An Investigation on the Enhanced Wear Behavior of Ultrasonically Stirred Cast A356/SiO2np Nano-composites

Abstract

:1. Introduction

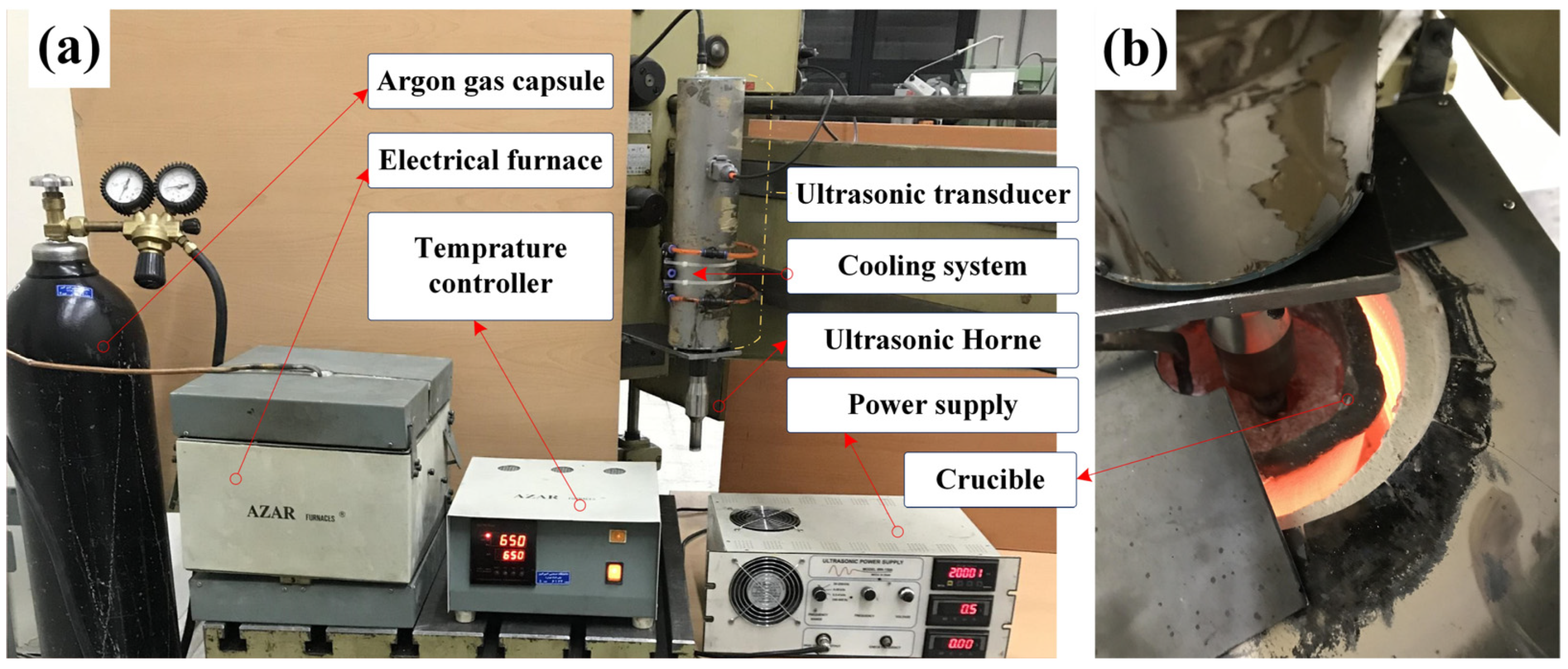

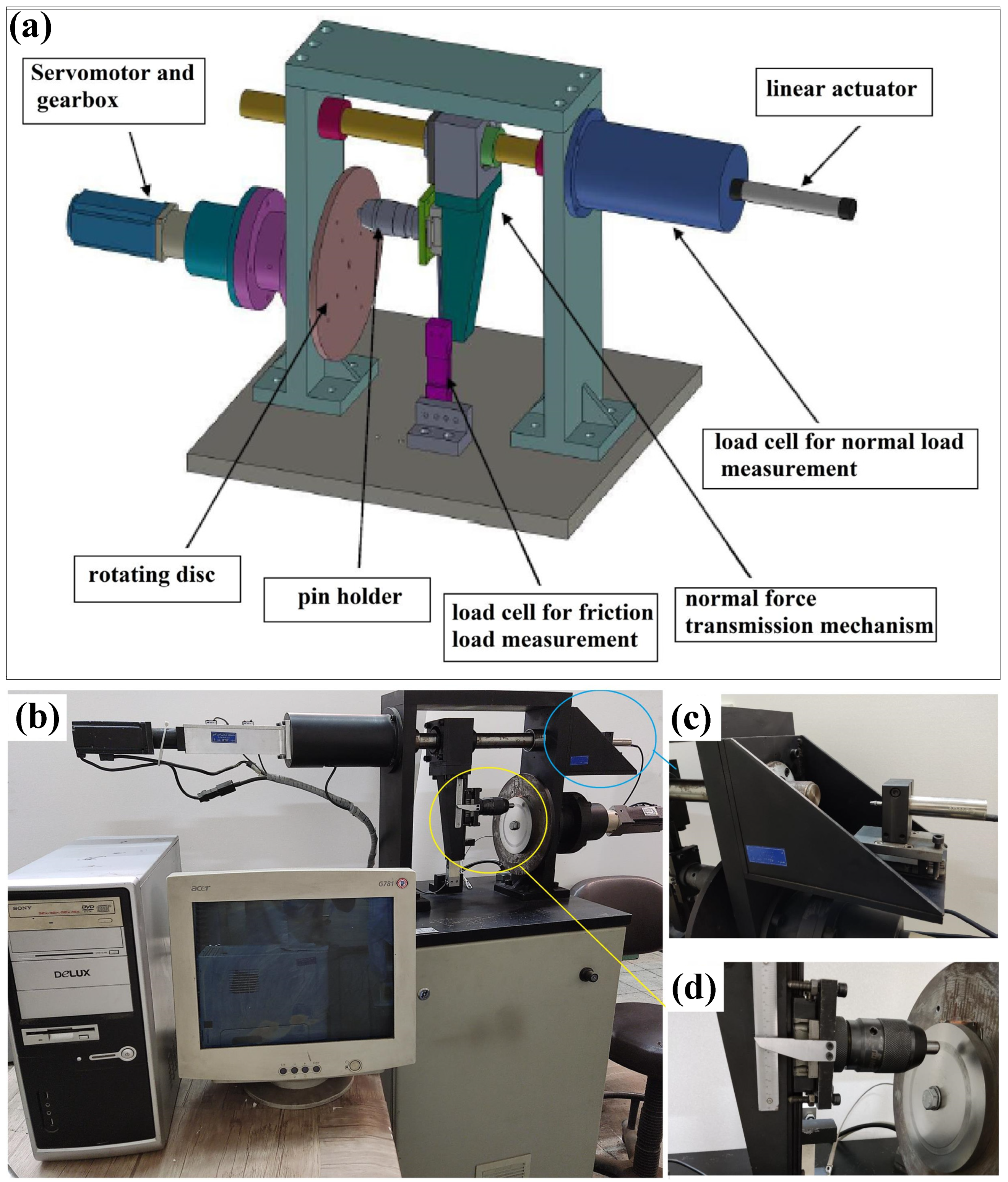

2. Materials and Methods

Characterization

3. Results and Discussion

3.1. Microstructural Evaluations

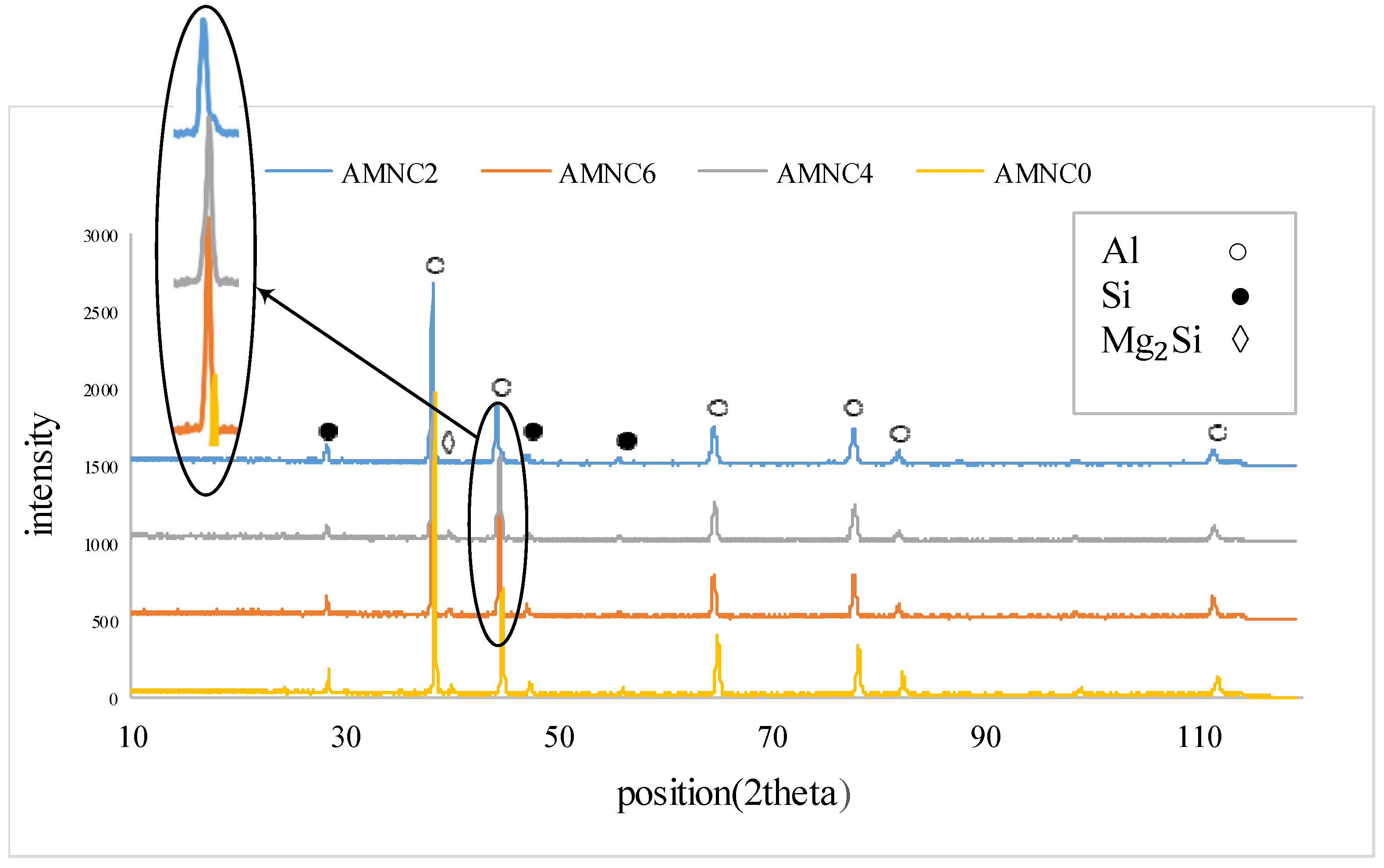

3.2. XRD Results

3.3. Hardness Results

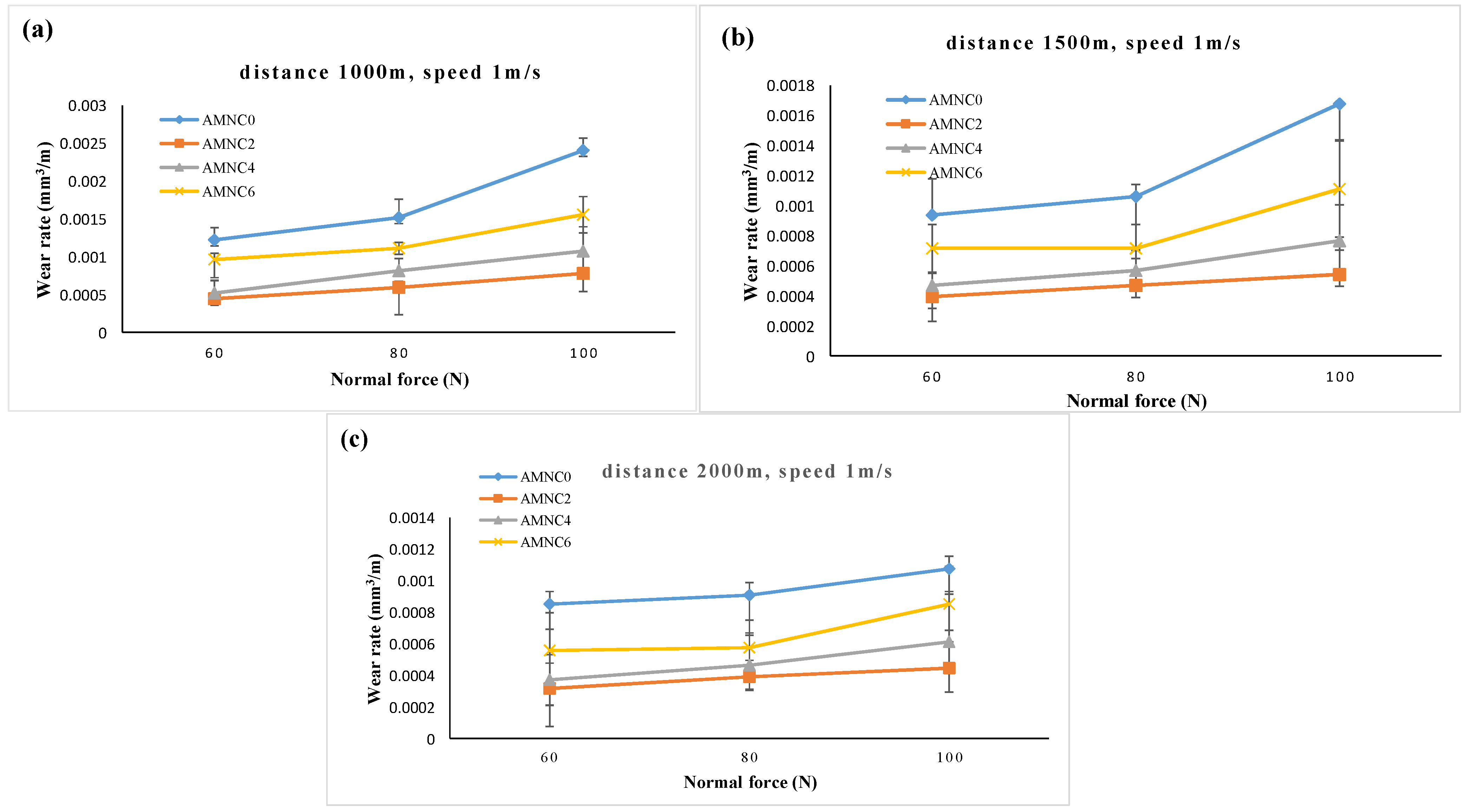

3.4. Wear Response

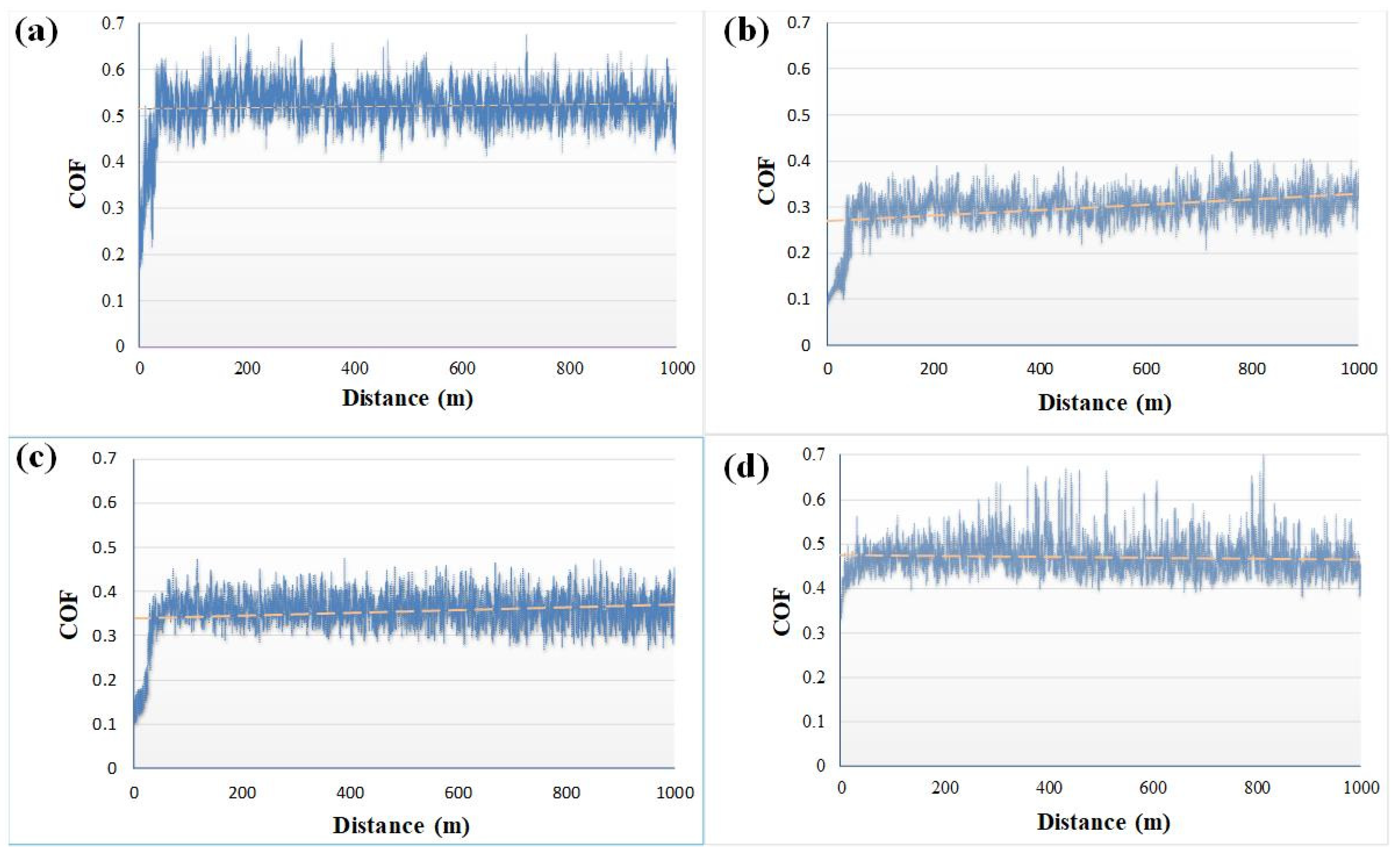

3.5. Coefficient of Friction

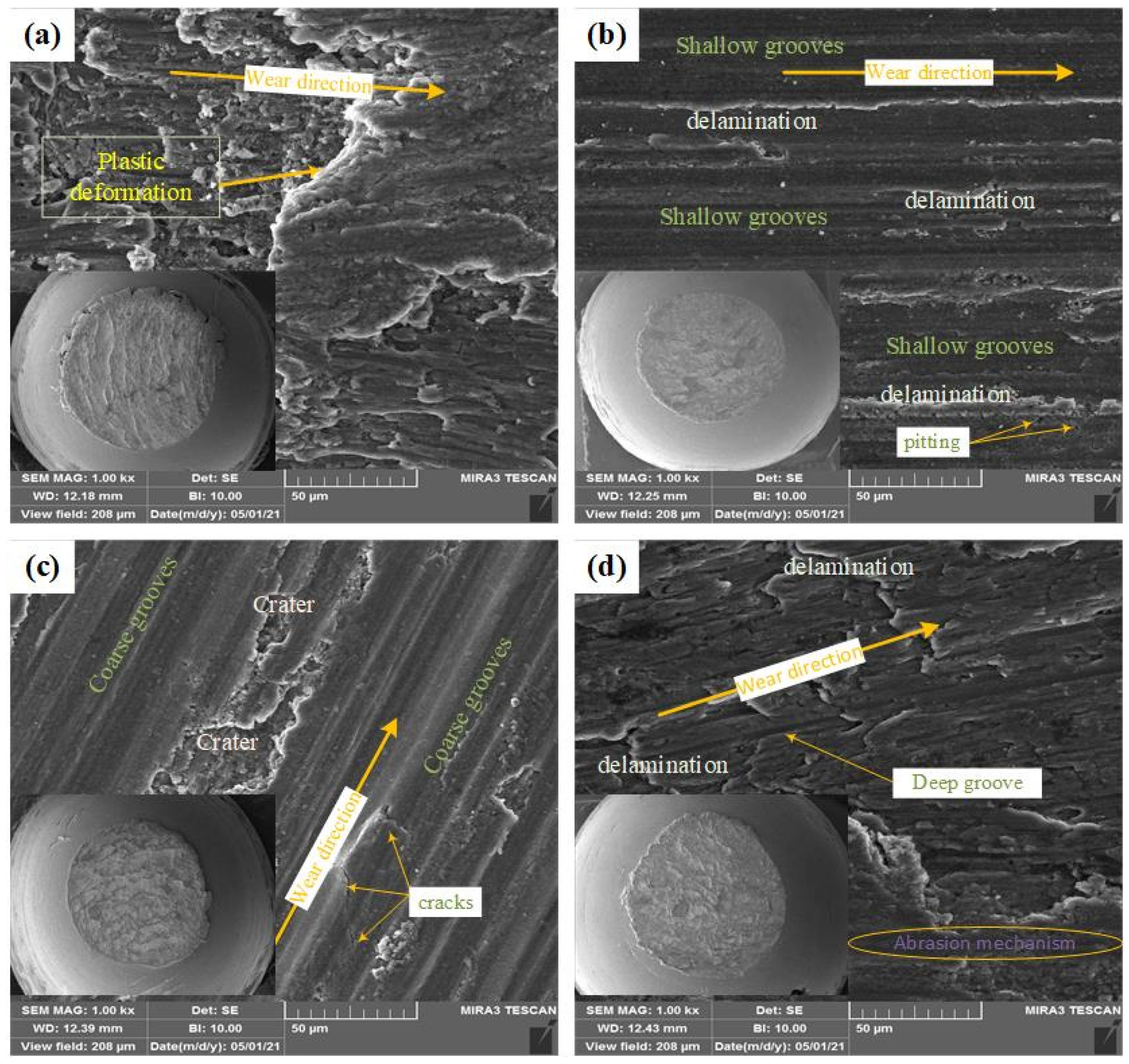

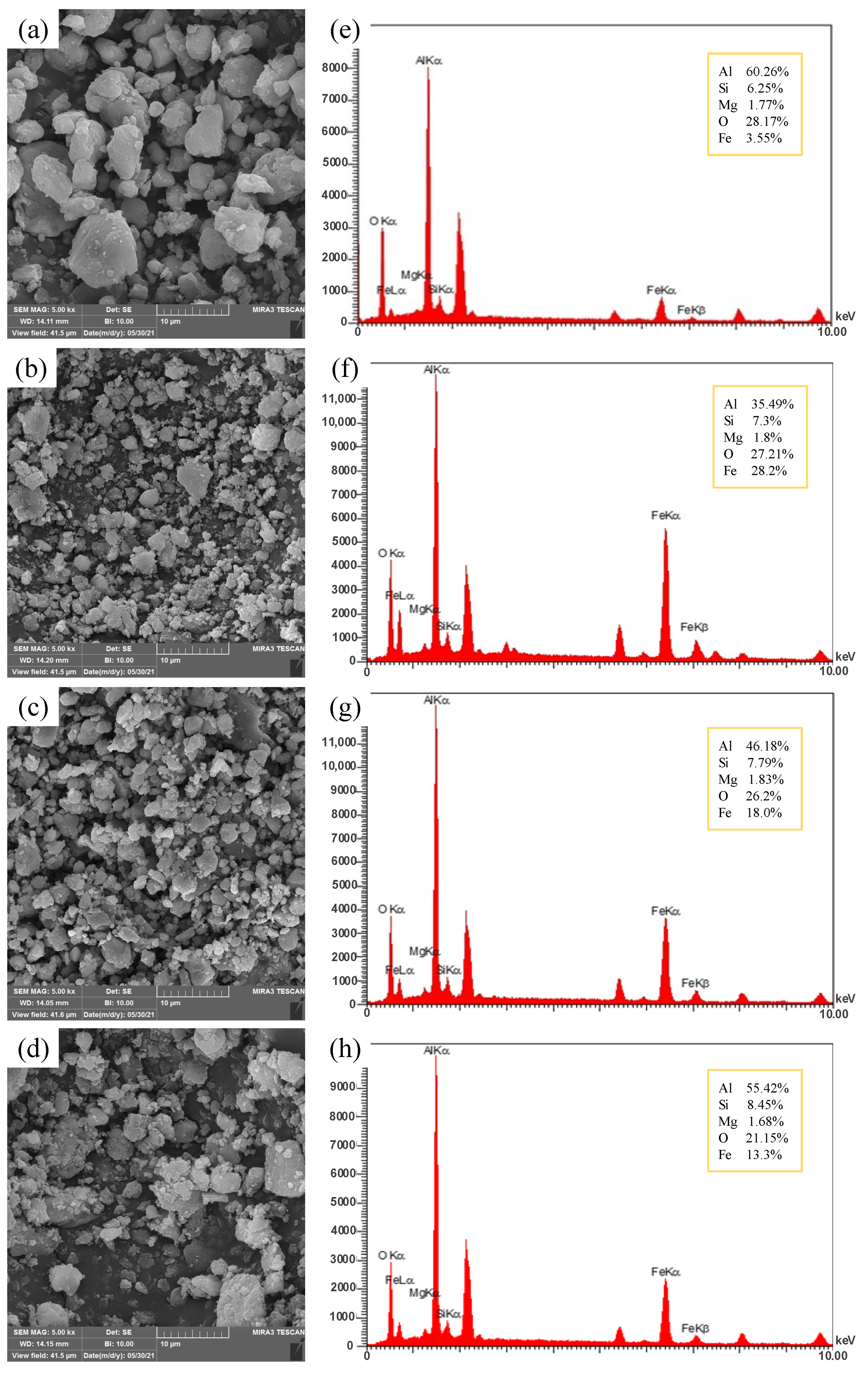

3.6. Wear Mechanisms

4. Conclusions

