Fabrication of Polarization Grating on N-Benzylideneaniline Polymer Liquid Crystal and Control of Diffraction Beam

Abstract

:1. Introduction

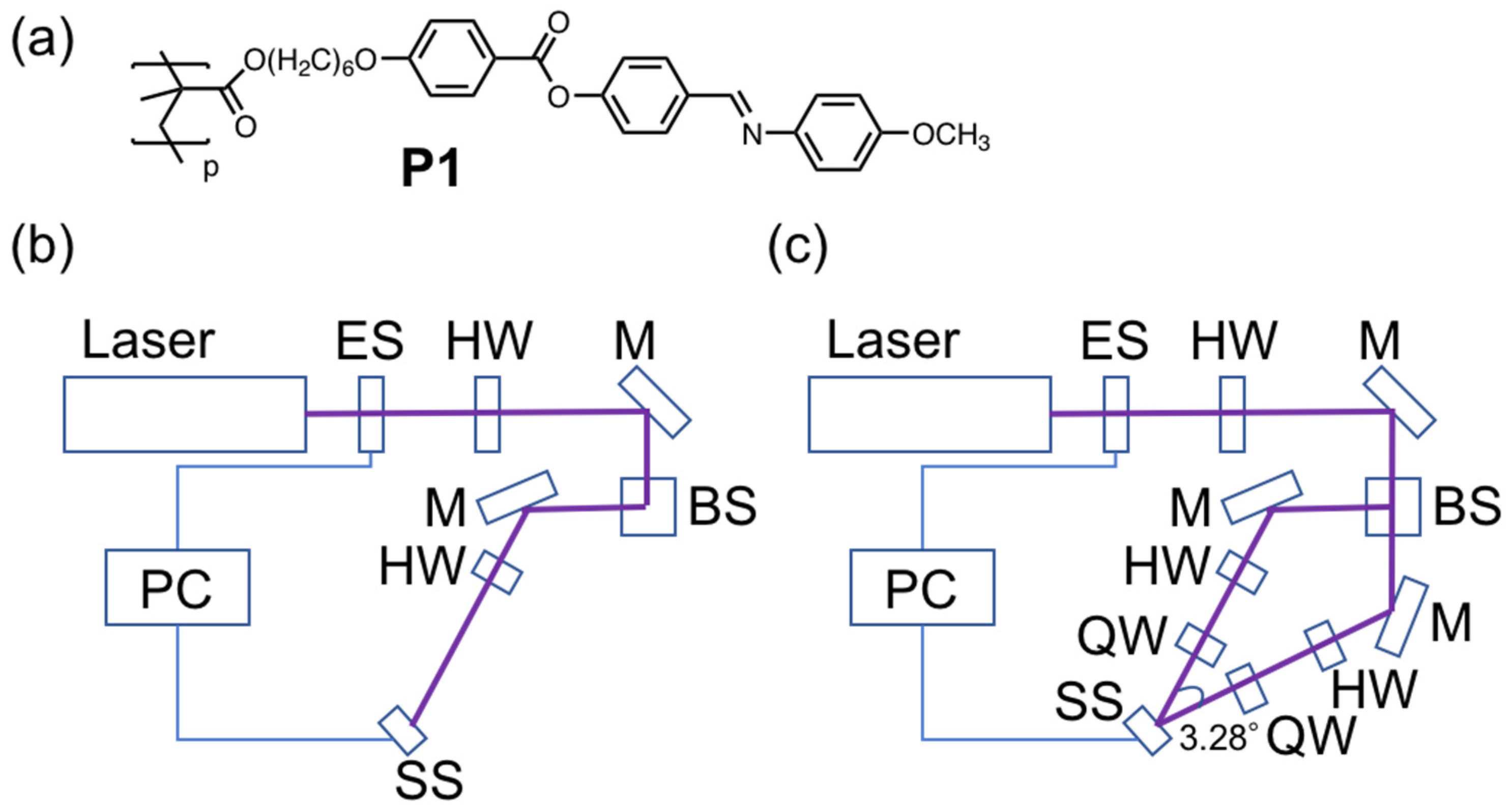

2. Materials and Methods

2.1. Material

2.2. Equipment

