Transport Properties of the Two-Dimensional Hole Gas for H-Terminated Diamond with an Al2O3 Passivation Layer

Abstract

:1. Introduction

2. Experiments

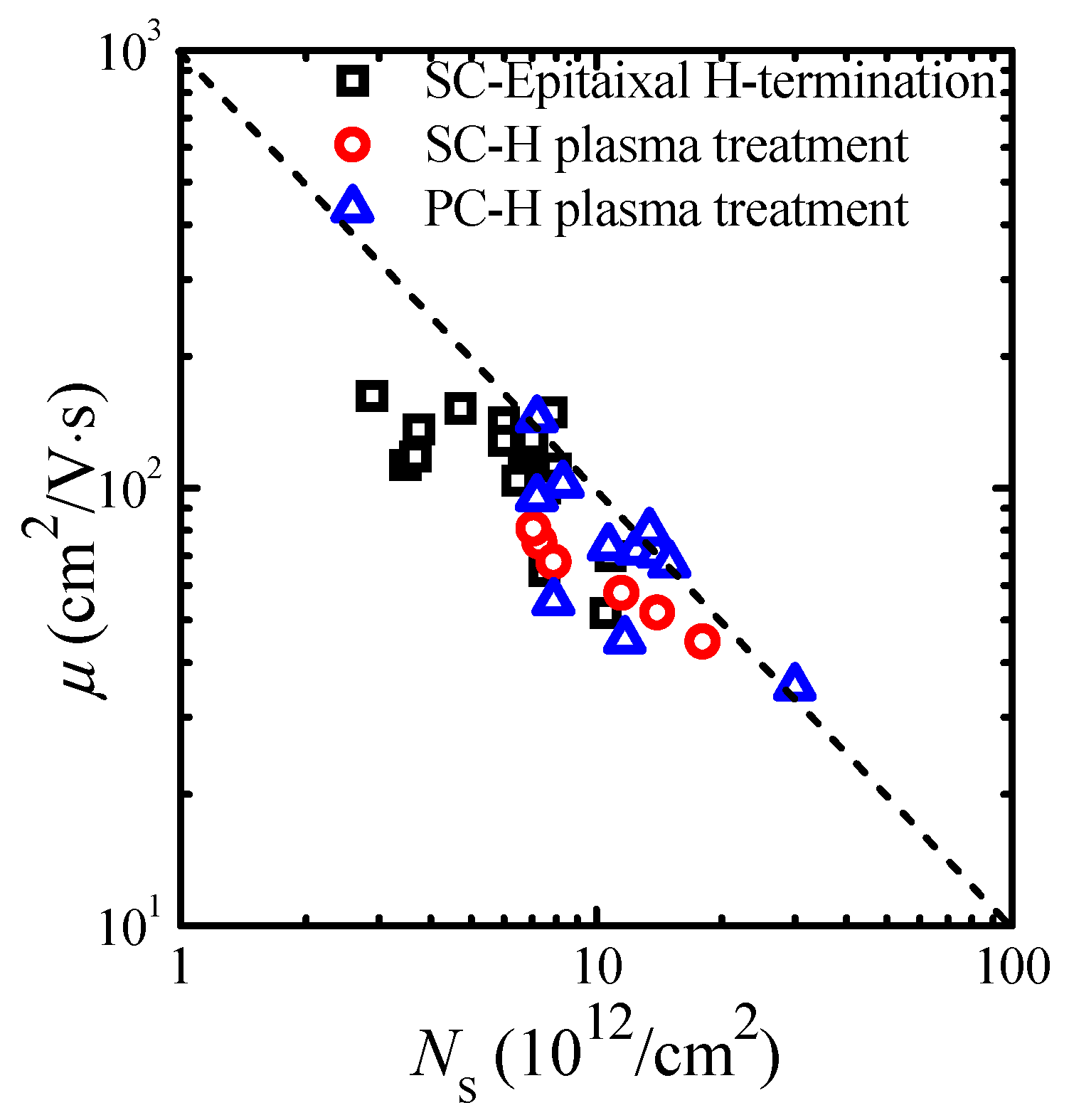

