Thermal Spike Responses and Structure Evolutions in Lithium Niobate on Insulator (LNOI) under Swift Ion Irradiation

Abstract

:1. Introduction

2. Materials and Methods

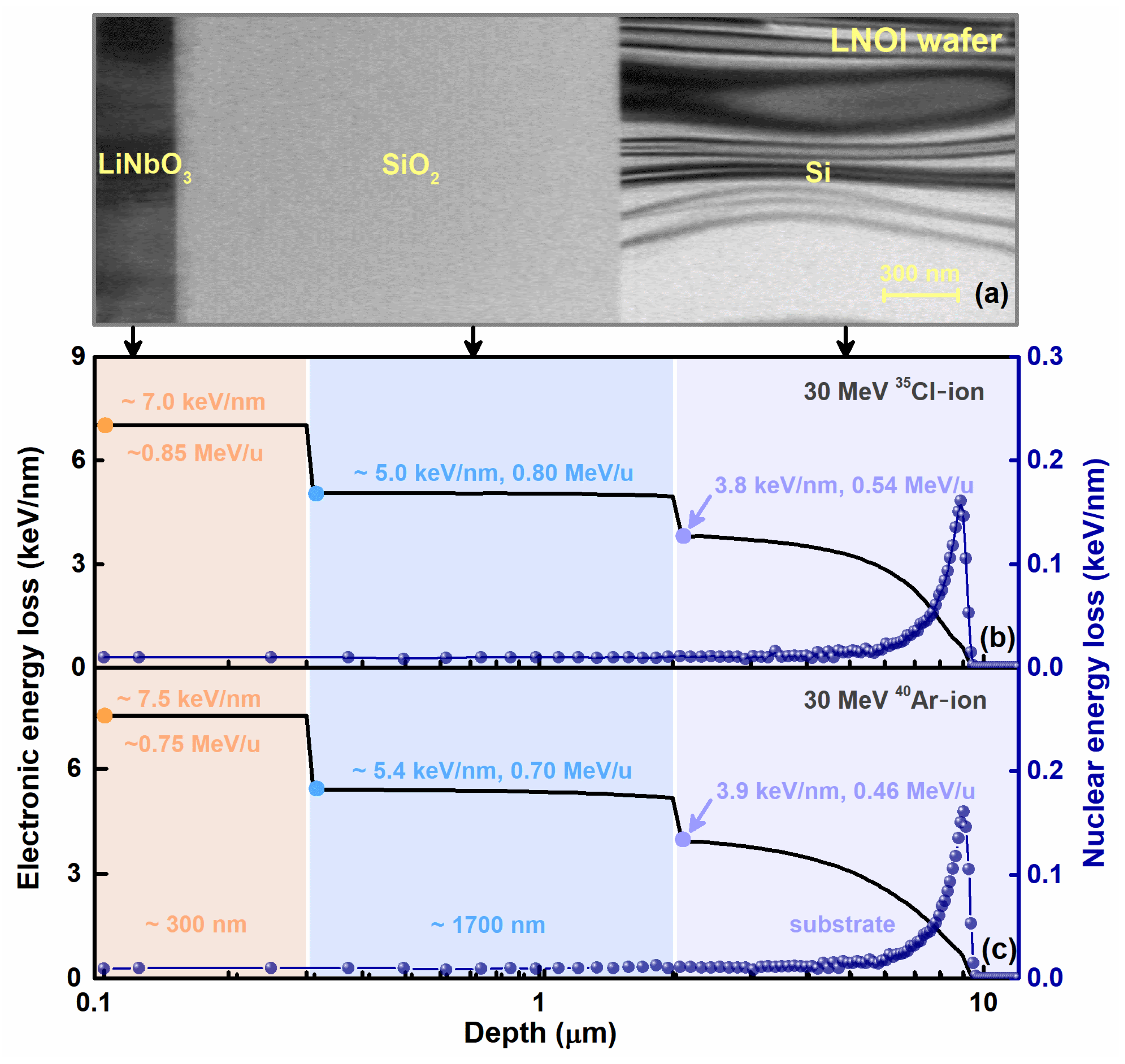

2.1. Sample Preparation and Ion Irradiation Process

2.2. Experimental Characterizations and Numerical Simulations

3. Results and Discussion

3.1. TEM Observations of Ion Irradiation Regions

3.2. Numerical Calculations of the iTS Model

3.3. RBS/Channeling Spectrometry of LNOI Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carr, J.M.; Langhe, D.S.; Ponting, M.T. Confined crystallization in polymer nanolayered films: A review. J. Mater. Res. 2012, 27, 1326–1350. [Google Scholar] [CrossRef] [Green Version]

