Effect of Longitudinal Magnetic Field on the Microstructure and Properties of A-TIG Welding with Different TiO2 Coating Amounts

Abstract

:1. Introduction

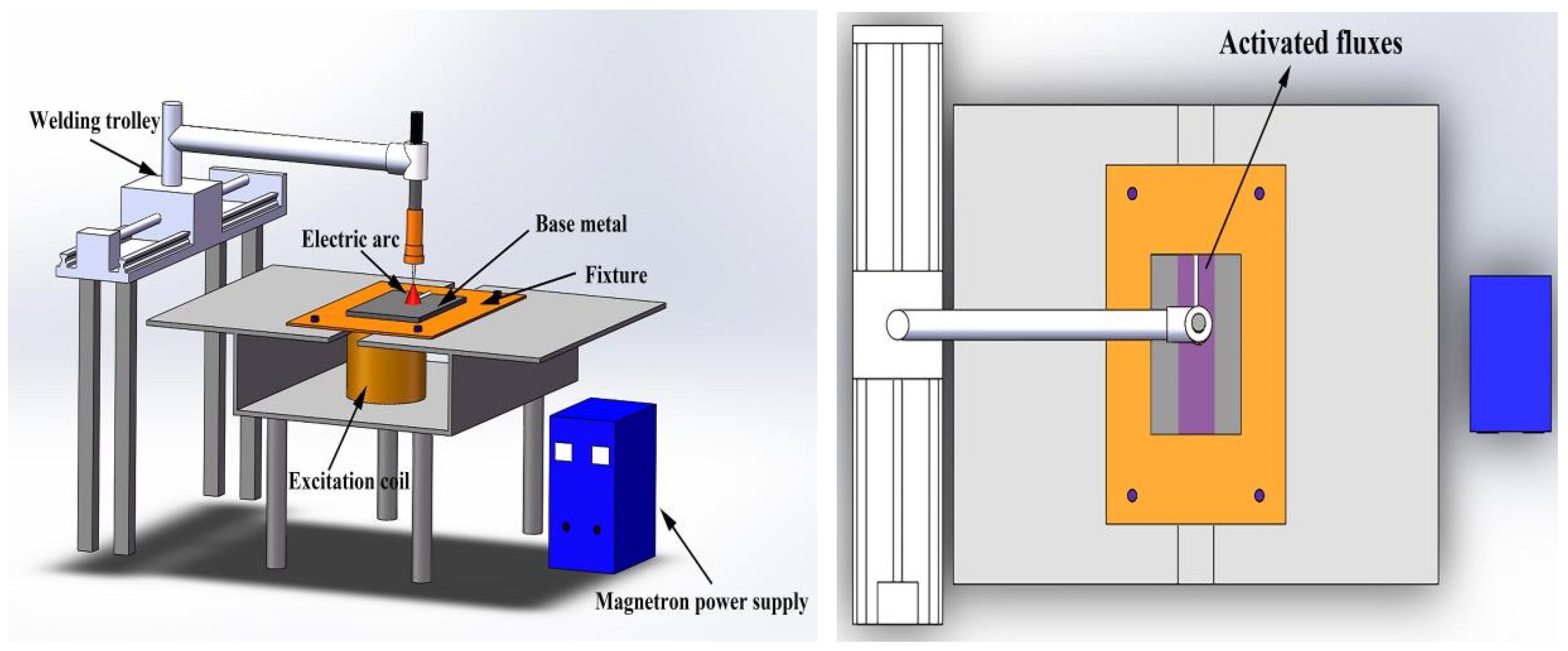

2. Materials and Methods

3. Experimental Results and Discussion

3.1. XRD Diffraction Analysis

