Synthesis of WS2 by Chemical Vapor Deposition: Role of the Alumina Crucible

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization Techniques

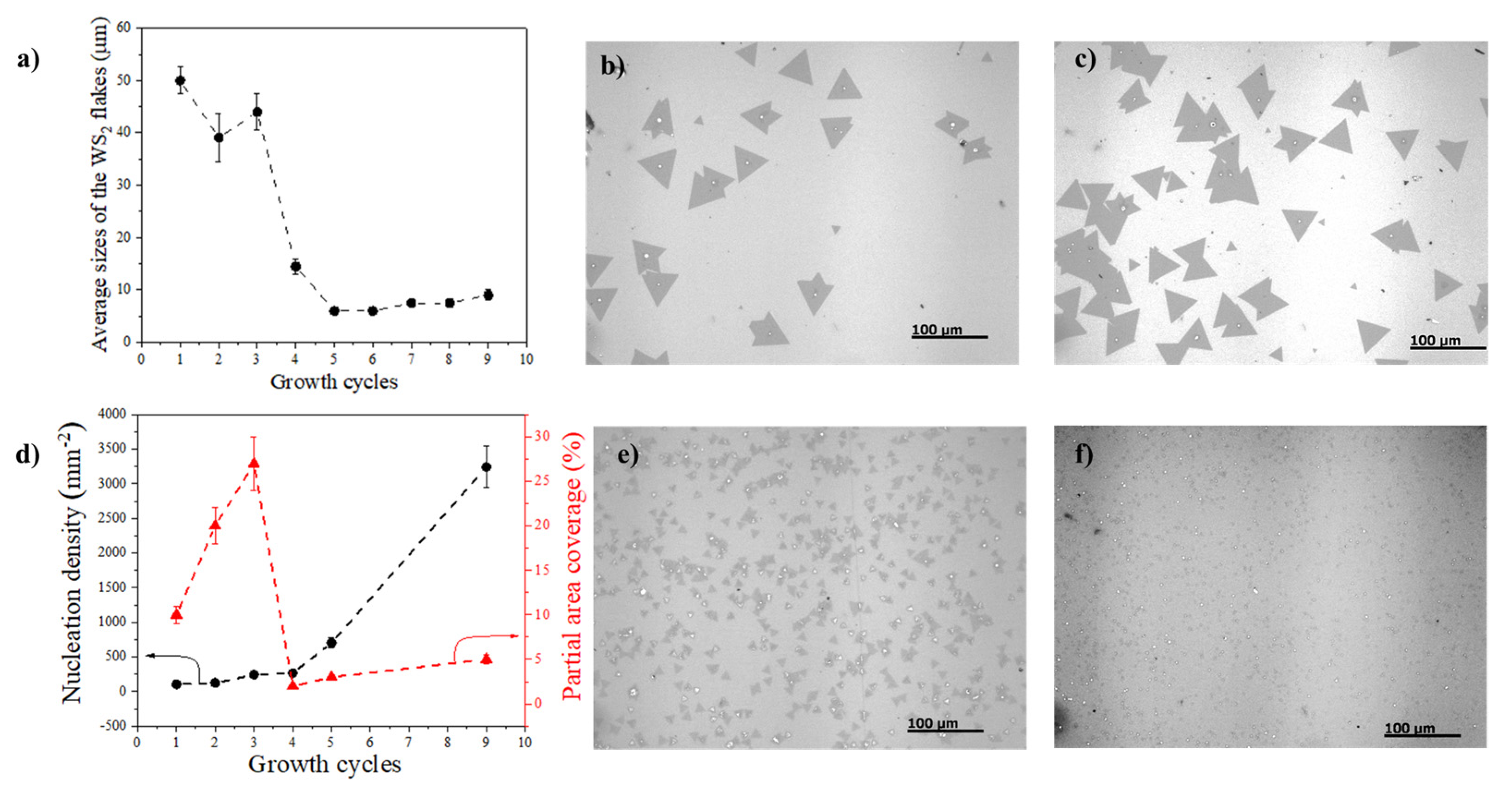

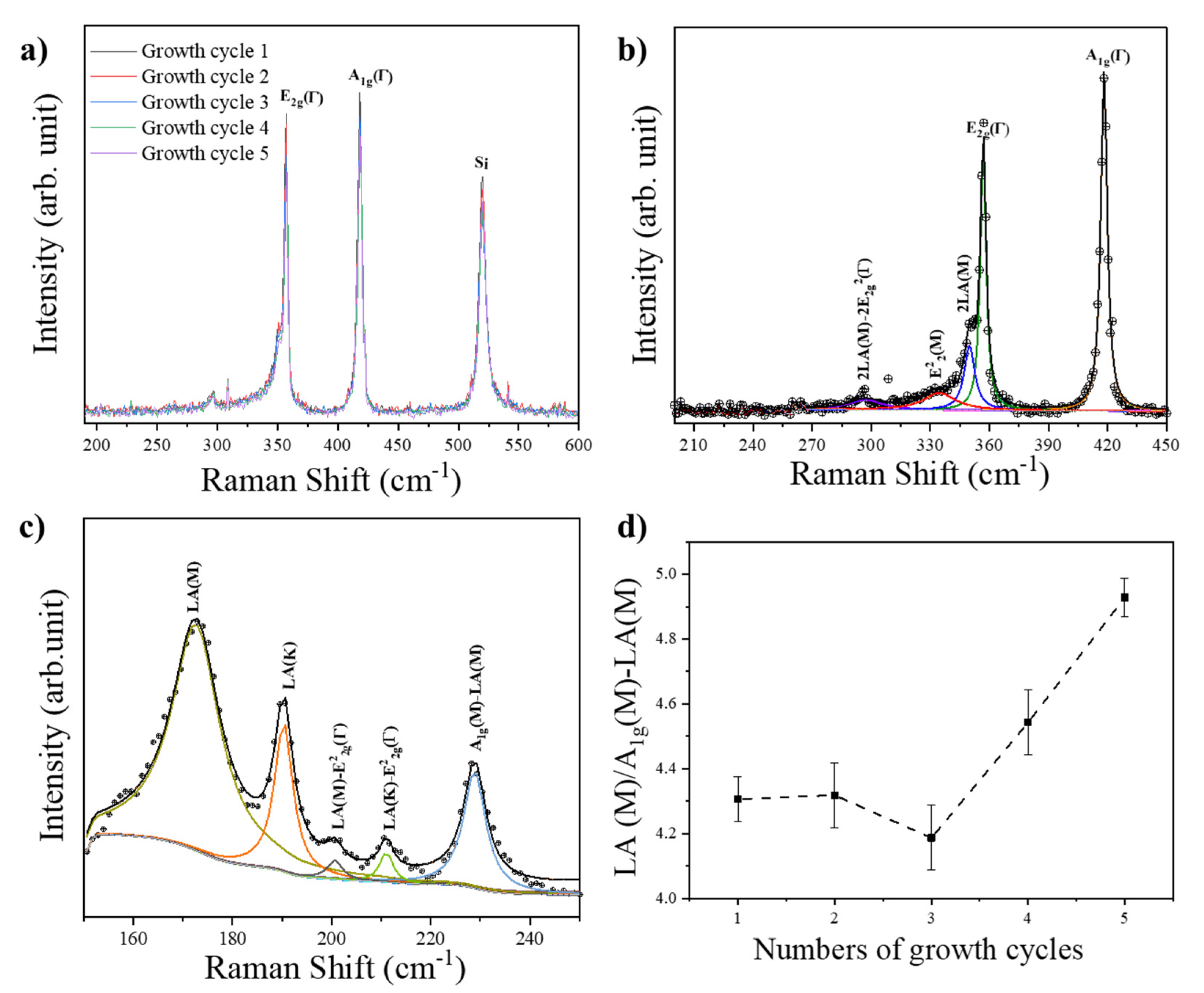

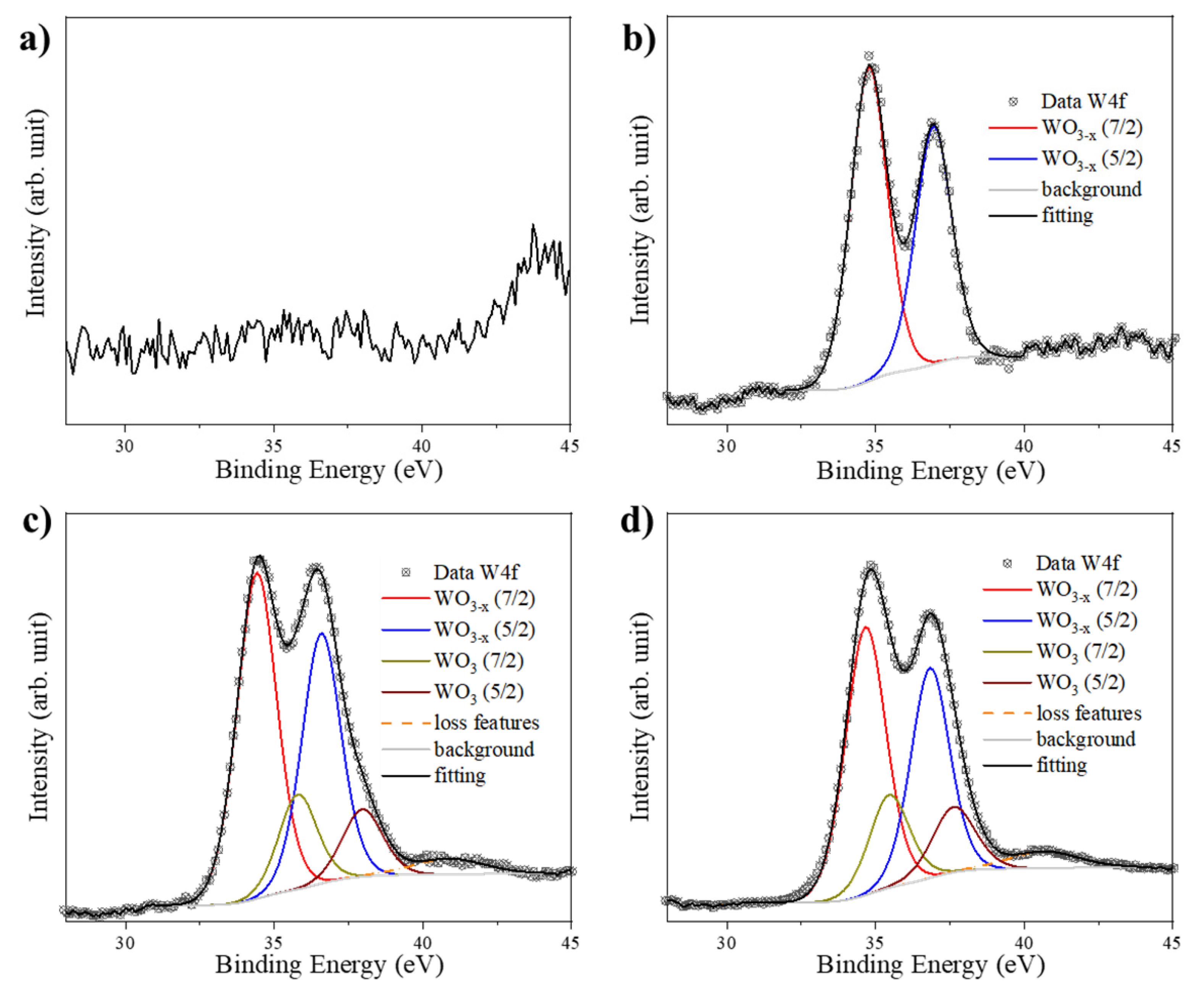

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chhowalla, M.; Jena, D.; Zhang, H. Two-dimensional semiconductors for transistors. Nat. Rev. Mater. 2016, 1, 1–15. [Google Scholar] [CrossRef]

- Tan, C.; Cao, X.; Wu, X.-J.; He, Q.; Yang, J.; Zhang, X.; Chen, J.; Zhao, W.; Han, S.; Nam, G.-H.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef] [PubMed]

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 1–15. [Google Scholar] [CrossRef]

- Ajayan, P.; Kim, P.; Banerjee, K. Two-dimensional van der Waals materials. Phys. Today 2016, 69, 38–44. [Google Scholar] [CrossRef] [Green Version]

- Lv, R.; Terrones, H.; Elías, A.L.; Perea-López, N.; Gutiérrez, H.R.; Cruz-Silva, E.; Rajukumar, L.P.; Dresselhaus, M.S.; Terrones, M. Two-dimensional transition metal dichalcogenides: Clusters, ribbons, sheets and more. Nano Today 2015, 10, 559–592. [Google Scholar] [CrossRef] [Green Version]

- Choi, W.; Choudhary, N.; Han, G.H.; Park, J.; Akinwande, D.; Lee, Y.H. Recent development of two-dimensional transition metal dichalcogenides and their applications. Mater. Today 2017, 20, 116–130. [Google Scholar] [CrossRef]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotech. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Ovchinnikov, D.; Allain, A.; Huang, Y.-S.; Dumcenco, D.; Kis, A. Electrical Transport Properties of Single-Layer WS2. ACS Nano 2014, 8, 8174–8181. [Google Scholar] [CrossRef]

