Growth, Structure, Spectroscopy, and Laser Operation of a “Mixed” Yb:(Y,Lu)3Al5O12 Garnet Crystal

Abstract

:1. Introduction

2. Experimental Section

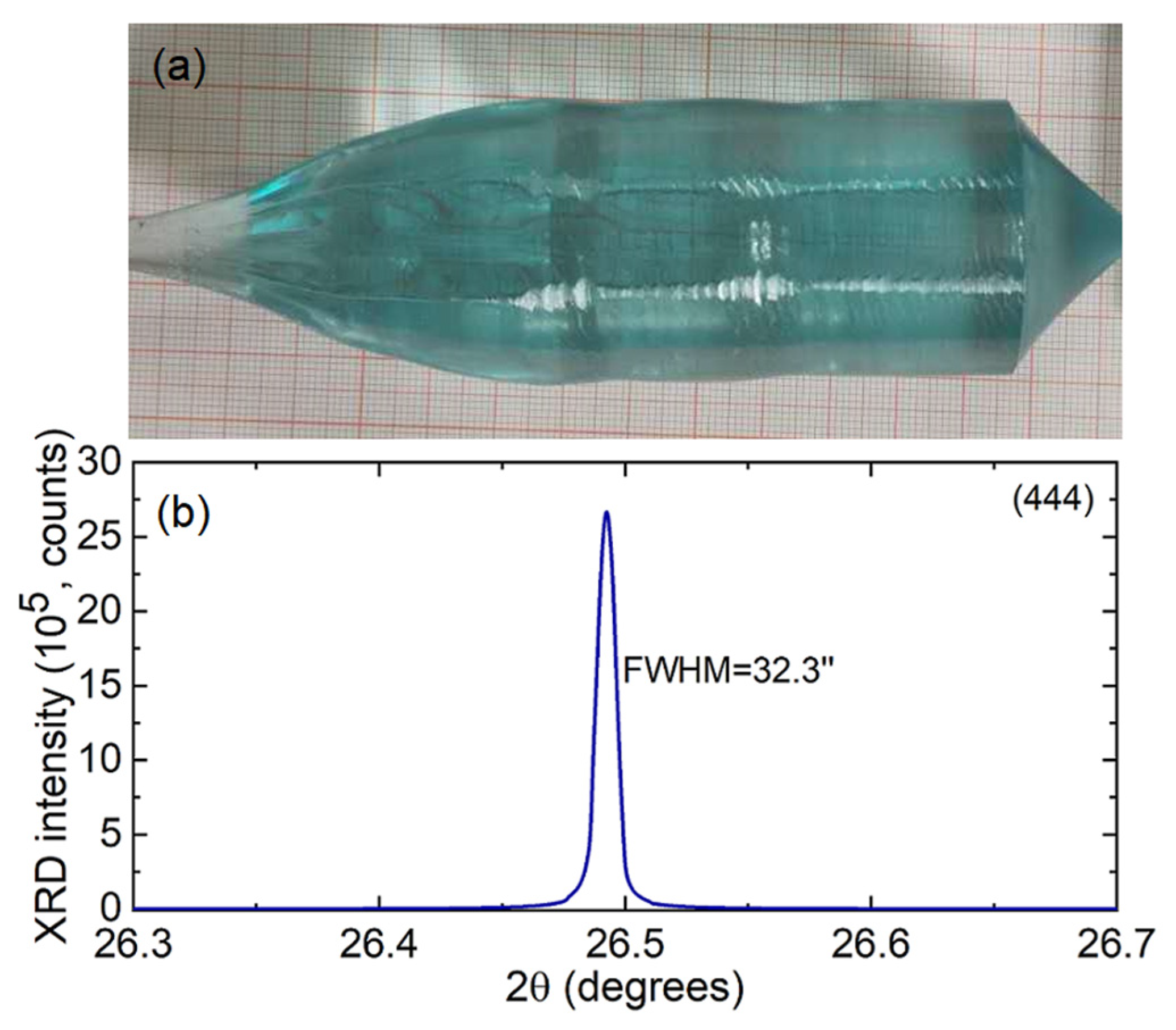

2.1. Crystal Growth

2.2. Characterization Methods

2.3. Laser Characterization

2.3.1. Laser Set-Up Using Ti:Sapphire Laser

2.3.2. Power Scaling Using Diode Pumping

3. Results and Discussion

3.1. Crystal Structure

3.2. Optical Spectroscopy

3.3. Laser Performance

3.3.1. Laser Performance Using Ti:Sapphire Pumping

3.3.2. Diode-Pumped Laser Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taira, T.; Tulloch, W.M.; Byer, R.L. Modeling of Quasi-Three-Level Lasers and Operation of Cw Yb:YAG Lasers. Appl. Opt. 1997, 36, 1867–1874. [Google Scholar] [CrossRef]