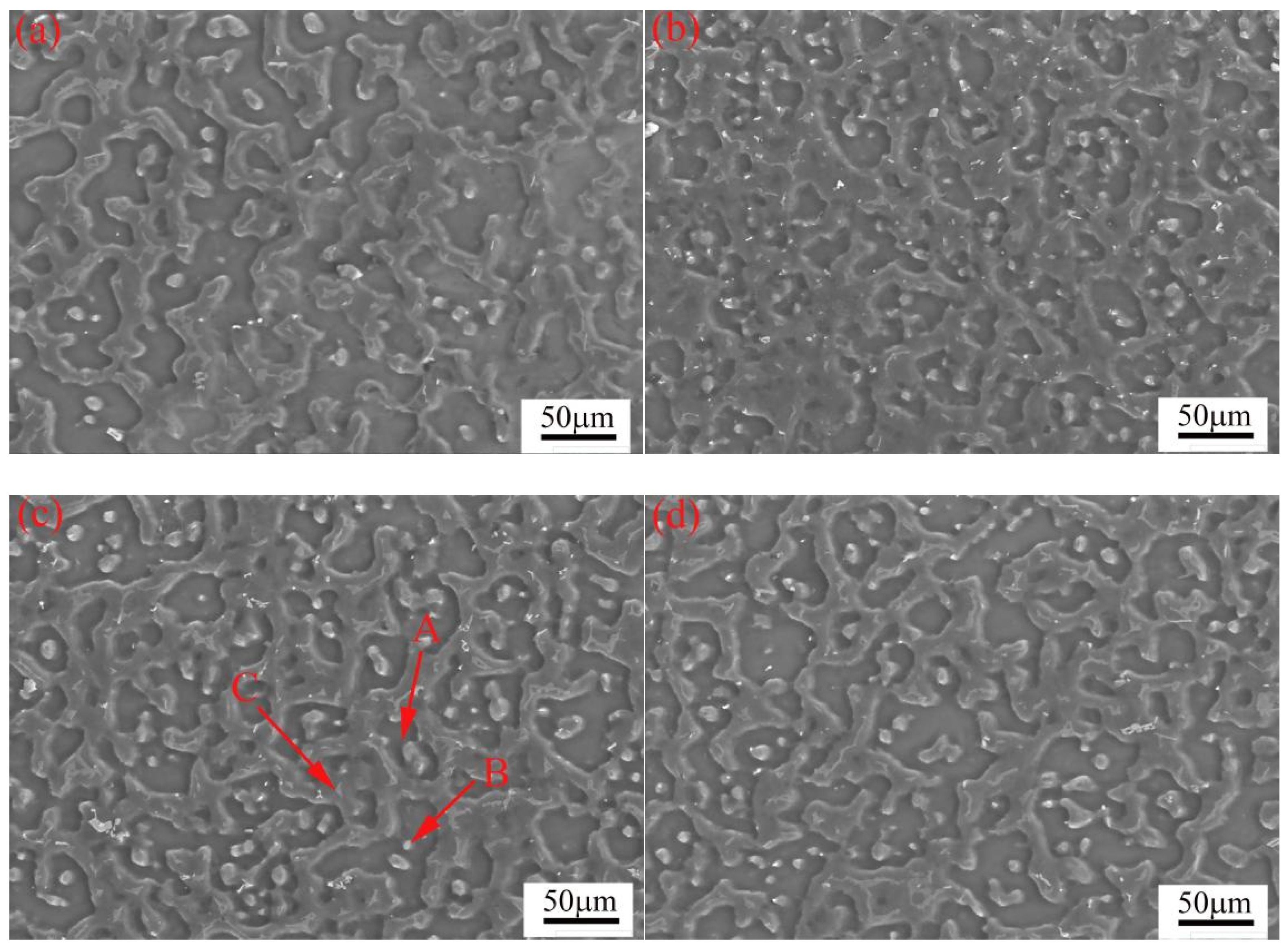

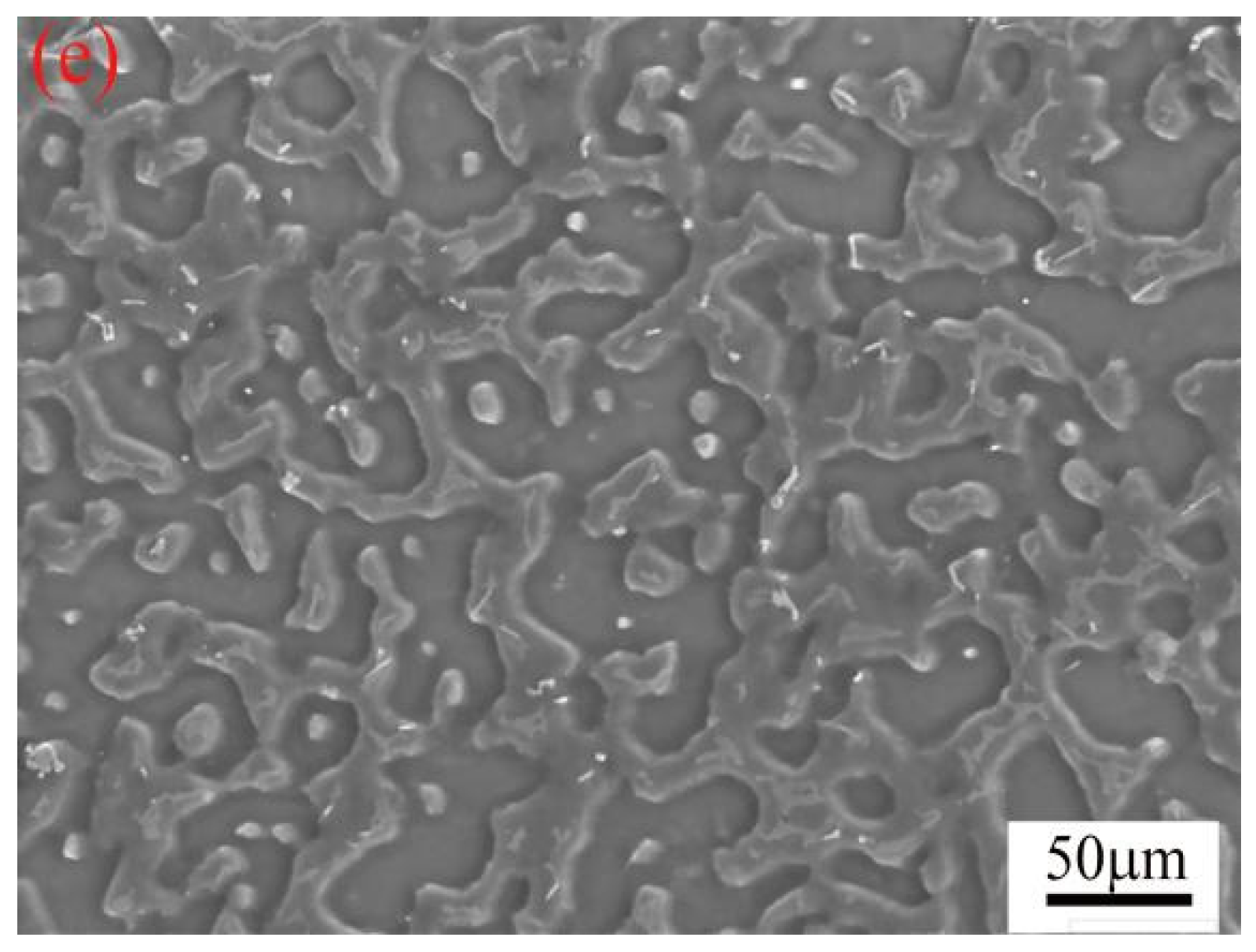

3.2. Effect of Magnetic Field on Microstructure

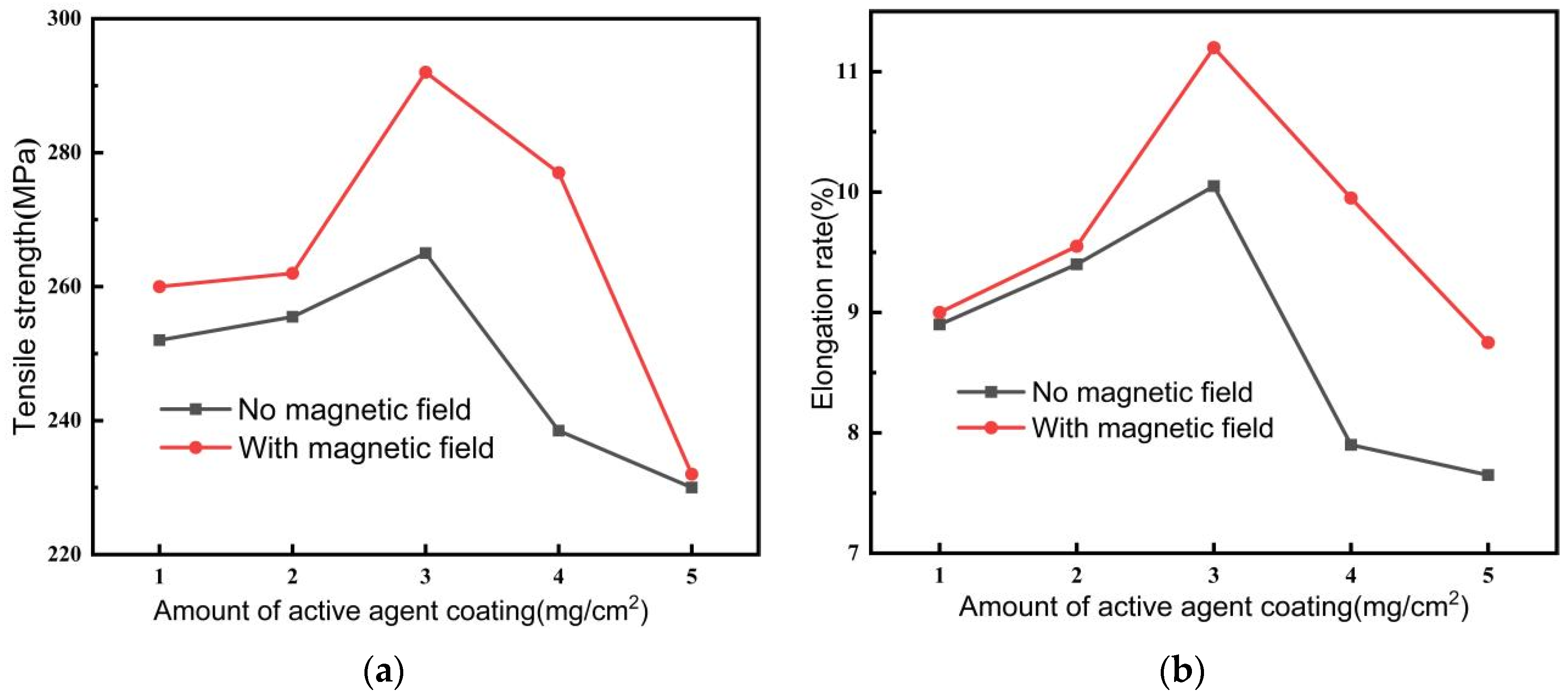

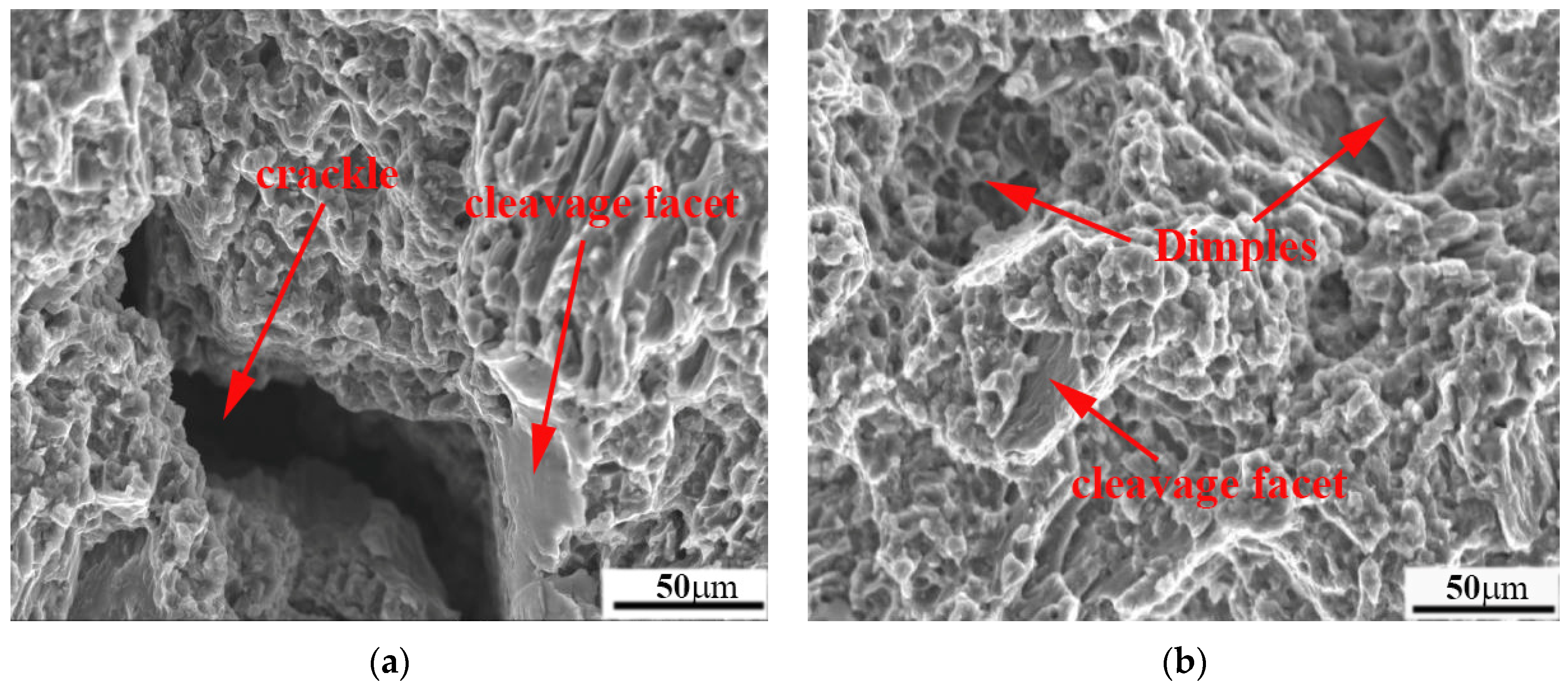

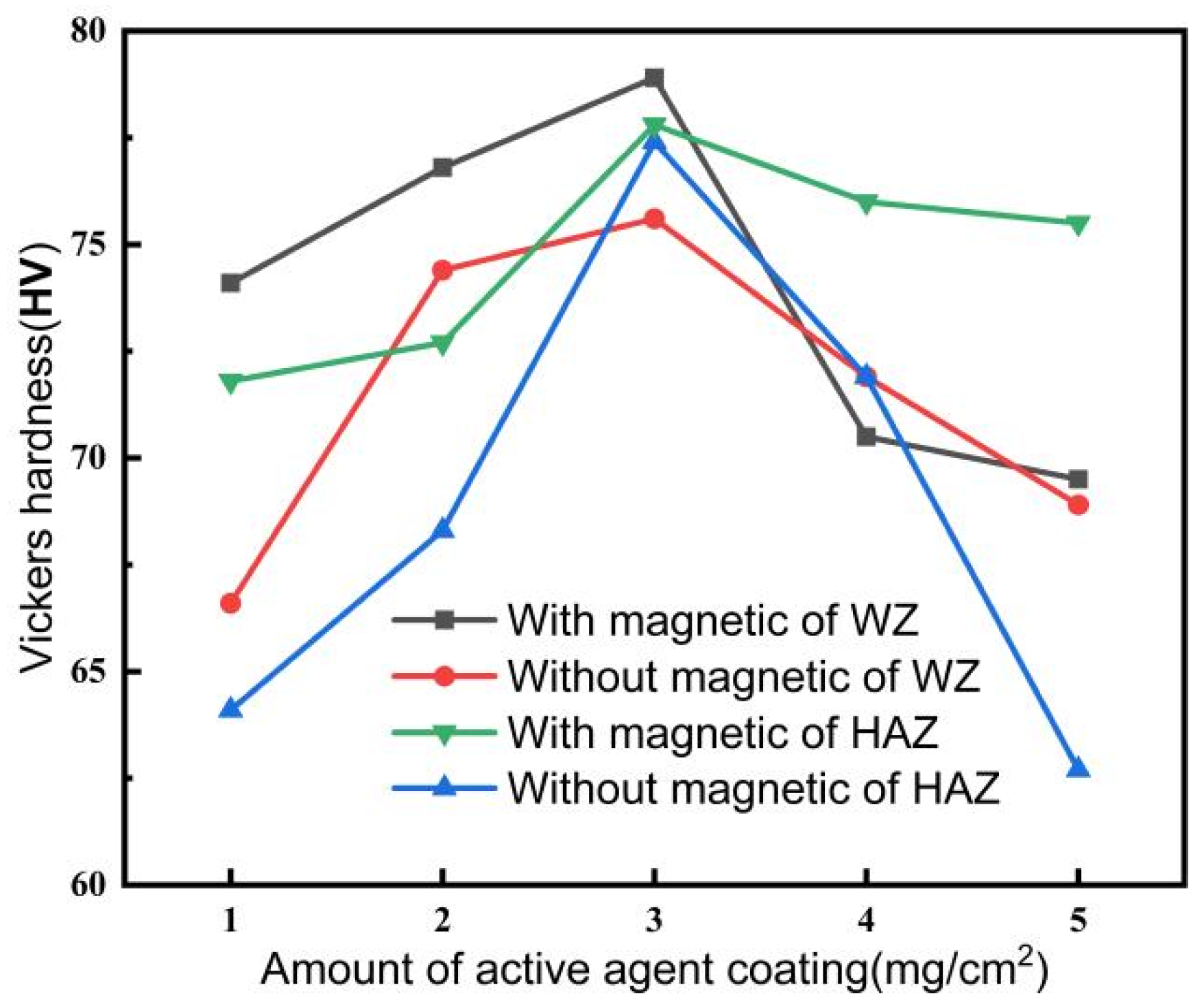

3.3. Effect of Magnetic Field on Mechanical Properties at Different Coating Amounts

4. Conclusions

- (1)

- The longitudinal magnetic field is introduced in the A-TIG welding process, and the grain size tends to decrease and then increase with the increase in the active agent coating under the effect of the magnetic field. When the active agent is too thick, it affects the fluidity of the molten pool during the welding process, hinders the heat dissipation in the weld zone and reduces the quality of the welded joint.

- (2)

- Under the conditions of magnetic field frequency 30 Hz and magnetic field current 1.5 A, the hardness, tensile strength and elongation of the welded joint reached their maximum values when the active agent coating was 3 mg/cm2, which were 78.9 HV in the welded joint and 77.8 HV in the heat-affected zone, 292 MPa in the tensile strength and 11.2% in the elongation, respectively.

- (3)