3. Results and Discussion

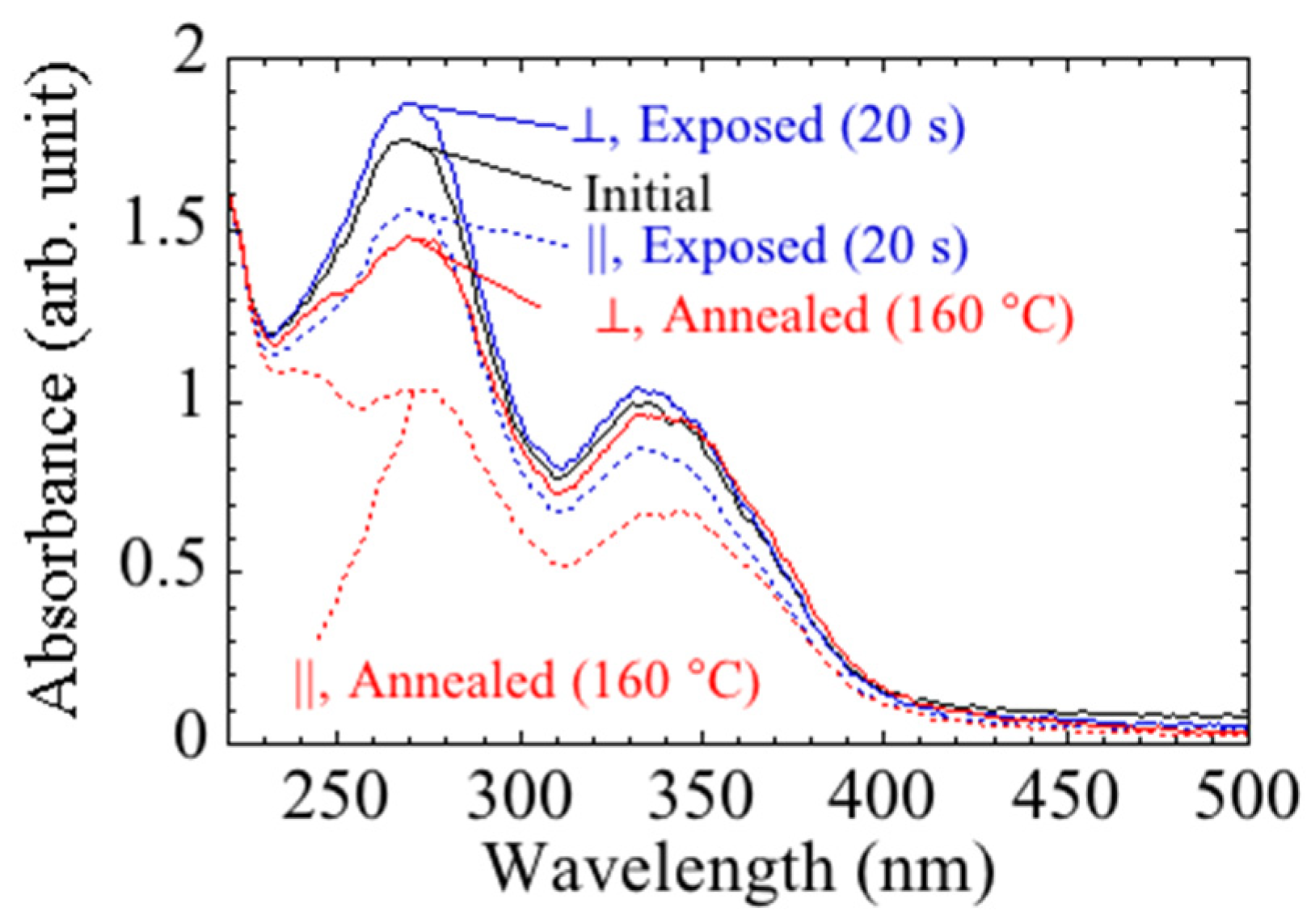

3.1. Photoalignment Behavior in Thin Films

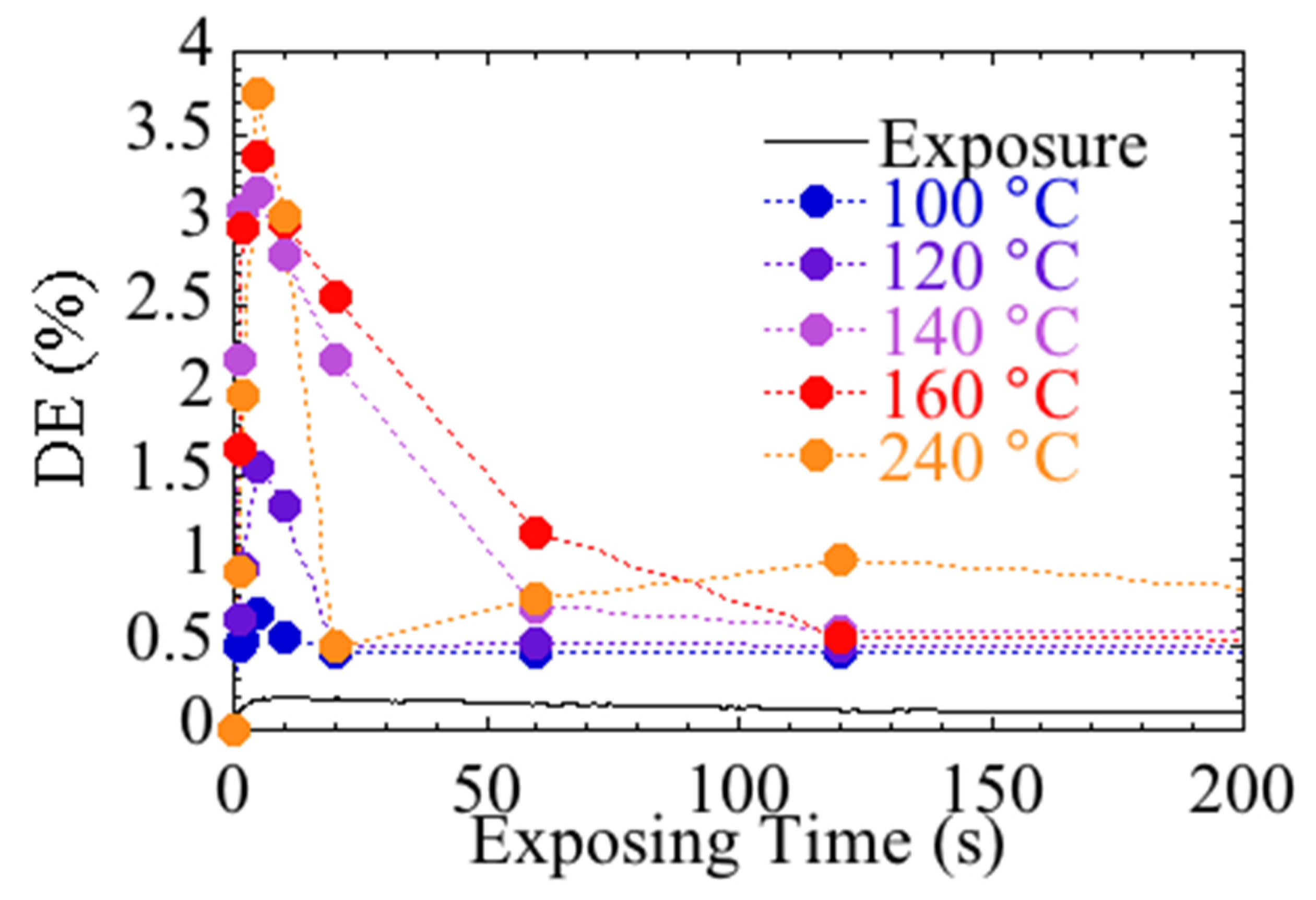

3.2. Photoalignment Behavior in Thick Films

3.3. Diffraction Control Using TN Cell

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, T.; Xie, J.; Zhou, Y.; Zhou, Y.; Yuan, Y.; Fan, F.; Wen, S. Recent Advances in Photoalignment Liquid Crystal Polarization Gratings and Their Applications. Crystals 2021, 11, 900. [Google Scholar] [CrossRef]

