Modeling Bainite Dual-Phase Steels: A High-Resolution Crystal Plasticity Simulation Study

Abstract

:1. Introduction

2. Modeling Framework

3. Materials and Methods

4. Simulation Setup

4.1. Fitting of CP Parameters

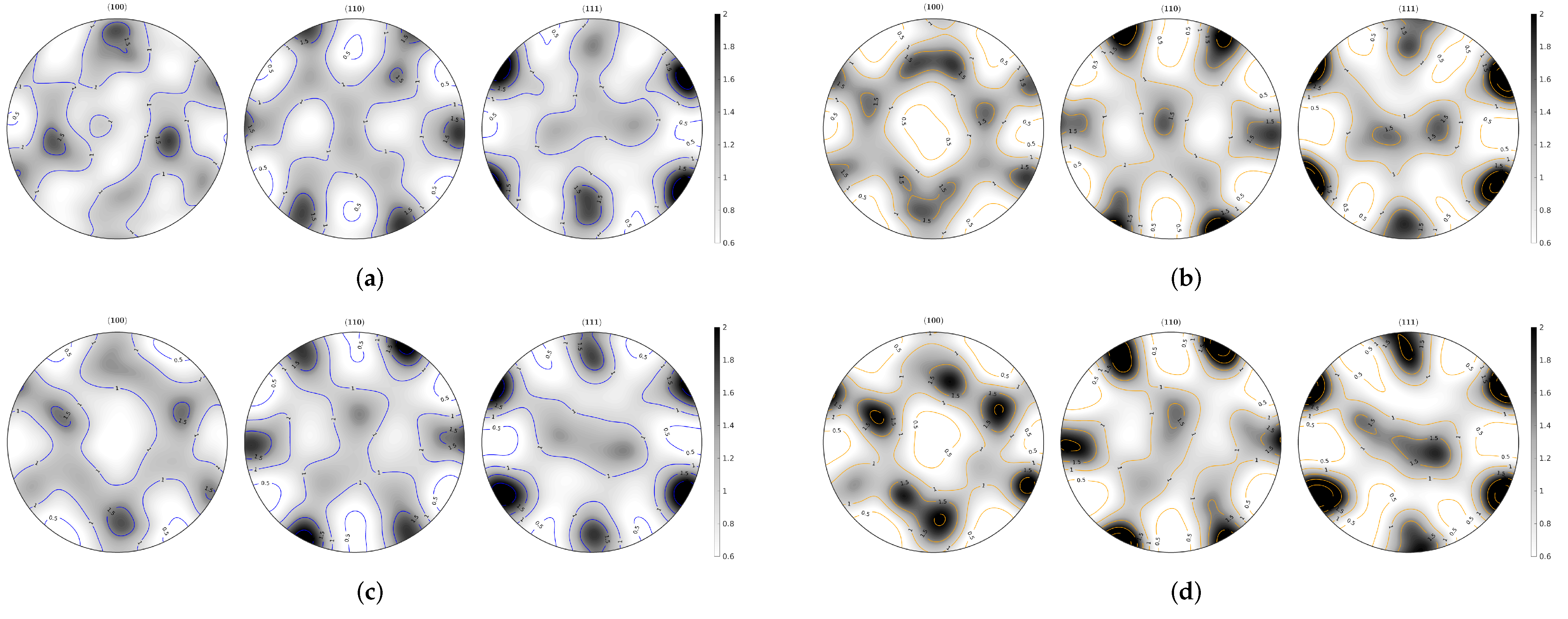

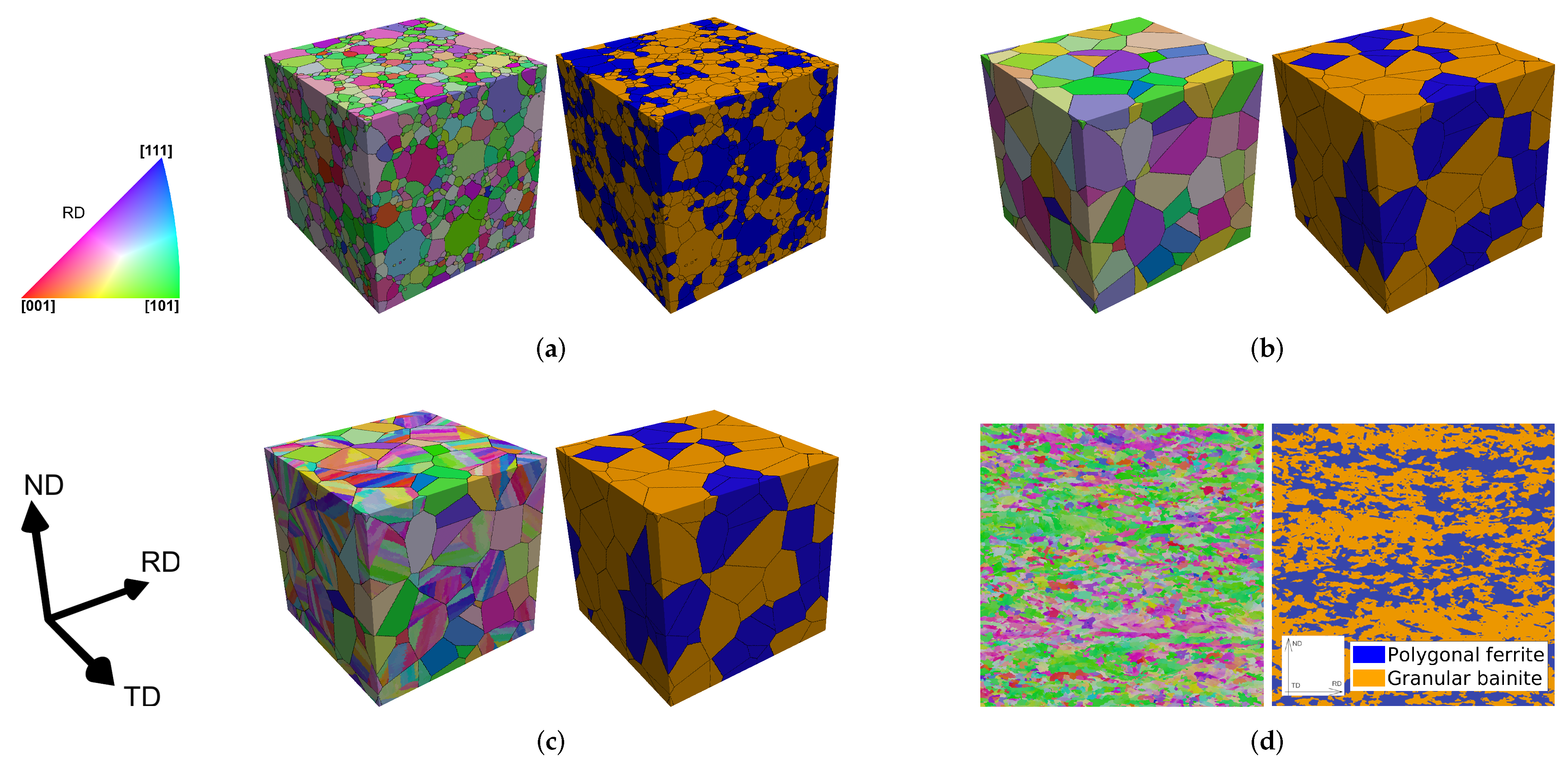

4.2. Representative Volume Element—RVE

- “3D-RVE”: described in Section 4.1.

