMnNi (b).

Author Contributions

Conceptualization, E.-W.H. and T.-N.L.; sample design and fabrications, A.-C.Y.; neutron diffraction experiments, M.-Y.L., T.K., S.H. and E.-W.H.; data analysis, T.-N.L. and M.-Y.L.; investigation, M.-Y.L.; project administration, E.-W.H.; resources, T.K., S.H. and A.-C.Y.; supervision, E.-W.H.; writing—original draft, T.-N.L.; writing—review and editing, T.K., S.H., J.J., S.-Y.L., A.-C.Y. and E.-W.H.; T.-N.L. and M.-Y.L. contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Higher Education Sprout Project of the National Yang Ming Chiao Tung University and Ministry of Education (MOE), Taiwan. The neutron-diffraction experiments were performed at the BL19 in the Materials and Life Science Experimental Facility of J-PARC with the proposals 2016A0322, 2018A0248, and 2018A0248. We acknowledge the Ministry of Science and Technology (MOST), Taiwan, for the financial support of grant No. MOST-108-2739-M-213-001 from the National Synchrotron Radiation Research Center (NSRRC) Neutron Cultivation Program in providing for the trip to J-PARC used in the present work. The authors are grateful for the support of the MOST Programs MOST 110-2224-E-007-001 and MOST 108-2221-E-009-131-MY4. This work was financially supported by the Center for the Semiconductor Technology Research of The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project of the Ministry of Education (MOE), Taiwan. It was also supported in part by the Ministry of Science and Technology (MOST), Taiwan, under grant MOST 110-2634-F-009-027. S.-Y.L. was supported by the National Research Foundation (NRF) grant funded by the Korean Government (2021R1A4A1031494, 2020K1A3A7A09078090).

Data Availability Statement

The data will be made available on request.

Acknowledgments

We sincerely thank Tamás Ungár for his Convolutional Multiple Whole Profile (CMWP) software. The high-quality samples were obtained from the High-Entropy Materials Center of the Featured Areas Research Center Program within the framework of the Higher Education Sprout Project of the Ministry of Education (MOE) in Taiwan. We greatly appreciate the financial support of the National Synchrotron Radiation Research Center (NSRRC) Neutron Program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [Green Version]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Miao, J.; Slone, C.E.; Smith, T.M.; Niu, C.; Bei, H.; Ghazisaeidi, M.; Pharr, G.M.; Mills, M.J. The evolution of the deformation substructure in a Ni-Co-Cr equiatomic solid solution alloy. Acta Mater. 2017, 132, 35–48. [Google Scholar] [CrossRef]

- Wang, B.; He, H.; Naeem, M.; Lan, S.; Harjo, S.; Kawasaki, T.; Nie, Y.; Kui, H.W.; Ungár, T.; Ma, D.; et al. Deformation of CoCrFeNi high entropy alloy at large strain. Scr. Mater. 2018, 155, 54–57. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Yao, M.J.; Pradeep, K.G.; Tasan, C.C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef] [Green Version]

- Joo, S.H.; Kato, H.; Jang, M.J.; Moon, J.; Tsai, C.W.; Yeh, J.W.; Kim, H.S. Tensile deformation behavior and deformation twinning of an equimolar CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2017, 689, 122–133. [Google Scholar] [CrossRef]

- Shabani, M.; Indeck, J.; Hazeli, K.; Jablonski, P.D.; Pataky, G.J. Effect of Strain Rate on the Tensile Behavior of CoCrFeNi and CoCrFeMnNi High-Entropy Alloys. J. Mater. Eng. Perform. 2019, 28, 4348–4356. [Google Scholar] [CrossRef] [Green Version]

- Huo, W.; Zhou, H.; Fang, F.; Hu, X.; Xie, Z.; Jiang, J. Strain-rate effect upon the tensile behavior of CoCrFeNi high-entropy alloys. Mater. Sci. Eng. A 2017, 689, 366–369. [Google Scholar] [CrossRef]

- Lam, T.-N.; Tsai, C.-W.; Chen, B.-K.; Lai, B.-H.; Liu, H.-C.; Kawasaki, T.; Harjo, S.; Lin, B.-H.; Huang, E.W. Element Effects of Mn and Ge on the Tuning of Mechanical Properties of High-Entropy Alloys. Metall. Mater. Trans. A 2020, 51, 5023–5028. [Google Scholar] [CrossRef]

- Ding, Q.; Zhang, Y.; Chen, X.; Fu, X.; Chen, D.; Chen, S.; Gu, L.; Wei, F.; Bei, H.; Gao, Y.; et al. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 2019, 574, 223–227. [Google Scholar] [CrossRef] [PubMed]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef] [Green Version]

- Gludovatz, B.; George, E.P.; Ritchie, R.O. Processing, Microstructure and Mechanical Properties of the CrMnFeCoNi High-Entropy Alloy. JOM 2015, 67, 2262–2270. [Google Scholar] [CrossRef]

- Thurston, K.V.S.; Gludovatz, B.; Hohenwarter, A.; Laplanche, G.; George, E.P.; Ritchie, R.O. Effect of temperature on the fatigue-crack growth behavior of the high-entropy alloy CrMnFeCoNi. Intermetallics 2017, 88, 65–72. [Google Scholar] [CrossRef]