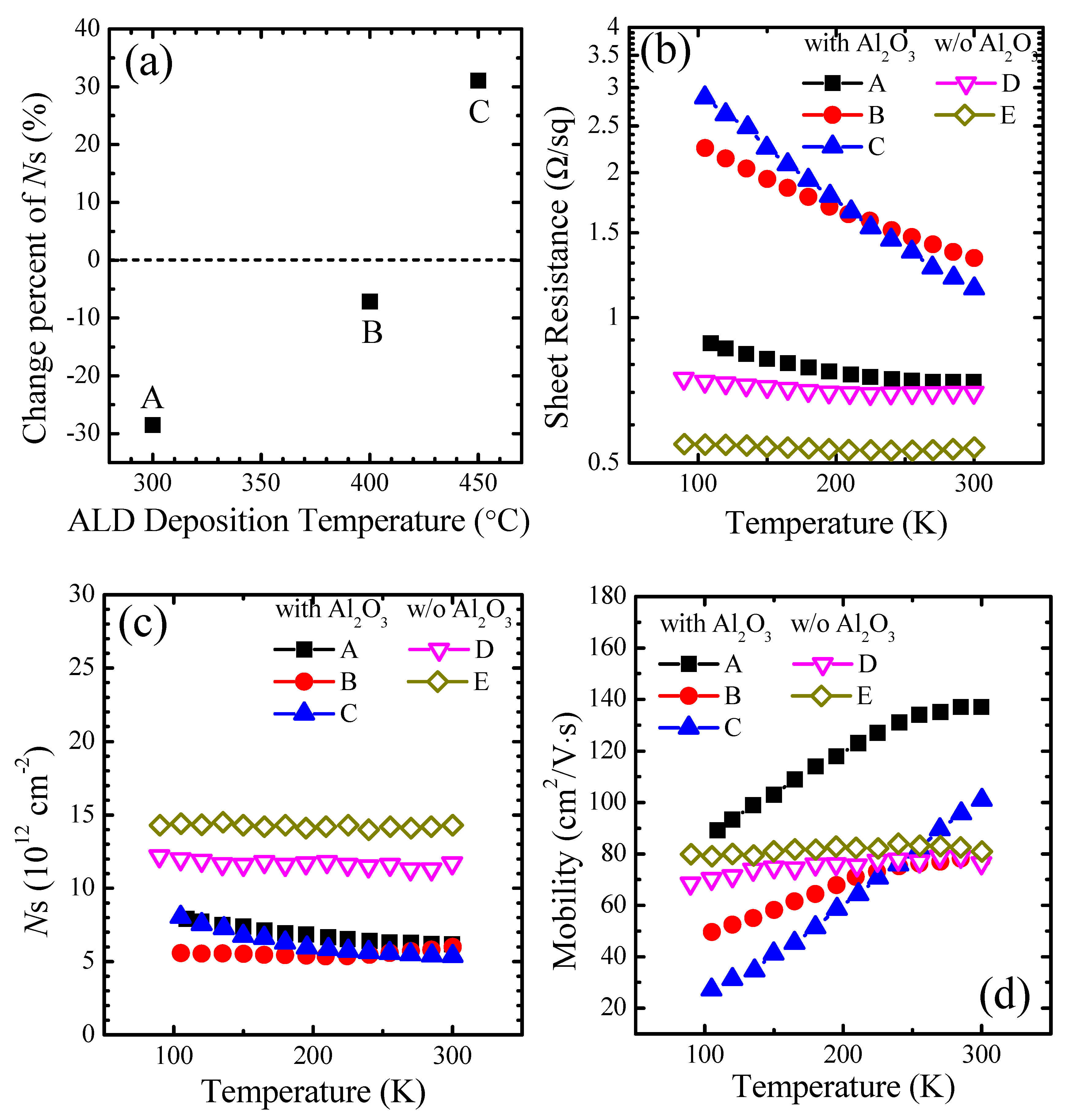

3. Results and Discussion

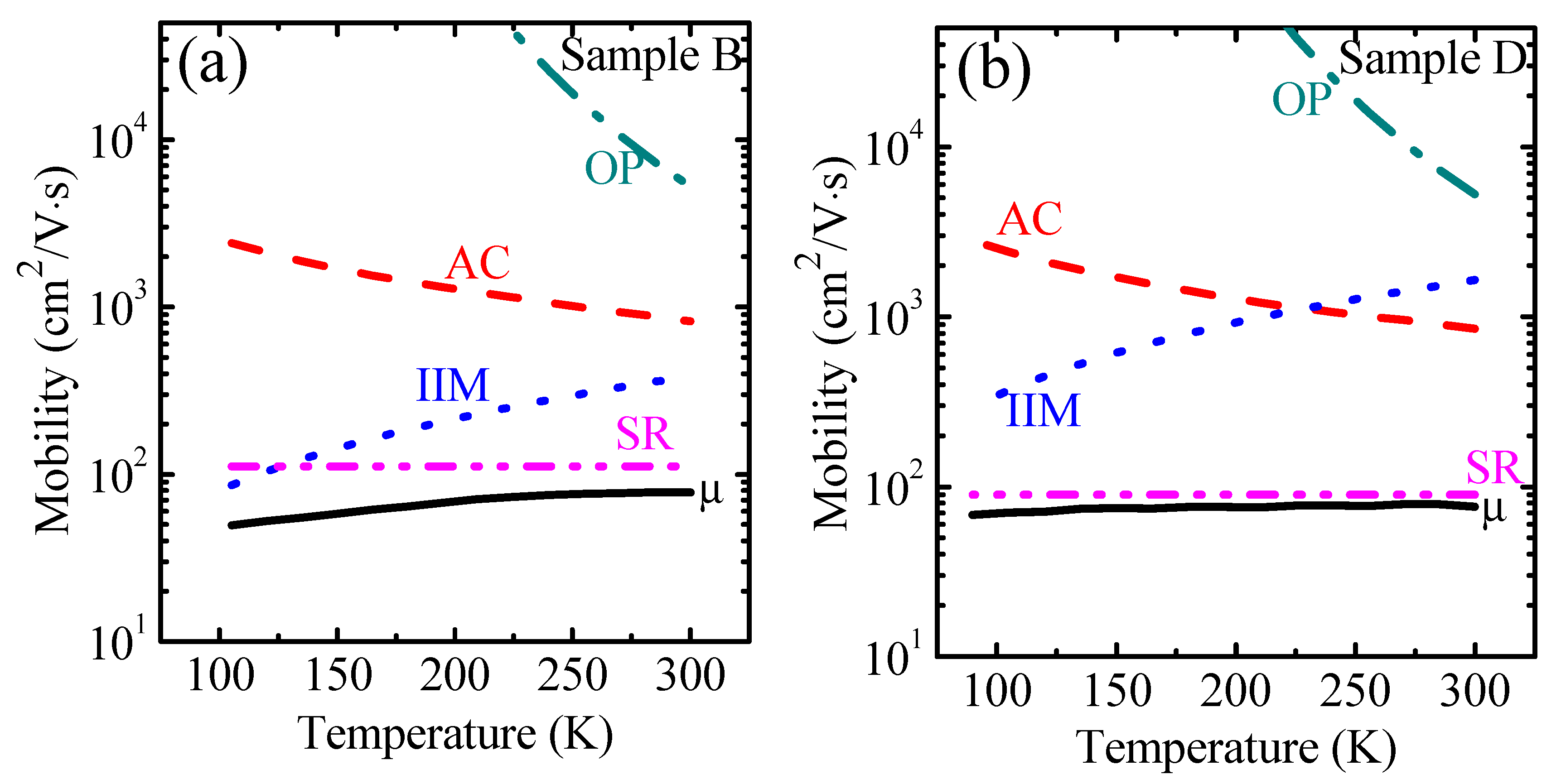

- (1)