- A proper ultrasonic melt treatment caused a better dispersion of the nanosilica reinforcements in the A356 aluminum alloy and refined the microstructure of the fabricated composite materials. Adding nanoparticles with 0.125 wt.% resulted in better wear resistance due to the synergistic improvement in both the reinforcing role of the nanosilica particles and ultrasonic efficiency. Adding more than this amount (0.125 wt.%), however, resulted in a relatively coarse microstructure due to the increase in viscosity and thus a decrease in the efficiency of ultrasonic waves;

- Based on the hardness profile in the longitudinal direction of the cast ingot, the highest hardness is measured at the bottom and then at the top of the cast ingot. The hardness of all samples reinforced with nanosilica particles was higher than the base alloy. Among these, the largest increase is obtained from the A356/0.125% SiO2 sample, exhibiting a 52% hardness increase;

- The pin-on-disc experiment revealed that all the composite samples have a lower weight loss rate compared to the monolithic material. Investigations showed that the nanocomposites have better wear resistance at higher forces; for example, the A356/0.125% SiO2 sample under the force of 100 N has recorded an improvement in wear resistance of about 68%;

- As much as 50% improvement of the COF in the sample with the optimal wt.% (A356/0.125% SiO2), and a reduction in the COF of all composite samples compared to the base alloy, is seen in this research. The COF in the composite samples did not change much with the increase in force, but the COF of the matrix alloy decreased with the addition of force;

