Studies of Dislocations in Type Ib, Type IIa HPHT and CVD Single Crystal Diamonds

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. HPHT SCDs (Type Ib)

3.2. HPHT SCDs (Type IIa)

3.3. CVD SCDs (Type IIa)

4. Discussion

5. Conclusions and Future Work

- Dislocations and dislocation bundles are present in all types of SCDs, the only exception being the type IIa HPHT grown SCDs. The technology of growing HPHT type IIa SCDs has advanced to a level where the samples show almost no dislocations or dislocation bundles. However, it is important to understand that only very few groups have perfected that technology, and the dislocation-free type IIa HPHT samples are still scarcely available.

- The line and point dislocations are present in type 1b HPHT SCDs, which have nitrogen impurities in the range of tens to hundreds ppm. If the dislocation density is high, the dislocations may fall in a line along the (111) or (112) directions. The dislocations may be related to the high concentration of nitrogen impurities in type 1b HPHT SCDs.

- The centre of the type 1b HPHT plate appears to have dense dislocation bundles. Their origin may lie in the substrates used for the HPHT diamond growth.

- While HPHT type Ib as well type IIa SCDs have mostly line dislocations, CVD SCDs appear to have point, line as well as aggregates of dislocations. The aggregate of dislocations is a big cluster of the dislocations. The dislocations as well as dislocation aggregates in CVD SCDs originate from the substrates.

- In CVD SCDs, the dislocations originate from the substrates and travel within angular cones of 20–30 degrees. Therefore, one effective way of eliminating dislocations in CVD SCDs may be to use perfect substrates. Perfect substrates are difficult to define, but HPHT type IIa SCDs may be a good starting choice.

- In CVD growth, the dislocations and aggregates also form during the growth and multiply. This results in a higher density of dislocations and dislocation bundles in CVD SCDs. A detailed optimization of the growth conditions is strongly needed to be performed in order to identify a parameter window in which dislocation-free growth may be possible on perfect substrates. This will be a direction for further work.

- By using substrates which are free of dislocations and defects, it is possible to eliminate dislocations originating from substrates in CVD SCDs. Currently we do not know how to grow CVD SCDs free of all dislocations. There are a few important studies, however, of CVD diamond growth indicating control and elimination of the dislocations [38,45,51]. Elimination of all dislocations in CVD SCDs is a future research problem.

Funding

Data Availability Statement

Conflicts of Interest

References

- Tran Thi, T.N.; Morse, J.; Caliste, D.; Fernandez, B.; Eon, D.; Härtwig, J.; Barbay, C.; Mer-Calfati, C.; Tranchant, N.; Arnault, J.C.; et al. Synchrotron Bragg diffraction imaging characterization of synthetic diamond crystals for optical and electronic power devices application. J. Appl. Crystallogr. 2017, 50, 561–569. [Google Scholar] [CrossRef] [PubMed]

- Tarun, A.; Lee, S.J.; Yap, C.M.; Finkelstein, K.; Misra, D.S. Impact of impurities and crystal defects on the performance of CVD diamond detectors. Diam. Rel. Mater. 2016, 63, 169–174. [Google Scholar] [CrossRef]

- Berderman, E.; Pomorski, M.; De Boer, W.; Ciobanu, M.; Dunst, S.; Grah, C.; Kis, M.; Koenig, W.; Lange, W.; Lohmann, W. Diamond detectors for hadron physics research. Diam. Rel. Mater. 2010, 19, 358–367. [Google Scholar] [CrossRef]

- Tallaire, A.; Mille, V.; Brinza, O.; Tran Thi, T.N.; Brom, J.M.; Loguinov, Y.; Achard, J. Thick CVD diamond films grown on high-quality type IIa HPHT diamond substrates from New Diamond Technology. Diam. Rel. Mater. 2017, 77, 146–152. [Google Scholar] [CrossRef]

- Holly, C.; Traub, M.; Hoffmann, D.; Widmann, C.; Brink, D.; Nebel, C.; Gotthardt, G.; Sozbir, M.C.; Benzel, C. Monocrystalline CVD diamond optics for high power applications. In High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications V; SPIE: Bellingham, WA, USA, 2016; Volume 9741, p. 974104. [Google Scholar]

- Shimaoka, T.; Koizumi, S.; Kaneko, J. Recent progress in diamond radiation detectors. Funct. Diam. 2021, 1, 205–220. [Google Scholar] [CrossRef]