- “3D-RVE no-substructure”: similar to “3D-RVE” but the implementation of the experimental grain size distribution is substituted by a Voronoi tesellation of 80 random seeds. The main difference with “3D-RVE” is the lower accuracy in the statistical representation of the texture, i.e., 80 grains compared to 10,000 grains.

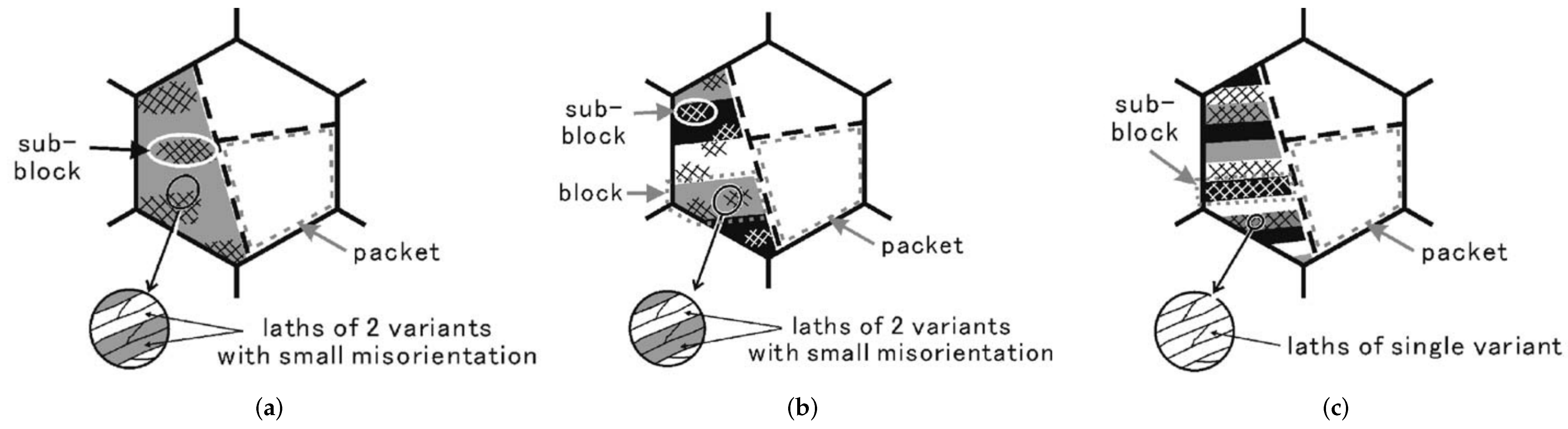

- “3D-RVE gb-substructure”: based on “3D-RVE no-substructure”. PF grains are kept unchanged. GB grains of “3D-RVE no-substructure” are used as prior austenite grains which is the input required in the microstructure generation tool of Gallardo-Basile et al. [31]. This tool is used to generate a lath-martensite substructure for the GB (justification for this at the end of this section). The following values for the input parameters of the tool are used: = 647 A.U. (arbitrary units of volume), A.U. (arbitrary units of length), = 9:3:1, and = 3°.

- “2D-RVE measured”: a direct 2D takeover of the measured crystallographic orientation of each pixel of the EBSD scan in Figure 4d. The phase is assigned according to the classification tool. Cleaning is performed with OIM software [32] for assigning a phase and an orientation to non-indexed pixels and the ones indexed as austenite (most of them are measuring errors).