- Examining the abraded surfaces revealed that the dominant wear mechanisms in the samples reinforced with nanosilica are mainly abrasion and delamination. Further, the amount of abrasion in the A356/0.125% SiO2 composite sample is higher and the destruction in this sample has reached its lowest level. EDS investigation of the wear debris showed that the iron transfer from the disc surface to the pin surface has taken place with the addition of nanosilica, and the iron transfer increased with higher hardness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hassan, S.F.; Gupta, M. Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement. Mater. Sci. Eng. A 2005, 392, 163–168. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Properties and deformation behaviour of Mg–Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

- Banerjee, S.; Poria, S.; Sutradhar, G.; Sahoo, P. Nano-indentation and corrosion characteristics of ultrasonic vibration assisted stir-cast AZ31–WC–graphite nano-composites. Int. J. Met. 2021, 15, 1058–1072. [Google Scholar] [CrossRef]

- Alipour, M.; Keshavamurthy, R.; Koppad, P.G.; Shakiba, A.; Reddy, N.C. Investigation of microstructure and mechanical properties of cast Al–10Zn–3.5 Mg–2.5 Cu nanocomposite reinforced with graphene nano sheets produced by ultrasonic assisted stir casting. Int. J. Met. 2022, 17, 935–946. [Google Scholar]