- Shellaiah, M.; Sun, K.W. Diamond-Based Electrodes for Detection of Metal Ions and Anions. Nanomaterials 2022, 12, 64. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, C.; Liu, J.; An, K.; Yan, X.; Hei, L.; Chen, L.; Wei, J.; Lu, F. The Interface and Mechanical Properties of a CVD Single Crystal Diamond Produced by Multilayered Nitrogen Doping Epitaxial Growth. Materials 2019, 12, 2492. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Lin, C.-N.; Ren, P.; Lu, Y.-J.; Shan, C.; Yu, S.F. Multiphoton Upconversion Emission from Diamond Single Crystal. ACS Appl. Mater. Interfaces 2018, 10, 18935–18941. [Google Scholar] [CrossRef]

- Shellaiah, M.; Chen, T.H.; Simon, T.; Li, L.-C.; Sun, K.W.; Ko, F.-H. An Affordable Wet Chemical Route to Grow Conducting Hybrid Graphite-Diamond Nanowires: Demonstration by A Single nanowire Device. Sci. Rep. 2017, 7, 11243. [Google Scholar] [CrossRef] [PubMed]

- Shellaiah, M.; Chen, T.H.; Simon, T.; Li, L.-C.; Sun, K.W.; Ko, F.-H. Effect of Metal Ions on Hybrid Graphite-Diamond Nanowire Growth: Conductivity Measurements From a Single Nanowire Device. Nanomaterials 2019, 9, 415. [Google Scholar] [CrossRef] [PubMed]

- Chrenko, R. 13C-doped diamond: Raman spectra. J. Appl. Phys. 1988, 63, 5873. [Google Scholar] [CrossRef]

- Banholzer, W.F.; Anthony, T.R. Isotope Enrichment During Diamond Growth. Diam. Rel. Mater. 1992, 1, 1157–1160. [Google Scholar] [CrossRef]

- Laraoui, A.; Dolde, F.; Burk, C.; Reinhard, F.; Wrachtrup, J.; Meriles, C. High-resolution correlation spectroscopy of 13C spins near a nitrogen-vacancy centre in diamond. Nat. Commun. 2013, 4, 1651. [Google Scholar] [CrossRef]

- Scharfenberger, B.; Munro, W.J.; Kae, N. Coherent control of a NV− centre near one adjacent 13C. New J. Phys. 2014, 16, 093043. [Google Scholar] [CrossRef]

- Dréau, A.; Maze, J.-R.; Lesik, M.; Roch, J.-F.; Jacques, V. High-resolution spectroscopy of single NV defects coupled with nearby 13C nuclear spins in diamond. Phys. Rev. B 2012, 85, 134107–134114. [Google Scholar] [CrossRef]

- Qiu, W.; Velisavljevic, N.; Baker, P.; Vohra, Y.; Weir, S. Calibration of an isotopically enriched C-13 layer pressure sensor to 156 GPa in a diamond anvil cell. Appl. Phys. Lett. 2004, 84, 5308–5310. [Google Scholar] [CrossRef]

- Novikov, N.; Podoba, A.; Shmegera, S.; Witek, A.; Zaitsev, A.; Denisenko, A.; Fahrner, W.; Werner, M. Influence of Isotopic Content On Diamond Thermal Conductivity. Diam. Rel. Mater. 1999, 8, 1602–1606. [Google Scholar] [CrossRef]

- Yap, C.M.; Tarun, A.; Xiao, S.; Misra, D.S. MPCVD growth of 13C-enriched diamond single crystals with nitrogen addition. Diam. Rel. Mater. 2016, 63, 2–11. [Google Scholar] [CrossRef]

- Lang, A.R. Dislocations in diamond and the origin of trigons. Proc. Roy. Soc. A 1964, 278, 234. [Google Scholar]

- Lang, A.R. Causes of Birefringence in Diamond. Nature 1967, 213, 248. [Google Scholar] [CrossRef]

- Lang, A.R.; Moore, M.; Makepeace, A.P.W. On the dilation of synthetic type Ib diamond by substitutional nitrogen impurity. Philos. Trans. Roy. Soc. A 1991, 337, 497. [Google Scholar]

- Lang, A.R. Topographic methods for studying defects in diamonds. Diam. Rel. Mater. 1993, 2, 106–114. [Google Scholar] [CrossRef]

- Lang, A.R. X-ray topographic and optical imaging studies of synthetic diamond. J. Appl. Crystallogr. 1994, 27, 988–1001. [Google Scholar] [CrossRef]