- Sáenz-Trevizo, A.; Hodge, A.M. Nanomaterials by design: A review of nanoscale metallic multilayers. Nanotechnology 2020, 31, 292002. [Google Scholar] [CrossRef] [PubMed]

- Balamurugan, B.; Mehta, B.R.; Avasthi, D.K. Modifying the nanocrystalline characteristics-structure, size, and surface states of copper oxide thin films by high-energy heavy-ion irradiation. J. Appl. Phys. 2002, 92, 3304–3310. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, W.; Wang, C. Grain growth and phase stability of nanocrystalline cubic zirconia under ion irradiation. Phys. Rev. B 2010, 82, 184105. [Google Scholar] [CrossRef]

- Yu, K.Y.; Chen, Y.; Li, J. Measurement of heavy ion irradiation induced in-plane strain in patterned face-centered-cubic metal films: An in situ study. Nano Lett. 2016, 16, 7481–7489. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, N.; Bufford, D.C. In situ study of heavy ion irradiation response of immiscible Cu/Fe multilayers. J. Nucl. Mater. 2016, 475, 274–279. [Google Scholar] [CrossRef] [Green Version]

- Rück, D.M. Ion induced modification of polymers at energies between 100 keV and 1 GeV applied for optical waveguides and improved metal adhesion. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atmos 2000, 166, 602–609. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, L.; Chen, F. Ion-cut lithium niobate on insulator technology: Recent advances and perspectives. Appl. Phys. Rev. 2021, 8, 011307. [Google Scholar] [CrossRef]

- Poberaj, G.; Hu, H.; Sohler, W. Lithium niobate on insulator (LNOI) for micro-photonic devices. Laser Photonics Rev. 2012, 6, 488–503. [Google Scholar] [CrossRef]

- Boes, A.; Corcoran, B.; Chang, L. Status and potential of lithium niobate on insulator (LNOI) for photonic integrated circuits. Laser Photonics Rev. 2018, 12, 1700256. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, S.; Hu, H. A compact photonic crystal micro-cavity on a single-mode lithium niobate photonic wire. J. Opt. 2016, 18, 035801. [Google Scholar] [CrossRef]

- Volk, M.F.; Suntsov, S.; Rüter, C.E. Low loss ridge waveguides in lithium niobate thin films by optical grade diamond blade dicing. Opt. Express 2016, 24, 1386–1391. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud, M.; Cai, L.; Bottenfield, C. Lithium niobate electro-optic racetrack modulator etched in Y-cut LNOI platform. IEEE Photonics J. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Niu, Y.; Lin, C.; Liu, X.; Chen, Y.; Hu, X.; Zhang, Y. Optimizing the efficiency of a periodically poled LNOI waveguide using in situ monitoring of the ferroelectric domains. Appl. Phys. Lett. 2020, 116, 101104. [Google Scholar] [CrossRef]

- Slautin, B.N.; Turygin, A.P.; Greshnyakov, E.D. Domain structure formation by local switching in the ion sliced lithium niobate thin films. Appl. Phys. Lett. 2020, 116, 152904. [Google Scholar] [CrossRef] [Green Version]

- Slautin, B.N.; Zhu, H.; Shur, V.Y. Submicron periodical poling by local switching in ion sliced lithium niobate thin films with a dielectric layer. Ceram. Int. 2021, 47, 32900–32904. [Google Scholar] [CrossRef]

- Akcoltekin, E.; Peters, T.; Meyer, R.; Duvenbeck, A. Creation of multiple nanodots by single ions. Nat. Nanotechnol. 2007, 2, 290–294. [Google Scholar] [CrossRef] [Green Version]

- Singhal, R.; Tripathi, A.; Avasthi, D.K. Synthesis of carbon nanowires by SHI irradiation of fullerene C70 thin film. Adv. Mater. Lett. 2013, 4, 413–417. [Google Scholar] [CrossRef]

- Gómez-Navarro, C.; De Pablo, P.J.; Gómez-Herrero, J. Tuning the conductance of single-walled carbon nanotubes by ion irradiation in the Anderson localization regime. Nat. Mater. 2005, 4, 534–539. [Google Scholar] [CrossRef]

