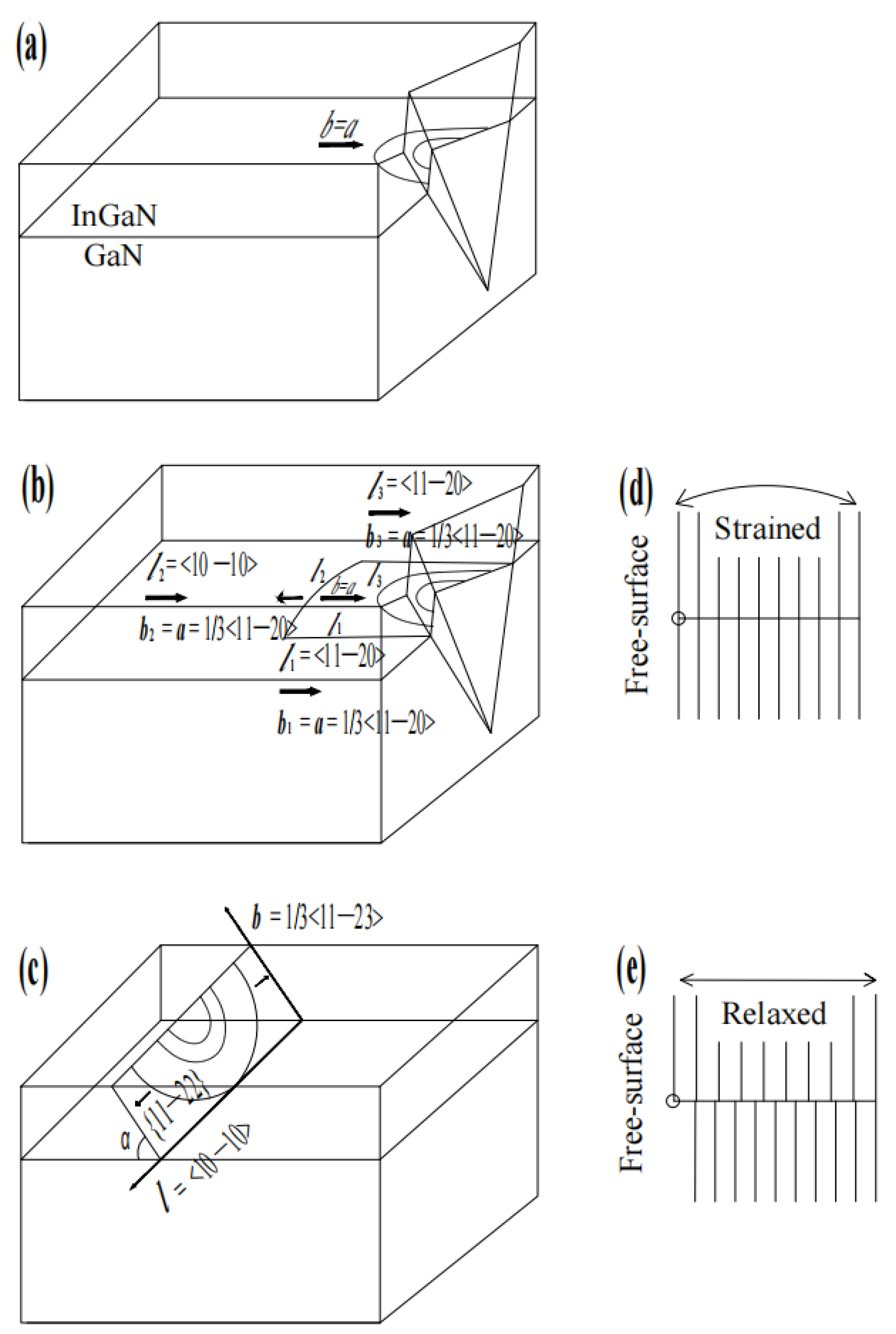

Transition from Screw-Type to Edge-Type Misfit Dislocations at InGaN/GaN Heterointerfaces