- Wierzchowsky, W.; Moore, M. Bragg-case images of stacking faults. Acta Cryst. A 1995, 51, 831–840. [Google Scholar] [CrossRef]

- Sumiya, H.; Toda, N.; Nishibayashi, Y.; Satoh, S. Crystalline perfection of high purity synthetic diamond crystal. J. Cryst. Growth 1997, 178, 485–494. [Google Scholar] [CrossRef]

- Sumiya, H.; Tamasaku, K. Large defect-free synthetic type IIa diamond crystals synthesized via high pressure and high temperature. Jpn. J. Appl. Phys. 2012, 51, 090102–090105. [Google Scholar] [CrossRef]

- Sumiya, H.; Harano, K.; Tamasaku, K. HPHT synthesis and crystalline quality of large high-quality (001) and (111) diamond crystals. Diam. Rel. Mater. 2015, 58, 221. [Google Scholar] [CrossRef]

- Macrander, A.T.; Krasnicki, S.; Zhong, Y.; Maj, J.; Chu, Y.S. Strain mapping with parts-per-million resolution in synthetic type Ib diamond plates. Appl. Phys. Lett. 2005, 87, 194113. [Google Scholar] [CrossRef]

- Moore, M.; Nailer, S.G.; Wierzchowski, W. Optical and X-ray Topographic Studies of Dislocations, Growth-Sector Boundaries and Stacking Faults in Synthetic Diamonds. Crystal 2016, 6, 71. [Google Scholar] [CrossRef]

- Gaukroger, M.; Martineau, P.; Crowder, M.; Friel, I.; Williams, S.; Twitchen, D.J. X-ray topography studies of dislocations in single crystal CVD diamond. Diam. Rel. Mater. 2008, 17, 262–269. [Google Scholar] [CrossRef]

- Martineau, P.; Gaukroger, M.P.; Guy, K.B.; Lawson, S.C.; Twitchen, D.J.; Friel, I.; Hansen, J.O.; Summerton, G.C.; Addison, T.P.G.; Burns, R. High crystalline quality single crystal chemical vapour deposition diamond. J. Phys. Condens. Matter 2009, 21, 362417. [Google Scholar] [CrossRef]