- Ghahremani, A.; Abdullah, A.; Arezoodar, A.F. Wear behavior of light-weight metal matrix nanocomposites. Ceram. Int. 2022, 48, 35947–35965. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Aravindan, S. Fabrication of Al5083/B4C surface composite by friction stir processing and its tribological characterization. J. Mater. Res. 2015, 4, 398–410. [Google Scholar] [CrossRef]

- Murthy, N.V.; Reddy, A.P.; Selvaraj, N.; Rao, C.S.P. Preparation of SiC based Aluminium metal matrix nano composites by high intensity ultrasonic cavitation process and evaluation of mechanical and tribological properties. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 149. [Google Scholar] [CrossRef]

- Venkatesh, R.; Rao, V.S. Thermal, corrosion and wear analysis of copper based metal matrix composites reinforced with alumina and graphite. Def. Technol. 2018, 14, 346–355. [Google Scholar] [CrossRef]

- Mavhungu, S.; Akinlabi, E.; Onitiri, M.; Varachia, F. Aluminum matrix composites for industrial use: Advances and trends. Procedia Manuf. 2017, 7, 178–182. [Google Scholar] [CrossRef]

- Xu, J.; Chen, L.; Choi, H.; Li, X. Theoretical study and pathways for nanoparticle capture during solidification of metal melt. J. Phys. Condens. Matter 2012, 24, 255304. [Google Scholar] [CrossRef]

- Pai, B.C.; Ramani, G.; Pillai, R.M.; Satyanarayana, K.G. Role of magnesium in cast aluminium alloy matrix composites. J. Mater. Sci. 1995, 30, 1903–1911. [Google Scholar] [CrossRef]

- Kobashi, M.; Choh, T. The wettability and the reaction for SiC particle/Al alloy system. J. Mater. Sci. 1993, 28, 684–690. [Google Scholar] [CrossRef]

- Glass, S.J.; RolfWaesche, K.U.; Naito, M. Effects of titanium on wettability and interfaces in aluminum/ceramic systems. In Characterization & Control of Interfaces for High Quality Advanced Materials; The American Ceramic Society: Columbus, OH, USA, 2005; p. 83. [Google Scholar]

- Nosko, M.; Nagy, Š.; Weber, L.; Maťko, I.; Mihalkovič, M.; Iždinský, K.; Orovčík, Ľ. Effect of Ca addition on interface formation in Al (Ca)/Al2O3 composites prepared by gas pressure assisted infiltration. Mater. Des. 2016, 108, 618–623. [Google Scholar] [CrossRef]

- An, Q.; Cong, X.-S.; Shen, P.; Jiang, Q.-C. Roles of alloying elements in wetting of SiC by Al. J. Alloys Compd. 2019, 784, 1212–1220. [Google Scholar] [CrossRef]

- Krishnan, P.K.; Arunachalam, R.; Husain, A.; Al-Maharbi, M. Studies on the influence of stirrer blade design on the microstructure and mechanical properties of a novel aluminum metal matrix composite. J. Manuf. Sci. Eng. 2021, 143, 021008. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Baharvandi, H.R.; Mirzaee, O. Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: Evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Compos. Part B Eng. 2013, 52, 262–268. [Google Scholar] [CrossRef]

- Malaki, M.; Fadaei Tehrani, A.; Niroumand, B.; Gupta, M. Wettability in metal matrix composites. Metals 2021, 11, 1034. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.F.; Niroumand, B.; Abdullah, A. Ultrasonically Stir Cast SiO2/A356 Metal Matrix Nanocomposites. Metals 2021, 11, 2004. [Google Scholar] [CrossRef]

- Jebeen Moses, J.; Joseph Sekhar, S. Investigation on the tensile strength and microhardness of AA6061/TiC composites by stir casting. Trans. Indian Inst. Met. 2017, 70, 1035–1046. [Google Scholar] [CrossRef]

- Bui, R.T.; Ouellet, R.; Kocaefe, D. A two-phase flow model of the stirring of Al-SiC composite melt. Metall. Mater. Trans. B 1994, 25, 607–618. [Google Scholar] [CrossRef]

- Yamamoto, T.; Suzuki, A.; Komarov, S.V.; Ishiwata, Y. Investigation of impeller design and flow structures in mechanical stirring of molten aluminum. J. Mater. Process. Technol. 2018, 261, 164–172. [Google Scholar] [CrossRef]

- Torotwa, I.; Ji, C. A study of the mixing performance of different impeller designs in stirred vessels using computational fluid dynamics. Designs 2018, 2, 10. [Google Scholar] [CrossRef]

- Wu, J.; Pullum, L. Performance analysis of axial-flow mixing impellers. AIChE J. 2000, 46, 489–498. [Google Scholar] [CrossRef]

- Mehta, V.R.; Sutaria, M.P. Investigation on the effect of stirring process parameters on the dispersion of SiC particles inside melting crucible. Met. Mater. Int. 2021, 27, 2989–3002. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Computational and experimental analysis of particulate distribution during Al–SiC MMC fabrication. Compos. Part A Appl. Sci. Manuf. 2007, 38, 719–729. [Google Scholar] [CrossRef]

- Abdullah, A.; Malaki, M.; Baghizadeh, E. On the impact of ultrasonic cavitation bubbles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 681–694. [Google Scholar] [CrossRef]

- Abdullah, A.; Pak, A.; Abdullah, M.M.; Shahidi, A.; Malaki, M. Study of the behavior of ultrasonic piezo-ceramic actuators by simulations. Electron. Mater. Lett. 2014, 10, 37–42. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X. Ultrasonic cavitation-based nanomanufacturing of bulk aluminum matrix nanocomposites. J. Manuf. Sci. Eng. 2007, 129, 497–501. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Recent developments on ultrasonic cavitation based solidification processing of bulk magnesium nanocomposites. Int. J. Met. 2008, 2, 57–65. [Google Scholar] [CrossRef]

- Puga, H.; Barbosa, J.; Teixeira, J.C.; Prokic, M. A new approach to ultrasonic degassing to improve the mechanical properties of aluminum alloys. J. Mater. Eng. Perform. 2014, 23, 3736–3744. [Google Scholar] [CrossRef]

