In Situ Analytical Methods for the Characterization of Mechanochemical Reactions

Abstract

:1. Introduction

2. Methods for In Situ Characterization during Mechanochemical Reactions

- (a)

- Pressure measurements inside the milling jar: this enables us to follow reactions, going along with changes of the pressure by release or consumption of gaseous components. However, this method does not provide any information on the structures of crystalline intermediates/products or the formation of amorphous phases formed during the reaction.

- (b)

- Temperature changes: the detection of temperature changes is suitable for endo/exothermic reactions but does not provide any structural information.

- (c)

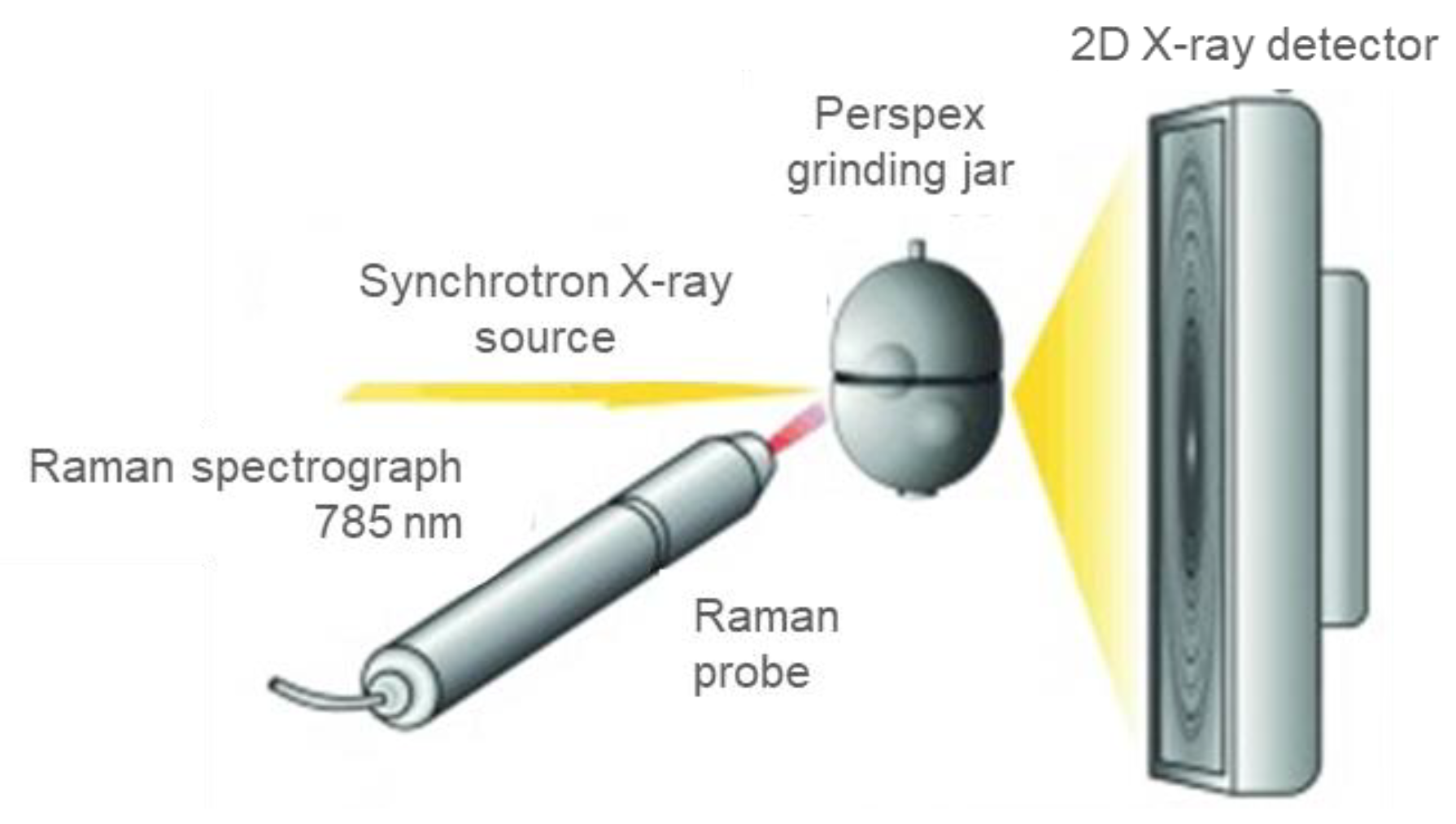

- X-ray powder diffraction: XRD is a powerful tool to monitor changes of crystal structure as well as of microstructure (variation of crystallite size, strain, defects etc.). The formation of amorphous phases can be monitored and phase quantification by Rietveld refinement is feasible. However, this method requires high energy X-ray (synchrotron) radiation and thorough modification of the milling vessel to allow the X-ray beam to pass through the jar. Not all jar material is suitable for mechanochemical reactions of hard materials because the energy input may be negatively affected by, say, too ‘soft’ jar materials. Conventional X-ray powder diffraction is sensitive to crystalline materials and their transformations but is unable to analyze atomic structures on a local or molecular state, for example in amorphous materials, gas phases, or liquids.

- (d)

- Raman spectroscopy: coupling a laser beam into a milling vessel can bridge this gap. Raman spectroscopy requires the use of translucent polymer jars. The combination of Raman and fast synchrotron X-ray diffraction experiments enables data collection on the same time scale to obtain information on a mechanochemical reaction.

- (e)

- NMR spectroscopy: the application of complementary methods such as NMR spectroscopy has shown that there exist further options for coupling analytical methods with the mechanochemical process.

- (f)