- Park, S.; Lang, M.; Tracy, C.L. Response of Gd2Ti2O7 and La2Ti2O7 to swift-heavy ion irradiation and annealing. Acta Mater. 2015, 93, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Han, X.; Liu, Y.; Crespillo, M.L. Latent tracks in ion-irradiated LiTaO3 crystals: Damage morphology characterization and thermal spike analysis. Crystals 2020, 10, 877. [Google Scholar] [CrossRef]

- Han, X.; Liu, Y.; Huang, Q. Swift heavy ion tracks in alkali tantalate crystals: A combined experimental and computational study. J. Phys. D Appl. Phys. 2019, 53, 105304. [Google Scholar] [CrossRef]

- Hu, H.; Yang, J.; Gui, L. Lithium niobate-on-insulator (LNOI): Status and perspectives. Silicon Photonics Photonic Integr. Circuits III SPIE 2012, 8431, 268–275. [Google Scholar]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atmos 2010, 268, 1818–1823. [Google Scholar] [CrossRef] [Green Version]

- Xue, H.; Zarkadoula, E.; Liu, P.; Jin, K.; Zhang, Y.; Weber, W.J. Amorphization due to electronic energy deposition in defective strontium titanate. Acta Mater. 2017, 127, 400–406. [Google Scholar] [CrossRef] [Green Version]

- Toulemonde, M.; Assmann, W.; Dufour, C.; Meftah, A.; Studer, F.; Trautmann, C. Experimental phenomena and thermal spike model description of ion tracks in amorphisable inorganic insulators. Mat. Fys. Medd. 2006, 52, 263–292. [Google Scholar]

- Waligorski, M.P.R.; Hamm, R.N.; Katz, R. The radial distribution of dose around the path of a heavy ion in liquid water. Int. J. Radiat. Appl. Instrumentation. Part D Nucl. Tracks Radiat. Meas. 1986, 11, 309–319. [Google Scholar] [CrossRef] [Green Version]

- Toulemondea, M.; Assmannb, W.; Dufoura, C.; Meftahc, A.; Trautmann, C. Nanometric transformation of the matter by short and intense electronic excitation: Experimental data versus inelastic thermal spike model. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atmos 2012, 277, 28–39. [Google Scholar] [CrossRef]

- Han, X.; Huang, Q.; Crespillo, M.L. Electronic energy loss and ion velocity correlation effects in track production in swift-ion-irradiated LiNbO3: A quantitative assessment between structural damage morphology and energy deposition. J. Mater. Sci. Technol. 2022, 116, 30–40. [Google Scholar] [CrossRef]

- Zhang, Y.; Sachan, R.; Pakarinen, O.H. Ionization-induced annealing of pre-existing defects in silicon carbide. Nat. Commun. 2015, 6, 8049. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Weber, W.J.; Jiang, W.; Halle’n, A.; Possnert, G. Damage evolution and recovery on both Si and C sublattices in Al-implanted 4H-SiC studied by RBS and NRA. J. Appl. Phys. 2002, 91, 6388. [Google Scholar] [CrossRef]

- Ishikawa, N.; Taguchi, T.; Ogawa, H. Comprehensive understanding of hillocks and ion tracks in ceramics irradiated with swift heavy ions. Quantum Beam Sci. 2020, 4, 43. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Y.; Xue, H. A coupled effect of nuclear and electronic energy loss on ion irradiation damage in lithium niobate. Acta Mater. 2016, 105, 429–437. [Google Scholar] [CrossRef] [Green Version]

- Sellami, N.; Crespillo, M.L.; Zhang, Y. Two-stage synergy of electronic energy loss with defects in LiTaO3 under ion irradiation. Mater. Res. Lett. 2018, 6, 339–344. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Liu, C.; Zhang, M.; Huang, Q.; Wang, X.; Liu, P. Thermal Spike Responses and Structure Evolutions in Lithium Niobate on Insulator (LNOI) under Swift Ion Irradiation. Crystals 2022, 12, 943. https://doi.org/10.3390/cryst12070943

Han X, Liu C, Zhang M, Huang Q, Wang X, Liu P. Thermal Spike Responses and Structure Evolutions in Lithium Niobate on Insulator (LNOI) under Swift Ion Irradiation. Crystals. 2022; 12(7):943. https://doi.org/10.3390/cryst12070943

Chicago/Turabian StyleHan, Xinqing, Cong Liu, Meng Zhang, Qing Huang, Xuelin Wang, and Peng Liu. 2022. "Thermal Spike Responses and Structure Evolutions in Lithium Niobate on Insulator (LNOI) under Swift Ion Irradiation" Crystals 12, no. 7: 943. https://doi.org/10.3390/cryst12070943