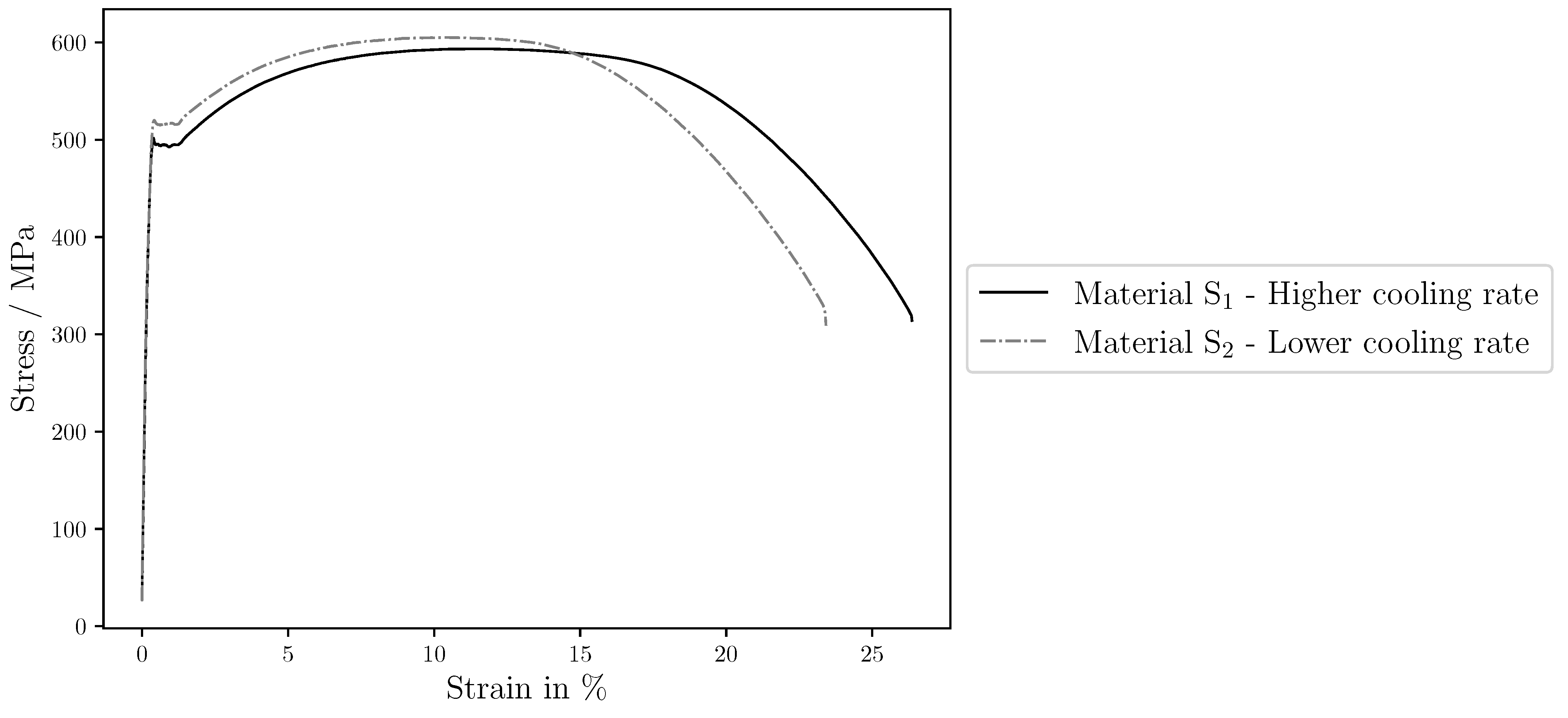

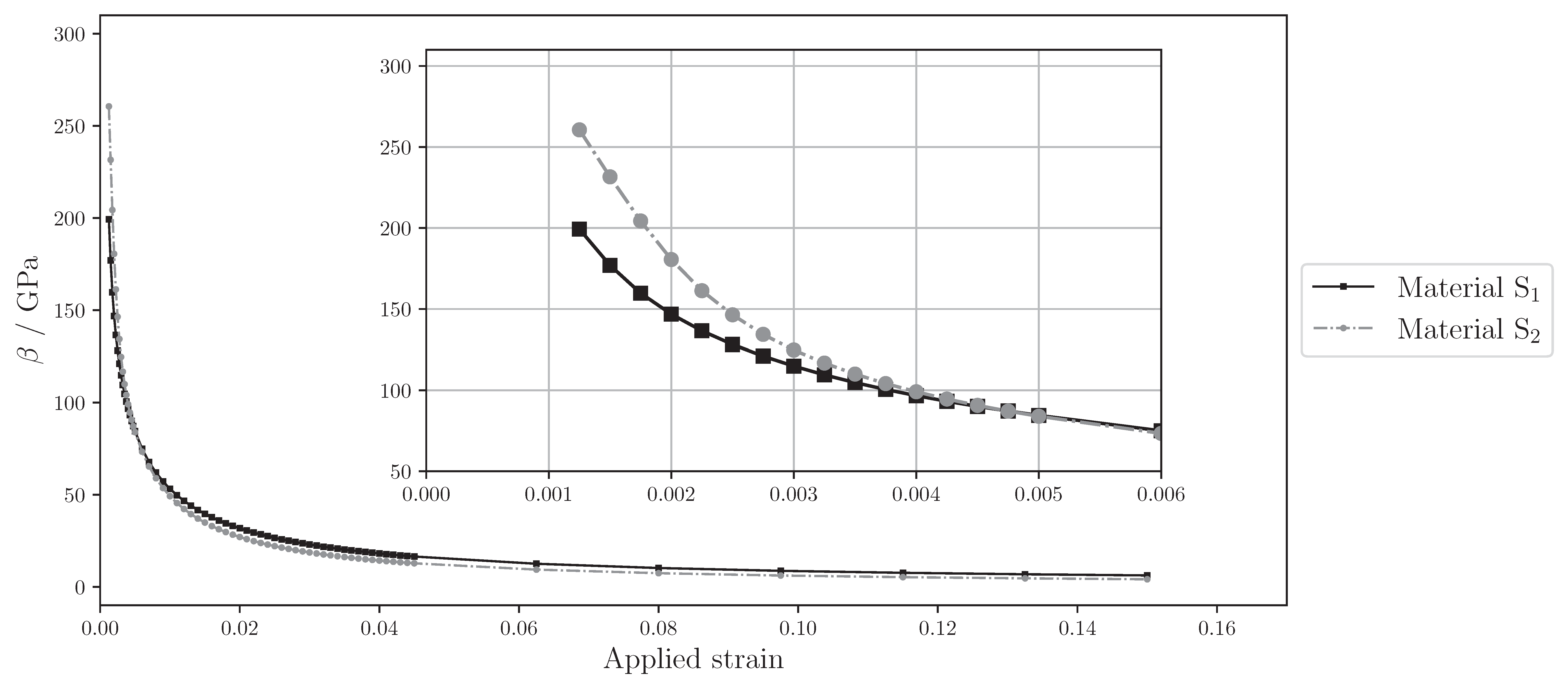

4.3. Mechanical Behavior of Materials S1 and S2

4.4. Microstructural Study of Ferritic Bainite

- Type-I voids at the PF–GB boundary.

- Type-II voids at the PF–PF boundary or in the PF grain.

- Type-III voids at the GB–GB boundary.

5. Results and Discussion

5.1. Fitting of CP Parameters

5.2. Representative Volume Element—RVE

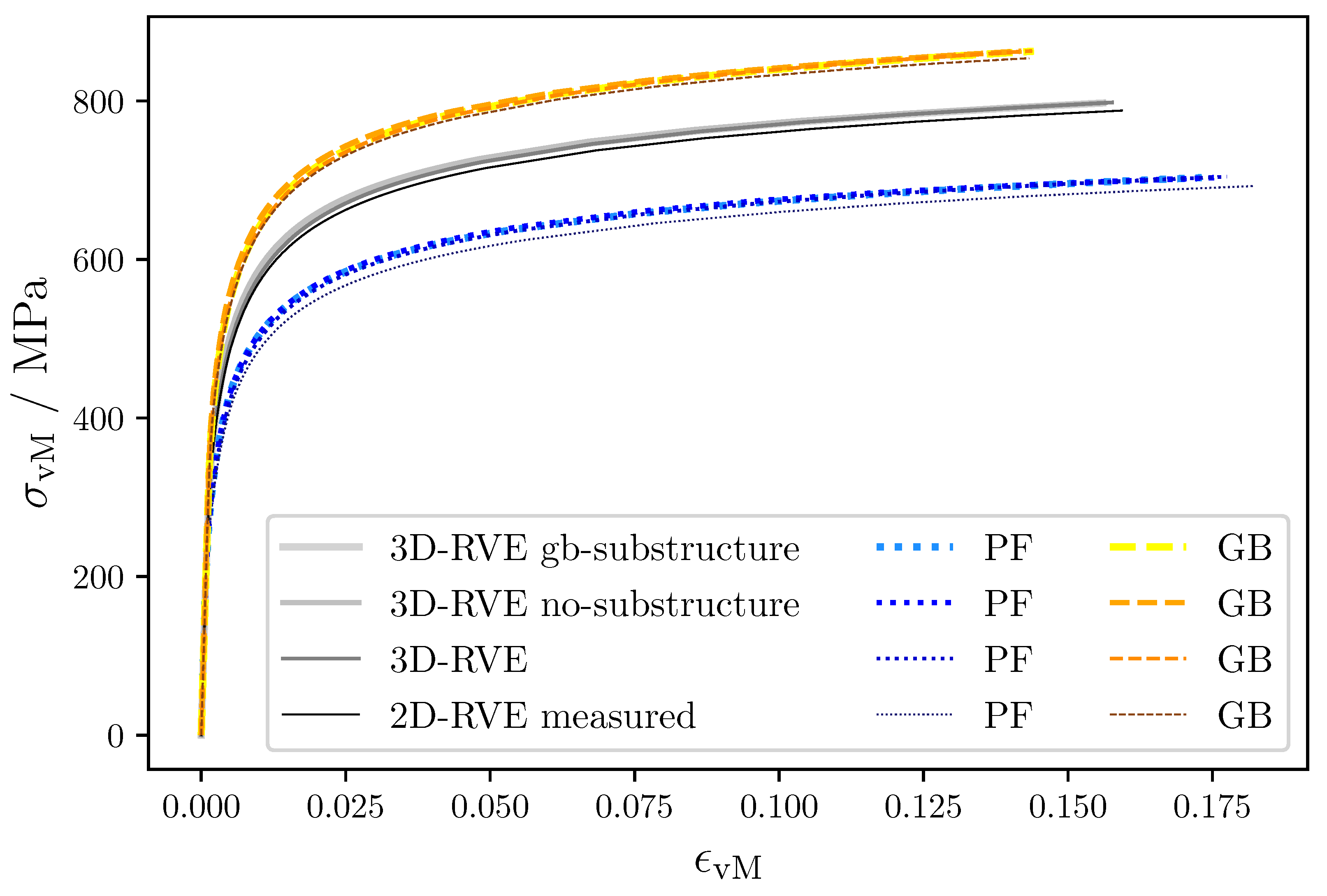

- Using a 2D- or a 3D-RVE. The 2D vs. 3D transition shows the biggest differences among all RVEs, but still the deviation is not significant. A small difference in the macroscopic results achieved from a 2D-RVE vs. a 3D-RVE has already been reported by Gallardo-Basile et al. [31]. There, a comparison was made between a 2D-RVE based on a direct measurement and a 3D-RVE with lath-like microstructure (similar to “2D-RVE measured” and “3D-RVE gb-substructure” in this manuscript). Additionally, a 2D-RVE with lath-like microstructure is created by cutting a slice of the 3D-RVE. In all the cases, the stress–strain curves showed small deviations from each other.

