High-Temperature Piezoelectric Response and Thermal Stability of BiGaO3 Modified BiFeO3–BaTiO3 Lead-Free Piezoelectric Ceramics

Abstract

:1. Introduction

2. Experimental Methods

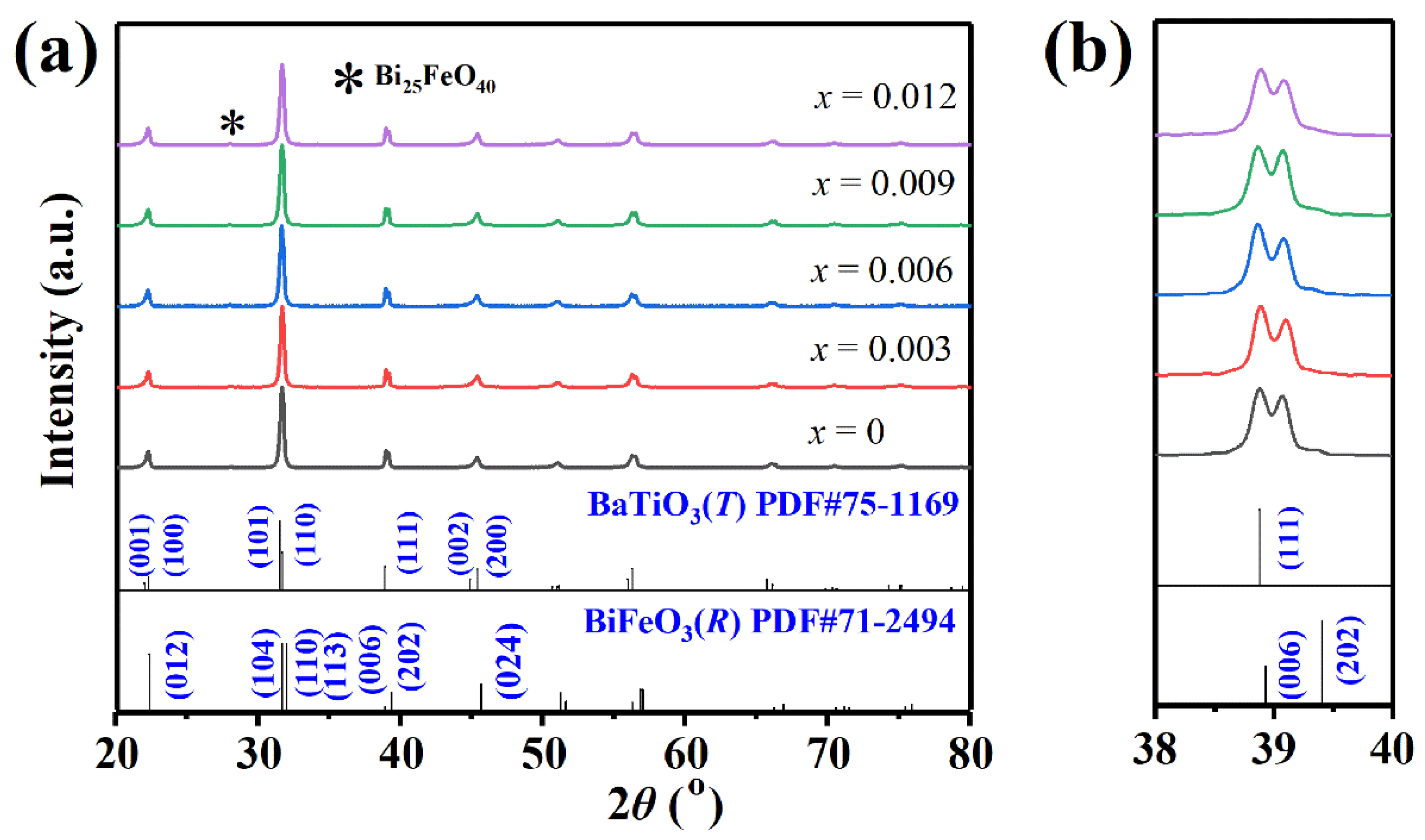

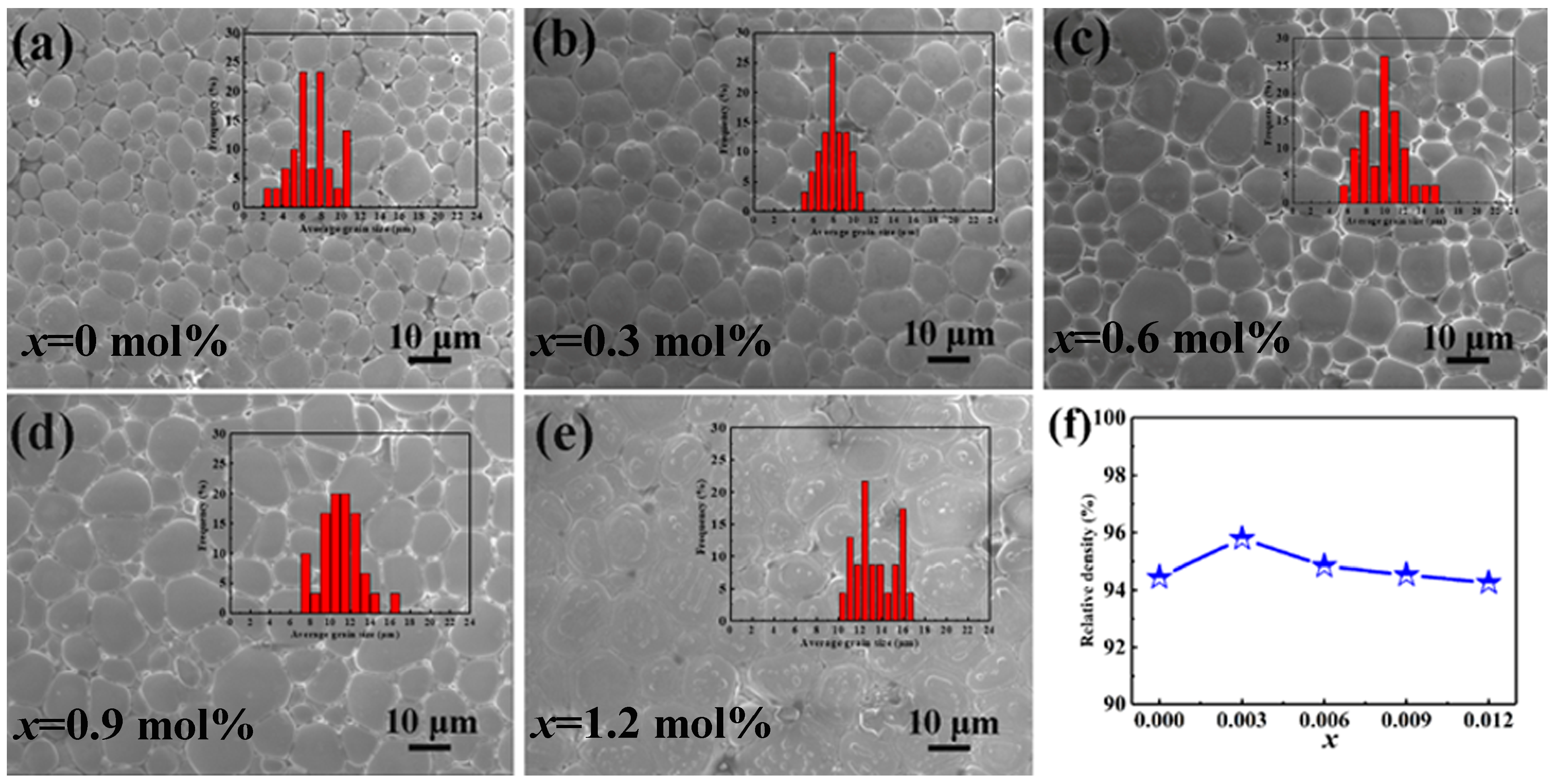

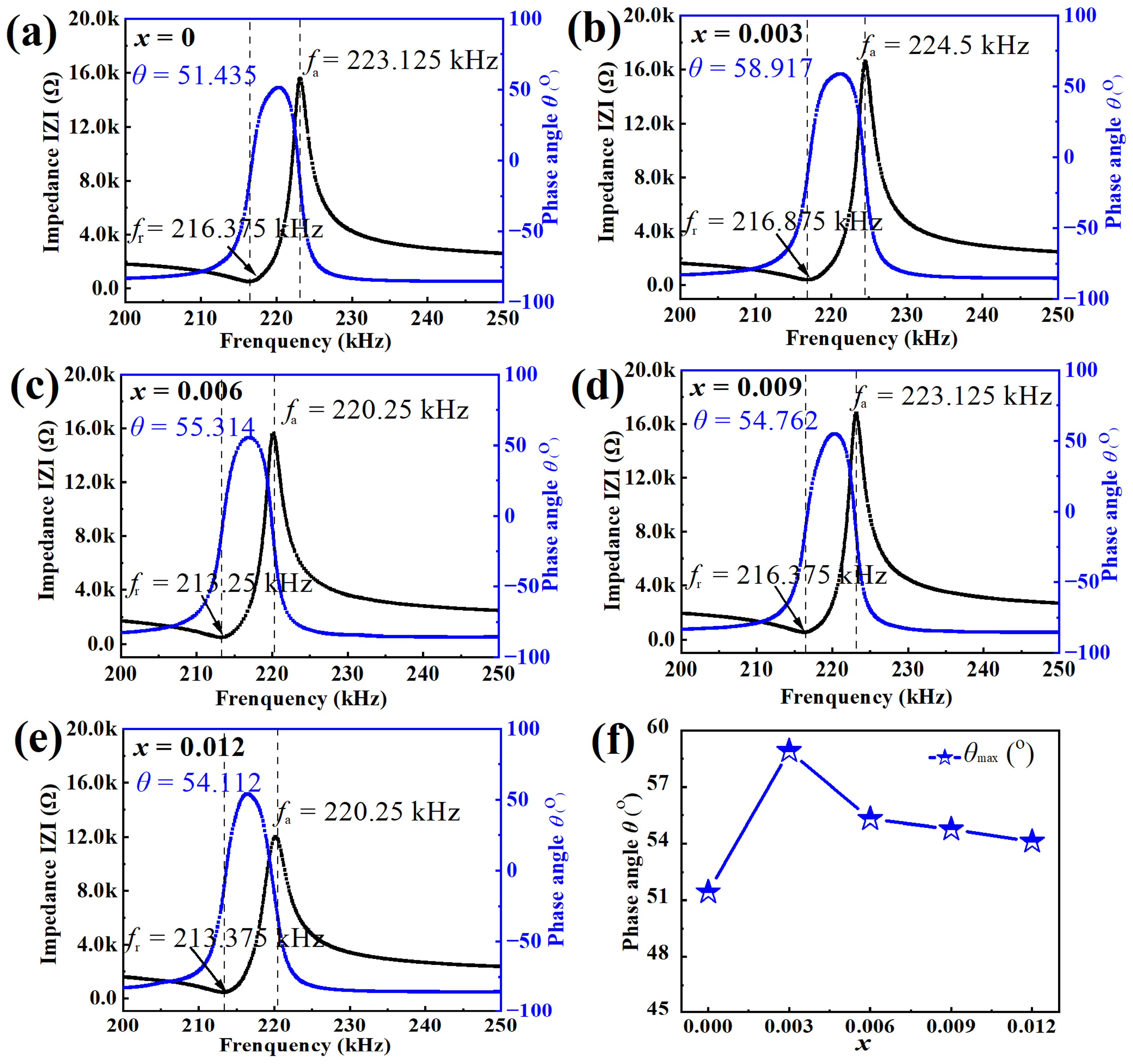

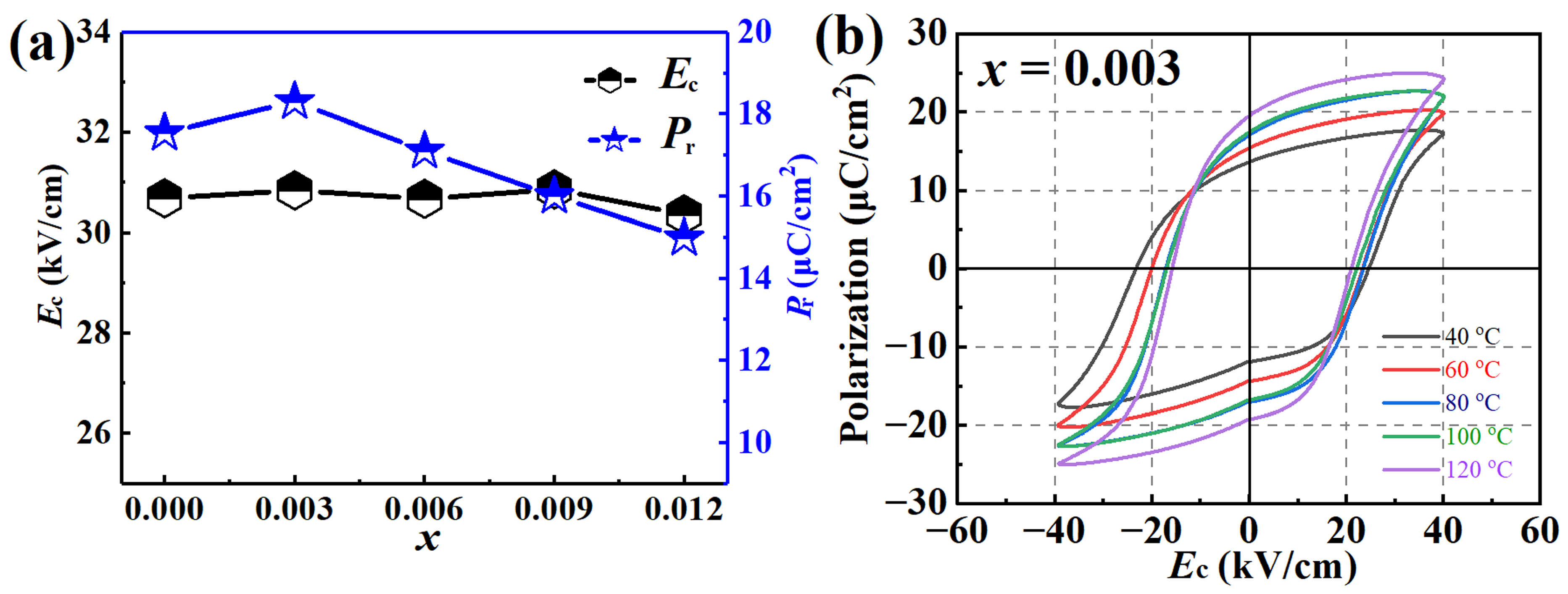

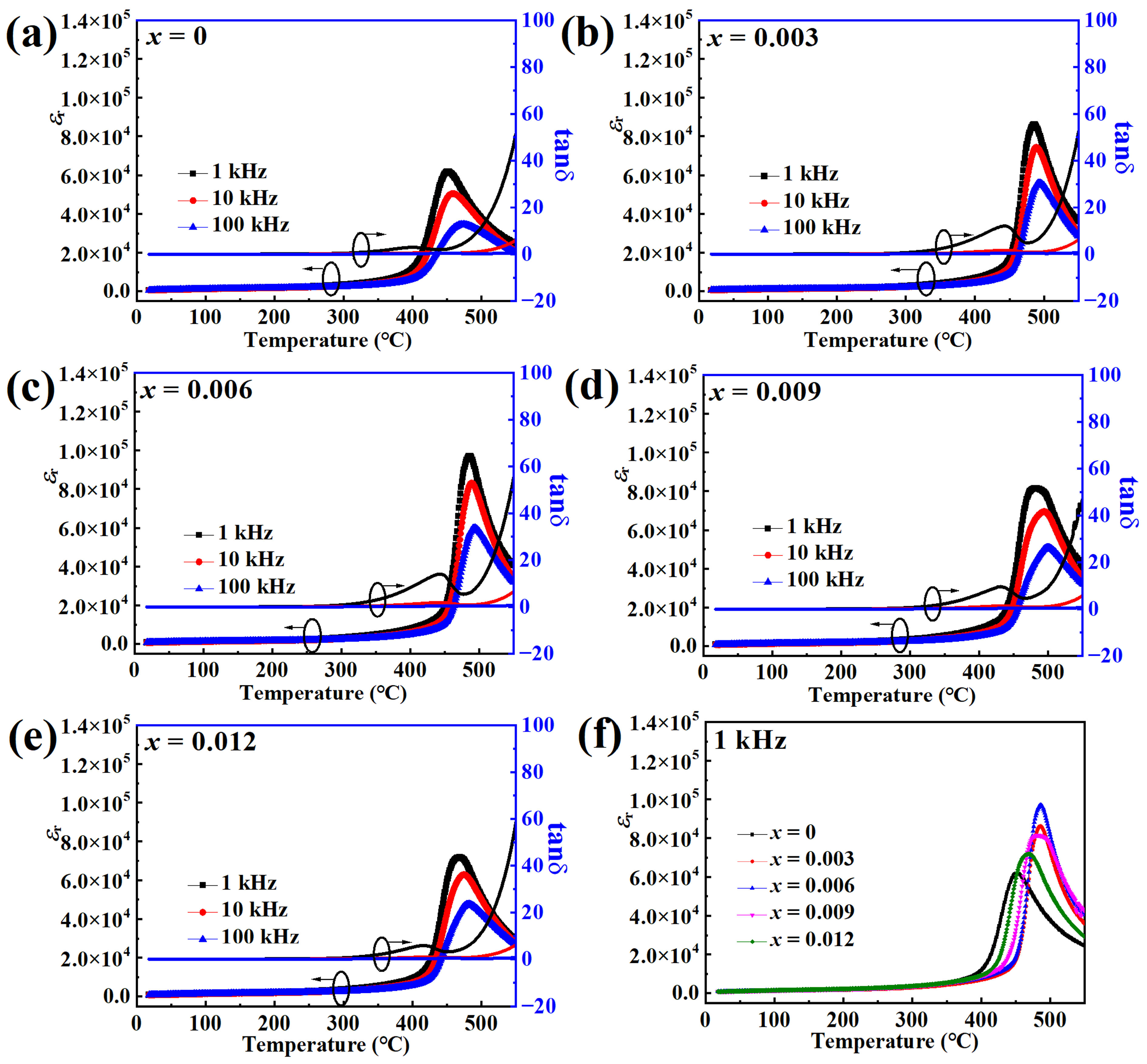

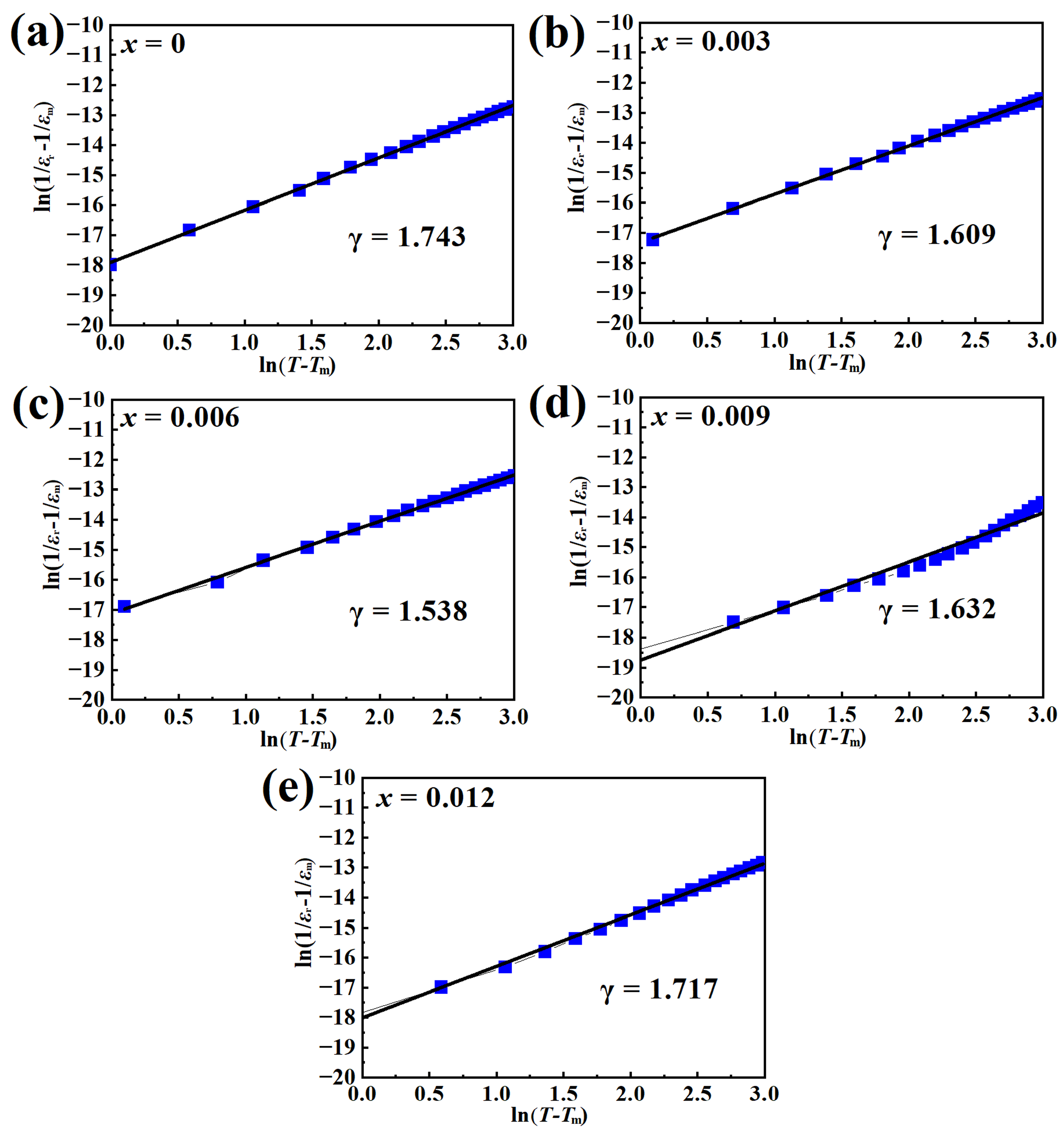

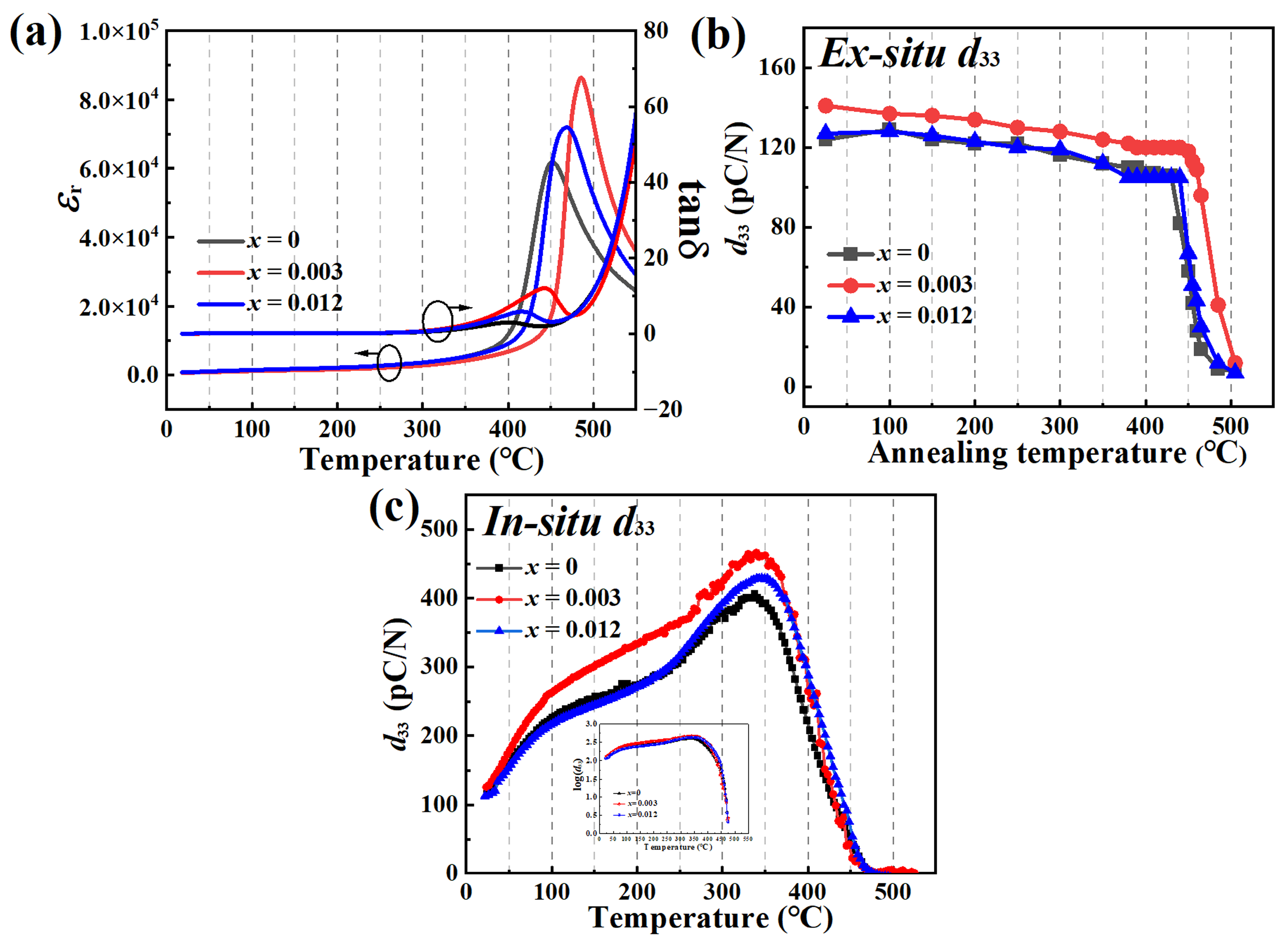

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, S.; Dong, X.; Mao, C.; Cao, F. Thermal Stability of (1−x)BiScO3−xPbTiO3 Piezoelectric Ceramics for High-Temperature Sensor Applications. J. Am. Ceram. Soc. 2006, 89, 3270–3272. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, C.; Liu, X.; Zhou, Q.; Chen, G.; Wang, H.; Li, W. Structural, microstructural and electrical properties of BiFeO3–BaTiO3 ceramics with high thermal stability. Mater. Res. Bull. 2012, 47, 4233–4239. [Google Scholar] [CrossRef]

- Guan, S.; Yang, H.; Chen, G.; Zhang, R. Microstructure, Piezoelectric, and Ferroelectric Properties of BZT-Modified BiFeO3-BaTiO3 Multiferroic Ceramics with MnO2 and CuO Addition. J. Electron. Mater. 2018, 47, 2625–2633. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, L.; Gu, X.; Zhang, Y.; Liao, R. Piezoelectric and dielectric properties of PbNb2O6-based piezoelectric ceramics with high Curie temperature. J. Mater. Process. Technol. 2008, 197, 170–173. [Google Scholar] [CrossRef]

- Fang, R.; Zhou, Z.; Liang, R.; Dong, X. Effects of CuO addition on the sinterability and electric properties in PbNb2O6-based ceramics. Ceram. Int. 2020, 46, 23505–23509. [Google Scholar] [CrossRef]

- Eitel, R.; Randall, C.; Shrout, T.; Park, S. Preparation and Characterization of High Temperature Perovskite Ferroelectrics in the Solid-Solution (1–x)BiScO3–xPbTiO3. Jpn. J. Appl. Phys. 2002, 41, 2099–2104. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, C.; Zhou, Q.; Chen, G.; Wang, H.; Li, W. Microstructural and electrical properties of Na1/2Bi1/2TiO3–(Na1/4Bi3/4)(Mg1/4Ti3/4)O3 piezoelectric ceramics. J. Alloys Compd. 2012, 542, 17–21. [Google Scholar] [CrossRef]