- Acoustic phonon (AC) scattering

- (2)

- Optical phonon (OP) scattering

- (3)

- Ionic impurity (IM) scattering

- (4)

- Surface roughness (SR) scattering

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wort, C.J.H.; Balmer, R.S. Diamond as an electronic material. Mater. Today 2008, 11, 22. [Google Scholar] [CrossRef]

- Hui, J.L.; Pang, L.Y.S.; Molloy, A.B.; Jones, F.; Whitfield, M.D.; Foord, J.S.; Richard, B.J. Mechanisms of surface conductivity in thin film diamond: Application to high performance devices. Carbon 1999, 37, 801. [Google Scholar]

- Kawarada, H.; Aoki, M.; Ito, M. Enhancement mode metal-semiconductor field effect transistors using homoepitaxial diamonds. Appl. Phys. Lett. 1994, 65, 1563. [Google Scholar] [CrossRef]

- Williams, O.A.; Jackman, R.B. High growth rate MWPECVD of single crystal diamond. Diam. Relat. Mater. 2004, 13, 325. [Google Scholar] [CrossRef]

- Looi, H.J.; Pang, L.Y.S.; Molloy, A.B.; Jones, F.; Foord, J.S.; Jackman, R.B. An insight into the mechanism of surface conductivity in thin film diamond. Diam. Relat. Mater. 1998, 7, 550. [Google Scholar] [CrossRef]

- Jiang, N.; Ho, T. Electrical properties of surface conductive layers of homoepitaxial diamond films. J. Appl. Phys. 1999, 85, 8267. [Google Scholar] [CrossRef]

- Hirama, K.; Sato, H.; Harada, Y.; Yamamoto, H.; Kasu, M. Diamond Field-Effect Transistors with 1.3 A/mm Drain Current Density by Al2O3 Passivation Layer. Jpn. J. Appl. Phys. 2012, 51, 090112. [Google Scholar]

- Ueda, K.; Kasu, M.; Yamauchi, Y.; Makimoto, T.; Schwitters, M.; Twitchen, D.J.; Scarsbrook, G.A.; Coe, S.E. Diamond FET using high-quality polycrystalline diamond with fT of 45 GHz and fmax of 120 GHz. IEEE Electron. Device Lett. 2006, 27, 57. [Google Scholar] [CrossRef]

- Imanishi, S.; Horikawa, K.; Oi, N.; Okubo, S.; Kageura, T.; Hiraiwa, A.; Kawarada, H. 3.8 W/mm RF Power Density for ALD Al2O3-Based Two-Dimensional Hole Gas Diamond MOSFET Operating at Saturation Velocity. IEEE Electron. Device Lett. 2018, 40, 279–281. [Google Scholar] [CrossRef]

- Zhou, C.J.; Wang, J.J.; Guo, J.C.; Yu, C.; He, Z.Z.; Liu, Q.B.; Gao, X.D.; Cai, S.J.; Feng, Z.H. Radiofrequency performance of hydrogenated diamond MOSFETs with alumina. Appl. Phys. Lett. 2019, 114, 063501. [Google Scholar] [CrossRef]

- Yu, C.; Zhou, C.J.; Guo, J.C.; He, Z.Z.; Wang, H.X.; Cai, S.J.; Feng, Z.H. 650 mW/mm output power density of H-terminated polycrystalline diamond MISFET at 10 GHz. Electron. Lett. 2020, 56, 334–335. [Google Scholar] [CrossRef]