- Baugher, B.W.H.; Churchill, H.O.H.; Yang, Y.; Jarillo-Herrero, P. Optoelectronic devices based on electrically tunable p–n diodes in a monolayer dichalcogenide. Nat. Nanotech. 2014, 9, 262–267. [Google Scholar] [CrossRef] [Green Version]

- Schuler, B.; Qiu, D.Y.; Refaely-Abramson, S.; Kastl, C.; Chen, C.T.; Barja, S.; Koch, R.J.; Ogletree, D.F.; Aloni, S.; Schwartzberg, A.M.; et al. Large Spin-Orbit Splitting of Deep In-Gap Defect States of Engineered Sulfur Vacancies in Monolayer WS2. Phys. Rev. Lett. 2019, 123, 076801. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-S.; Patel, M.; Kim, J.; Jeong, M.S. Growth of Wafer-Scale Standing Layers of WS2 for Self-Biased High-Speed UV–Visible–NIR Optoelectronic Devices. ACS Appl. Mater. Interfaces 2018, 10, 3964–3974. [Google Scholar] [CrossRef] [PubMed]

- Lan, C.; Zhou, Z.; Zhou, Z.; Li, C.; Shu, L.; Shen, L.; Li, D.; Dong, R.; Yip, S.; Ho, J.C. Wafer-scale synthesis of monolayer WS2 for high-performance flexible photodetectors by enhanced chemical vapor deposition. Nano Res. 2018, 11, 3371–3384. [Google Scholar] [CrossRef]

- Duan, X.; Wang, C.; Pan, A.; Yu, R.; Duan, X. Two-dimensional transition metal dichalcogenides as atomically thin semiconductors: Opportunities and challenges. Chem. Soc. Rev. 2015, 44, 8859–8876. [Google Scholar] [CrossRef] [PubMed]

- Zeng, H.; Liu, G.-B.; Dai, J.; Yan, Y.; Zhu, B.; He, R.; Xie, L.; Xu, S.; Chen, X.; Yao, W.; et al. Optical signature of symmetry variations and spin-valley coupling in atomically thin tungsten dichalcogenides. Sci. Rep. 2013, 3, 1608. [Google Scholar] [CrossRef] [Green Version]

- Zheng, W.; Jiang, Y.; Hu, X.; Li, H.; Zeng, Z.; Wang, X.; Pan, A. Light Emission Properties of 2D Transition Metal Dichalcogenides: Fundamentals and Applications. Adv. Opt. Mater. 2018, 6, 1800420. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Z.; Dong, J.; Yi, D.; Niu, J.; Wu, M.; Lin, L.; Yin, R.; Li, M.; Zhou, J.; et al. Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil. Sci. Bull. 2017, 62, 1074–1080. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Yao, Y.; Sendeku, M.G.; Yin, L.; Zhan, X.; Wang, F.; Wang, Z.; He, J. Recent Progress in CVD Growth of 2D Transition Metal Dichalcogenides and Related Heterostructures. Adv. Mater. 2019, 31, 1901694. [Google Scholar] [CrossRef]

- Cong, C.; Shang, J.; Wu, X.; Cao, B.; Peimyoo, N.; Qiu, C.; Sun, L.; Yu, T. Synthesis and Optical Properties of Large-Area Single-Crystalline 2D Semiconductor WS2 Monolayer from Chemical Vapor Deposition. Adv. Opt. Mater. 2014, 2, 131–136. [Google Scholar] [CrossRef]

- McCreary, K.M.; Hanbicki, A.T.; Jernigan, G.G.; Culbertson, J.C.; Jonker, B.T. Synthesis of Large-Area WS2 monolayers with Exceptional Photoluminescence. Sci. Rep. 2016, 6, 19159. [Google Scholar] [CrossRef]

- Kang, K.N.; Godin, K.; Yang, E.-H. The growth scale and kinetics of WS2 monolayers under varying H2 concentration. Sci. Rep. 2015, 5, 13205. [Google Scholar] [CrossRef]

- Liu, P.; Luo, T.; Xing, J.; Xu, H.; Hao, H.; Liu, H.; Dong, J. Large-Area WS2 Film with Big Single Domains Grown by Chemical Vapor Deposition. Nanoscale Res. Lett. 2017, 12, 558. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Y.; Tan, H.; Wang, X.; Warner, J.H. Hydrogen Addition for Centimeter-Sized Monolayer Tungsten Disulfide Continuous Films by Ambient Pressure Chemical Vapor Deposition. Chem. Mater. 2017, 29, 4904–4911. [Google Scholar] [CrossRef]