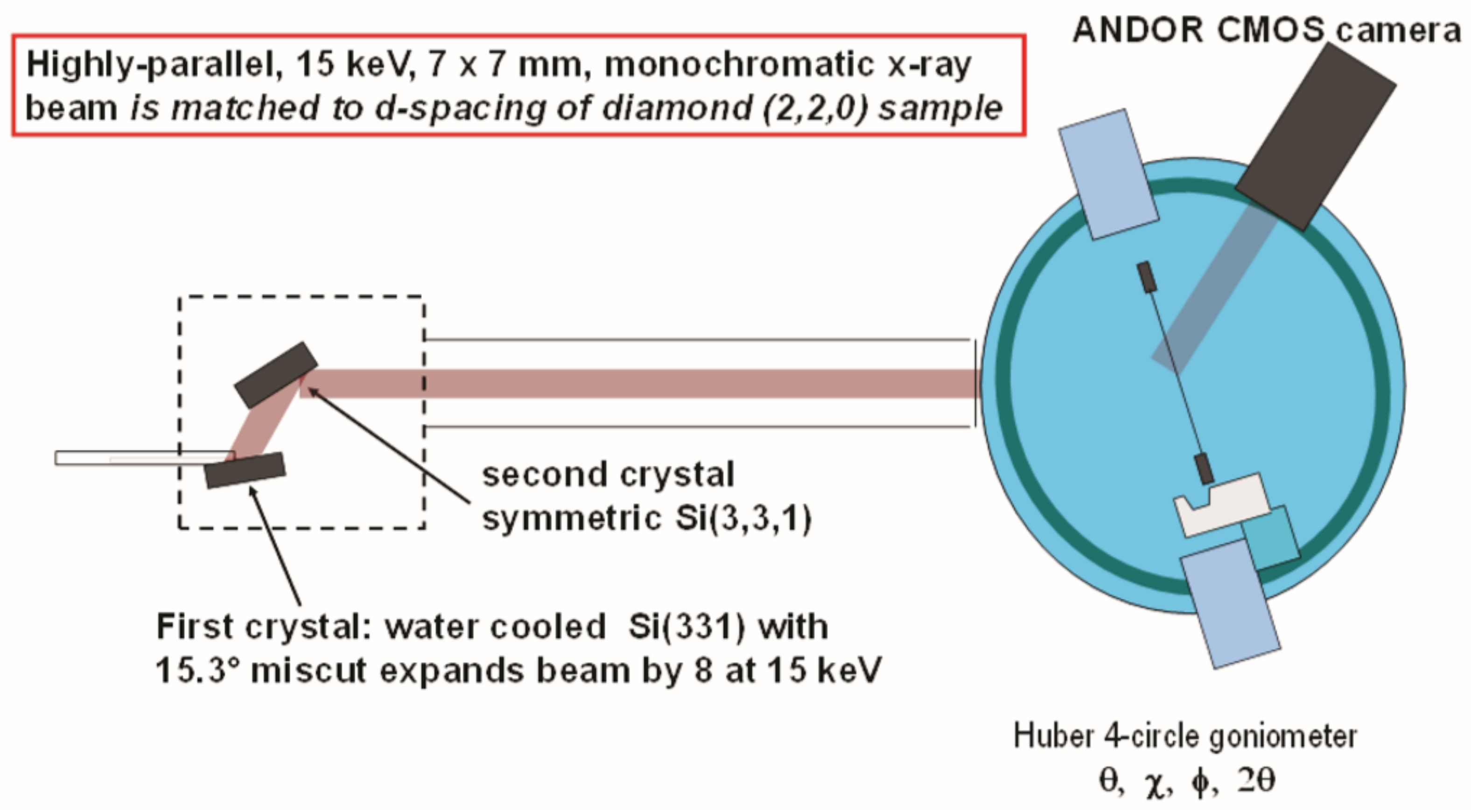

- Finkelstein, K.; Jones, R.; Pauling, A.; Brown, Z.; Tarun, A.; Jupitz, S.; Sagan, D.; Misra, D.S. Monochromatic X-ray Topographic Capability at CHESS. 2016. Available online: http://news.chess.cornell.edu/articles/2015/Finkelstein151123.html (accessed on 7 April 2023).

- Tamasaku, K.; Ueda, T.; Miwa, D.; Ishikawa, T. Goniometric and topographic characterization of synthetic type IIa diamonds. J. Phys. D Appl. Phys. 2005, 38, A61. [Google Scholar] [CrossRef]

- Tsoutsouva, M.; Oliveira, V.; Baruchel, J.; Camel, D.; Marie, B.; Lafford, T. Characterization of defects in mono-like silicon for photovoltaic applications by Bragg diffraction imaging. J. Appl. Crystallogr. 2015, 48, 645–654. [Google Scholar] [CrossRef]

- Yang, G.L.; Jones, R.; Klein, F.; Finkelstein, K.; Livingston, K. Rocking Curve Imaging For Diamond Radiator Crystal Selection. Diam. Rel. Mater. 2010, 19, 719–722. [Google Scholar] [CrossRef]

- Prokhorov, I.; Ralchenko, V.; Bolshakov, A.; Polskiy, A.; Vlasov, A.; Subbotin, I.; Podurets, K.; Pashaev, E.; Sozontov, E. Analysis of synthetic diamond single crystals by X-ray topography and double crystal diffractometry. Crystallogr. Rep. 2013, 58, 1010–1016. [Google Scholar] [CrossRef]

- Boussadi, A.; Tallaire, A.; Kasu, M. Reduction of dislocation densities in single crystal CVD diamond by confinement in the lateral sector. Diam. Rel. Mater. 2018, 83, 162–169. [Google Scholar] [CrossRef]

- Masuya, S.; Kasu, M. Dislocations in chemical vapor deposition (111) single crystal diamond observed by synchrotron X-ray topography and their relation with etch pits. Diam. Rel. Mater. 2018, 90, 40–46. [Google Scholar] [CrossRef]

- Umezawa, H.; Kato, Y.; Watanabe, H.; Omer, A.; Yamaguchi, H.; Shikata, S. Characterization of crystallographic defects in homoepitaxial diamond films by synchrotron X-ray topography and cathodoluminescence. Diam. Rel. Mater. 2011, 20, 523–526. [Google Scholar] [CrossRef]

- Burns, R.C.; Chumakov, A.I.; Connel, S.H.; Dube, D.; Godfried, H.P.; Hansen, J.O.; Hartwig, J.; Hoszowska, J.; Massiello, F.; Mkhonza, L.; et al. HPHT growth and x-ray characterization of high-quality type IIa diamond. J. Phys. Condense. Matter 2009, 21, 364224–364237. [Google Scholar] [CrossRef] [PubMed]