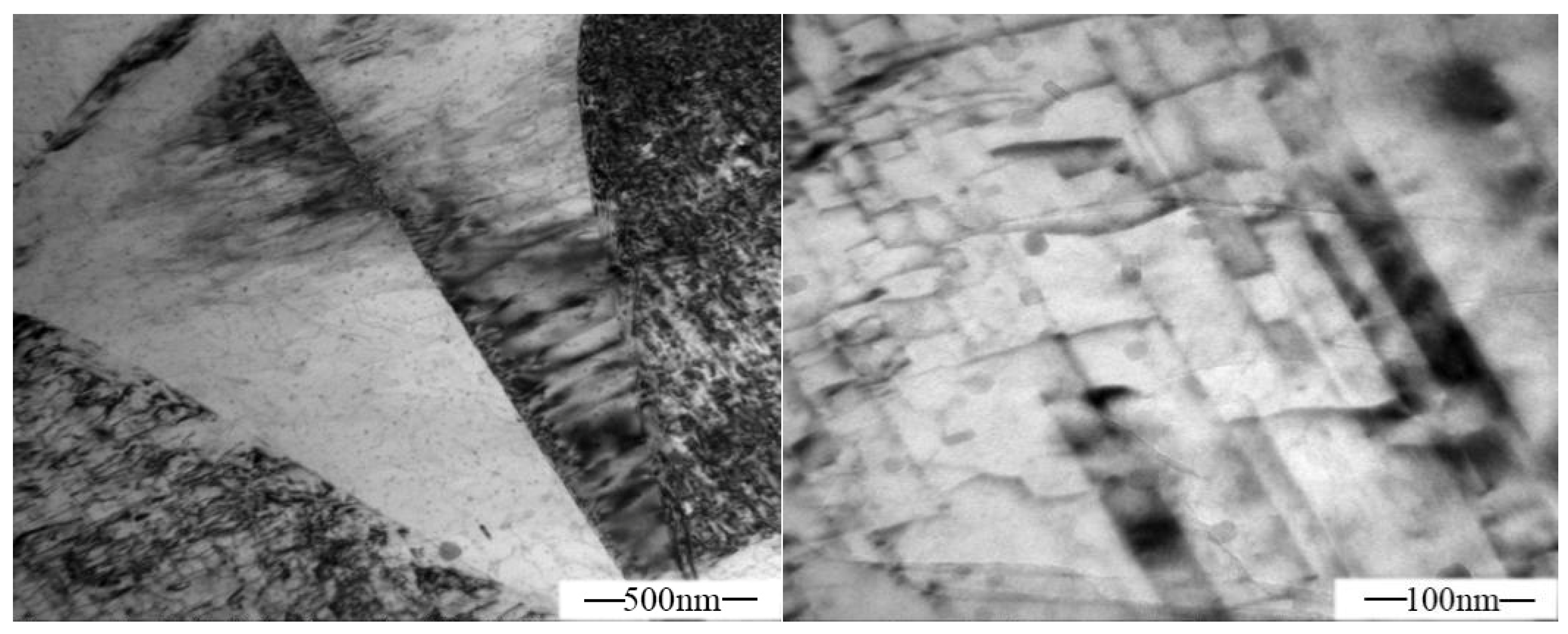

- For the active agent coating amount of 3 mg/cm2 the addition of the magnetic field is beneficial to the precipitation of the second phase in the welded joint and refines the grain, resulting in a reduction in the average grain size by 1.43 μm. TEM analysis found the magnetic field to be under the action of a 3 mg/cm2 coated amount of dislocation near the twinning, which reduces welding defects and improves the quality of the joint.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.M. Interfacial behavior of welded joints of magnesium alloys and heterogeneous materials and study of weldability. Welding 2009, 74, 42–48. [Google Scholar]

- Zeng, R.; Ke, W.; Xu, Y.; Han, E.; Zhu, Z. Recent developments and application prospects of Mg alloys. J. Met. 2001, 37, 53–58. [Google Scholar]

- Hu, X.; Xu, D. Welding methods of magnesium alloys and their process elements. Light Alloy Process. Technol. 2006, 34, 9–13. [Google Scholar]

- Hu, Y.; Zhao, C.; Deng, J. Current status and prospects of research on welding technology for magnesium alloys. Therm. Process. Technol. 2010, 39, 124–128. [Google Scholar]

- Wang, W.X.; Zhang, L.; Zhang, H.X. Research status and development of welding of magnesium alloy materials. Welding 2009, 7, 54–59. [Google Scholar]

- Ma, X.B.; Zhu, H.G. Magnesium alloy and its welding technology. Shanghai Nonferrous Met. 2008, 29, 184–193. [Google Scholar]