- Nersisyan, S.R.; Tabiryan, N.V.; Steeves, D.M.; Kimball, B. Optical Axis Gratings in Liquid Crystals and their use for Polarization insensitive optical switching. J. Nonlinear Opt. Phys. Mater. 2009, 18, 1–47. [Google Scholar] [CrossRef]

- Oh, C.; Kim, J.; Muth, J.; Serati, S.; Escuti, M.J. High-Throughput Continuous Beam Steering Using Rotating Polarization Gratings. IEEE Photonics Technol. Lett. 2010, 22, 200–202. [Google Scholar] [CrossRef]

- Chen, H.; Weng, Y.; Xu, D.; Tabiryan, N.V.; Wu, S.-T. Beam steering for virtual/augmented reality displays with a cycloidal diffractive waveplate. Opt. Express 2016, 24, 7287–7298. [Google Scholar] [CrossRef] [Green Version]

- Tabirian, N.V.; Roberts, D.; Liao, Z.; Ouskova, E.; Sigley, J.; Tabirian, A.; Slagle, J.; McConney, M.; Bunning, T.J. Size, weight, and power breakthrough in nonmechanical beam and line-of-sight steering with geo-phase optics. Appl. Opt. 2021, 60, G154–G161. [Google Scholar] [CrossRef]

- Kim, J.; Oh, C.; Serati, S.; Escuti, M.J. Wide-angle, nonmechanical beam steering with high throughput utilizing polarization gratings. Appl. Opt. 2011, 50, 2636–2639. [Google Scholar] [CrossRef]

- Kudenov, M.W.; Escuti, M.J.; Dereniak, E.L.; Oka, K. White-light channeled imaging polarimeter using broadband polarization gratings. Appl. Opt. 2011, 50, 2283–2293. [Google Scholar] [CrossRef] [Green Version]

- Ono, H.; Wada, T.; Kawatsuki, N. Polarization imaging screen using vector gratings fabricated by photocrosslinkable polymer liquid crystals. Jpn. J. Appl. Phys. 2012, 51, 030202. [Google Scholar] [CrossRef]

- Xiong, J.; Tan, G.; Zhan, T.; Wu, S.-T. Wide-view augmented reality display with diffractive cholesteric liquid crystal lens array. J. Soc. Inf. Disp. 2020, 28, 450–456. [Google Scholar] [CrossRef]

- Zhan, T.; Zou, J.; Xiong, J.; Liu, X.; Chen, H.; Yang, J.; Liu, S.; Dong, Y.; Wu, S.-T. Practical Chromatic Aberration Correction in Virtual Reality Displays Enabled by Cost-Effective Ultra-Broadband Liquid Crystal Polymer Lenses. Adv. Opt. Mater. 2020, 8, 1901360. [Google Scholar] [CrossRef]

- Zhan, T.; Lee, Y.-H.; Wu, S.-T. High-resolution additive light field near-eye display by switchable Pancharatnam–Berry phase lenses. Opt. Express 2018, 26, 4863–4872. [Google Scholar] [CrossRef]

- Zhan, T.; Xiong, J.; Tan, G.; Lee, Y.-H.; Yang, J.; Liu, S.; Wu, S.-T. Improving near-eye display resolution by polarization multiplexing. Opt. Express 2019, 27, 15327–15334. [Google Scholar] [CrossRef]

- Xiong, J.; Wu, S. Rigorous coupled-wave analysis of liquid crystal polarization gratings. Opt. Express 2020, 28, 35960–35971. [Google Scholar] [CrossRef]

- Wang, Q.-H.; Ji, C.-C.; Li, L.; Deng, H. Dual-view integral imaging 3D display by using orthogonal polarizer array and polarization switcher. Opt. Express 2016, 24, 9–16. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Yin, K.; Wu, S.-T. Reflective polarization volume gratings for high efficiency waveguide-coupling augmented reality displays. Opt. Express 2017, 25, 27008–27014. [Google Scholar] [CrossRef]

- Packham, C.; Escuti, M.; Ginn, J.; Oh, C.; Quijano, I.; Boreman, G. Polarization Gratings: A Novel Polarimetric Component for Astronomical Instruments. Public. Astron. Soc. Pac. 2011, 122, 1471–1478. [Google Scholar] [CrossRef] [Green Version]

- Nikolova, L.; Todorov, T. Diffraction efficiency and selectivity of polarization holographic recording. Opt. Acta 1984, 31, 579–588. [Google Scholar] [CrossRef]

- Bomzon, Z.; Biener, G.; Kleiner, V.; Hasman, E. Space-variant Pancharatnam-Berry phase optical elements with computer-generated subwavelength gratings. Opt. Lett. 2002, 27, 1141–1143. [Google Scholar] [CrossRef]

- Gori, F. Measuring Stokes parameters by means of a polarization grating. Opt. Lett. 1999, 24, 584–586. [Google Scholar] [CrossRef]

- Roberts, D.; Kaim, S.; Tabiryan, N.V.; McConney, M.; Bunning, T.J. Polarization-independent diffractive waveplate optics. In Proceedings of the 2018 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2018; pp. 1–11. [Google Scholar]

- Tabiryan, N.; Roberts, D.; Steeves, D.; Kimball, B. 4G Optics: New Technology Extends Limits to the Extremes. Photonics Spectra 2017, 51, 46–50. [Google Scholar]

- Tabiryan, N.V.; Roberts, D.E.; Liao, Z.; Hwang, J.; Moran, M.; Ouskova, O.; Pshenichnyi, A.; Sigley, J.; Tabirian, A.; Vergara, R.; et al. Advances in Transparent Planar Optics: Enabling Large Aperture, Ultrathin Lenses. Adv. Opt. Mater. 2021, 9, 2001692. [Google Scholar] [CrossRef]

- Nersisyan, S.R.; Tabiryan, N.V.; Steeves, D.M.; Kimball, B.R. The Promise of Diffractive Waveplates. Opt. Photonics News 2010, 21, 41–45. [Google Scholar] [CrossRef]

- Zhan, T.; Lee, Y.-H.; Tan, G.; Xiong, J.; Yin, K.; Gou, F.; Zou, J.; Zhang, N.; Zhao, D.; Yang, J.; et al. Pancharatnam-Berry optical elements for head-up and near-eye displays. J. Opt. Soc. Am. B 2019, 36, D52–D65. [Google Scholar] [CrossRef]

- Honma, M.; Nose, T. Twisted nematic liquid crystal polarization grating with the handedness conservation of a circularly polarized state. Opt. Express 2012, 20, 18449–18458. [Google Scholar] [CrossRef] [PubMed]

- Honma, M.; Nose, T. Highly efficient twisted nematic liquid crystal polarization gratings achieved by microrubbing. Appl. Phys. Lett. 2012, 101, 041107. [Google Scholar] [CrossRef]

- Hisano, K.; Ota, M.; Aizawa, M.; Akamatsu, N.; Barrett, C.J. Shishido, A. Single-step creation of polarization gratings by scanning wave photopolymerization with unpolarized light. J. Opt. Soc. Am. B 2019, 36, D112–D118. [Google Scholar] [CrossRef]

- Noda, K.; Kawai, K.; Sasaki, T.; Kawatsuki, N.; Ono, H. Multilevel anisotropic diffractive optical elements fabricated by means of stepping photo-alignment technique using photo-cross-linkable polymer liquid crystals. Appl. Opt. 2014, 53, 2556. [Google Scholar] [CrossRef]

- Emoto, A.; Wada, T.; Shioda, T.; Sasaki, T.; Manabe, S.; Kawatsuki, N.; Ono, H. Vector gratings fabricated by polarized rotation exposure to hydrogen-bonded liquid crystalline polymers. Jpn. J. Appl. Phys. 2011, 50, 032502. [Google Scholar] [CrossRef]

- Sasaki, T.; Izawa, M.; Noda, K.; Nishioka, E.; Kawatsuki, N.; Ono, H. Temporal formation of optical anisotropy and surface relief during polarization holographic recording in polymethylmethacrylate with azobenzene side groups. Appl. Phys. B Lasers Opt. 2014, 114, 373–380. [Google Scholar] [CrossRef]

- Sasaki, T.; Nishioka, E.; Noda, K.; Kondo, M.; Kawatsuki, N.; Ono, H. Analysis of Non-Sinusoidal Surface Relief Structures Induced by Elliptical Polarization Holography on Azobenzene-Containing Polymeric Films. Jpn. J. Appl. Phys. 2014, 53, 02BB06. [Google Scholar] [CrossRef]

- Kawatsuki, N.; Hosoda, R.; Kondo, M.; Sasaki, T.; Ono, H. Molecularly oriented surface relief formation in polymethacrylates comprising N-benzylideneaniline derivative side groups. Jpn. J. Appl. Phys. 2014, 53, 128002. [Google Scholar] [CrossRef]

- Kawatsuki, N. Photoalignment and Photoinduced Molecular Reorientation of Photosensitive Materials. Chem. Lett. 2011, 40, 548–554. [Google Scholar] [CrossRef]

- Ito, A.; Norisada, Y.; Inada, S.; Kondo, M.; Sasaki, T.; Sakamoto, M.; Ono, H.; Kawatsuki, N. Photoinduced Reorientation and Photofunctional Control of Liquid Crystalline Copolymers with in Situ-Formed N-Benzylideneaniline Derivative Side Groups. Langmuir 2021, 37, 1164–1172. [Google Scholar] [CrossRef] [PubMed]

- Nisizono, T.; Kondo, M.; Kawatsuki, N. Photoinduced Molecular Reorientation of a Liquid Crystalline Polymer with a High Birefringence. Chem. Lett. 2021, 50, 912–915. [Google Scholar] [CrossRef]

- Sakai, A.; Nnishizono, T.; Kondo, M.; Sasaki, T.; Sakamoto, M.; Ono, H.; Kawatsuki, N. Birefringence control of photoalignable liquid crystalline polymers based on an in situ exchange of oriented mesogenic side groups. Chem. Lett. 2021, 50, 91–93. [Google Scholar] [CrossRef]

- Yamaguchi, R.; Sasaki, R.; Inoue, K. Driving Voltage in Reverse Mode Cell Using Reactive Mesogen: Effect of UV Absorption of Liquid Crystal. J. Photopolm. Sci. 2018, 31, 301. [Google Scholar] [CrossRef] [Green Version]

- Shishido, A.; Ishiguro, M.; Ikeda, T. Circular Arrangement of Mesogens Induced in Bragg-type Polarization Holograms of Thick Azobenzene Copolymer Films with a Tolane Moiety. Chem. Lett. 2007, 36, 1146–1147. [Google Scholar] [CrossRef]

- Sarkissian, H.; Serak, S.V.; Tabiryan, N.V.; Glebov, L.B.; Rotar, V.; Zeldovich, B.Y. Polarization- controlled switching between diffraction orders in transverse-periodically aligned nematic liquid crystals. Opt. Lett. 2006, 31, 2248–2250. [Google Scholar] [CrossRef]

- Wu, S.T.; Efron, U.; Hess, L.D. Birefringence measurements of liquid crystals. Appl. Opt. 1984, 23, 3911–3915. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kondo, M.; Fujita, K.; Sasaki, T.; Sakamoto, M.; Ono, H.; Kawatsuki, N. Fabrication of Polarization Grating on N-Benzylideneaniline Polymer Liquid Crystal and Control of Diffraction Beam. Crystals 2022, 12, 273. https://doi.org/10.3390/cryst12020273

Kondo M, Fujita K, Sasaki T, Sakamoto M, Ono H, Kawatsuki N. Fabrication of Polarization Grating on N-Benzylideneaniline Polymer Liquid Crystal and Control of Diffraction Beam. Crystals. 2022; 12(2):273. https://doi.org/10.3390/cryst12020273

Chicago/Turabian StyleKondo, Mizuho, Kyohei Fujita, Tomoyuki Sasaki, Moritsugu Sakamoto, Hiroshi Ono, and Nobuhiro Kawatsuki. 2022. "Fabrication of Polarization Grating on N-Benzylideneaniline Polymer Liquid Crystal and Control of Diffraction Beam" Crystals 12, no. 2: 273. https://doi.org/10.3390/cryst12020273