- Online gas analysis: coupling of the milling vessel with a gas dosing and a gas detection system based on IR or mass spectrometry finally enables monitoring of structural changes during mechanocatalysis simultaneously with the operando quantification of gaseous reaction products [34].

3. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IUPAC. Compendium of Chemical Terminology. In The “Gold Book”, 2nd ed.; McNaught, A.D., Wilkinson, A., Eds.; Blackwell Scientific Publications: Oxford, UK, 1997; ISBN 0-9678550-9-8. [Google Scholar] [CrossRef]

- McCormick, P.G.; Froes, F.H. The fundamentals of mechanochemical processing. JOM 1998, 50, 61–65. [Google Scholar] [CrossRef]

- Takacs, L. Quicksilver from cinnabar: The first documented mechanochemical reaction? JOM 2000, 52, 12–13. [Google Scholar] [CrossRef]

- Lea, M.C., IV. Disruption of the silver haloid molecule by mechanical force. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1892, 34, 46–50. [Google Scholar] [CrossRef] [Green Version]

- Ling, A.R.; Baker, J.L. XCVI—Halogen derivatives of quinone. Part III. Derivatives of quinhydrone. J. Chem. Soc. Trans. 1893, 63, 1314–1327. [Google Scholar] [CrossRef]

- Ostwald, W. Die Chemische Literatur und die Organisation der Wissenschaft. In Handbuch der Allgemeinen Chemie; Ostwald, W., Drucker, C., Eds.; Akademische Verlagsgesellschaft mbH: Leipzig, Germany, 1919; pp. 70–77. [Google Scholar]

- Baláž, P.; Dutková, E. Fine milling in applied mechanochemistry. Miner. Eng. 2009, 22, 681–694. [Google Scholar] [CrossRef]

- Gomollón-Bel, F. Ten Chemical Innovations That Will Change Our World: IUPAC Identifies Emerging Technologies in Chemistry with Potential to Make Our Planet More Sustainable. Chem. Int. 2019, 41, 12–17. [Google Scholar] [CrossRef]

- Boldyrev, V.V.; Tkácová, K. Mechanochemistry of Solids: Past, Present, and Prospects. J. Mater. Synth. Process. 2000, 8, 121–132. [Google Scholar] [CrossRef]

- Baláž, P. Mechanochemistry in Minerals Engineering. In Mechanochemistry in Nanoscience and Minerals Engineering; Springer: Berlin/Heidelberg, Germany, 2008; pp. 257–296. [Google Scholar]

- Boldyrev, V.V. Mechanochemistry and mechanical activation of solids. Uspekhi Khimii 2006, 75, 203–216. [Google Scholar]