- Shikata, S. Diamond dislocations analysis by X-ray topography. Funct. Diam. 2022, 2, 174. [Google Scholar] [CrossRef]

- Shvydko, Y.; Blank, V.; Terentyev, S. Diamond X-ray optics: Transparent, resilient, high-resolution and waveform preserving. MRS Bull. 2017, 42, 437–444. [Google Scholar] [CrossRef]

- Stoupin, S.; Krawczyk, T.; Liu, Z.; Franck, C. Selection of CVD Diamond Crystals for X-ray Monochromator Applications Using X-ray Diffraction Imaging. Crystals 2019, 9, 396–406. [Google Scholar] [CrossRef]

- Wang, R.; Lin, F.; Niu, G.; Su, J.; Yan, X.; Wei, Q.; Wang, W.; Wang, K.; Yu, C.; Wang, H.-X. Reducing Threading Dislocations of CVD Single Crystal Diamond via In Situ Tungsten Incorporation. Materials 2022, 15, 444. [Google Scholar] [CrossRef] [PubMed]

- Luo, T.; Lindner, L.; Blinder, R.; Capelli, M.; Langer, J. Rapid determination of single substitutional nitrogen N0s concentration in diamond from UV-Vis spectroscopy. Appl. Phys. Lett. 2022, 121, 064002. [Google Scholar] [CrossRef]

- Kazuchits, V.N.; Kazuchits, N.M.; Rusetskiy, M.S.; Korolik, O.V.; Konovalova, A.V.; Ignatenko, O.V. Rapid HPHT annealing of Synthetic Ib-type Diamond. Carbon 2021, 174, 180. [Google Scholar] [CrossRef]

- Fujita, N.; Blumenau, A.T.; Jones, R.; Oberg, S.; Briddon, P.R. Theoretical studies on <100> dislocations in single crystal CVD diamond. Phys. Status Solidi 2006, 203, 3070–3075. [Google Scholar]

- Pinto, H.; Jones, R. Theory of the birefringence due to dislocations in single crystal CVD diamond. J. Phys. Condense. Matter 2009, 21, 364220–364227. [Google Scholar] [CrossRef]

- Ruaff, A.L.; Vohra, Y.K. Multimegabar Pressure Using Synthetic Diamond Anvils. Appl. Phys. Lett. 1989, 55, 232. [Google Scholar] [CrossRef]

- Li, F.; Zhang, J.; Wang, X.; Zhang, M.; Wang, H. Fabrication of Low Dislocation Density, Single-Crystalline Diamond via Two-Step Epitaxial Lateral Overgrowth. Crystals 2017, 7, 114. [Google Scholar] [CrossRef]

| Rocking curve mapping | Rocking curve is measured for each detector pixel at a Bragg angle corresponding to a crystal plane. For each detector pixel, the FWHM is calculated from the rocking curve, and an FWHM map is created. The higher the value of FWHM, the higher the concentration of dislocations at the location. The entire crystal is illuminated with an X-ray monochromatic beam. |

| XRT image at a crystal plane | The sample XRT image is taken at a particular Bragg angle corresponding to a crystal plane. The image contains the dislocations, dislocation bundles and stacking faults evident with different contrast on a grey background. The entire crystal is illuminated with an X-ray monochromatic beam. |

| White-beam XRT imaging | The sample is illuminated perpendicular to the direction of incidence of a continuous X-ray beam. The XRT image is generated on a detector and contains the dislocations, dislocation bundles and stacking faults evident with different contrast on a grey background. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misra, D.S. Studies of Dislocations in Type Ib, Type IIa HPHT and CVD Single Crystal Diamonds. Crystals 2023, 13, 657. https://doi.org/10.3390/cryst13040657

Misra DS. Studies of Dislocations in Type Ib, Type IIa HPHT and CVD Single Crystal Diamonds. Crystals. 2023; 13(4):657. https://doi.org/10.3390/cryst13040657

Chicago/Turabian StyleMisra, Devi Shanker. 2023. "Studies of Dislocations in Type Ib, Type IIa HPHT and CVD Single Crystal Diamonds" Crystals 13, no. 4: 657. https://doi.org/10.3390/cryst13040657

APA StyleMisra, D. S. (2023). Studies of Dislocations in Type Ib, Type IIa HPHT and CVD Single Crystal Diamonds. Crystals, 13(4), 657. https://doi.org/10.3390/cryst13040657