- Tekmen, C.; Saday, F.; Cocen, U.; Ljungberg, L.Y. An investigation of the effect of SiC reinforcement coating on the wettability of Al/SiC system. J. Compos. Mater. 2008, 42, 1671–1679. [Google Scholar] [CrossRef]

- Feng, A.; McCoy, B.J.; Munir, Z.A.; Cagliostro, D. Wettability of transition metal oxide surfaces. Mater. Sci. Eng. A 1998, 242, 50–56. [Google Scholar] [CrossRef]

- Eskin, G.I. Ultrasonic Treatment of Light Alloy Melts; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced metal matrix nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, J.-Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.-M.; Mathaudhu, S.; Li, X.-C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Eskin, G.I.; Eskin, D.G. Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt. Ultrason. Sonochemistry 2003, 10, 297–301. [Google Scholar] [CrossRef]

- Tzanakis, I.; Xu, W.W.; Eskin, D.G.; Lee, P.D.; Kotsovinos, N. In situ observation and analysis of ultrasonic capillary effect in molten aluminium. Ultrason. Sonochemistry 2015, 27, 72–80. [Google Scholar] [CrossRef]

- Liu, X.; Jia, S.; Nastac, L. Ultrasonic cavitation-assisted molten metal processing of cast A356-nanocomposites. Int. J. Met. 2014, 8, 51–58. [Google Scholar] [CrossRef]

- Gallego-Juárez, J.A.; Graff, K.F. Power Ultrasonics: Applications of High-Intensity Ultrasound; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Donthamsetty, S.; Suresh Babu, P. Experiments on the wear characteristics of A356 MMNCs fabricated using ultrasonic cavitation. Int. J. Automot. Mech. Eng. 2017, 14, 4589–4602. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Jayashree, P.K.; Shankar, M.C.G.; Kini, A.; Sharma, S.S.; Shetty, R. Review on effect of silicon carbide (SiC) on stir cast aluminium metal matrix composites. Int. J. Curr. Eng. Technol. 2013, 3, 1061–1071. [Google Scholar]

- Abedini, R.; Abdullah, A.; Alizadeh, Y. Ultrasonic assisted hot metal powder compaction. Ultrason. Sonochemistry 2017, 38, 704–710. [Google Scholar] [CrossRef]

- Sarvi Hampa, P.; Razfar, M.R.; Malaki, M.; Maleki, A. The role of dry aero-acoustical lubrication and material softening in ultrasonically assisted milling of difficult-to-cut AISI 304 steels. Trans. Indian Inst. Met. 2015, 68, 43–49. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

- Abdullah, A.; Malaki, M.; Eskandari, A. Strength enhancement of the welded structures by ultrasonic peening. Mater. Des. 2012, 38, 7–18. [Google Scholar] [CrossRef]

- Shafiei-Zarghani, A.; Kashani-Bozorg, S.F.; Hanzaki, A.Z. Wear assessment of Al/Al2O3 nano-composite surface layer produced using friction stir processing. Wear 2011, 270, 403–412. [Google Scholar] [CrossRef]

- Hosseini, N.; Karimzadeh, F.; Abbasi, M.H.; Enayati, M.H. A comparative study on the wear properties of coarse-grained Al6061 alloy and nanostructured Al6061–Al2O3 composites. Tribol. Int. 2012, 54, 58–67. [Google Scholar] [CrossRef]

- Alam, M.T.; Arif, S.; Ansari, A.H. Wear behaviour and morphology of stir cast aluminium/SiC nanocomposites. Mater. Res. Express 2018, 5, 045008. [Google Scholar] [CrossRef]

- Sharma, A.; Fujii, H.; Paul, J. Influence of reinforcement incorporation approach on mechanical and tribological properties of AA6061- CNT nanocomposite fabricated via FSP. J. Manuf. Process. 2020, 59, 604–620. [Google Scholar] [CrossRef]

- Suresh, R.; Siddeshkumar, N. Investigation on dry sliding wear behavior of AA5083/nano-Al2O3 metal matrix composites. Rev. Metal. 2022, 58, e213. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Rajabi, S.; Shirvanimoghaddam, K.; Baharvandi, H. Wear and friction behavior of nanosized TiB2 and TiO2 particle-reinforced casting A356 aluminum nanocomposites: A comparative study focusing on particle capture in matrix. J. Compos. Mater. 2015, 49, 3665–3681. [Google Scholar] [CrossRef]

- George, S.M.; Priya, R.; Vijayakumar, G.N.S.; Pradeep, J.A. Study on mechanical characteristics of the nano-TiC reinforced Al6061 metal matrix composites. Mater. Today Proc. 2022, 62, 2224–2229. [Google Scholar] [CrossRef]

- Miyajima, T.; Iwai, Y. Effects of reinforcements on sliding wear behavior of aluminum matrix composites. Wear 2003, 255, 606–616. [Google Scholar] [CrossRef]

- Hosseini, N.; Karimzadeh, F.; Abbasi, M.; Enayati, M.H. Tribological properties of Al6061–Al2O3 nanocomposite prepared by milling and hot pressing. Mater. Des. 2010, 31, 4777–4785. [Google Scholar] [CrossRef]

- Abdollahi, A.; Alizadeh, A.; Baharvandi, H.R. Dry sliding tribological behavior and mechanical properties of Al2024–5 wt.% B4C nanocomposite produced by mechanical milling and hot extrusion. Mater. Des. 2014, 55, 471–481. [Google Scholar] [CrossRef]

- Hutchings, I.; Shipway, P. Tribology: Friction and Wear of Engineering Materials; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Saba, F.; Zhang, F.; Liu, S.; Liu, T. Reinforcement size dependence of mechanical properties and strengthening mechanisms in diamond reinforced titanium metal matrix composites. Compos. Part B Eng. 2019, 167, 7–19. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Ahamed, A. Friction and wear behaviour of cast Al 6063 based in situ metal matrix composites. Wear 2011, 271, 1928–1939. [Google Scholar] [CrossRef]