- Yao, H.; Liu, L.; Wang, Z.; Li, H.; Chen, L.; Pam, M.E.; Chen, W.; Yang, H.Y.; Zhang, W.; Shi, Y. Significant photoluminescence enhancement in WS2 monolayers through Na2S treatment. Nanoscale 2018, 10, 6105–6112. [Google Scholar] [CrossRef] [PubMed]

- Yorulmaz, B.; Özden, A.; Şar, H.; Ay, F.; Sevik, C.; Perkgöz, N.K. CVD growth of monolayer WS2 through controlled seed formation and vapor density. Mater. Sci. Semicond. Processing 2019, 93, 158–163. [Google Scholar] [CrossRef]

- Xu, Z.; Lv, Y.; Li, J.; Huang, F.; Nie, P.; Zhang, S.; Zhao, S.; Zhao, S.; Wei, G. CVD controlled growth of large-scale WS2 monolayers. RSC Adv. 2019, 9, 29628–29635. [Google Scholar] [CrossRef] [Green Version]

- Shi, B.; Zhou, D.; Fang, S.; Djebbi, K.; Feng, S.; Zhao, H.; Tlili, C.; Wang, D. Facile and Controllable Synthesis of Large-Area Monolayer WS2 Flakes Based on WO3 Precursor Drop-Casted Substrates by Chemical Vapor Deposition. Nanomaterials 2019, 9, 578. [Google Scholar] [CrossRef] [Green Version]

- Meng, L.; Hu, S.; Yan, W.; Feng, J.; Li, H.; Yan, X. Controlled synthesis of large scale continuous monolayer WS2 film by atmospheric pressure chemical vapor deposition. Chem. Phys. Lett. 2020, 739, 136945. [Google Scholar] [CrossRef]

- Cohen, A.; Patsha, A.; Mohapatra, P.K.; Kazes, M.; Ranganathan, K.; Houben, L.; Oron, D.; Ismach, A. Growth-Etch Metal–Organic Chemical Vapor Deposition Approach of WS2 Atomic Layers. ACS Nano 2021, 15, 526–538. [Google Scholar] [CrossRef]

- Shi, B.; Zhou, D.; Qiu, R.; Bahri, M.; Kong, X.; Zhao, H.; Tlili, C.; Wang, D. High-efficiency synthesis of large-area monolayer WS2 crystals on SiO2/Si substrate via NaCl-assisted atmospheric pressure chemical vapor deposition. Appl. Surf. Sci. 2020, 533, 147479. [Google Scholar] [CrossRef]

- Chen, Y. Growth of a Large, Single-Crystalline WS2 Monolayer for High-Performance Photodetectors by Chemical Vapor Deposition. Micromachines 2021, 12, 137. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Ji, Q.; Ju, J.; Yuan, H.; Shi, J.; Gao, T.; Ma, D.; Liu, M.; Chen, Y.; et al. Controlled Growth of High-Quality Monolayer WS2 Layers on Sapphire and Imaging Its Grain Boundary. ACS Nano 2013, 7, 8963–8971. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Fang, R.; Zhu, L.; Geng, Z.; He, X. CVD growth of monolayer WS2 through controlled growth temperature and time. Ferroelectrics 2020, 562, 51–57. [Google Scholar] [CrossRef]

- Wang, J.; Luo, Y.; Cai, X.; Shi, R.; Wang, W.; Li, T.; Wu, Z.; Zhang, X.; Peng, O.; Amini, A.; et al. Multiple Regulation over Growth Direction, Band Structure, and Dimension of Monolayer WS2 by a Quartz Substrate. Chem. Mater. 2020, 32, 2508–2517. [Google Scholar] [CrossRef]

- Zafar, A.; Zafar, Z.; Zhao, W.; Jiang, J.; Zhang, Y.; Chen, Y.; Lu, J.; Ni, Z. Sulfur-Mastery: Precise Synthesis of 2D Transition Metal Dichalcogenides. Adv. Funct. Mater. 2019, 29, 1809261. [Google Scholar] [CrossRef]

- do Nascimento Barbosa, A.; Mendoza, C.A.D.; Figueroa, N.J.S.; Terrones, M.; Júnior, F.L.F. Luminescence enhancement and Raman characterisation of defects in WS2 monolayers treated with low-power N2 plasma. Appl. Surf. Sci. 2021, 535, 147685. [Google Scholar] [CrossRef]