- Using the experimental grain size distribution or the one created from Voronoi tesellation of random seeds. Similar results were obtained from the “3D-RVE”, where the experimental grain size distribution was used and the “3D-RVE no-substructure”, where Voronoi tesellation is used. This is expected since the constitutive law used is not size dependent.

- Representing the experimental texture (low texture index) with 80 or 10 k grains. Similar results were obtained from “3D-RVE” and “3D-RVE no-substructure”.

- Including the substructure modeling of bainitic ferrite or not. Similar results were obtained from “3D-RVE no-substructure” and “3D-RVE gb-substructure”.

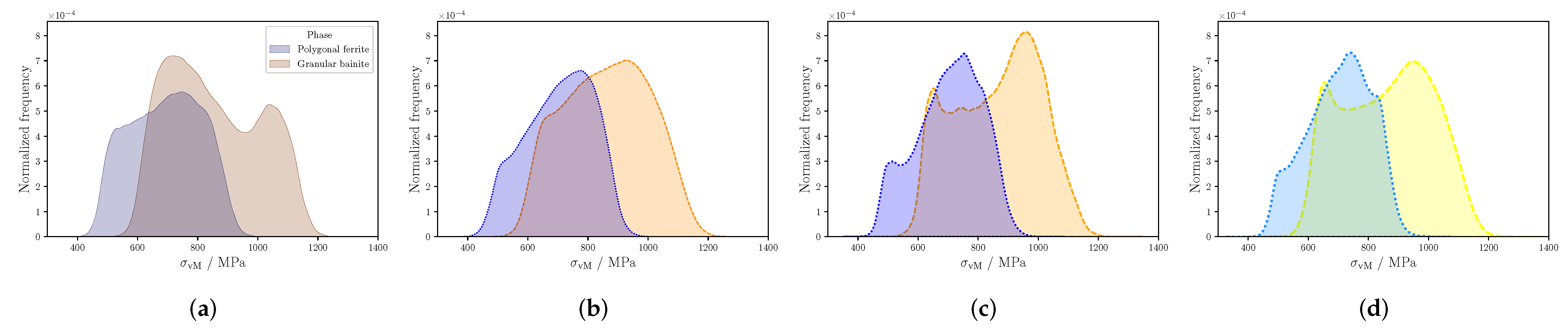

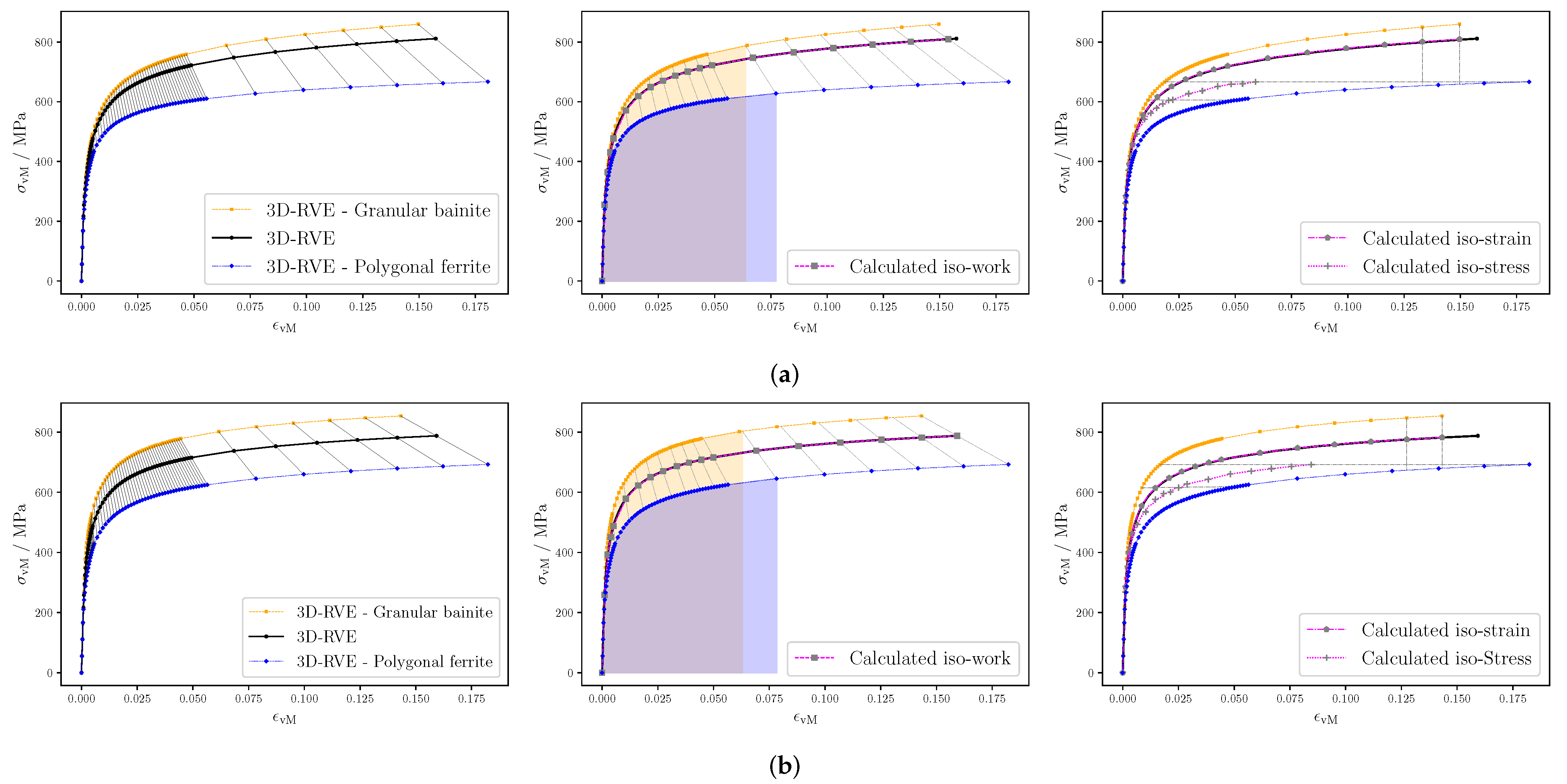

5.3. Mechanical Behavior S1 and S2

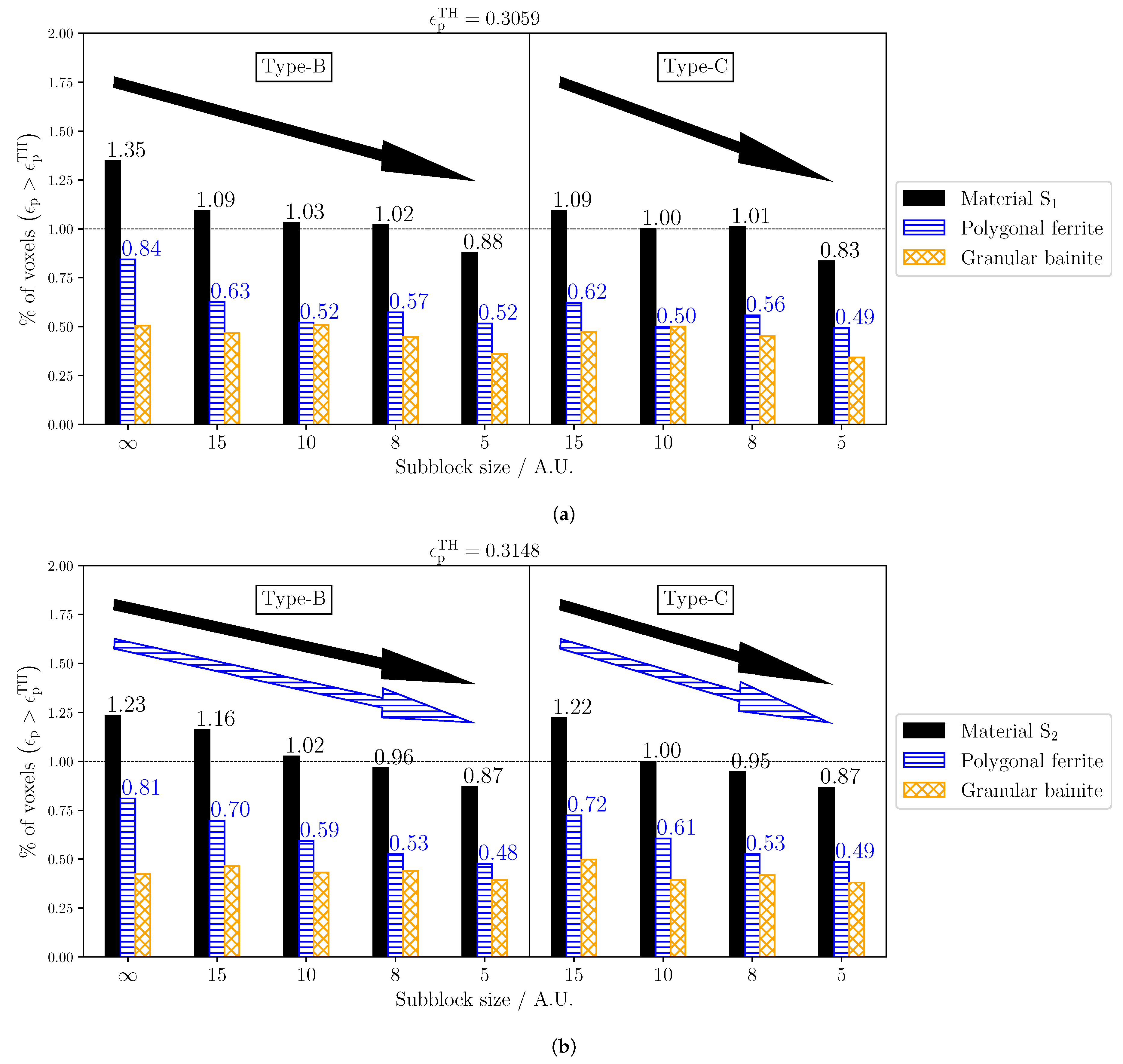

5.4. Microstructural Study of Ferritic Bainite

6. Conclusions

- The CP parameters of PF and GB are determined for both materials. For GB, they are determined following an inverse modeling procedure based on measuring a post mortem nanoindentation imprint by atomic force microscopy and comparing it to a simulated one. For PF, they are determined by fitting the macroscopic stress–strain curves of the tensile tests.

- The heterogeneity of the microscopic results among the different RVEs is discussed. The von Mises stress–strain curves show no significant differences among the RVEs. This suggested that for the utilized CP model, the main inputs required to predict the macroscopic behavior are the phase fraction and the CP parameters of each phase. In contrast to the macroscopic response, the microscopic responses (stress distributions are shown) are clearly different for the different RVEs.

- The average stress and the plastic strain are analyzed for each phase of both materials. It is shown that the onset of the plastic deformation of PF is almost the same for both materials, but the GB plasticity is delayed for S, which contains a higher PF fraction.