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.; Xiao, D.; Zhu, J. Superior Piezoelectric Properties in Potassium–Sodium Niobate Lead-Free Ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef] [PubMed]

- Guan, S.; Yang, H.; Zhao, Y.; Zhang, R. Effect of Li2CO3 addition in BiFeO3-BaTiO3 ceramics on the sintering temperature, electrical properties and phase transition. J. Alloys Compd. 2018, 735, 386–393. [Google Scholar] [CrossRef]

- Zuo, R.; Fu, J. Rhombohedral–Tetragonal Phase Coexistence and Piezoelectric Properties of (NaK)(NbSb)O3–LiTaO3–BaZrO3 Lead-Free Ceramics. J. Am. Ceram. Soc. 2011, 94, 1467–1470. [Google Scholar] [CrossRef]

- Zuo, R.; Fu, J.; Lu, S.; Xu, Z. Normal to Relaxor Ferroelectric Transition and Domain Morphology Evolution in (K,Na)(Nb,Sb)O3–LiTaO3–BaZrO3 Lead-Free Ceramics. J. Am. Ceram. Soc. 2011, 94, 4352–4357. [Google Scholar] [CrossRef]

- Wang, D.; Wang, G.; Murakami, S.; Fan, Z.; Feteiraz, A.; Zhou, D.; Sun, S.; Zhao, Q.; Reaney, I. BiFeO3-BaTiO3: A new generation of lead-free electroceramics. J. Adv. Dielectr. 2018, 8, 1830004. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Kounga, A.; Aulbach, E.; Ehrenberg, H.; Rödel, J. Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3–BaTiO3–K0.5Na0.5NbO3 System. Appl. Phys. Lett. 2017, 91, 112906. [Google Scholar] [CrossRef]

- Eerenstein, W.; Mathur, N.; Scott, J. Multiferroic and magnetoelectric materials. Nature 2006, 442, 759–765. [Google Scholar] [CrossRef]