- James, S.L.; Adams, C.J.; Bolm, C.; Braga, D.; Collier, P.; Friščić, T.; Grepioni, F.; Harris, K.D.M.; Hyett, G.; Jones, W.; et al. Mechanochemistry: Opportunities for New and Cleaner Synthesis. Chem. Soc. Rev. 2011, 41, 413–447. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takacs, L. The historical development of mechanochemistry. Chem. Soc. Rev. 2013, 42, 7649–7659. [Google Scholar] [CrossRef]

- Baláž, P.; Achimovičová, M.; Baláž, M.; Billik, P.; Cherkezova-Zheleva, Z.; Criado, J.M.; Delogu, F.; Dutková, E.; Gaffet, E.; Gotor, F.J.; et al. Hallmarks of mechanochemistry: From nanoparticles to technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lapshin, O.V.; Lapshin, O.V.; Boldyreva, E.V.; Boldyrev, V.V. Role of Mixing and Milling in Mechanochemical Synthesis (Review). Russ. J. Inorg. Chem. 2021, 66, 433–453. [Google Scholar] [CrossRef]

- Michalchuk, A.A.L.; Boldyreva, E.V.; Belenguer, A.M.; Emmerling, F.; Boldyrev, V.V. Tribochemistry, Mechanical Alloying, Mechanochemistry: What Is in a Name? Front. Chem. 2021, 9, 685789. [Google Scholar] [CrossRef] [PubMed]

- Boldyreva, E. Mechanochemistry of inorganic and organic systems: What is similar, what is different? Chem. Soc. Rev. 2013, 42, 7719–7738. [Google Scholar] [CrossRef] [PubMed]

- Do, J.-L.; Friščić, T. Mechanochemistry: A Force of Synthesis. ACS Cent. Sci. 2017, 3, 13–19. [Google Scholar] [CrossRef] [Green Version]

- Huot, J.; Ravnsbæk, D.B.; Zhang, J.; Cuevas, F.; Latroche, M.; Jensen, T.R. Mechanochemical synthesis of hydrogen storage materials. Prog. Mater. Sci. 2013, 58, 30–75. [Google Scholar] [CrossRef]

- Baláž, M.; Zorkovská, A.; Blazquez, J.S.; Daneu, N.; Baláž, P. Mechanochemistry of copper sulphides: Phase interchanges during milling. J. Mater. Sci. 2017, 52, 11947–11961. [Google Scholar] [CrossRef]

- Mamatha, M.; Bogdanović, B.; Felderhoff, M.; Pommerin, A.; Schmidt, W.; Schüth, F.; Weidenthaler, C. Mechanochemical preparation and investigation of properties of magnesium, calcium and lithium–magnesium alanates. J. Alloys Compd. 2006, 407, 78–86. [Google Scholar] [CrossRef]

- Mi, G.M.; Saito, F. Mechanochemical Polymorphic Transformation of Photocatalyst Material TiO2 and Its Dependence on the Milling Operation. In Advanced Material Science and Technology, Pts 1 and 2; Tan, Y., Ju, D.Y., Eds.; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2011; Volume 675–677, pp. 283–286. [Google Scholar]

- Rounaghi, S.A.; Eshghi, H.; Scudino, S.; Vyalikh, A.; Vanpoucke, D.E.P.; Gruner, W.; Oswald, S.; Rashid, A.R.K.; Khoshkhoo, M.S.; Scheler, U.; et al. Mechanochemical route to the synthesis of nanostructured Aluminium nitride. Sci. Rep. 2016, 6, 33375. [Google Scholar] [CrossRef] [Green Version]

- Fan, G.J.; Guo, F.Q.; Hu, Z.Q.; Quan, M.X.; Lu, K. Amorphization of selenium induced by high-energy ball milling. Phys. Rev. B 1997, 55, 11010–11013. [Google Scholar] [CrossRef] [Green Version]

- Ogino, Y.; Murayama, S.; Yamasaki, T. Influence of milling atmosphere on amorphization of chromium and Cr-Cu powders by ball milling. J. Less Common Met. 1991, 168, 221–235. [Google Scholar] [CrossRef]