- Wang, C.A.; Fan, T.Y.; Lacovara, P.; Choi, H.K.; Aggarwal, R.L. Room-Temperature Diode-Pumped Yb:YAG Laser. Opt. Lett. 1991, 16, 1089–1091. [Google Scholar]

- Aggarwal, R.L.; Ripin, D.J.; Ochoa, J.R.; Fan, T.Y. Measurement of Thermo-Optic Properties of Y3Al5O12, Lu3Al5O12, YAIO3, LiYF4, LiLuF4, BaY2F8, KGd(WO4)2, and KY(WO4)2 Laser Crystals in the 80–300K Temperature Range. J. Appl. Phys. 2005, 98, 103514. [Google Scholar] [CrossRef]

- Paschotta, R.; Schaer, S.F.; der Au, J.A.; Keller, U.; Moser, M.; Hönninger, C. High-Power Diode-Pumped Passively Mode-Locked Yb:YAG Lasers. Opt. Lett. 1999, 24, 1281–1283. [Google Scholar]

- Emanuel, M.A.; Avizonis, P.V.; Monroe, R.S.; Honea, E.C.; Harris, D.G.; Beach, R.J.; Mitchell, S.C.; Payne, S.A.; Skidmore, J.A.; Sutton, S.B. High-Power Dual-Rod Yb:YAG Laser. Opt. Lett. 2000, 25, 805–807. [Google Scholar]

- Innerhofer, E.; Südmeyer, T.; Brunner, F.; Häring, R.; Aschwanden, A.; Paschotta, R.; Hönninger, C.; Kumkar, M.; Keller, U. 60-W Average Power in 810-Fs Pulses from a Thin-Disk Yb:YAG Laser. Opt. Lett. 2003, 28, 367–369. [Google Scholar] [CrossRef]

- Canibano, H.; Ródenas, A.; Jaque, D.; Petrosyan, A.G.; Boulon, G.; Guyot, Y.; Brenier, A.; Eganyan, A. Growth, Spectroscopic, and Laser Properties of Yb3+-Doped Lu3Al5O12 Garnet Crystal. JOSA B 2006, 23, 676–683. [Google Scholar]

- Veselský, K.; Šulc, J.; Jelínková, H.; Nejezchleb, K.; Škoda, V. Yb Doping Concentration and Temperature Influence on Yb:LuAG Thermal Lensing. In Solid State Lasers XXV: Technology and Devices; SPIE: Bellingham, WA, USA, 2016; Volume 9726, pp. 281–286. [Google Scholar]

- Fredrich-Thornton, S.T.; Beil, K.; Peters, R.; Tellkamp, F.; Kränkel, C.; Petermann, K.; Huber, G. Thermal and Laser Properties of Yb:LuAG for KW Thin Disk Lasers. Opt. Express 2010, 18, 20712–20722. [Google Scholar]

- Fu, Y.; Li, J.; Wang, C.; Xie, T.; Li, W.; Wu, L.; Pan, Y. Fabrication and Properties of Highly Transparent Yb:LuAG Ceramics. J. Alloys Compd. 2016, 664, 595–601. [Google Scholar] [CrossRef]

- Nakao, H.; Ueda, K.; Shirakawa, A.; Yagi, H.; Yanagitani, T. CW and Mode-Locked Operation of Yb3+-Doped Lu3Al5O12 Ceramic Laser. Opt. Express 2012, 20, 15385–15391. [Google Scholar] [CrossRef]

- Yu, H.; Xu, J.; Xu, Z.; Xu, X.; Liang, X.; Zhao, Z.; He, J.; Li, J. LD Pumped Yb:LuAG Mode-Locked Laser with 7.63ps Duration. Opt. Express 2009, 17, 11537–11542. [Google Scholar]