Abstract

1. Introduction

2. Materials and Methods

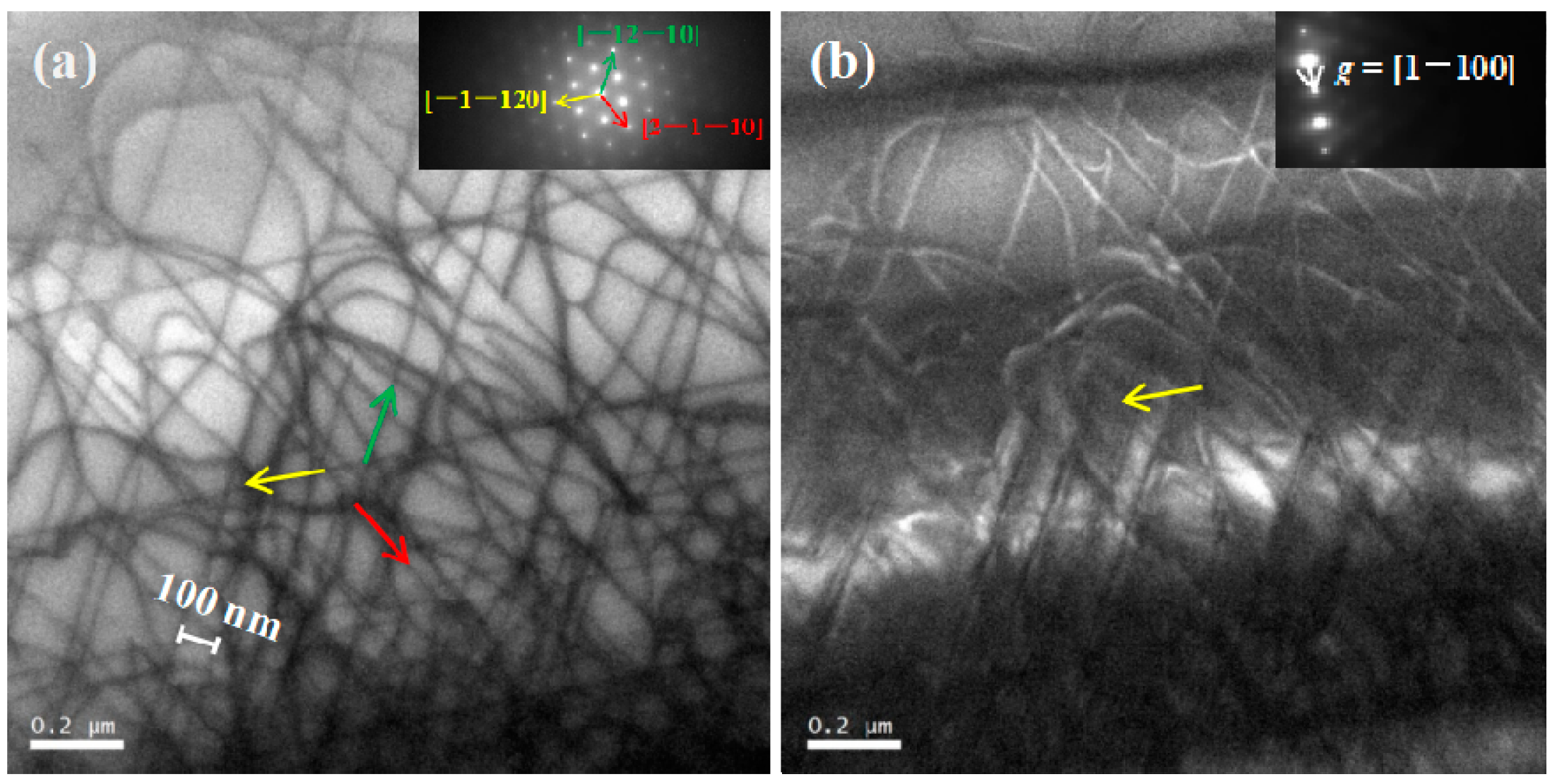

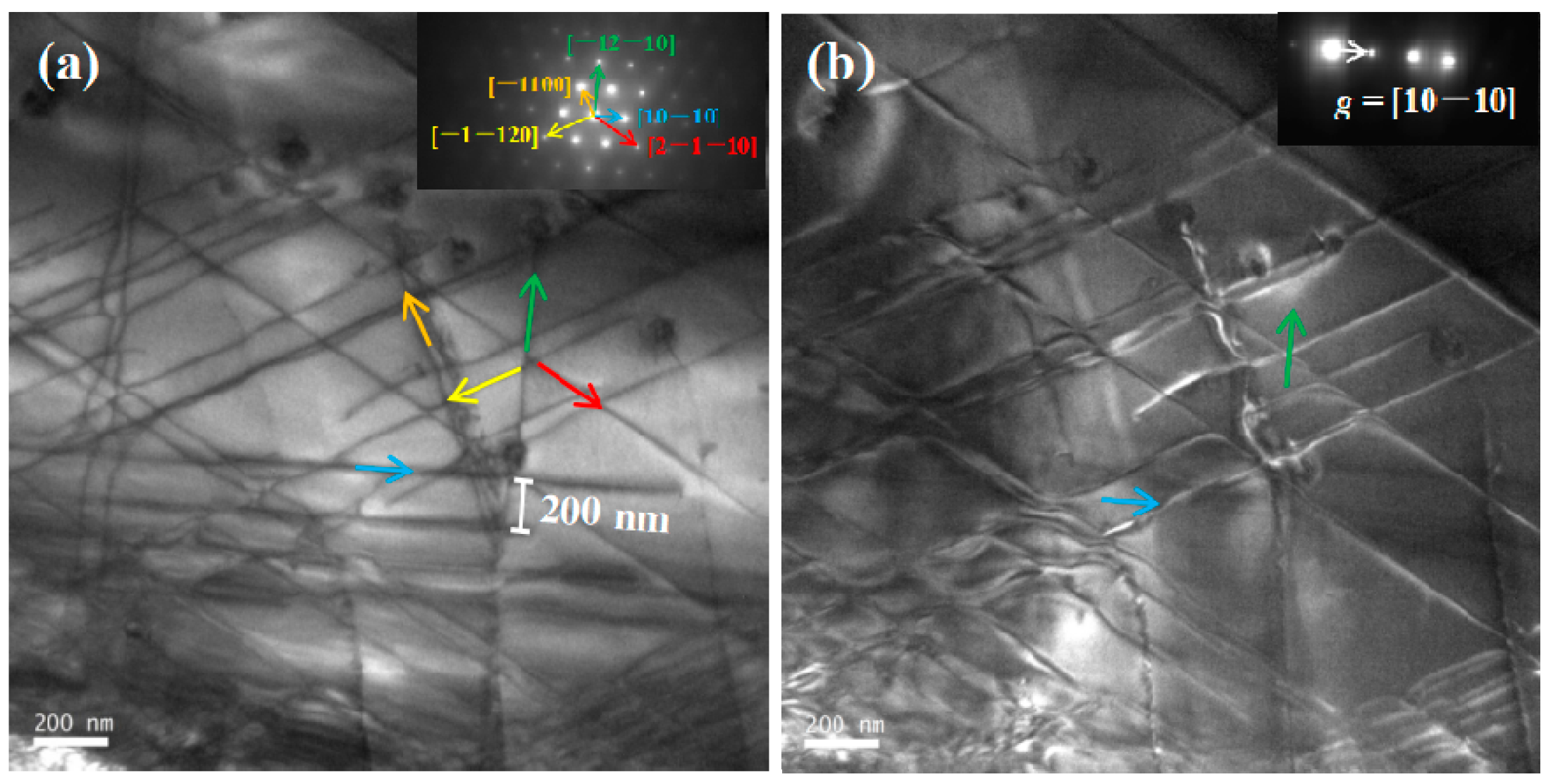