- Guan, S.; Yang, H.; Qiao, G.; Sun, Y.; Qin, F.; Hou, H. Effects of Li2CO3 and CuO as Composite Sintering Aids on the Structure, Piezoelectric Properties, and Temperature Stability of BiFeO3-BaTiO3 Ceramics. J. Electron. Mater. 2020, 49, 6199–6207. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, J.; Guo, J.; Cheng, Z.; Wang, J.; Liu, H.; Zhang, S. Excellent thermal stability and aging behaviors in BiFeO3–BaTiO3 piezoelectric ceramics with rhombohedral phase. J. Am. Ceram. Soc. 2020, 103, 374–381. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Chen, J.; Cheng, J.; Tan, Q. Enhanced aging behaviors and electric thermal stabilities in 0.75BiFeO3–0.25BaTiO3 piezoceramics by Mn modifications. J. Am. Ceram. Soc. 2021, 104, 5547–5556. [Google Scholar] [CrossRef]

- Luo, F.; Li, Z.; Chen, J.; Yang, Y.; Zhang, D.; Zhang, M.; Hao, Y. High piezoelectric properties in 0.7BiFeO3–0.3BaTiO3 ceramics with MnO and MnO2 addition. J. Eur. Ceram. Soc. 2022, 42, 954–964. [Google Scholar] [CrossRef]

- Kumar, M.; Srinivas, A.; Suryanarayana, S. Structure property relations in BiFeO3/BaTiO3 solid solutions. J. Appl. Phys. 2000, 87, 855–862. [Google Scholar] [CrossRef]

- Gheorghiu, F.; Ianculescu, A.; Postolache, P.; Lupu, N.; Dobromir, M.; Luca, D.; Mitoseriu, L. Preparation and properties of (1−x)BiFeO3–xBaTiO3 multiferroic ceramics. J. Alloys Compd. 2010, 506, 862–867. [Google Scholar] [CrossRef]

- Yao, Z.; Xu, C.; Liu, H.; Hao, H.; Cao, M.; Wang, Z.; Song, Z.; Hu, W.; Ullah, A. Greatly reduced leakage current and defect mechanism in atmosphere sintered BiFeO3–BaTiO3 high temperature piezoceramics. J. Mater. Sci. Mater. Electron. 2014, 25, 4975–4982. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Z.; Wei, X.; Yao, X. Ferroelectric and Ferromagnetic Properties of 0.7BiFe1–xCrxO3–0.3BaTiO3 Solid Solutions. J. Am. Ceram. Soc. 2008, 91, 3731–3734. [Google Scholar] [CrossRef]

- Guan, S.; Yang, H.; Liu, G.; Qiao, G.; Zhang, R.; Chen, D.; Jiang, M.; Sun, Y. Effect of BiScO3 doping on the structure and properties of BiFeO3-BaTiO3 piezoelectric ceramics. J. Electroceram. 2019, 43, 26–33. [Google Scholar] [CrossRef]

- Wang, D.; Khesro, A.; Murakami, S.; Feteira, A.; Zhao, Q.; Reaney, I. Temperature dependent, large electromechanical strain in Nd-doped BiFeO3-BaTiO3 lead-free ceramics. J. Eur. Ceram. Soc. 2017, 37, 1857–1860. [Google Scholar] [CrossRef] [Green Version]

- Guan, S.; Yang, H.; Zhang, R.; Pang, J.; Jiang, M.; Sun, Y. Structure, piezoelectric, ferroelectric and dielectric properties of leadfree ceramics 0.67BiFeO3–0.33BaTiO3–xBiGaO3+0.0035MnO2. J. Mater. Sci. Mater. Electron. 2018, 29, 16872–16879. [Google Scholar] [CrossRef]

- Belik, A.; Rusakov, D.; Furubayashi, T.; Takayama-Muromachi, E. BiGaO3-Based Perovskites: A Large Family of Polar Materials. Chem. Mater. 2012, 24, 3056–3064. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Z.; Qu, S.; Wei, X.; Chen, J. Microstructure and properties of Ga-modified 0.7BiFeO3-0.3BaTiO3 solid solution. Chin. Sci. Bull. 2007, 52, 2747–2752. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhou, C.; Yang, H.; Yuan, C.; Chen, G.; Cao, L.; Fan, Q. Piezoelectric and ferroelectric properties of Ga modified BiFeO3–BaTiO3 lead-free ceramics with high Curie temperature. J. Mater. Sci. Mater. Electron. 2014, 25, 196–201. [Google Scholar] [CrossRef]

- Lee, M.; Kim, D.; Park, J.; Kim, S.; Song, T.; Kim, M.; Kim, W.; Do, D.; Jeong, I. High-Performance Lead-Free Piezoceramics with High Curie Temperatures. Adv. Mater. 2015, 27, 6976–6982. [Google Scholar] [CrossRef]

- Akram, F.; Malik, R.; Khan, S.; Hussain, A.; Lee, S.; Lee, M.; In, C.; Song, T.; Kim, W.; Sung, Y.; et al. Electromechanical properties of ternary BiFeO3−0.35BaTiO3–BiGaO3 piezoelectric ceramics. J. Electroceram. 2018, 41, 93–98. [Google Scholar] [CrossRef]

- Lee, M.; Kim, D.; Choi, H.; Kim, M.; Song, T.; Kim, W.; Do, D. Thermal Quenching Effects on the Ferroelectric and Piezoelectric Properties of BiFeO3−BaTiO3 Ceramics. ACS Appl. Electron. Mater. 2019, 1, 1772–1780. [Google Scholar] [CrossRef]

- Leontsev, S.; Eitel, R. Dielectric and Piezoelectric Properties in Mn-Modified (1–x)BiFeO3–xBaTiO3 Ceramics. J. Am. Ceram. Soc. 2009, 12, 2957–2961. [Google Scholar] [CrossRef]

- Li, Q.; Wei, J.; Cheng, J.; Chen, J. High temperature dielectric, ferroelectric and piezoelectric properties of Mn-modified BiFeO3-BaTiO3 lead-free ceramics. J. Mater. Sci. 2017, 52, 229–237. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J. Perovskite BiFeO3–BaTiO3 Ferroelectrics: Engineering Properties by Domain Evolution and Thermal Depolarization Modification. Adv. Electron. Mater. 2020, 6, 2000079. [Google Scholar] [CrossRef]