- Asahina, T.; Katoh, K.; Tokisue, H. Fatigue strength of friction welded joints of AZ31 magnesium alloy. J. Jpn. Inst. Ligh. Met. 1994, 44, 147–151. [Google Scholar] [CrossRef]

- Seung Hwan, C.P.; Yutaka, S.S.; Hiroyuki, K. Effect of micro-texture on fracture location in friction stir weld of Mg alloy AZ61 during tensile test. Scr. Mater. 2003, 49, 161–166. [Google Scholar]

- Nakata, K.; Inoki, S.; Nagano, Y.; Hashimoto, T.; Johgan, S.; Ushio, M. Weldability of friction stir welding of AZ91D magnesium alloy thixomolded sheet. J. Jpn. Inst. Light Met. 2001, 51, 52–58. [Google Scholar] [CrossRef] [Green Version]

- Gurevich, S.M.; Zamokov, V.N.; Kushirenko, N.A. Improving the penetration of titanium alloys when they are welded by tungsten arc process. Autom. Weld. 1965, 18, 1–5. [Google Scholar]

- Ma, Z.; Zhou, P.; Tian, L.; Li, Z. Current status of research on the mechanism of A-TIG welding melt depth. Therm. Process. Technol. 2012, 41, 177–181. [Google Scholar]

- Li, H. A comparison of TIG and A-TIG welding of stainless steel heat exchangers. J. Luzhou Vocat. Tech. Coll. 2011, 4, 81–83. [Google Scholar]

- Zhou, M.; Shen, J.; Hu, D.; Gao, R.; Li, S. Effects of heat treatment on the activated flux TIG-welded AZ31 magnesium alloy joints.Int. Adv. Manuf. Technol. 2017, 92, 3983–3990. [Google Scholar] [CrossRef]

- Heiple, C.R.; Roper, J.R.; Stagner, R.T.; Aden, R.J. Surface active element effects on the shape of GTA-laser and electron beam welds. Weld. Res. Suppl. 1983, 62, 72–77. [Google Scholar]

- Liu, L.; Zhang, Z.D.; Shen, Y. Effect of reactive agents on the depth of melt in TIG welding of magnesium alloys. J. Met. 2006, 42, 399–404. [Google Scholar]

- Kou, S.; Wang, Y.H. Weld pool convection and its effect. Weld. Res. Suppl. 1986, 65, 63–70. [Google Scholar]

- Rosenthal, D. Mathematical theory of heat distribution during welding and cutting. Weld. J. 1941, 20, 220–231. [Google Scholar]

- Xiao, Y.H.; Ouden, G.D. Measurement of surface tension of liquid metals and alloys under arc welding conditions. Mater. Sci. Technol. 1977, 13, 791–804. [Google Scholar] [CrossRef]

- Mills, K.C.; Keene, B.J. Factors affecting variable weld penetration. Int. Mater. Rev. 1990, 35, 185–216. [Google Scholar] [CrossRef]

- Keene, B.J. Review of data for the surface tension of iron and its binary alloys. Int. Mater. Rev. 1988, 33, 1–37. [Google Scholar] [CrossRef]

- Shirali, A.A. Effect of trace elements on weld penetration of TIG/GTA welds. Join. Sci. 1992, 1, 167–175. [Google Scholar]

- Liu, X.D. Study of activating fluxes based on oxide for A-TIG welding. Mod. Weld. 2014, 134, 24–27. [Google Scholar]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. About the influence of a steady magnetic field on weld pool dynamics in partial penetration high power laser beam welding of thick aluminium parts. Int. J. Heat Mass Transf. 2013, 60, 309–321. [Google Scholar] [CrossRef]

- Su, Y.H.; Liu, Z.J.; Wang, Y.; Zhang, G. Influence of magnetic field parameters on the organization and properties of AZ31 welded joints. J. Weld. 2007, 28, 45–49. [Google Scholar]

- Su, Y.; Liu, Z.; Liu, D. Effect of magnetic field on microstructure and properties of magnesium alloy welded joint with GTAW. Manuf. Process Technol. 2011, 189, 3507–3511. [Google Scholar] [CrossRef]

- Su, Y.; Wen, X.; Liu, D.; Liu, Z. Effect of magnetic field current on the fatigue properties of welded joints of magnesium alloys. J. Weld. 2011, 32, 79–82. [Google Scholar]

- Zhang, X.Y.; Tu, J.; Liu, Q. High-resolution electron microscopy study of the {10-11} twin boundary and twinning dislocation analysis in deformed polycrystalline cobalt. Scr. Mater. 2012, 67, 991–994. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Zhu, Y.T.; Liu, Q. Deformation twinning in polycrystalline Co during room temperature dynamic plastic deformation. Scr. Mater. 2010, 63, 387–390. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Si | Cu | Fe | Mg |

|---|---|---|---|---|---|---|

| 8.3–9.7 | 0.35–1 | 0.15–0.5 | <0.01 | <0.03 | <0.005 | Balance |

| Welding Current (A) | Welding Voltage (V) | Welding Speed (mm/min) | Arc Length (mm) | Argon Gas Flow (L/min) | Angle of Tungsten Tip (°) | Tungsten Pole Diameter (mm) |

|---|---|---|---|---|---|---|

| 80 | 17 | 300 | 2 | 18 | 60 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Su, Y.; Zhang, G.; Wang, R.; Cai, X. Effect of Longitudinal Magnetic Field on the Microstructure and Properties of A-TIG Welding with Different TiO2 Coating Amounts. Crystals 2023, 13, 66. https://doi.org/10.3390/cryst13010066

Liu X, Su Y, Zhang G, Wang R, Cai X. Effect of Longitudinal Magnetic Field on the Microstructure and Properties of A-TIG Welding with Different TiO2 Coating Amounts. Crystals. 2023; 13(1):66. https://doi.org/10.3390/cryst13010066

Chicago/Turabian StyleLiu, Xintong, Yunhai Su, Guiqing Zhang, Ruiqi Wang, and Xianglin Cai. 2023. "Effect of Longitudinal Magnetic Field on the Microstructure and Properties of A-TIG Welding with Different TiO2 Coating Amounts" Crystals 13, no. 1: 66. https://doi.org/10.3390/cryst13010066