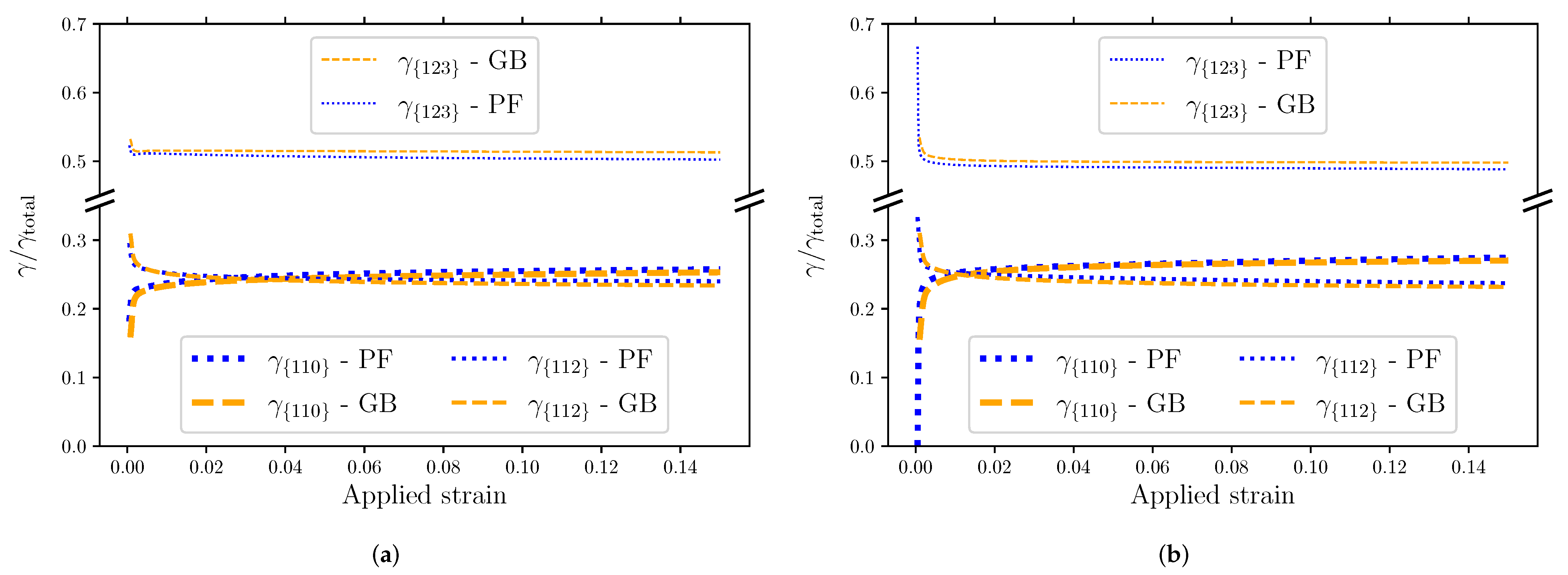

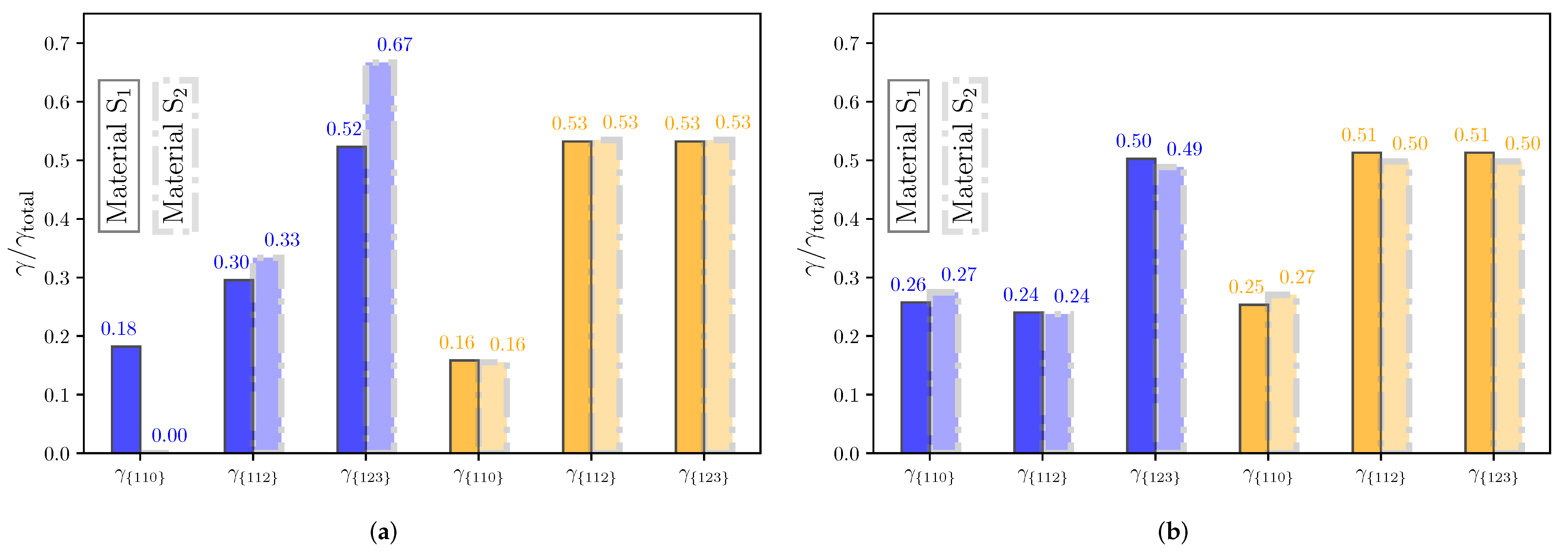

- The contributions per slip plane family to the total cumulative plastic shear are calculated. The main difference in both materials is exhibited at the early stage of the deformation. For material S, the partioning of strain is made between {1 2 3} and {1 1 2}, while for material S, the {1 1 0} contributes 0.18% from the start.

- The strain partioning is calculated to be similar for both materials, except at the early stage of deformation, where material S2 is closer to iso-strain behavior while S1 is closer to iso-stress behavior. Both materials followed the iso-work assumption with only small deviations compared to the iso-strain and iso-stress which exhibited significant deviations.

- Ductile damage initiation is indicated by the fraction of points where the ductile damage parameter, , surpasses a certain threshold value at the final deformation stage. The contribution of both phases is shown to be significant. For GB, no direct correlation can be seen between damage initiation and sub-block size. For PF, the damage decreases with the sub-block size. It is shown that ductile damage initiation can be linked to a coarse bainitic substructure because of the accumulation of plastic strain at PF–PF boundaries (type-II voids).

- Material S has a higher PF phase fraction but a lower ultimate elongation compared to S. It is hypothesized that this can be explained by the preference of S to form type-I voids (PF–GB), which may interfere with the full utilization of the plastic capacity of PF.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ishikawa, N.; Shinmiya, T.; Shikanai, N.; Muraoka, R.; Kakihara, S. Recent advance in high strength linepipes for heavy sour service. In Proceedings of the Pipeline Technology Conference, Hannover, Germany, 22–23 April 2009; EITEP: Hannover, Germany, 2009; pp. 12–14. [Google Scholar]

- Kobayashi, K.; Omura, T.; Takahashi, N.; Minato, I.; Yamamoto, A. Advanced technologies for manufacturing high strength sour grade UOE line pipe. In Proceedings of the 2010 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010; Volume 44212, pp. 289–297. [Google Scholar]

- Rosado, D.B.; Waele, W.D.; Vanderschueren, D.; Hertelé, S. Latest developments in mechanical properties and metallurgical features of high strength line pipe steels. Int. J. Sustain. Constr. Des. 2013, 4. [Google Scholar] [CrossRef] [Green Version]

- Javaheri, V.; Pohjonen, A.; Asperheim, J.I.; Ivanov, D.; Porter, D. Physically based modeling, characterization and design of an induction hardening process for a new slurry pipeline steel. Mater. Des. 2019, 182, 108047. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels; Institute of Materials, IOM Communications Ltd.: London, UK, 2001. [Google Scholar]

- Entezari, E.; González-Velxaxzquez, J.L.; López, D.R.; Zúñiga, M.A.B.; Szpunar, J.A. Review of Current Developments on High Strength Pipeline Steels for HIC Inducing Service. Frat. Integrità Strutt. 2022, 16, 20–45. [Google Scholar] [CrossRef]

- Xu, X.N.; Tian, Y.; Ye, Q.B.; Misra, R.D.K.; Wang, Z.D. The Significant Impact of the Characteristics of Granular Structure and Granular Bainite on the Mechanisms Contributing to Strength–Ductility Combination. J. Mater. Eng. Perform. 2022, 30, 7479–7487. [Google Scholar] [CrossRef]

- Fang, H.-s.; Feng, C.; Zheng, Y.-k.; Yang, Z.-g.; Bai, B.-z. Creation of Air-Cooled Mn Series Bainitie Steels. J. Iron Steel Res. Int. 2008, 15, 1–9. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Ekrami, A. Effect of ferrite volume fraction on work hardening behavior of high bainite dual phase (DP) steels. Mater. Sci. Eng. A 2008, 477, 306–310. [Google Scholar] [CrossRef]

- Ishikawa, N.; Yasuda, K.; Sueyoshi, H.; Endo, S.; Ikeda, H.; Morikawa, T.; Higashida, K. Microscopic deformation and strain hardening analysis of ferrite–bainite dual-phase steels using micro-grid method. Acta Mater. 2015, 97, 257–268. [Google Scholar] [CrossRef]