- Fathy, A.; Shehata, F.; Abdelhameed, M.; Elmahdy, M. Compressive and wear resistance of nanometric alumina reinforced copper matrix composites. Mater. Des. (1980–2015) 2012, 36, 100–107. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Fathy, A.; Abu-Oqail, A.; Elmetwaly, H.T.; Wagih, A. Structural, mechanical and tribological properties of Cu–ZrO2/GNPs hybrid nanocomposites. Ceram. Int. 2020, 46, 7586–7594. [Google Scholar] [CrossRef]

- Kerr, I.; Priest, M.; Okamoto, Y.; Fujita, M. Friction and wear performance of newly developed automotive bearing materials under boundary and mixed lubrication regimes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 321–331. [Google Scholar] [CrossRef]

- Guo, Q.B.; Rong, M.Z.; Jia, G.L.; Lau, K.T.; Zhang, M.Q. Sliding wear performance of nano-SiO2/short carbon fiber/epoxy hybrid composites. Wear 2009, 266, 658–665. [Google Scholar] [CrossRef]

- Zhang, G.; Chang, L.; Schlarb, A.K. The roles of nano-SiO2 particles on the tribological behavior of short carbon fiber reinforced PEEK. Compos. Sci. Technol. 2009, 69, 1029–1035. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Akhlaghi, F. Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribol. Int. 2016, 102, 28–37. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S.; Mondal, D.P.; Dixit, G. RETRACTED: Dry sliding wear behaviour of cast high strength aluminium alloy (Al–Zn–Mg) and hard particle composites. Wear 2009, 267, 1688–1695. [Google Scholar] [CrossRef]

- Lakshmipathy, J.; Kulendran, B. Reciprocating wear behavior of 7075Al/SiC in comparison with 6061Al/Al2O3 composites. Int. J. Refract. Met. Hard Mater. 2014, 46, 137–144. [Google Scholar] [CrossRef]

- Krishnan, P.; Lakshmanan, P.; Palani, S.; Arumugam, A.; Kulothungan, S. Analyzing the hardness and wear properties of SiC and hBN reinforced aluminum hybrid nanocomposites. Mater. Today Proc. 2022, 62, 566–571. [Google Scholar] [CrossRef]

- Alipour, M.; Eslami-Farsani, R. Synthesis and characterization of graphene nanoplatelets reinforced AA7068 matrix nanocomposites produced by liquid metallurgy route. Mater. Sci. Eng. A 2017, 706, 71–82. [Google Scholar] [CrossRef]

- Almomani, M.A.; Hayajneh, M.T.; Alelaumi, S.M. Applying Taguchi method to study the wear behaviour of ZA-27 alloy-based composites reinforced with SiC nanoparticles. Int. J. Cast Met. Res. 2019, 32, 229–241. [Google Scholar] [CrossRef]

- Dinaharan, I.; Murugan, N.; Thangarasu, A. Development of empirical relationships for prediction of mechanical and wear properties of AA6082 aluminum matrix composites produced using friction stir processing. Eng. Sci. Technol. Int. J. 2016, 19, 1132–1144. [Google Scholar] [CrossRef]

- Sharifi, E.M.; Karimzadeh, F. Wear behavior of aluminum matrix hybrid nanocomposites fabricated by powder metallurgy. Wear 2011, 271, 1072–1079. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Aravindan, S.; Vipin. Wear Characteristics of Al5083 Surface Hybrid Nano-composites by Friction Stir Processing. Trans. Indian Inst. Met. 2016, 70, 1111–1129. [Google Scholar] [CrossRef]

| Zn | Mn | Cu | Fe | Ti | Mg | Si | Al | Material |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 7.5 | Balance | wt.% |

| Value | Unit | Properties and Test Method |

|---|---|---|

| 210–240 | m2/g | Specific surface area (CTAB adsorption) |

| 30–50 | nm | Main particle size (TEM) |

| 2.65 | g/cm3 | Density |

| 0.13–0.15 | g/cm3 | Tamped density ISO-787-11 |

| 1.3 | Wm−1 K | Thermal conductivity |

| 12.3 | 10−6 K−1 | Thermal expansion coeff. |

| 1830 | °C | Melting point |

| ≤98.5 | % | SiO2 Content ISO 3262/17 |

| Distance (m) | Speed (m/s) | Normal Force (N) | Nanosilica (g) | Parameter |

|---|---|---|---|---|

| 1000, 1500, 2000 | 1 | 60, 80, 100 | 0, 2, 4, 6 | Value |

| AMNC6 | AMNC4 | AMNC2 | AMNC0 | Samples |

|---|---|---|---|---|

| 2.5 | 1.6 | 1.2 | 0.6 | Porosity(%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghahremani, A.; Abdullah, A.; Fallahi Arezoodar, A.; Gupta, M. An Investigation on the Enhanced Wear Behavior of Ultrasonically Stirred Cast A356/SiO2np Nano-composites. Crystals 2023, 13, 722. https://doi.org/10.3390/cryst13050722

Ghahremani A, Abdullah A, Fallahi Arezoodar A, Gupta M. An Investigation on the Enhanced Wear Behavior of Ultrasonically Stirred Cast A356/SiO2np Nano-composites. Crystals. 2023; 13(5):722. https://doi.org/10.3390/cryst13050722

Chicago/Turabian StyleGhahremani, Ahmad, Amir Abdullah, Alireza Fallahi Arezoodar, and Manoj Gupta. 2023. "An Investigation on the Enhanced Wear Behavior of Ultrasonically Stirred Cast A356/SiO2np Nano-composites" Crystals 13, no. 5: 722. https://doi.org/10.3390/cryst13050722

APA StyleGhahremani, A., Abdullah, A., Fallahi Arezoodar, A., & Gupta, M. (2023). An Investigation on the Enhanced Wear Behavior of Ultrasonically Stirred Cast A356/SiO2np Nano-composites. Crystals, 13(5), 722. https://doi.org/10.3390/cryst13050722