- Thurston, K.V.S.; Gludovatz, B.; Yu, Q.; Laplanche, G.; George, E.P.; Ritchie, R.O. Temperature and load-ratio dependent fatigue-crack growth in the CrMnFeCoNi high-entropy alloy. J. Alloys Compd. 2019, 794, 525–533. [Google Scholar] [CrossRef] [Green Version]

- Seifi, M.; Li, D.; Yong, Z.; Liaw, P.K.; Lewandowski, J.J. Fracture Toughness and Fatigue Crack Growth Behavior of As-Cast High-Entropy Alloys. JOM 2015, 67, 2288–2295. [Google Scholar] [CrossRef]

- Lam, T.-N.; Lee, S.Y.; Tsou, N.-T.; Chou, H.-S.; Lai, B.-H.; Chang, Y.-J.; Feng, R.; Kawasaki, T.; Harjo, S.; Liaw, P.K.; et al. Enhancement of fatigue resistance by overload-induced deformation twinning in a CoCrFeMnNi high-entropy alloy. Acta Mater. 2020, 201, 412–424. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. General Structure Analysis System (GSAS). Los Alamos Natl. Lab. Rep. LAUR 2004, 86–748. [Google Scholar]

- Ribarik, G.; Ungar, T.; Gubicza, J. MWP-fit a program for multiple whole-profile fitting of diffraction peak profiles by ab initio theoretical functions. J. Appl. Crystallogr. 2001, 34, 669–676. [Google Scholar] [CrossRef] [Green Version]

- Ribárik, G. Modeling of Diffraction Patterns Based on Microstructural Properties. Ph.D. Thesis, Eötvös University, Budapest, Hungary, 2008. [Google Scholar]

- Lam, T.-N.; Chou, Y.-S.; Chang, Y.-J.; Sui, T.-R.; Yeh, A.-C.; Harjo, S.; Lee, S.Y.; Jain, J.; Lai, B.-H.; Huang, E.W. Comparing Cyclic Tension-Compression Effects on CoCrFeMnNi High-Entropy Alloy and Ni-Based Superalloy. Crystals 2019, 9, 420. [Google Scholar] [CrossRef] [Green Version]

- Huang, E.W.; Chou, H.S.; Tu, K.N.; Hung, W.S.; Lam, T.N.; Tsai, C.W.; Chiang, C.Y.; Lin, B.H.; Yeh, A.C.; Chang, S.H.; et al. Element Effects on High-Entropy Alloy Vacancy and Heterogeneous Lattice Distortion Subjected to Quasi-equilibrium Heating. Sci. Rep. 2019, 9, 14788. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, E.W.; Lin, C.-M.; Juang, J.-Y.; Chang, Y.-J.; Chang, Y.-W.; Wu, C.-S.; Tsai, C.-W.; Yeh, A.-C.; Shieh, S.R.; Wang, C.-P.; et al. Deviatoric deformation kinetics in high entropy alloy under hydrostatic compression. J. Alloys Compd. 2019, 792, 116–121. [Google Scholar] [CrossRef]

- Huang, E.W.; Lin, C.-M.; Jain, J.; Shieh, S.R.; Wang, C.-P.; Chuang, Y.-C.; Liao, Y.-F.; Zhang, D.-Z.; Huang, T.; Lam, T.-N.; et al. Irreversible phase transformation in a CoCrFeMnNi high entropy alloy under hydrostatic compression. Mater. Today Commun. 2018, 14, 10–14. [Google Scholar] [CrossRef]

- Huang, E.W.; Yu, D.; Yeh, J.-W.; Lee, C.; An, K.; Tu, S.-Y. A study of lattice elasticity from low entropy metals to medium and high entropy alloys. Scr. Mater. 2015, 101, 32–35. [Google Scholar] [CrossRef] [Green Version]

- Huang, E.W.; Barabash, R.; Jia, N.; Wang, Y.-D.; Ice, G.E.; Clausen, B.; Horton, J.; Liaw, P.K. Slip-System-Related Dislocation Study from In-Situ Neutron Measurements. Metall. Mater. Trans. A 2008, 39, 3079–3088. [Google Scholar] [CrossRef]

- Balogh, L.; Ribárik, G.; Ungár, T. Stacking faults and twin boundaries in fcc crystals determined by x-ray diffraction profile analysis. J. Appl. Phys. 2006, 100, 023512. [Google Scholar] [CrossRef]

- Ribárik, G.; Jóni, B.; Ungár, T. The Convolutional Multiple Whole Profile (CMWP) Fitting Method, a Global Optimization Procedure for Microstructure Determination. Crystals 2020, 10, 623. [Google Scholar] [CrossRef]

- Wilkens, M. The determination of density and distribution of dislocations in deformed single crystals from broadened X-ray diffraction profiles. Phys. Status Solidi 1970, 2, 359. [Google Scholar] [CrossRef]

- Oh, H.S.; Kim, S.J.; Odbadrakh, K.; Ryu, W.H.; Yoon, K.N.; Mu, S.; Kormann, F.; Ikeda, Y.; Tasan, C.C.; Raabe, D.; et al. Engineering atomic-level complexity in high-entropy and complex concentrated alloys. Nat. Commun. 2019, 10, 2090. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).