- Tang, C.-j.; Liu, S.-l.; Shang, C.-j. Micromechanical behavior and failure mechanism of F/B multi-phase high performance steel. J. Iron Steel Res. Int. 2016, 23, 489–494. [Google Scholar] [CrossRef]

- Tu, X.; Ren, Y.; Shi, X.; Yan, W.; Shi, Q.; Shan, Y.; Li, C. Effect of distribution characters of ferrite/bainite on deformation compatibility in dual-phase pipeline steel: Experimental and numerical study. Mater. Today Commun. 2022, 33, 104923. [Google Scholar] [CrossRef]

- Tu, X.; Shi, X.; Shan, Y.; Yan, W.; Shi, Q.; Li, Y.; Li, C.; Yang, K. Tensile deformation damage behavior of a high deformability pipeline steel with a ferrite and bainite microstructure. Mater. Sci. Eng. A 2020, 793, 139889. [Google Scholar] [CrossRef]

- Tu, X.; Shi, X.; Yan, W.; Li, C.; Shi, Q.; Shan, Y.; Yang, K. Tensile deformation behavior of ferrite-bainite dual-phase pipeline steel. Mater. Sci. Eng. A 2022, 831, 142230. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization, and multiscale methods in crystal plasticity finite element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Roters, F. Advanced Material Models for the Crystal Plasticity Finite Element Method—Development of a General CPFEM Framework. Ph.D. Dissertation, RWTH Aachen, Aachen, Germany, 2011. [Google Scholar]

- Raabe, D.; Sachtleber, M.; Zhao, Z.; Roters, F.; Zaefferer, S. Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation. Acta Mater. 2001, 49, 3433–3441. [Google Scholar] [CrossRef]

- Zaafarani, N.; Raabe, D.; Singh, R.N.; Roters, F.; Zaefferer, S. Three-dimensional investigation of the texture and microstructure below a nanoindent in a Cu single crystal using 3D EBSD and crystal plasticity finite element simulations. Acta Mater. 2006, 54, 1863–1876. [Google Scholar] [CrossRef]

- Raabe, D.; Roters, F. Using texture components in crystal plasticity finite element simulations. Int. J. Plast. 2004, 20, 339–361. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Diehl, M.; Yan, D.; Roters, F.; Raabe, D. Strain localization and damage in dual phase steels investigated by coupled in situ deformation experiments-crystal plasticity simulations. Int. J. Plast. 2014, 63, 198–210. [Google Scholar] [CrossRef] [Green Version]

- Tasan, C.C.; Diehl, M.; Yan, D.; Zambaldi, C.; Shanthraj, P.; Roters, F.; Raabe, D. Integrated experimental-numerical analysis of stress and strain partitioning in multi-phase alloys. Acta Mater. 2014, 81, 386–400. [Google Scholar] [CrossRef]

- Roters, F.; Diehl, M.; Shanthraj, P.; Eisenlohr, P.; Reuber, C.; Wong, S.L.; Maiti, T.; Ebrahimi, A.; Hochrainer, T.; Fabritius, H.-O.; et al. DAMASK—The Düsseldorf Advanced Material Simulation Kit for Modelling Multi-Physics Crystal Plasticity, Damage, and Thermal Phenomena from the Single Crystal up to the Component Scale. Comput. Mater. Sci. 2019, 158, 420–478. [Google Scholar] [CrossRef]

- Hutchinson, J.W. Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lond. Ser. A 1976, 348, 101–127. [Google Scholar] [CrossRef]

- Jentner, R.M.; Srivastava, K.; Scholl, S.; Best, J.P.; Kirchlechner, C.; Dehm, G. Local strength of bainitic and ferritic HSLA steel constituents understood using correlative electron microscopy and microcompression testing. SSRN Electron. J. 2023. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4408322 (accessed on 5 April 2023).

- Jentner, R.M.; Tsai, S.-P.; Welle, A.; Srivastava, K.; Scholl, S.; Best, J.P.; Kirchlechner, C.; Dehm, G. Automated Classification of Granular Bainite and Polygonal Ferrite by Electron Backscatter Diffraction Verified through Local Structural and Mechanical Analyses. SSRN Electron. J. 2023. [Google Scholar] [CrossRef]

- Jentner, R.M.; Srivastava, K.; Scholl, S.; Gallardo-Basile, F.-J.; Best, J.P.; Kirchlechner, C.; Dehm, G. Unsupervised clustering of nanoindentation data for microstructural reconstruction: Challenges in phase discrimination. Materialia 2023, 28, 101750. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Gallardo-Basile, F.-J.; Roters, F.; Jentner, R.M.; Best, J.P.; Kirchlechner, C.; Srivastava, K.; Scholl, S.; Diehl, M. Application of a nanoindentation-based approach for parameter identification to a crystal plasticity model for bcc metals. MSEA, 2022; submitted. [Google Scholar]

- Groeber, M.A.; Jackson, M.A. DREAM.3D: A Digital Representation Environment for the Analysis of Microstructure in 3D. Integr. Mater. Manuf. Innov. 2014, 3, 56–72. [Google Scholar] [CrossRef] [Green Version]

- Ostoja-Starzewski, M. Material spatial randomness: From statistical to representative volume element. Probabilistic Eng. Mech. 2006, 21, 112–132. [Google Scholar] [CrossRef]

- Gallardo-Basile, F.-J.; Naunheim, Y.; Roters, F.; Diehl, M. Lath Martensite Microstructure Modeling: A High-Resolution Crystal Plasticity Simulation Study. Materials 2021, 14, 691. [Google Scholar] [CrossRef]

- EDAX. TSL OIM Analysis 7, Version 7.3.1; EDAX: Pleasanton, CA, USA, 2017.

- Bhadeshia, H.; Honeycombe, R. Formation of Martensite. In Steels: Microstructure and Properties; Butterworth-Heinemann: Oxford, UK; Elsevier: London, UK, 2017; pp. 135–177. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Christian, J.W. Bainite in steels. Metall. Trans. A 1990, 21, 767–797. [Google Scholar] [CrossRef]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 273–275, 40–57. [Google Scholar] [CrossRef]

- Wayman, C.; Bhadeshia, H. Phase transformations, nondiffusive. In Physical Metallurgy; Butterworth-Heinemann: Oxford, UK; Elsevier: London, UK, 1996; pp. 1507–1554. [Google Scholar] [CrossRef]

- Murata, Y. Formation Mechanism of Lath Martensite in Steels. Mater. Trans. 2018, 59, 151–164. [Google Scholar] [CrossRef] [Green Version]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhara, T.; Maki, T.; Hansen, N. The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Maki, T.; Tsuzaki, K.; Tamura, I. The Morphology of Microstructure Composed of Lath Martensites in Steels. Trans. ISIJ 1980, 20, 207–214. [Google Scholar] [CrossRef] [Green Version]

- Nishiyama, Z. X-ray investigation of the mechanism of the transformation from face centered cubic lattice to body centered cubic. Sci. Rep. Tohoku Univ. 1934, 23, 637–664. [Google Scholar]

- Wassermann, G. Ueber den Mechanismus der α→γ-Umwandlung des Eisens. Mitt. K.-Wilh.-Inst. Eisenforsch. 1935, 17, 149–155. [Google Scholar]

- Kurdjumow, G.; Sachs, G. Über den mechanismus der stahlhärtung. Z. Phys. 1930, 64, 325–343. [Google Scholar] [CrossRef]