- Baer, C.R.E.; Petermann, K.; Marchese, S.V.; Peters, R.; Engqvist, A.G.; Huber, G.; Keller, U.; Golling, M.; Kränkel, C.; Maas, D.J.H.C.; et al. Efficient Femtosecond High Power Yb:Lu2O3 Thin Disk Laser. Opt. Express 2007, 15, 16966–16971. [Google Scholar]

- Kisel, V.; Rudenkov, A.; Petrosyan, A.; Hovhannesyan, K.; Yasukevich, A.; Kuleshov, N. Spectroscopy and Continuous Wave Laser Performance of Yb3+:LuAlO3 Crystal. Opt. Lett. 2016, 41, 5805–5808. [Google Scholar]

- Lin, H.; Tonelli, M.; Pirzio, F.; Agnesi, A.; Volpi, A.; Di Lieto, A.; Cittadino, G. Crystal Growth, Spectroscopic Characterization, and Sub-100 Femtosecond Mode-Locked Operation of a Yb:LiLuF4 Laser. JOSA B 2016, 33, 2350–2356. [Google Scholar] [CrossRef]

- Dong, J.; Ueda, K.; Kaminskii, A.A. Laser-Diode Pumped Efficient Yb:LuAG Microchip Lasers Oscillating at 1030 and 1047 Nm. Laser Phys. Lett. 2010, 7, 726–733. [Google Scholar] [CrossRef]

- Basyrova, L.; Maksimov, R.; Shitov, V.; Baranov, M.; Mikhaylovsky, V.; Khubetsov, A.; Dymshits, O.; Mateos, X.; Loiko, P. Effect of SiO2 Addition on Structural and Optical Properties of Yb:Lu3Al5O12 Transparent Ceramics Based on Laser Ablated Nanopowders. J. Alloys Compd. 2019, 806, 717–725. [Google Scholar] [CrossRef]

- Basyrova, L.; Loiko, P.; Maksimov, R.; Shitov, V.; Serres, J.M.; Griebner, U.; Petrov, V.; Aguiló, M.; Díaz, F.; Mateos, X. Comparative Study of Yb:Lu3Al5O12 and Yb:Lu2O3 Laser Ceramics Produced from Laser-Ablated Nanopowders. Ceram. Int. 2021, 47, 6633–6642. [Google Scholar] [CrossRef]

- Kuwano, Y.; Suda, K.; Ishizawa, N.; Yamada, T. Crystal Growth and Properties of (Lu,Y)3Al5O12. J. Cryst. Growth 2004, 260, 159–165. [Google Scholar] [CrossRef]

- Pirri, A.; Toci, G.; Li, J.; Xie, T.; Pan, Y.; Babin, V.; Beitlerova, A.; Nikl, M.; Vannini, M. High Efficiency Laser Action in Mildly Doped Yb:LuYAG Ceramics. Opt. Mater. 2017, 73, 312–318. [Google Scholar] [CrossRef]

- Balashov, V.V.; Zakharov, L.Y.; Inyushkin, A.V.; Kanaev, A.Y.; Kozlov, A.B.; Kozlova, S.M.; Koromyslov, A.L.; Lopukhin, K.V.; Luzanov, V.A.; Pervakov, K.S.; et al. Comparative Study of LuxY1-xAG (x = 0..1) Laser Ceramics Doped with 5% Yb3+. Ceram. Int. 2022, 48, 6294–6301. [Google Scholar] [CrossRef]

- Tian, R.; Tian, R.; Pan, M.; Zhang, L.; Zhang, L.; Qi, H. Crystal Growth and Spectral Properties of (Yb0.15Lu0.85xY0.85-0.85x)3Al5O12 Single Crystals. Chin. Opt. Lett. 2022, 20, 121601. [Google Scholar] [CrossRef]

- Cheng, S.; Xu, X.; Li, D.; Zhou, D.; Wu, F.; Zhao, Z.; Xu, J. Growth and Spectroscopic Properties of Yb:Lu1.5Y1.5Al5O12 Mixed Crystal. Opt. Mater. 2010, 33, 112–115. [Google Scholar] [CrossRef]

- Lv, S.; Gao, C.; Tian, Z.; Su, X.; Wang, G.; Zhu, G.; Wang, B.; Kumar, S.; Xu, X.; Yu, H.; et al. Diode-Pumped Continuous-Wave Dual-Wavelength and Q-Switched Yb:LuYAG Lasers. Opt. Commun. 2021, 478, 126356. [Google Scholar] [CrossRef]