- Kawarada, H.; Yamada, T.; Xu, D.; Kitabayashi, Y.; Shibata, M.; Matsumura, D.; Kobayashi, M.; Saito, T.; Kudo, T.; Inaba, M.; et al. Diamond MOSFETs using 2D Hole Gas with 1700V Breakdown Voltage. In Proceedings of the 28th ISPSD, Prague, Czech Republic, 12–16 June 2016; p. 483. [Google Scholar]

- Ghasemi, M.H.; Abouei, V.; Moshtaghi, M.; Noghani, M.T. The effect of removing worn particles by ultrasonic cleaning on the wear characterization of LM13 alloy. Surf. Eng. Appl. Electrochem. 2015, 51, 382–388. [Google Scholar] [CrossRef]

- Masafumi, K.; Ishii, H.; Shirai, Y.; Ohmi, T. High-corrosion-resistance Al2O3 passivation-film formation by selective oxidation on austenitic stainless steel containing Al. J. Vac. Sci. Technol. A Vac. Surf. Film. 2011, 29, 021002. [Google Scholar]

- Hiraiwa, A.; Daicho, A.; Kurihara, S.; Yokoyama, Y.; Kawarada, H. Refractory two-dimensional hole gas on hydrogenated diamond surface. J. Appl. Phys. 2012, 112, 124504. [Google Scholar]

- Ren, Z.; Lv, D.; Xu, J.; Zhang, J.; Zhang, J.; Su, K.; Zhang, C.; Hao, Y. High temperature (300 °C) ALD grown Al2O3 on hydrogen terminated diamond: Band offset and electrical properties of the MOSFETs. Appl. Phys. Lett. 2020, 116, 013503. [Google Scholar] [CrossRef]

- Liu, J.W.; Oosato, H.; Da, B.; Koide, Y. Fixed charges investigation in Al2O3/hydrogenated-diamond metal-oxide semiconductor capacitors. Appl. Phys. Lett. 2020, 117, 163502. [Google Scholar] [CrossRef]

- Sasama, Y.; Kageura, T.; Komatsu, K.; Moriyama, S.; Inoue, J.; Imura, M.; Watanabe, K.; Taniguchi, T.; Uchihashi, T.; Takahide, Y. Charge-carrier mobility in hydrogen-terminated diamond field-effect transistors. J. Appl. Phys. 2020, 127, 185707. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.F.; Liu, G.P.; Ren, Z.Y.; Zhang, J.C.; Hao, Y. Mobility of two-dimensional hole gas in H-terminated diamond. Phys. Status Solidi (RRL) 2018, 12, 1700401. [Google Scholar] [CrossRef]

- Wang, J.J.; He, Z.Z.; Yu, C.; Song, X.B.; Wang, H.X.; Lin, F.; Feng, Z.H. Comparison of field-effect transistors on polycrystalline and single-crystal diamonds. Diam. Relat. Mater. 2016, 70, 114–117. [Google Scholar] [CrossRef]

- Wang, J.J.; He, Z.Z.; Yu, C.; Song, X.B.; Xu, P.; Zhang, P.W.; Guo, H.; Liu, J.L.; Li, C.M.; Cai, S.J.; et al. Rapid deposition of polycrystalline diamond film by DC arc plasma jet technique and its RF MESFETs. Diam. Relat. Mater. 2014, 43, 43–48. [Google Scholar] [CrossRef]

- Koizumi, S.; Nebel, C.; Nesladek, M. (Eds.) Physics and Applications of CVD Diamond; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Camarchia, V.; Cappelluti, F.; Ghione, G.; Limiti, E.; Moran, D.A.J.; Pirola, M. An overview on recent developments in RF and microwave power H-terminated diamond MESFET technology. In Proceedings of the 2014 International Workshop on Integrated Nonlinear Microwave and Millimetre-Wave Circuits (INMMiC), Leuven, Belgium, 2–4 April 2014; IEEE: New York, NY, USA, 2014. ISBN 978-1-4799-3454-6/14/. [Google Scholar]

- Hiraiwa, A.; Matsumura, D.; Kawarada, H. Effect of atomic layer deposition temperature on current conduction in Al2O3 films formed using H2O oxidant. J. Appl. Phys. 2016, 120, 084504. [Google Scholar]