- Shi, W.; Lin, M.-L.; Tan, Q.-H.; Qiao, X.-F.; Zhang, J.; Tan, P.-H. Raman and photoluminescence spectra of two-dimensional nanocrystallites of monolayer WS2 and WSe2. 2D Mater. 2016, 3, 025016. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Wang, H.; Chan, W.; Manolatou, C.; Rana, F. Absorption of light by excitons and trions in monolayers of metal dichalcogenide MoS2: Experiments and theory. Phys. Rev. B 2014, 89, 205436. [Google Scholar] [CrossRef] [Green Version]

- Lan, C.; Li, C.; Ho, J.C.; Liu, Y. 2D WS2: From Vapor Phase Synthesis to Device Applications. Adv. Electron. Mater. 2021, 7, 2000688. [Google Scholar] [CrossRef]

- Safeer, S.H.; Moutinho, M.V.O.; Barreto, A.R.J.; Archanjo, B.S.; Pandoli, O.G.; Cremona, M.; da Costa, M.E.H.M.; Freire, F.L.; Carozo, V. Sodium-Mediated Low-Temperature Synthesis of Monolayers of Molybdenum Disulfide for Nanoscale Optoelectronic Devices. ACS Appl. Nano Mater. 2021, 4, 4172–4180. [Google Scholar] [CrossRef]

- Yang, P.; Zou, X.; Zhang, Z.; Hong, M.; Shi, J.; Chen, S.; Shu, J.; Zhao, L.; Jiang, S.; Zhou, X.; et al. Batch solution of 6-inch uniform monolayer molybdenum disulfide catalysed by sodium in glass. Nat. Comm. 2018, 9, 979. [Google Scholar] [CrossRef]

- Han, W.; Liu, K.; Yang, S.; Wang, F.; Su, J.; Jin, B.; Li, H.; Zhai, T. Salt-assisted chemical vapor deposition of two-dimensional materials. Sci. China Chem. 2019, 62, 1300–1311. [Google Scholar] [CrossRef]

| Growth Cycles | Neutral Exciton | Trion | X0/XT Ratio | ||||

|---|---|---|---|---|---|---|---|

| Position (nm) | FWHM (10−2eV) | CCD Mean Intensity (103 Counts) | Position (nm) | FWHM (10−2eV) | CCD Mean Intensity (103 Counts) | ||

| 1 | 636.98 | 13.2 | 3.8 | 647.28 | 20.0 | 1.0 | 3.57 |

| 2 | 636.65 | 14.1 | 6.4 | 647.6 | 19.2 | 1.7 | 3.79 |

| 3 | 635.99 | 12.6 | 10.4 | 645.9 | 20.0 | 2.6 | 4,00 |

| 4 | 637.65 | 16.2 | 0.8 | 649.60 | 20.0 | 0.3 | 2.32 |

| 5 | 638.31 | 17.8 | 0.4 | 656.25 | 20.0 | 0.2 | 1.69 |

| Crucible | Concentration Relative % | Ratio | ||

|---|---|---|---|---|

| W 4f | ||||

| Oxidation state (+5) | Oxidation state (+6) | Loss features | (+6)/(+5) | |

| Virgin crucible | 0 | 0 | 0 | --- |

| Firth growth | 100 | 0 | 0 | 0 |

| Third growth | 75 | 21 | 4.0 | 0.28 |

| Ninth growth | 71 | 25 | 4.0 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stand, N.; Mendoza, C.D.; Freire, F.L., Jr. Synthesis of WS2 by Chemical Vapor Deposition: Role of the Alumina Crucible. Crystals 2022, 12, 835. https://doi.org/10.3390/cryst12060835

Stand N, Mendoza CD, Freire FL Jr. Synthesis of WS2 by Chemical Vapor Deposition: Role of the Alumina Crucible. Crystals. 2022; 12(6):835. https://doi.org/10.3390/cryst12060835

Chicago/Turabian StyleStand, Neileth, Cesar D. Mendoza, and Fernando L. Freire, Jr. 2022. "Synthesis of WS2 by Chemical Vapor Deposition: Role of the Alumina Crucible" Crystals 12, no. 6: 835. https://doi.org/10.3390/cryst12060835

APA StyleStand, N., Mendoza, C. D., & Freire, F. L., Jr. (2022). Synthesis of WS2 by Chemical Vapor Deposition: Role of the Alumina Crucible. Crystals, 12(6), 835. https://doi.org/10.3390/cryst12060835