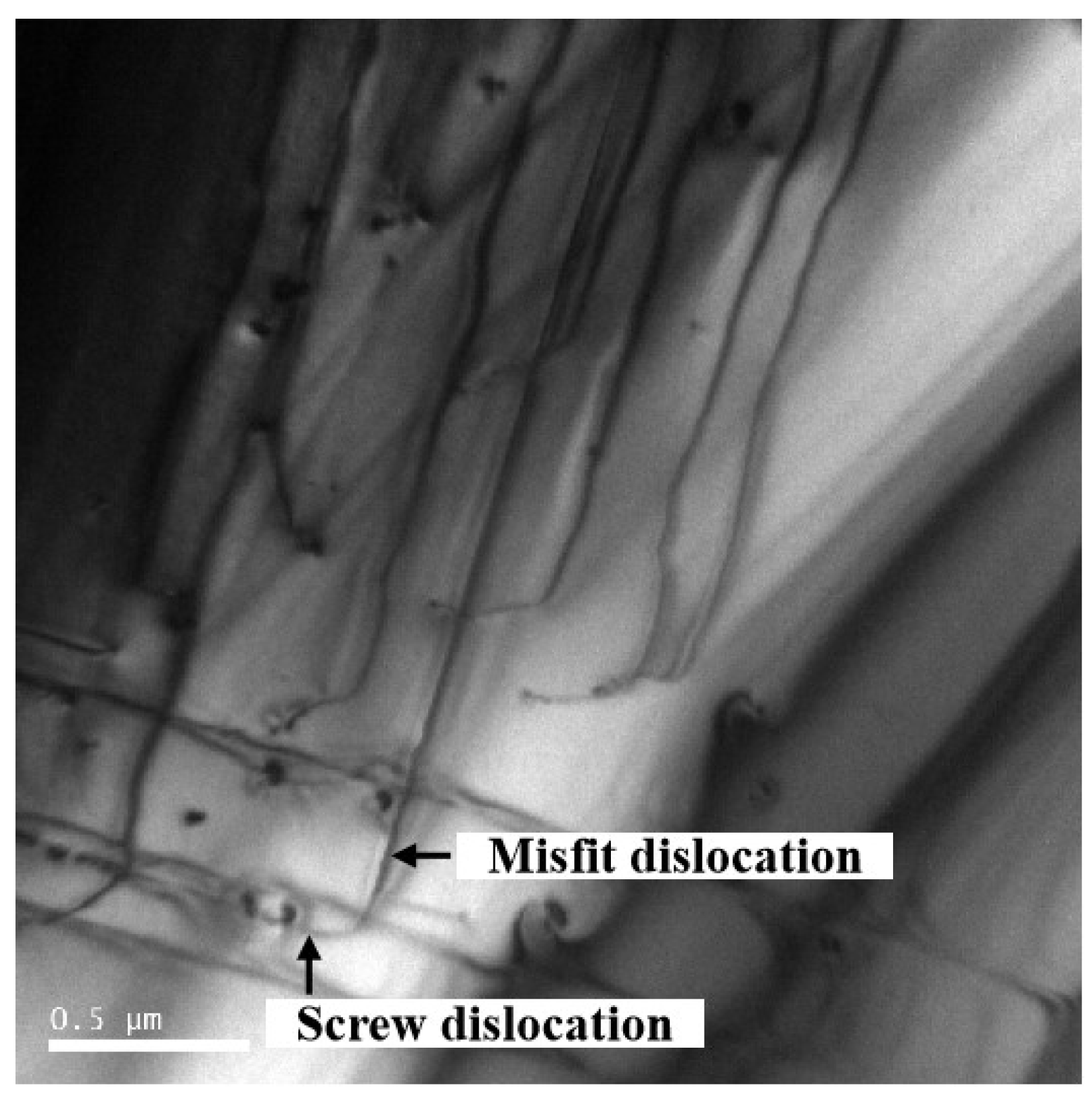

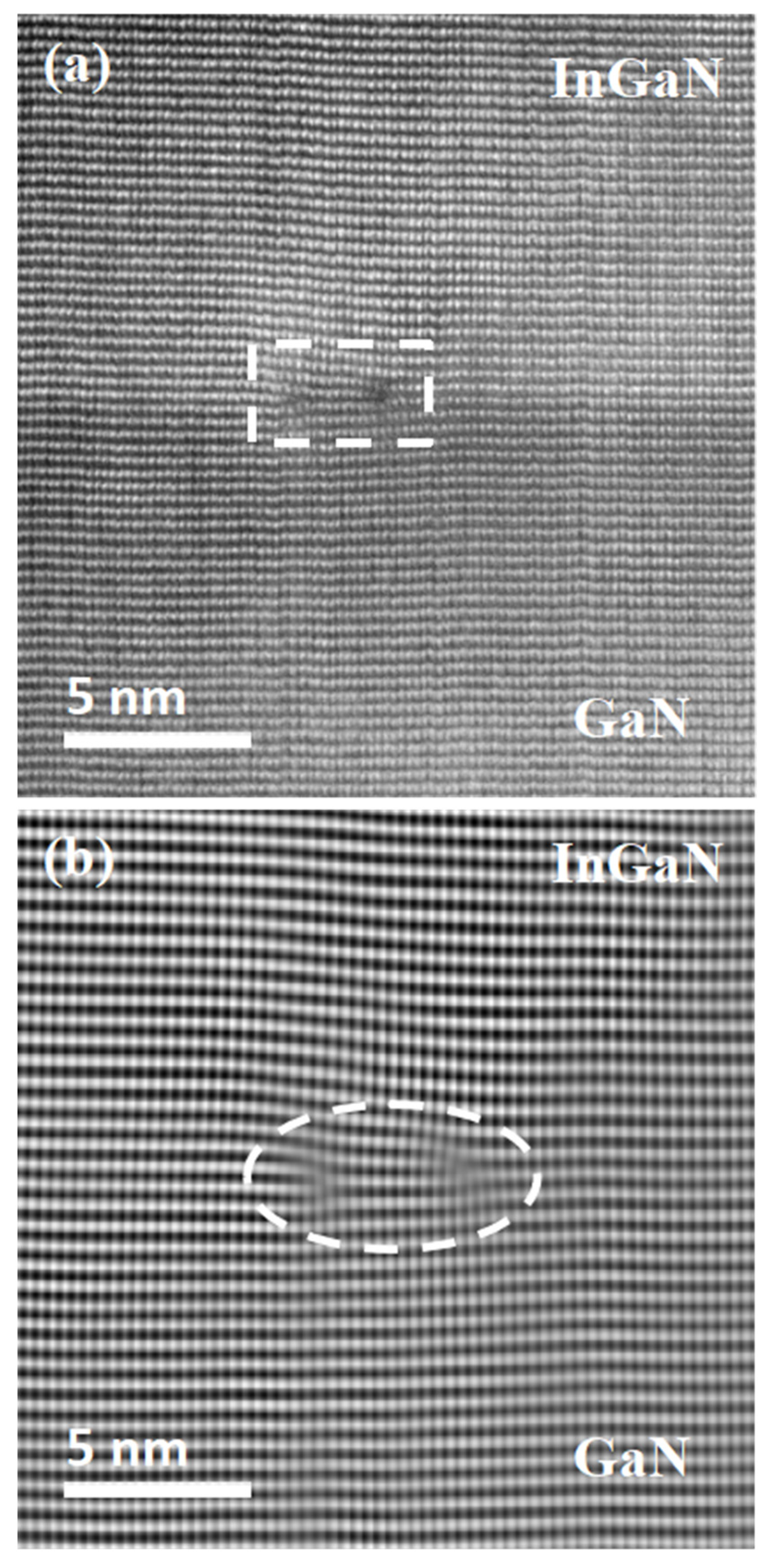

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nakamura, S.; Mukai, T.; Senoh, M. Candela-class high-brightness InGaN/AlGaN double-heterostructure blue-light-emitting diodes. Appl. Phys. Lett. 1994, 64, 1687. [Google Scholar] [CrossRef]