- Shim, J.B.; Yoshikawa, A.; Nikl, M.; Pejchal, J.; Yoon, D.H.; Isshiki, M.; Fukuda, T. Growth and Characterization of Yb3+-Doped (Lu,Y)AlO3 Fiber Single Crystals Grown by the Micro-Pulling-down Method. Jpn. J. Appl. Phys. Part. 1 Regul. Pap. Short. Notes Rev. Pap. 2004, 43, 7661–7664. [Google Scholar] [CrossRef]

- Kaminskii, A.A.; Rhee, H.; Lux, O.; Eichler, H.J.; Bagayev, S.N.; Yagi, H.; Ueda, K.; Shirakawa, A.; Dong, J. Stimulated Raman Scattering in “Garnet” Lu3Al5O12 Ceramics—A Novel Host-Materiel for Ln- and TM-Lasant Ions. Laser Phys. Lett. 2011, 8, 458–464. [Google Scholar] [CrossRef]

- Papagelis, K.; Ves, S. Infrared Spectroscopy and Lattice Dynamical Calculations of Gd3Al5O12, Tb3Al5O12 and Lu3Al5O12 Single Crystals. J. Phys. Chem. Solids 2003, 64, 599–605. [Google Scholar] [CrossRef]

- Tang, F.; Cao, Y.; Huang, J.; Liu, H.; Guo, W.; Wang, W. Fabrication and Laser Behavior of Composite Yb:YAG Ceramic. J. Am. Ceram. Soc. 2012, 95, 56–69. [Google Scholar] [CrossRef]

- Tauc, J. Optical Properties and Electronic Structure of Amorphous Ge and Si. Mater. Res. Bull. 1968, 3, 37–46. [Google Scholar] [CrossRef]

- Xu, Y.; Ching, W.Y. Electronic Structure of Yttrium Aluminum Garnet. Phys. Rev. B 1999, 59, 10530. [Google Scholar] [CrossRef]

- Jubu, P.R.; Yam, F.K.; Igba, V.M.; Beh, K.P. Tauc-Plot Scale and Extrapolation Effect on Bandgap Estimation from UV–Vis–NIR Data—A Case Study of β-Ga2O3. J. Solid. State Chem. 2020, 290, 121576. [Google Scholar] [CrossRef]

- Brik, M.G.; Srivastava, A.M.; Popov, A.I. A Few Common Misconceptions in the Interpretation of Experimental Spectroscopic Data. Opt. Mater. 2022, 127, 112276. [Google Scholar] [CrossRef]

- Aull, B.F.; Jenssen, H.P. Vibronic Interactions in Nd: YAG Resulting in Nonreciprocity of Absorption and Stimulated Emission Cross Sections. IEEE J. Quantum Electron. 1982, 18, 925–930. [Google Scholar] [CrossRef]

- Fan, T.Y.; Wynne, R.; Daneu, J.L. Thermal Coefficients of the Expansion and Refractive Index in YAG. Appl. Opt. 1999, 38, 3282–3284. [Google Scholar]

- Payne, S.A.; Chase, L.L.; Smith, L.K.; Kway, W.L.; Wyers, W.F. Infrared Cross-Section Measurements for Crystals Doped with Er3+, Tm3+, and Ho3+. IEEE J. Quantum Electron. 1992, 28, 2619–2630. [Google Scholar] [CrossRef]