- Tsukioka, K.; Okushi, H. Hall mobility and scattering mechanism of holes in boron-doped homoepitaxial chemical vapor deposition diamond thin films. Jpn. J. Appl. Phys. 2006, 45, 8571. [Google Scholar] [CrossRef]

- Tsukioka, K. Scattering mechanisms of carriers in natural diamond. Jpn. J. Appl. Phys. 2001, 40, 3108. [Google Scholar] [CrossRef]

- Davies, J.H. The Physics of Low-Dimensional Semiconductors: An Introduction; Cambridge University Press: Cambridge, UK, 1998; p. 365. [Google Scholar]

- Pernot, J.; Volpe, P.N.; Omnès, F.; Muret, P.; Mortet, V.; Haenen, K.; Teraji, T. Hall hole mobility in boron-doped homoepitaxial diamond. Phys. Rev. B 2010, 81, 205203. [Google Scholar] [CrossRef]

- Sussmann, R.S. CVD Diamond for Electronic Devices and Sensors; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; ISBN 978-0-470-06532-7. [Google Scholar]

- Brooks, H. Advances in Electronics and Electron Physics; Marton, L., Ed.; Academic Press: New York, NY, USA, 1955; p. 158. [Google Scholar]

- Zanato, D.; Gokden, S.; Balkan, N.; Ridley, B.K.; Schaff, W.J. The effect of interface-roughness and dislocation scattering on low temperature mobility of 2D electron gas in GaN/AlGaN. Semicond. Sci. Technol. 2004, 19, 427. [Google Scholar] [CrossRef]

| Sample Name | Before Al2O3 Deposition | After Al2O3 Deposition | Al2O3 Deposition Temperature (°C) | ||||

|---|---|---|---|---|---|---|---|

| Rs (Ω/sq) | Ns (1012/cm2) | μ (cm2/V·s) | Rs (Ω/sq) | Ns (1012/cm2) | μ (cm2/V·s) | ||

| A | 8727 | 4.715 | 152 | 7360 | 6.18 | 137 | 450 |

| B | 9271 | 6.461 | 104 | 13,300 | 6 | 77.9 | 400 |

| C | 8332 | 7.512 | 99.7 | 11,500 | 5.37 | 101 | 300 |

| D | 7000 | 11.7 | 76.4 | —— | - | ||

| E | 5380 | 14.3 | 80.9 | —— | - | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, C.; Zhou, C.; Guo, J.; He, Z.; Ma, M.; Wang, H.; Bu, A.; Feng, Z. Transport Properties of the Two-Dimensional Hole Gas for H-Terminated Diamond with an Al2O3 Passivation Layer. Crystals 2022, 12, 390. https://doi.org/10.3390/cryst12030390

Yu C, Zhou C, Guo J, He Z, Ma M, Wang H, Bu A, Feng Z. Transport Properties of the Two-Dimensional Hole Gas for H-Terminated Diamond with an Al2O3 Passivation Layer. Crystals. 2022; 12(3):390. https://doi.org/10.3390/cryst12030390

Chicago/Turabian StyleYu, Cui, Chuangjie Zhou, Jianchao Guo, Zezhao He, Mengyu Ma, Hongxing Wang, Aimin Bu, and Zhihong Feng. 2022. "Transport Properties of the Two-Dimensional Hole Gas for H-Terminated Diamond with an Al2O3 Passivation Layer" Crystals 12, no. 3: 390. https://doi.org/10.3390/cryst12030390

APA StyleYu, C., Zhou, C., Guo, J., He, Z., Ma, M., Wang, H., Bu, A., & Feng, Z. (2022). Transport Properties of the Two-Dimensional Hole Gas for H-Terminated Diamond with an Al2O3 Passivation Layer. Crystals, 12(3), 390. https://doi.org/10.3390/cryst12030390