- Ponce, F.A.; Bour, D.P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 1997, 386, 351–359. [Google Scholar] [CrossRef]

- Ponce, F.A.; Srinivasan, S.; Bell, A.; Geng, L.; Liu, R.; Stevens, M.; Cai, J.; Omiya, H.; Marui, H.; Tanaka, S. Microstructure and electronic properties of InGaN alloys. Phys. Status Solidi 2003, 240, 273–284. [Google Scholar] [CrossRef]

- Ho, I.; Stringfellow, G.B. Solid phase immiscibility in GaInN. Appl. Phys. Lett. 1996, 69, 2701–2703. [Google Scholar] [CrossRef]

- Srinivasan, S.; Geng, L.; Liu, R.; Ponce, F.A.; Narukawa, Y.; Tanaka, S. Slip systems and misfit dislocations in InGaN epilayers. Appl. Phys. Lett. 2003, 83, 5187–5189. [Google Scholar] [CrossRef]

- Liu, R.; Mei, J.; Srinivasan, S.; Omiya, H.; Ponce, F.A.; Cherns, D.; Narukawa, Y.; Mukai, T. Misfifit Dislocation Generation in InGaN Epilayers on Free-Standing GaN. Jpn. J. Appl. Phys. 2006, 45, L549. [Google Scholar] [CrossRef]

- Iwaya, M.; Yamamoto, T.; Iida, D.; Kondo, Y.; Sowa, M.; Matsubara, H.; Ishihara, K.; Takeuchi, T.; Kamiyama, S.; Akasaki, I. Relationship between misfit-dislocation formation and initial threading-dislocation density in GaInN/GaN heterostructures. Jpn. J. Appl. Phys. 2015, 54, 115501. [Google Scholar] [CrossRef]

- Li, Q.T.; Minj, A.; Chauvat, M.P.; Chen, J.; Ruterana, P. Interface dislocations in InxGa1−xN/GaN heterostructures. Phys. Status Solidi A 2017, 214, 1600442. [Google Scholar] [CrossRef]

- Moneta, J.; Siekacz, M.; Grzanka, E.; Schulz, T.; Markurt, T.; Albrecht, M.; Smalc-Koziorowska, J. Peculiarities of plastic relaxation of (0001) InGaN epilayers and their consequences for pseudo-substrate application. Appl. Phys. Lett. 2018, 113, 031904. [Google Scholar] [CrossRef]

- Floro, J.A.; Follstaedt, D.M.; Provencio, P.; Hearne, S.J.; Lee, S.R. Misfit dislocation formation in the Al-GaN/GaN heterointerface. J. Appl. Phys. 2004, 96, 7087. [Google Scholar] [CrossRef]

- Ichimura, M.; Narayan, J. Role of surface step on misfit dislocation nucleation and critical thickness in semiconductor heterostructures. Mater. Sci. Eng. B 1995, 31, 299–303. [Google Scholar] [CrossRef]

- Andrews, A.M.; Romanov, A.E.; Speck, J.S.; Bobeth, M.; Pompe, W. Development of cross-hatch morphology during growth of lattice mismatched layers. Appl. Phys. Lett. 2000, 77, 3740–3742. [Google Scholar] [CrossRef]

- Matthews, J.; Blakeslee, A. Defects in epitaxial multilayers: I. Misfit dislocations. J. Cryst. Growth 1974, 27, 118–125. [Google Scholar] [CrossRef]

- Lü, W.; Li, D.B.; Li, C.R.; Zhang, Z. Generation and behavior of pure-edge threading misfit dislocations in InxGa1−xN/GaN multiple quantum wells. J. Appl. Phys. 2004, 96, 5267–5270. [Google Scholar] [CrossRef]