- Tan, Y.; Zhou, C.; Wang, J.; Yao, K.; Yuan, C.; Xu, J.; Li, Q.; Rao, G. Probing the in-time piezoelectric responses and depolarization behaviors related to ferroelectricrelaxor transition in BiFeO3–BaTiO3 ceramics by in-situ process. J. Mater. Sci. Mater. Electron. 2021, 32, 1197–1203. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, B.; Zhao, L.; Wang, K. Enhanced insulating and piezoelectric properties of BiFeO3-BaTiO3-Bi0.5Na0.5TiO3 ceramics with high Curie temperature. J. Am. Ceram. Soc. 2019, 102, 7355–7365. [Google Scholar] [CrossRef]

- Rojac, T.; Bencan, A.; Malic, B.; Tutuncu, G.; Jones, J.; Daniels, J.; Damjanovic, D. BiFeO3 Ceramics: Processing, Electrical, and Electromechanical Properties. J. Am. Ceram. Soc. 2014, 97, 1993–2011. [Google Scholar] [CrossRef]

- Pradhan, S.; Roul, B. Improvement of multiferroic and leakage property in monophasic BiFeO3. Physica B 2011, 406, 3313–3317. [Google Scholar] [CrossRef]

- Bah, M.; Podor, R.; Retoux, R.; Delorme, F.; Nadaud, K.; Giovannelli, F.; Monot-Laffez, I.; Ayral, A. Real-Time Capturing of Microscale Events Controlling the Sintering of Lead-Free Piezoelectric Potassium-Sodium Niobate. Small 2022, 18, 2106825. [Google Scholar] [CrossRef]

- Li, F.; Wang, L.; Jin, L.; Lin, D.; Li, J.; Li, Z.; Xu, Z.; Zhang, S. Piezoelectric Activity in Perovskite Ferroelectric Crystals. IEEE T. Ultrason. Ferr. 2015, 62, 18–32. [Google Scholar] [CrossRef]

- Zhou, Q.; Yuan, D.; Zhou, C.; Yang, H.; Yuan, C. Development of BNKT-BiGaO3 Lead-free Ceramics. Piezoelectr. Acoustoopt. 2010, 32, 423–425. [Google Scholar]

- Zheng, Q.; Luo, L.; Lam, K.; Jiang, N.; Guo, Y.; Lin, D. Enhanced ferroelectricity, piezoelectricity, and ferromagnetism in Nd-modified BiFeO3-BaTiO3 lead-free ceramics. J. Appl. Phys. 2014, 116, 184101. [Google Scholar] [CrossRef]

- Wang, Y.; Pu, Y.; Li, X.; Zheng, H.; Gao, Z. Evolution from ferroelectric to diffused ferroelectric, and relaxor ferroelectric in BaTiO3-BiFeO3 solid solutions. Mater. Chem. Phys. 2016, 183, 247–253. [Google Scholar] [CrossRef]

- Zhou, C. Study on Electrical Properties and Mechanism of BNT–BKT–BiMeO3(Me=Fe, Cr, Co) Lead-free Piezoelectric Ceramics. Ph.D. Thesis, Central South University, Changsha, China, 2008; pp. 1–145. [Google Scholar]

- Wan, Y.; Li, Y.; Li, Q.; Zhou, W.; Zheng, Q.; Wu, X.; Xu, C.; Zhu, B.; Lin, D. Microstructure, Ferroelectric, Piezoelectric, and Ferromagnetic Properties of Sc-Modified BiFeO3–BaTiO3 Multiferroic Ceramics with MnO2 Addition. J. Am. Ceram. Soc. 2014, 97, 1809–1818. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S.; Cross, L.; Jang, S.; Newnham, R. Electrostrictive effect in lead magnesium niobate single crystals. J. Appl. Phys. 1980, 51, 1142–1145. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, G.; Pan, C.; Tong, P.; Yang, J.; Zhu, X.; Yin, L.; Song, W.; Sun, Y. Simultaneously enhanced piezoelectricity and curie temperature in BiFeO3-based high temperature piezoelectrics. J. Eur. Ceram. Soc. 2021, 41, 7645–7653. [Google Scholar] [CrossRef]

- Zeng, F.; Zhang, Y.; Tu, Z.; Ge, X.; Wang, F.; Hao, M.; Zhang, J.; Wang, Y.; Chen, X.; Lu, W.; et al. Large electric field-induced strain in BiFeO3-based ceramics by tuning defect dipoles and phase structure. Ceram. Int. 2021, 47, 14097–14106. [Google Scholar] [CrossRef]

- Lv, X.; Zhang, X.; Wu, J. Nano-domains in lead-free piezoceramics: A review. J. Mater. Chem. A 2020, 8, 10026–10073. [Google Scholar] [CrossRef]

- Huang, C.; Cai, K.; Wang, Y.; Bai, Y.; Guo, D. Revealing the real high temperature performance and depolarization characteristics of piezoelectric ceramics by combined in situ techniques. J. Mater. Chem. C 2018, 6, 1433–1444. [Google Scholar] [CrossRef]

- Budimir, M.; Damjanovic, D.; Setter, N. Piezoelectric response and free-energy instability in the perovskite crystals BaTiO3, PbTiO3, and Pb(Zr,Ti)O3. Phys. Rev. B 2006, 73, 174106. [Google Scholar] [CrossRef] [Green Version]

- Cheng, S.; Zhang, B.; Ai, S.; Yu, H.; Wang, X.; Yang, J.; Zhou, C.; Zhao, J.; Rao, G. Enhanced piezoelectric properties and thermal stability of Bi0.5Na0.5TiO3 modified BiFeO3-BaTiO3 ceramics with morphotropic phase boundary. J. Mater. 2023, 9, 464–471. [Google Scholar]