| Parameter | Lu3+ Content, at.% | Yb3+ Content, at.% | Stoichiometry |

|---|---|---|---|

| Melt | 21.2 | 15.0 | (Y0.638Lu0.212Yb0.150)3Al5O12 |

| Crystal | 23.3 | 16.6 | (Y0.601Lu0.233Yb0.166)3Al5O12 |

| KRE | 1.10 | 1.11 | - |

| Parameter | Value |

|---|---|

| Crystal system | cubic |

| Space group (IT number, Z) | d–O10h (No. 230, Z = 8) |

| Hall symbol | -I 4bd 2c 3 |

| Laue class | m-3m |

| Reduced number of S.O. | 24 |

| General multiplicity | 96 |

| Calculated density (g/cm3) | 6.869 |

| Lattice constants: a = b = c (Å) | 11.9790(0) |

| α = β = γ (deg.) | 90 |

| Unit-cell volume (Å3) | 1718.944(0) |

| 2θ range (deg.) | 5–80 |

| 2θ step | 0.02 |

| Radiation | Cu Kα1 (λ = 1.5418 Å) |

| No. of reflections | 100 |

| Refinement software | Match!-version 3.0 software |

| Reliability factors | Rp = 6.07%, Rwp = 7.95%, Rexp = 3.83% and χ2 = 4.31 |

| Atoms | Sites | x/a | y/b | z/c | O.F. | Biso, Å2 |

|---|---|---|---|---|---|---|

| Y | 24c | 1/8 | 0 | 1/4 | 0.601 | 1.112(0) |

| Lu | 24c | 1/8 | 0 | 1/4 | 0.233 | 1.112(0) |

| Yb | 24c | 1/8 | 0 | 1/4 | 0.166 | 1.112(0) |

| Al1 | 16a | 0 | 0 | 0 | 1 | 1.131(2) |

| Al2 | 24d | 0.3750(0) | 0 | 1/4 | 1 | 1.636(8) |

| O | 96h | −0.0323(7) | 0.0541(3) | 0.1521(7) | 1 | 2.011(1) |

| Yb3+ Multiplet | E, cm−1 | ||

|---|---|---|---|

| 2S+1LJ | (Y,Lu)AG | YAG | LuAG |

| 2F7/2 | 0 | 0 | 0 |

| 578 | 565 | 602 | |

| 613 | 612 | 643 | |

| 771 | 785 | 764 | |

| 2F5/2 | 10,333 | 10,327 | 10,333 |

| 10,636 | 10,650 | 10,643 | |

| 10,915 | 10,923 | 10,908 |

| Crystal | σabs, 10−20 cm2 | λabs, nm | Δλabs, nm | σSE, 10−20 cm2 | λem, nm | τrad, ms |

|---|---|---|---|---|---|---|

| (Y,Lu)AG | 0.80 | 969.2 | <3 | 2.53 | 1030.6 | 1.00 |

| 0.78 | 941.0 | 19 | ||||

| YAG | 0.80 | 969.0 | 2.5 | 2.31 | ~1030 | 0.95 |

| 0.77 | ~942 | ~18 | ||||

| LuAG | 0.73 | 969.0 | <3 | 2.76 | 1030.4 | 1.01 |

| 0.79 | 940.7 | ~20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slimi, S.; Loiko, P.; Pan, M.; Lehoux, P.; Jambunathan, V.; Smrz, M.; Mocek, T.; Wang, Y.; Chen, W.; Petrov, V.; et al. Growth, Structure, Spectroscopy, and Laser Operation of a “Mixed” Yb:(Y,Lu)3Al5O12 Garnet Crystal. Crystals 2023, 13, 1588. https://doi.org/10.3390/cryst13111588

Slimi S, Loiko P, Pan M, Lehoux P, Jambunathan V, Smrz M, Mocek T, Wang Y, Chen W, Petrov V, et al. Growth, Structure, Spectroscopy, and Laser Operation of a “Mixed” Yb:(Y,Lu)3Al5O12 Garnet Crystal. Crystals. 2023; 13(11):1588. https://doi.org/10.3390/cryst13111588

Chicago/Turabian StyleSlimi, Sami, Pavel Loiko, Mingyan Pan, Pauline Lehoux, Venkatesan Jambunathan, Martin Smrz, Tomas Mocek, Yicheng Wang, Weidong Chen, Valentin Petrov, and et al. 2023. "Growth, Structure, Spectroscopy, and Laser Operation of a “Mixed” Yb:(Y,Lu)3Al5O12 Garnet Crystal" Crystals 13, no. 11: 1588. https://doi.org/10.3390/cryst13111588

APA StyleSlimi, S., Loiko, P., Pan, M., Lehoux, P., Jambunathan, V., Smrz, M., Mocek, T., Wang, Y., Chen, W., Petrov, V., Solé, R. M., Aguiló, M., Díaz, F., Camy, P., & Mateos, X. (2023). Growth, Structure, Spectroscopy, and Laser Operation of a “Mixed” Yb:(Y,Lu)3Al5O12 Garnet Crystal. Crystals, 13(11), 1588. https://doi.org/10.3390/cryst13111588