- Greninger, A.B.; Troiano, A.R. The mechanism of Martensite formation. JOM 1949, 1, 590–598. [Google Scholar] [CrossRef]

- Josefsson, B. Microscopy and Microanalysis of Bainitic Weld Metal. Ph.D. Dissertation, Chalmers University, Gothenburg, Sweeden, 1989. [Google Scholar]

- De-Castro, D.; Eres-Castellanos, A.; Vivas, J.; Caballero, F.G.; San-Martín, D.; Capdevila, C. Morphological and crystallographic features of granular and lath-like bainite in a low carbon microalloyed steel. Mater. Charact. 2022, 184, 111703. [Google Scholar] [CrossRef]

- Aaronson, H.I.; Wells, C. Sympathetic Nucleation of Ferrite. JOM 1956, 8, 1216–1223. [Google Scholar] [CrossRef]

- Chilton, J.; Barton, C.; Speich, G. Martensite transformation in low-carbon steels. J. Iron Steel Inst. 1970, 208, 184–193. [Google Scholar]

- Zhang, M.-X.; Kelly, P.M. Crystallography of carbide-free bainite in a hard bainitic steel. Mater. Sci. Eng. A 2006, 438–440, 272–275. [Google Scholar] [CrossRef]

- Davenport, E.S.; Bain, E.C. Transformation of austenite at constant subcritical temperatures. Metall. Mater. Trans. B 1970, 1, 3503–3530. [Google Scholar] [CrossRef]

- Davenport, A. The crystallography of upper bainite. Repub. Steel Res. Rep. Proj. 1974, 12051, 1–35. [Google Scholar]

- Landheer, H.; Offerman, S.E.; Petrov, R.H.; Kestens, L.A.I. The role of crystal misorientations during solid-state nucleation of ferrite in austenite. Acta Mater. 2009, 57, 1486–1496. [Google Scholar] [CrossRef]

- Abbasi, M.; Kim, D.-I.; Nelson, T.W.; Abbasi, M. EBSD and reconstruction of pre-transformation microstructures, examples and complexities in steels. Mater. Charact. 2014, 95, 219–231. [Google Scholar] [CrossRef]

- Tamura, M.O.I.; Tomota, Y. In Proceedings of the 3rd International Conference on the Strength of Metals and Alloys, Cambridge, UK, 20–25 August 1973.

- Voigt, W. Über die Beziehung zwischen den beiden Elastizitätskonstanten isotroper Körper. Ann. Phys. 1889, 38, 573–587. [Google Scholar] [CrossRef] [Green Version]

- Reuss, A. Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. Z. Angew. Math. Und Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Bouaziz, O.; Buessler, P. Mechanical behaviour of multiphase materials: An intermediate mixture law without fitting parameter. Rev. Métall. 2002, 99, 71–77. [Google Scholar] [CrossRef]

- Furuhara, T.; Kawata, H.; Morito, S.; Maki, T. Crystallography of upper bainite in Fe–Ni–C alloys. Mater. Sci. Eng. A 2006, 431, 228–236. [Google Scholar] [CrossRef]

- Lou, Y.; Huh, H. Prediction of ductile fracture for advanced high strength steel with a new criterion: Experiments and simulation. J. Mater. Process. Technol. 2013, 213, 1284–1302. [Google Scholar] [CrossRef]

| Property | (MPa) | UTS (MPa) | UE (%) | Grain Size (m) | (mrd) | CRSS (MPa) | (10/m) | Cooling Rate | |

|---|---|---|---|---|---|---|---|---|---|

| Material—Phase | |||||||||

| —Polygonal ferrite (25%) | 495 | 593 | 26 | 4.7 ± 0.6 | 1.34 | 153 ± 4 | 0.9 ± 0.1 | low | |

| —Granular bainite (75%) | 1.66 | 183 ± 7 | 2.1 ± 0.9 | ||||||

| —Polygonal ferrite (41%) | 518 | 605 | 23 | 4.2 ± 0.6 | 1.43 | 194 ± 6 | 2.8 ± 0.3 | high | |

| —Granular bainite (59%) | 1.91 | 221 ± 7 | 7.1 ± 0.7 | ||||||

| Material Phase | —Polygonal Ferrite | —Granular Bainite | —Polygonal Ferrite | —Granular Bainite | |

|---|---|---|---|---|---|

| Property | |||||

| CRSS for {1 1 0} / MPa | 151 ± 3 | 180 ± 10 | 188 ± 6 | - | |

| CRSS for {1 1 2} / MPa | 163 ± 9 | - | 197 ± 10 | 222 ± 11 | |

| CRSS for {1 2 3} / MPa | 148 ± 6 | 187 ± 9 | 195 ± 10 | 221 ± 9 | |

| Property | (GPa) | (GPa) | (GPa) | (MPa) | (MPa) | (GPa) | (−) | n (−) | a (−) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Material—Phase | ||||||||||

| —Polygonal ferrite (25%) | 233.3 | 135.5 | 118.0 | 101.9 | 341.7 | 446.3 | 0.04 | 20 | 6.05 | |

| —Granular bainite (75%) | 143.8 | 662.7 | 506.9 | 10.3 | ||||||

| —Polygonal ferrite (41%) | 119.2 | 408.1 | 237.2 | 6.5 | ||||||

| —Granular bainite (59%) | 209.8 | 497.7 | 417.1 | 5.7 | ||||||

| Property | Experimental (MPa) | Simulation (MPa) | Experimental (MPa) | Simulation (MPa) | |||

|---|---|---|---|---|---|---|---|

| Material—Phase | |||||||

| S | Polygonal ferrite (25%) | 495 | 413 | 373 | 593 | 598 | 514 |

| Granular bainite (75%) | 428 | 629 | |||||

| S | Polygonal ferrite (41%) | 518 | 455 | 409 | 604 | 606 | 549 |

| Granular bainite (59%) | 487 | 649 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallardo-Basile, F.-J.; Roters, F.; Jentner, R.M.; Srivastava, K.; Scholl, S.; Diehl, M. Modeling Bainite Dual-Phase Steels: A High-Resolution Crystal Plasticity Simulation Study. Crystals 2023, 13, 673. https://doi.org/10.3390/cryst13040673

Gallardo-Basile F-J, Roters F, Jentner RM, Srivastava K, Scholl S, Diehl M. Modeling Bainite Dual-Phase Steels: A High-Resolution Crystal Plasticity Simulation Study. Crystals. 2023; 13(4):673. https://doi.org/10.3390/cryst13040673

Chicago/Turabian StyleGallardo-Basile, Francisco-José, Franz Roters, Robin M. Jentner, Kinshuk Srivastava, Sebastian Scholl, and Martin Diehl. 2023. "Modeling Bainite Dual-Phase Steels: A High-Resolution Crystal Plasticity Simulation Study" Crystals 13, no. 4: 673. https://doi.org/10.3390/cryst13040673

APA StyleGallardo-Basile, F.-J., Roters, F., Jentner, R. M., Srivastava, K., Scholl, S., & Diehl, M. (2023). Modeling Bainite Dual-Phase Steels: A High-Resolution Crystal Plasticity Simulation Study. Crystals, 13(4), 673. https://doi.org/10.3390/cryst13040673