- Jacobsen, C.J.H.; Zhu, J.J.; Lindeløv, H.; Jiang, J.Z. Synthesis of ternary nitrides by mechanochemical alloying. J. Mater. Chem. 2002, 12, 3113–3116. [Google Scholar] [CrossRef]

- Chen, Y.; Williams, J.S. Competitive gas-solid reactions realized by ball milling of Zr in ammonia gas. J. Mater. Res. 1996, 11, 1500–1506. [Google Scholar] [CrossRef]

- Ogino, Y.; Yamasaki, T.; Miki, M.; Atsumi, N.; Yoshioka, K. Synthesis of TiN and (Ti, Al)N powders by mechanical alloying in nitrogen gas. Scr. Met. Mater. 1993, 28, 967–971. [Google Scholar] [CrossRef]

- Schwarz, R.; Petrich, R.; Saw, C. The synthesis of amorphous Ni-Ti alloy powders by mechanical alloying. J. Non-Cryst. Solids 1985, 76, 281–302. [Google Scholar] [CrossRef]

- Hatchard, T.D.; Genkin, A.; Obrovac, M.N. Rapid mechanochemical synthesis of amorphous alloys. AIP Adv. 2017, 7, 045201. [Google Scholar] [CrossRef] [Green Version]

- Yoshimoto, S.; Ohashi, F.; Ohnishi, Y.; Nonami, T. Synthesis of polyaniline–montmorillonite nanocomposites by the mechanochemical intercalation method. Synth. Met. 2004, 145, 265–270. [Google Scholar] [CrossRef]

- Qu, J.; Zhang, Q.; Li, X.; He, X.; Song, S. Mechanochemical approaches to synthesize layered double hydroxides: A review. Appl. Clay Sci. 2016, 119, 185–192. [Google Scholar] [CrossRef]

- Buyanov, R.A.; Molchanov, V.V.; Boldyrev, V.V. Mechanochemical activation as a tool of increasing catalytic activity. Catal. Today 2009, 144, 212–218. [Google Scholar] [CrossRef]

- Immohr, S.; Felderhoff, M.; Weidenthaler, C.; Schüth, F. An Orders-of-Magnitude Increase in the Rate of the Solid-Catalyzed CO Oxidation by In Situ Ball Milling. Angew. Chem. Int. Ed. 2013, 52, 12688–12691. [Google Scholar] [CrossRef]

- Schreyer, H.; Immohr, S.; Schüth, F. Oscillatory combustion of propene during in situ mechanical activation of solid catalysts. J. Mater. Sci. 2017, 52, 12021–12030. [Google Scholar] [CrossRef] [Green Version]

- Porcheddu, A.; Colacino, E.; De Luca, L.; Delogu, F. Metal-Mediated and Metal-Catalyzed Reactions under Mechanochemical Conditions. ACS Catal. 2020, 10, 8344–8394. [Google Scholar] [CrossRef]

- Tan, D.; García, F. Main group mechanochemistry: From curiosity to established protocols. Chem. Soc. Rev. 2019, 48, 2274–2292. [Google Scholar] [CrossRef] [Green Version]

- Boldyrev, V.V.; Avvakumov, E.G. Mechanochemistry of Inorganic Solids. Russ. Chem. Rev. 1971, 40, 847–859. [Google Scholar] [CrossRef]

- Topsøe, H. Developments in operando studies and in situ characterization of heterogeneous catalysts. J. Catal. 2003, 216, 155–164. [Google Scholar] [CrossRef]

- Liu, D.; Shadike, Z.; Lin, R.; Qian, K.; Li, H.; Li, K.; Wang, S.; Yu, Q.; Liu, M.; Ganapathy, S.; et al. Review of Recent Development of In Situ/Operando Characterization Techniques for Lithium Battery Research. Adv. Mater. 2019, 31, e1806620. [Google Scholar] [CrossRef]

- Weidenthaler, C. 1. Weidenthaler, C. 1 In situ tools for the exploration of structure–property relationships. In Crystallography in Materials Science: From Structure-Property Relationships to Engineering; Susan, S., Claudia, W., Eds.; De Gruyter: Berlin, Germany, 2021; pp. 1–54. [Google Scholar]

- von Colbe, J.M.B.; Felderhoff, M.; Bogdanović, B.; Schüth, F.; Weidenthaler, C. One-step direct synthesis of a Ti-doped sodium alanate hydrogen storage material. Chem. Commun. 2005, 36, 4732–4734. [Google Scholar] [CrossRef]

- Takacs, L. Self-sustaining reactions induced by ball milling. Prog. Mater. Sci. 2002, 47, 355–414. [Google Scholar] [CrossRef]

- Tschakarov, C.; Gospodinov, G.; Bontschev, Z. Über den Mechanismus der mechanochemischen Synthese anorganischer Verbindungen. J. Solid State Chem. 1982, 41, 244–252. [Google Scholar] [CrossRef]

- Tschakarov, C.; Rusanov, V.; Gospodinov, G. Untersuchungen zum Mechanismus der Mechanochemischen Synthese von Verbindungen aus dem System SnS mit Hilfe des Mössbauer-Effektes. J. Solid State Chem. 1985, 59, 265–271. [Google Scholar] [CrossRef]

- Friščić, T.; Halasz, I.; Beldon, P.J.; Belenguer, A.M.; Adams, F.; Kimber, S.; Honkimäki, V.; Dinnebier, R.E. Real-time and in situ monitoring of mechanochemical milling reactions. Nat. Chem. 2012, 5, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Halasz, I.; Kimber, S.; Beldon, P.J.; Belenguer, A.M.; Adams, F.; Honkimäki, V.; Nightingale, R.C.; Dinnebier, R.E.; Friščić, T. In situ and real-time monitoring of mechanochemical milling reactions using synchrotron X-ray diffraction. Nat. Protoc. 2013, 8, 1718–1729. [Google Scholar] [CrossRef] [PubMed]

- Halasz, I.; Puškarić, A.; Kimber, S.A.J.; Beldon, P.J.; Belenguer, A.M.; Adams, F.; Honkimäki, V.; Dinnebier, R.E.; Patel, B.; Jones, W.; et al. Real-Time In Situ Powder X-ray Diffraction Monitoring of Mechanochemical Synthesis of Pharmaceutical Cocrystals. Angew. Chem. Int. Ed. 2013, 52, 11538–11541. [Google Scholar] [CrossRef] [PubMed]

- Halasz, I.; Friščić, T.; Kimber, S.A.J.; Užarević, K.; Puškarić, A.; Mottillo, C.; Julien, P.; Štrukil, V.; Honkimäki, V.; Dinnebier, R.E. Quantitative in situ and real-time monitoring of mechanochemical reactions. Faraday Discuss. 2014, 170, 203–221. [Google Scholar] [CrossRef] [PubMed]

- Užarević, K.; Štrukil, V.; Mottillo, C.; Julien, P.A.; Puškarić, A.; Friščić, T.; Halasz, I. Exploring the Effect of Temperature on a Mechanochemical Reaction by in Situ Synchrotron Powder X-ray Diffraction. Cryst. Growth Des. 2016, 16, 2342–2347. [Google Scholar] [CrossRef]

- Biliškov, N.; Borgschulte, A.; Užarević, K.; Halasz, I.; Lukin, S.; Milošević, S.; Milanović, I.; Novaković, J.G. In-Situ and Real-time Monitoring of Mechanochemical Preparation of Li2Mg(NH2BH3)4 and Na2Mg(NH2BH3)4 and Their Thermal Dehydrogenation. Chem.—Eur. J. 2017, 23, 16274–16282. [Google Scholar] [CrossRef] [Green Version]

- Tumanov, N.; Ban, V.; Poulain, A.; Filinchuk, Y. 3D-printed jars for ball-milling experiments monitoredin situby X-ray powder diffraction. J. Appl. Crystallogr. 2017, 50, 994–999. [Google Scholar] [CrossRef]

- Lampronti, G.I.; Michalchuk, A.A.L.; Mazzeo, P.P.; Belenguer, A.M.; Sanders, J.K.M.; Bacchi, A.; Emmerling, F. Changing the game of time resolved X-ray diffraction on the mechanochemistry playground by downsizing. Nat. Commun. 2021, 12, 6134. [Google Scholar] [CrossRef]

- Ban, V.; Sadikin, Y.; Lange, M.; Tumanov, N.; Filinchuk, Y.; Černý, R.; Casati, N. Innovative In Situ Ball Mill for X-ray Diffraction. Anal. Chem. 2017, 89, 13176–13181. [Google Scholar] [CrossRef]

- Batzdorf, M.S.L.; Fischer, D.-C.F.; Wilke, D.-C.M.; Wenzel, D.-I.K.-J.; Emmerling, F. Direct In Situ Investigation of Milling Reactions Using Combined X-ray Diffraction and Raman Spectroscopy. Angew. Chem. Int. Ed. 2015, 54, 1799–1802. [Google Scholar] [CrossRef]

- Amrute, A.P.; Łodziana, Z.; Schreyer, H.; Weidenthaler, C.; Schüth, F. High-surface-area corundum by mechanochemically induced phase transformation of boehmite. Science 2019, 366, 485–489. [Google Scholar] [CrossRef]

- Rathmann, T.; Petersen, H.; Reichle, S.; Schmidt, W.; Amrute, A.P.; Etter, M.; Weidenthaler, C. In situ synchrotron X-ray diffraction studies monitoring mechanochemical reactions of hard materials: Challenges and limitations. Rev. Sci. Instrum. 2021, 92, 114102. [Google Scholar] [CrossRef] [PubMed]

- Petersen, H.; Reichle, S.; Leiting, S.; Losch, P.; Kersten, W.; Rathmann, T.; Tseng, J.; Etter, M.; Schmidt, W.; Weidenthaler, C. In Situ Synchrotron X-ray Diffraction Studies of the Mechanochemical Synthesis of ZnS from Its Elements. Chem.—Eur. J. 2021, 27, 12451–12452. [Google Scholar] [CrossRef] [PubMed]

- Baláž, P.; Aláčová, A.; Achimovičová, M.; Ficeriová, J.; Godočíková, E. Mechanochemistry in hydrometallurgy of sulphide minerals. Hydrometallurgy 2005, 77, 9–17. [Google Scholar] [CrossRef]

- Boldyreva, E. Defogging the view through a milling jar. Nat. Chem. 2022, 14, 10–12. [Google Scholar] [CrossRef]

- Lin, H.-L.; Zhang, G.-C.; Hsu, P.-C.; Lin, S.-Y. A portable fiber-optic Raman analyzer for fast real-time screening and identifying cocrystal formation of drug-coformer via grinding process. Microchem. J. 2013, 110, 15–20. [Google Scholar] [CrossRef]

- Gracin, D.; Štrukil, V.; Friščić, T.; Halasz, I.; Užarević, K. Laboratory Real-Time and In Situ Monitoring of Mechanochemical Milling Reactions by Raman Spectroscopy. Angew. Chem. Int. Ed. 2014, 53, 6193–6197. [Google Scholar] [CrossRef] [Green Version]

- Kulla, H.; Wilke, M.; Fischer, F.; Röllig, M.; Maierhofer, C.; Emmerling, F. Warming up for mechanosynthesis—Temperature development in ball mills during synthesis. Chem. Commun. 2017, 53, 1664–1667. [Google Scholar] [CrossRef]

- Schiffmann, J.G.; Emmerling, F.; Martins, I.C.; Van Wüllen, L. In-situ reaction monitoring of a mechanochemical ball mill reaction with solid state NMR. Solid State Nucl. Magn. Reson. 2020, 109, 101687. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weidenthaler, C. In Situ Analytical Methods for the Characterization of Mechanochemical Reactions. Crystals 2022, 12, 345. https://doi.org/10.3390/cryst12030345

Weidenthaler C. In Situ Analytical Methods for the Characterization of Mechanochemical Reactions. Crystals. 2022; 12(3):345. https://doi.org/10.3390/cryst12030345

Chicago/Turabian StyleWeidenthaler, Claudia. 2022. "In Situ Analytical Methods for the Characterization of Mechanochemical Reactions" Crystals 12, no. 3: 345. https://doi.org/10.3390/cryst12030345

APA StyleWeidenthaler, C. (2022). In Situ Analytical Methods for the Characterization of Mechanochemical Reactions. Crystals, 12(3), 345. https://doi.org/10.3390/cryst12030345