- Guo, Q.; Li, F.; Xia, F.; Gao, X.; Wang, P.; Hao, H.; Sun, H.; Liu, H.; Zhang, S. High-Performance Sm-Doped Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3-Based Piezoceramics. ACS Appl. Electron. Mater. 2019, 11, 43359–43367. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Guo, Q.; Li, F.; Xia, F.; Hao, H.; Sun, H.; Liu, H.; Zhang, S. Pb(In1/2Nb1/2)O3-PbZrO3-PbTiO3 ternary ceramics with temperature-insensitive and superior piezoelectric property. J. Eur. Ceram. Soc. 2022, 42, 3848–3856. [Google Scholar] [CrossRef]

- Yi, W.; Lu, Z.; Liu, X.; Huang, D.; Jia, Z.; Chen, Z.; Wang, X.; Zhu, H. Excellent piezoelectric performance of Bi-compensated 0.69BiFeO3-0.31BaTiO3 lead-free piezoceramics. J. Mater. Sci. Mater. Electron. 2021, 32, 22637–22644. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, T.; Shi, D.; Xiao, P.; Zheng, Q.; Xu, C.; Lam, K.; Lin, D. Strong piezoelectricity and multiferroicity in BiFeO3–BaTiO3–NdCoO3 lead-free piezoelectric ceramics with high Curie temperature for current sensing application. J. Mater. Sci. Mater. Electron. 2017, 28, 5531–5547. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, L.; Zhang, B.; Wang, K. Lead-free 0.7BiFeO3-0.3BaTiO3 high-temperature piezoelectric ceramics: Nano-BaTiO3 raw powder leading to a distinct reaction path and enhanced electrical properties. Ceram. Int. 2019, 45, 10438–10447. [Google Scholar] [CrossRef]

| Composition | Phase | Lattice | Volume | Fitting |

|---|---|---|---|---|

| fraction | parameters | (VR/VT) (Å3) | parameter | |

| a c (Å) | Rwp/Rp | |||

| x = 0 | R3c 29.478 | 5.64780 (3) | 386.48 (6) | Rwp = 0.0402 |

| 13.99083 (6) | Rp = 0.0296 | |||

| P4 mm 70.522 | 3.99613 (1) | 63.98 (2) | ||

| 4.00659 (1) | ||||

| x = 0.003 | R3c 38.808 | 5.65280 (2) | 388.76 (2) | Rwp = 0.0425 |

| 14.04836 (9) | Rp = 0.03 | |||

| P4 mm 61.192 | 3.99815 (5) | 64.11 (8) | ||

| 4.01106 (1) | ||||

| x = 0.006 | R3c 41.662 | 5.68791 (5) | 388.58 (9) | Rwp = 0.0422 |

| 13.86928 (7) | Rp = 0.0299 | |||

| P4 mm 58.338 | 3.99785 (9) | 64.25 (1) | ||

| 4.02001 (1) | ||||

| x = 0.009 | R3c 37.181 | 5.69049 (9) | 388.10 (4) | Rwp = 0.0439 |

| 13.83939 (5) | Rp = 0.0317 | |||

| P4 mm 62.819 | 3.99542 (0) | 63.89 (6) | ||

| 4.00266 (2) | ||||

| x = 0.012 | R3c 35.102 | 5.65378 (9) | 389.47 (8) | Rwp = 0.0358 |

| 14.06932 (2) | Rp = 0.0253 | |||

| P4 mm 64.898 | 3.99647 (3) | 63.95 (2) | ||

| 4.00407 (4) |

| Systems | d33 (pC/N) | kp | Ec (kV/cm) | Pr (μc/cm2) | Tc (°C) | Td (°C) | Ref. |

|---|---|---|---|---|---|---|---|

| 0.725BiFe0.98Sc0.02O3 − 0.275BaTiO3 + 0.01MnO2 | 127 | 0.366 | 48 | 19.1 | 636 | 450 | [55] |

| 0.67BiFeO3 − 0.33BaTiO3 + 0.02BiGaO3 + 0.0035MnO2 | 170 | 0.306 | 22.059 | 25 | 434 | 422 | [25] |

| 0.75 BiFeO3 − 0.25BaTiO3 + MnO2 | 116 | - | 39.3 | 22.9 | 619 | 469 | [32] |

| 0.75 BiFeO3 − 0.25BaTiO3 + 0.01NdCoO3 + 0.01MnO2 | 110 | - | - | 8.2 | 605 | 525 | [56] |

| 0.7BF − 0.3BT(SBT) | 210 | 0.34 | 30 | 31.2 | 514 | 400 | [57] |

| 0.67Bi1.05(Fe0.97Ga0.03) − 0.33BaTiO3 (water-quenching) | 402 | - | - | - | 454 | [29] | |

| 0.67BiFeO3 − 0.33BaTiO3 + 0.01BiGaO3(water-quenching) | 454 | 451 | [31] | ||||

| 0.7BiFeO3 − 0.297BaTiO3 − 0.003BiGaO3 + 0.01MnO2 | 466 (340 °C) 141 (RT) | 0.314 | 30.84 | 18.3 | 485.2 | 465 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, S.; Yang, H.; Cheng, S.; Tan, H.; Qiao, G.; Chen, Q.; Xu, J.; Yuan, L.; Wang, X.; Yang, L. High-Temperature Piezoelectric Response and Thermal Stability of BiGaO3 Modified BiFeO3–BaTiO3 Lead-Free Piezoelectric Ceramics. Crystals 2023, 13, 1026. https://doi.org/10.3390/cryst13071026

Guan S, Yang H, Cheng S, Tan H, Qiao G, Chen Q, Xu J, Yuan L, Wang X, Yang L. High-Temperature Piezoelectric Response and Thermal Stability of BiGaO3 Modified BiFeO3–BaTiO3 Lead-Free Piezoelectric Ceramics. Crystals. 2023; 13(7):1026. https://doi.org/10.3390/cryst13071026

Chicago/Turabian StyleGuan, Shibo, Huabin Yang, Shuai Cheng, Hua Tan, Guanjun Qiao, Qiaohong Chen, Jiwen Xu, Linna Yuan, Xueting Wang, and Ling Yang. 2023. "High-Temperature Piezoelectric Response and Thermal Stability of BiGaO3 Modified BiFeO3–BaTiO3 Lead-Free Piezoelectric Ceramics" Crystals 13, no. 7: 1026. https://doi.org/10.3390/cryst13071026

APA StyleGuan, S., