Thermal Deformation Behavior and Interface Microstructure Analysis of 2205/Q345 Hot Compression Composite

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Materials

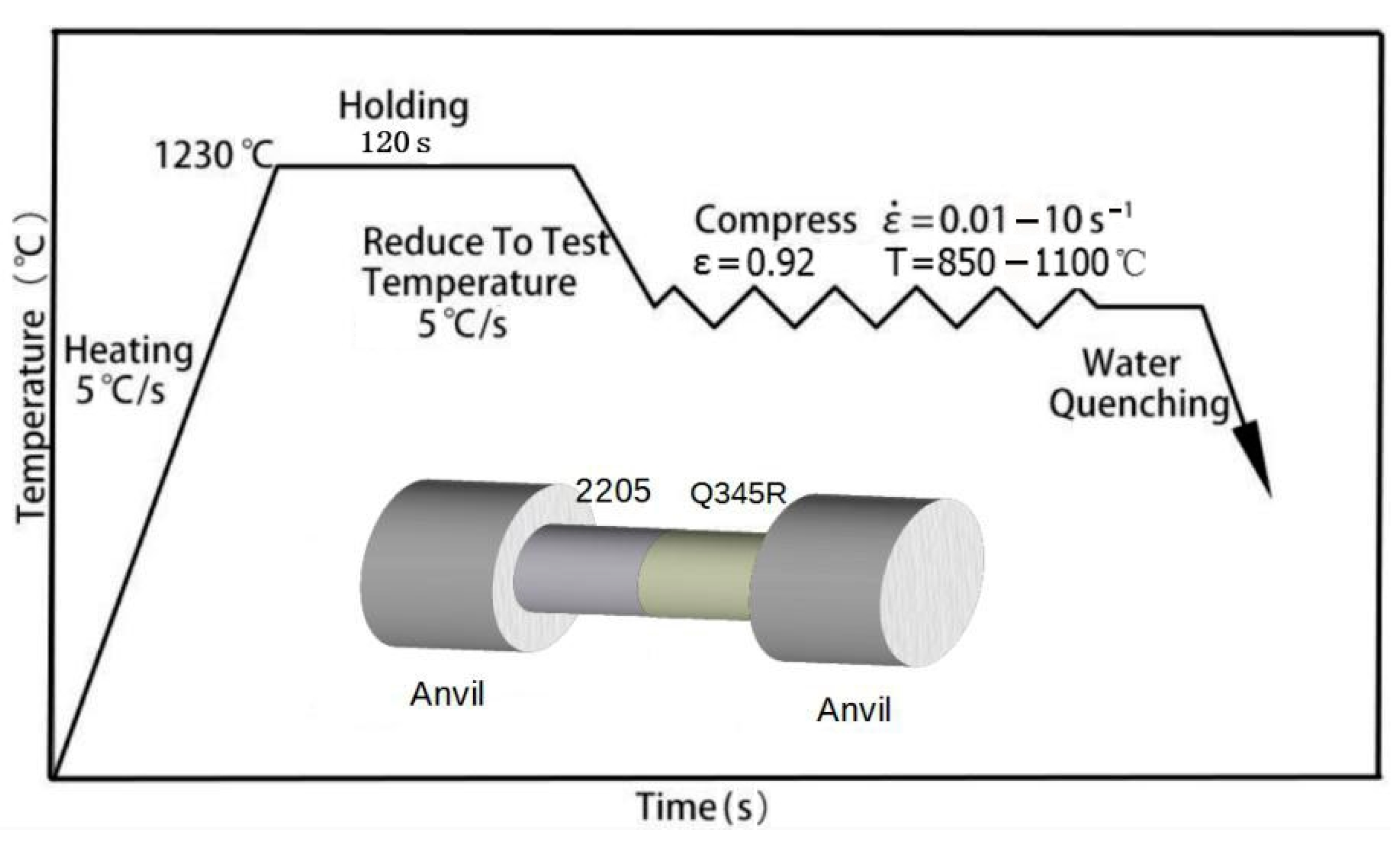

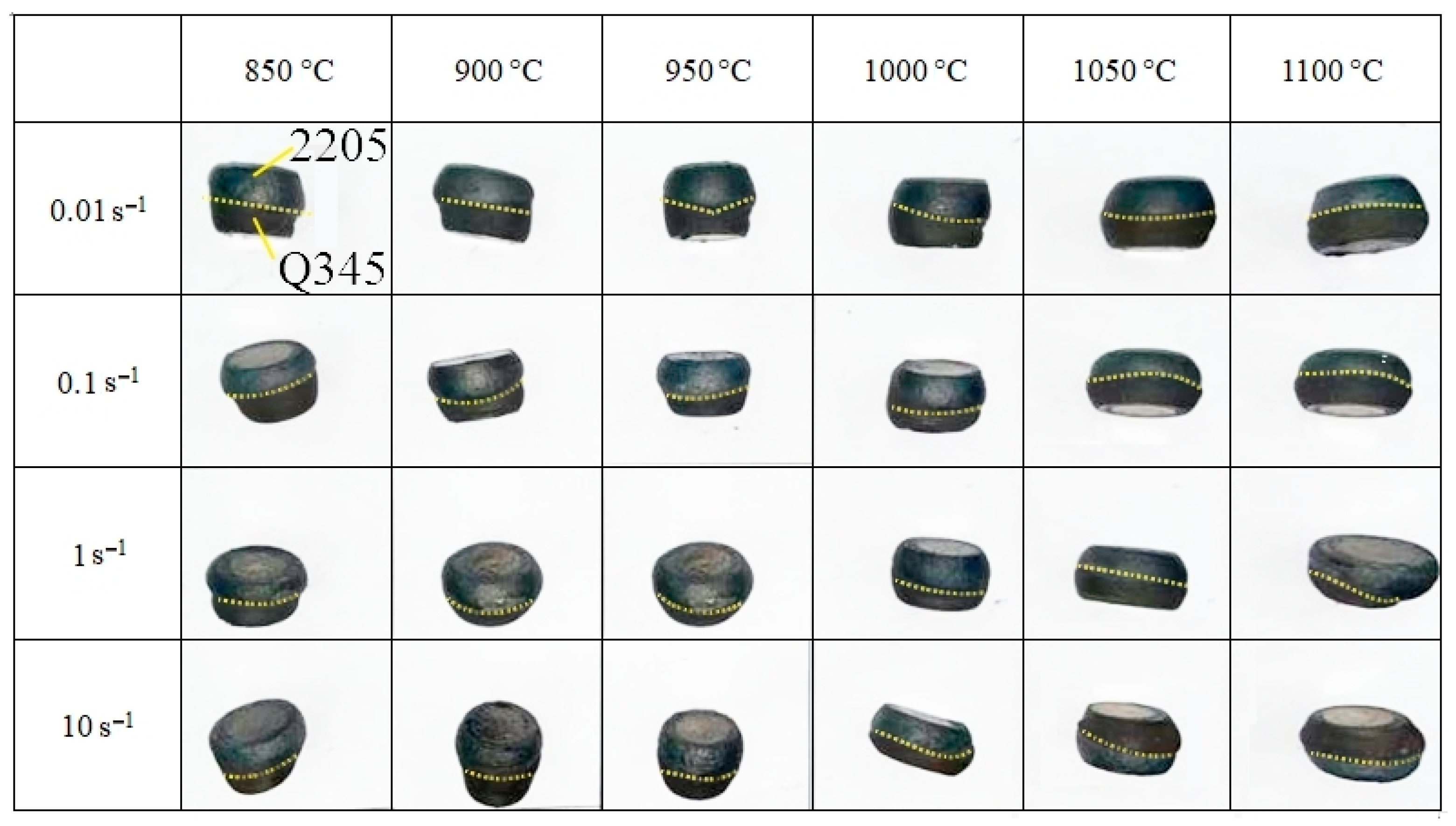

2.2. Experiment Method

3. Results and Discussion

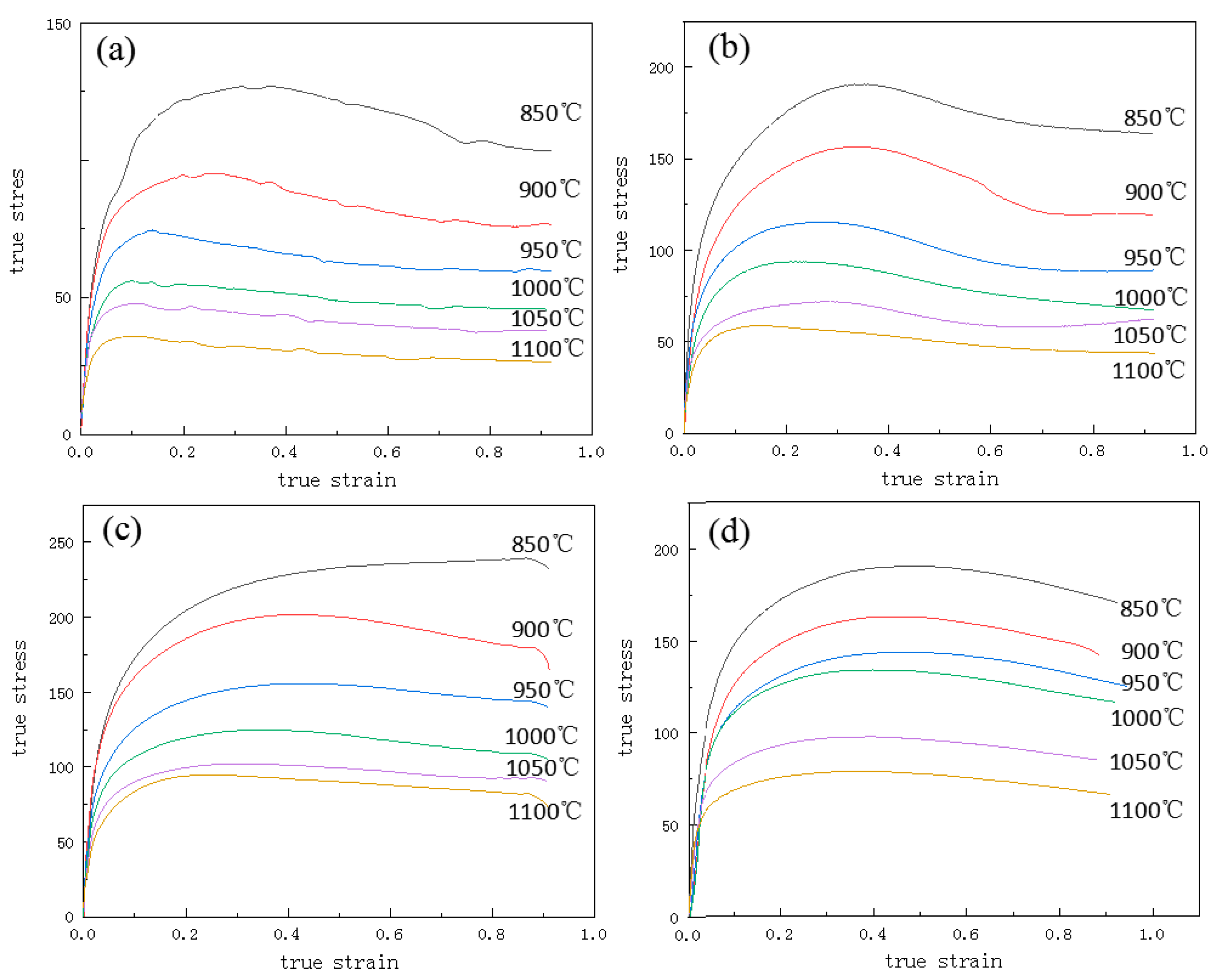

3.1. Stress–Strain Curve

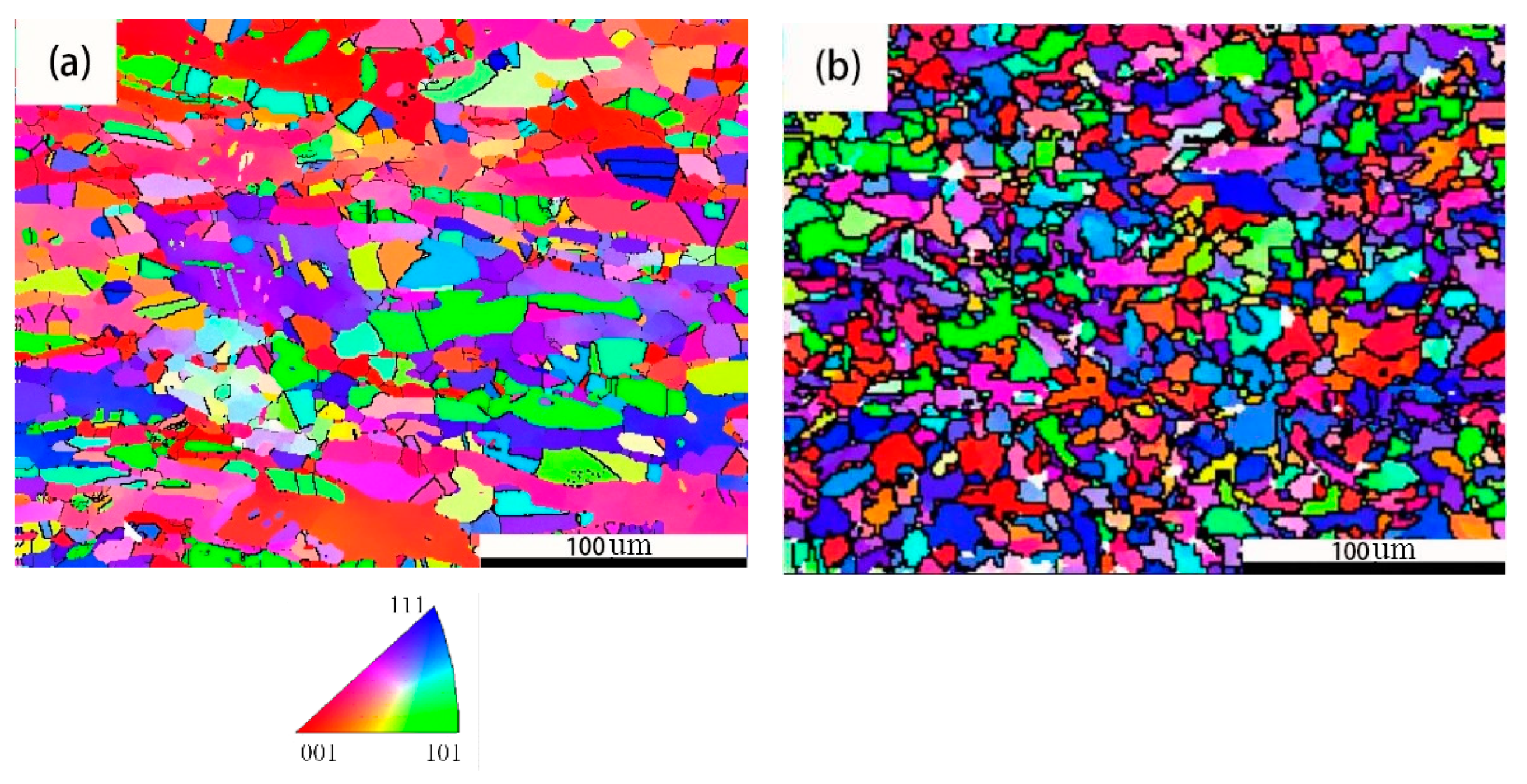

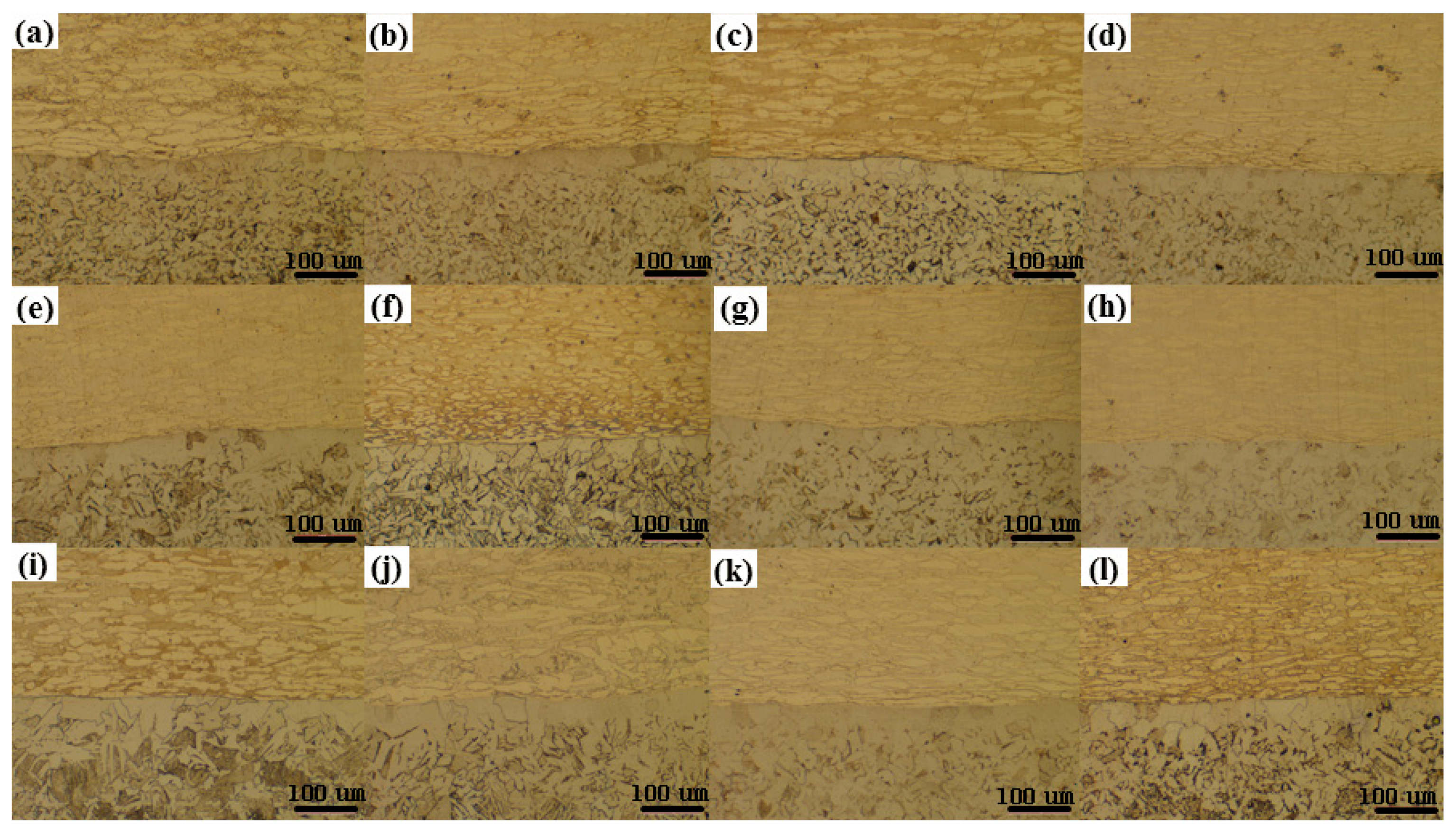

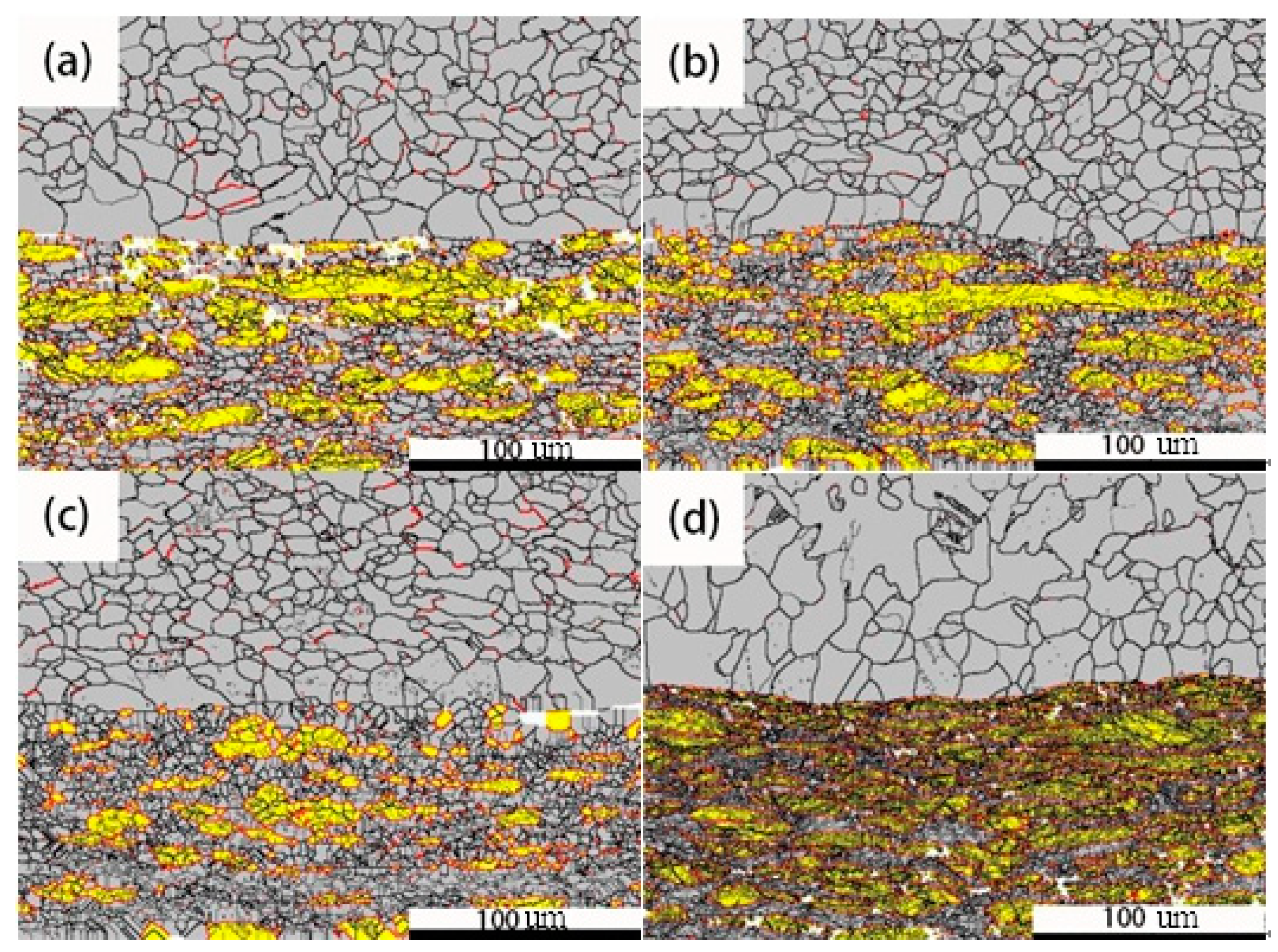

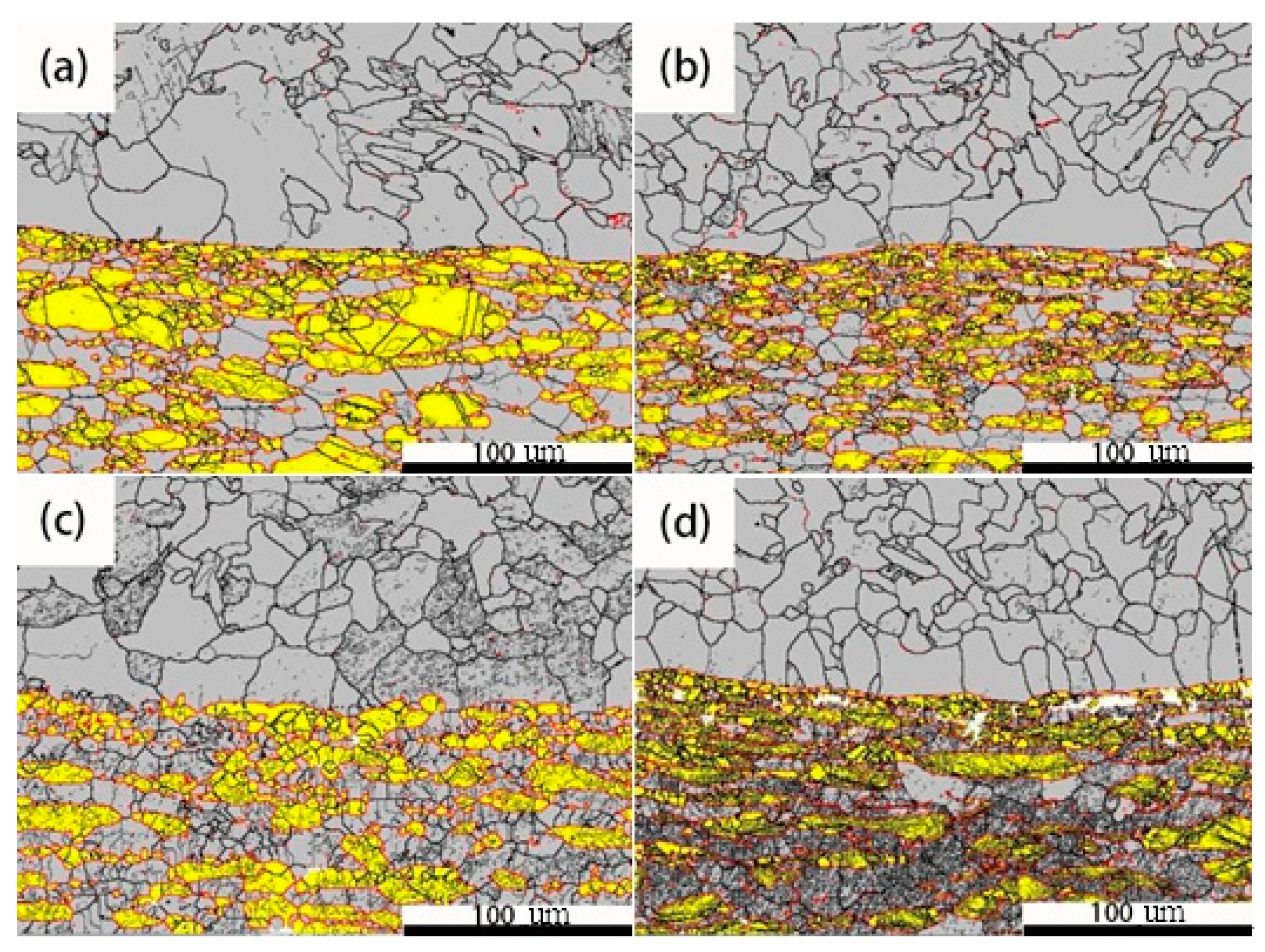

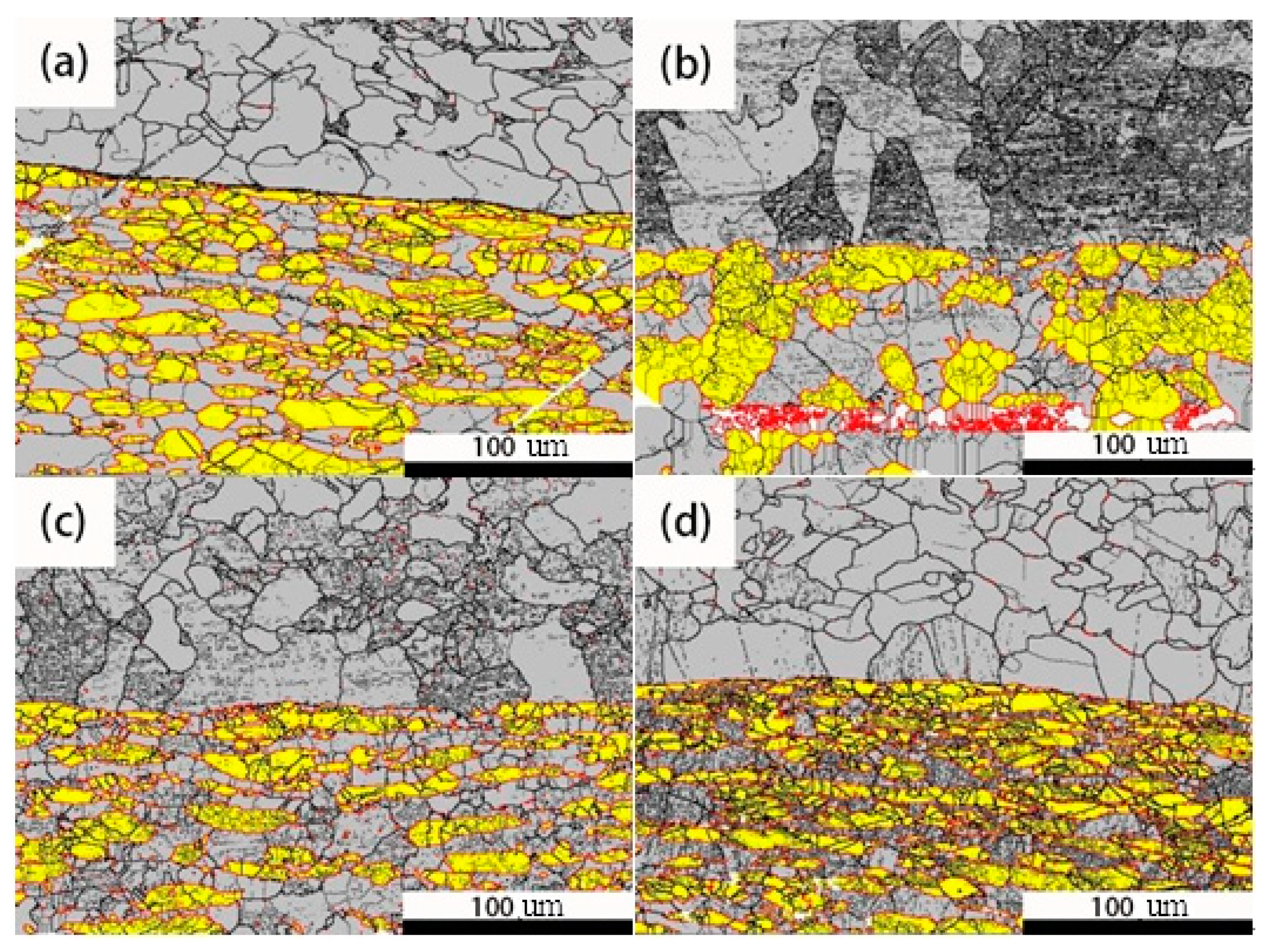

3.2. Microstructure Analysis of Composite Interface

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramkumar, K.D.; Singh, A.; Raghuvanshi, S.; Bajpai, A.; Solanki, T.; Arivarasu, M.; Arivazhagan, N.; Narayanan, S. Metallurgical and mechanical characterization of dissimilar welds of austenitic stainless steel and super-duplex stainless steel—A comparative study. J. Manuf. Processes 2015, 19, 212–232. [Google Scholar] [CrossRef]

- Poshadel, A.C.; Gharghouri, M.A.; Dawson, P.R. Dawson. Initiation and Propagation of Plastic Yielding in Duplex Stainless Steel. Metall. Mater. Trans. A 2019, 50, 1202–1230. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.Y.; Jia, Y.F.; Xuan, F.Z. Micro-deformation evolutions of the constituent phases in duplex stainless steel during cyclic nanoindentation. Sci. Rep. 2018, 8, 6199. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Li, S.L.; Zhang, H.L.; Wang, X.T.; Wang, Y.L. Characterization of Impact Deformation Behavior of a Thermally Aged Duplex Stainless Steel by EBSD. Acta Metall. Sin. 2018, 31, 798–806. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Hu, S.; Shen, J.; Han, J.; Zhu, Z. Effects of Cr content on the microstructure and properties of 26Cr-3.5Mo-2Ni and 29Cr-3.5Mo-2Ni super ferritic stainless steels. J. Mater. Sci. Technol. 2016, 32, 552. [Google Scholar] [CrossRef]

- Momeni, A.; Dehghani, K.; Poletti, M.C. Law of mixture used to model the flow behavior of a duplex stainless steel at high temperatures. Mater. Chem. Phys. 2013, 139, 747. [Google Scholar] [CrossRef]

- Farnoush, H.; Momeni, A.; Dehghani, K.; Mohandesi, J.A. Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases. Mater. Des. 2010, 31, 220. [Google Scholar] [CrossRef]

- Pinol-Jue, A.; Iza-Mendia, A.; Gutierrez, I. δ/γ interface boundary sliding as a mechanism for strain accommodation during hot deformation in a duplex stainless steel. Metall. Mater. Trans. A 2000, 31, 1671. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Li, G.; Tang, Z.; Ma, M. Microstructural Evolution and Flow Behavior of 2205 and 2507 Duplex Stainless Steel during Double Pass Hot Compressive Deformation. Chin. J. Mater. Res. 2016, 30, 888–896. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Zhou, X.; Liu, C.; Yu, L.; Li, C.; Ning, B. Processing maps and microstructural evolution of the type 347H austenitic heat-resistant stainless steel. J. Mater. Res. 2015, 30, 2090–2100. [Google Scholar] [CrossRef]

- Chen, Z. Research and Prediction of Hot Workability of 2205 Duplex Stainless Steel and Mechanical Properties of Stainless Steel Clad Plate. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2011. [Google Scholar] [CrossRef]

- Jeon, J.; Kim, C.; Yoo, H.; Cho, J.; Kim, D. Reliability of Processing Map and Influence of Sigma Phase Precipitation on Hot Workability of Duplex Stainless Steel. J. Nanosci. Nanotechnol. 2020, 20, 4509–4512. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Wu, R.; Xiong, W.; Song, S. Effect of finishing rolling temperature on microstructure and mechanical properties of C-Mn hot-rolled dual phase steel. Heat Treat. Met. 2017, 42, 124–127. [Google Scholar] [CrossRef]

- Zhao, P.; Du, C.; Zhao, Z. Effects of Cooling Process after Rolling on Microstructure and Mechanical Properties of Hot-rolled Dual-phase Steel DP590. Shandong Metall. 2016, 38, 44–47. [Google Scholar] [CrossRef]

- Song, Y.; Wang, S.; Zhao, G.; Li, Y.; Juan, L.; Jian, Z. Hot deformation behavior and microstructural evolution of 2205 duplex stainless steel. Mater. Res. Express 2020, 7, 046510. [Google Scholar] [CrossRef]

- Chen, L.; Wang, L.; Du, X.; Liu, X. Hot deformation behavior of 2205 duplex stainless steel: Hot deformation behavior of 2205 duplex stainless steel. Acta Metall. Sin. 2010, 46, 52–56. [Google Scholar] [CrossRef]

- Liu, Y.; Li, P.; Liu, K.; Huang, X.; Zhao, H. Effect of heat treatments on the properties of explosive clad plates 2205 DSS-Q345R. Chin. J. Ship Res. 2016, 11, 128–132. [Google Scholar] [CrossRef]

- Bi, Z.; Ding, B.; Zhang, F.; Jin, S. Performance Analysis of Large Area 25 Duplex Stainless Steel Composite Plate. Welded Pipe Tube 2010, 33, 25–28. [Google Scholar] [CrossRef]

- Momeni, A.; Dehghani, K. Hot working behavior of 2205 austenite–ferrite duplex stainless steel characterized by constitutive equations and processing maps. Mater. Sci. Eng. A 2011, 528, 1448–1454. [Google Scholar] [CrossRef]

| Steel | C | Cr | Mo | Ni | Si | S | Mn | P | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | 0.025 | 21.83 | 3.09 | 5.45 | 0.58 | 0.003 | 1.13 | 0.024 | 0.1699 | Bal. |

| Q345 | 0.20 | 0.25 | 0.10 | 0.012 | 0.50 | 0.035 | 1.70 | 0.035 | 0.012 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liu, P.; Zhao, G.; Li, J.; Zhi, C. Thermal Deformation Behavior and Interface Microstructure Analysis of 2205/Q345 Hot Compression Composite. Crystals 2022, 12, 301. https://doi.org/10.3390/cryst12020301

Wang X, Liu P, Zhao G, Li J, Zhi C. Thermal Deformation Behavior and Interface Microstructure Analysis of 2205/Q345 Hot Compression Composite. Crystals. 2022; 12(2):301. https://doi.org/10.3390/cryst12020301

Chicago/Turabian StyleWang, Xiaoyang, Pengtao Liu, Guanghui Zhao, Juan Li, and Chenchen Zhi. 2022. "Thermal Deformation Behavior and Interface Microstructure Analysis of 2205/Q345 Hot Compression Composite" Crystals 12, no. 2: 301. https://doi.org/10.3390/cryst12020301

APA StyleWang, X., Liu, P., Zhao, G., Li, J., & Zhi, C. (2022). Thermal Deformation Behavior and Interface Microstructure Analysis of 2205/Q345 Hot Compression Composite. Crystals, 12(2), 301. https://doi.org/10.3390/cryst12020301