- Hsu, P.S.; Young, E.C.; Romanov, A.E.; Fujito, K.; DenBaars, S.P.; Nakamura, S.; Speck, J.S. Misfit dislocation formation via pre-existing threading dislocation glide in (112¯2) semipolar heteroepitaxy. Appl. Phys. Lett. 2011, 99, 081912. [Google Scholar] [CrossRef]

- Hossain, M.A.; Hasan, M.M.; Islam, M.R. Strain Relaxation via Misfit Dislocation in Step-Graded InGaN Heteroepitaxial Layers Grown on Semipolar (11-22) and (1-101) GaN. Int. J. Appl. Phys. Math. 2012, 2, 49. [Google Scholar] [CrossRef]

- Leyer, M.; Stellmach, J.; Meissner, C.; Pristovsek, M.; Kneissl, M. The critical thickness of InGaN on (0001)GaN. J. Cryst. Growth 2008, 310, 4913–4915. [Google Scholar] [CrossRef]

- Holec, D.; Costa, P.; Kappers, M.; Humphreys, C. Critical thickness calculations for InGaN/GaN. J. Cryst. Growth 2007, 303, 314–317. [Google Scholar] [CrossRef]

- Fischer, A.; Kühne, H.; Richter, H. New Approach in Equilibrium Theory for Strained Layer Relaxation. Phys. Rev. Lett. 1994, 73, 2712–2715. [Google Scholar] [CrossRef]

- Ponce, F.A.; Cherns, D.; Young, W.T.; Steeds, J.W. Characterization of dislocations in GaN by transmission electron diffraction and microscopy techniques. Appl. Phys. Lett. 1996, 69, 770–772. [Google Scholar] [CrossRef]

- Liu, R.; Mei, J.; Srinivasan, S.; Ponce, F.A.; Omiya, H.; Narukawa, Y.; Mukai, T. Generation of misfit dislocations by ba-sal-plane slip in InGaN/GaN heterostructures. Appl. Phys. Lett. 2006, 89, 201911. [Google Scholar] [CrossRef]

- Matthews, J.W.; Mader, S.; Light, T.B. Accommodation of Misfit Across the Interface Between Crystals of Semicon-ducting Elements or Compounds. J. Appl. Phys. 1970, 41, 3800. [Google Scholar] [CrossRef]

- Peierls, R. The size of a dislocation. Proc. Phys. Soc. 1940, 52, 34. [Google Scholar] [CrossRef]

- Nabarro, F.R.N. Dislocations in a simple cubic lattice. Proc. Phys. Soc. 1947, 59, 256–272. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Minj, A.; Ling, Y.; Wang, C.; He, S.; Ge, X.; He, C.; Guo, C.; Wang, J.; Bao, Y.; et al. Transition from Screw-Type to Edge-Type Misfit Dislocations at InGaN/GaN Heterointerfaces. Crystals 2023, 13, 1027. https://doi.org/10.3390/cryst13071027

Li Q, Minj A, Ling Y, Wang C, He S, Ge X, He C, Guo C, Wang J, Bao Y, et al. Transition from Screw-Type to Edge-Type Misfit Dislocations at InGaN/GaN Heterointerfaces. Crystals. 2023; 13(7):1027. https://doi.org/10.3390/cryst13071027

Chicago/Turabian StyleLi, Quantong, Albert Minj, Yunzhi Ling, Changan Wang, Siliang He, Xiaoming Ge, Chenguang He, Chan Guo, Jiantai Wang, Yuan Bao, and et al. 2023. "Transition from Screw-Type to Edge-Type Misfit Dislocations at InGaN/GaN Heterointerfaces" Crystals 13, no. 7: 1027. https://doi.org/10.3390/cryst13071027

APA StyleLi, Q., Minj, A., Ling, Y., Wang, C., He, S., Ge, X., He, C., Guo, C., Wang, J., Bao, Y., Liu, Z., & Ruterana, P. (2023). Transition from Screw-Type to Edge-Type Misfit Dislocations at InGaN/GaN Heterointerfaces. Crystals, 13(7), 1027. https://doi.org/10.3390/cryst13071027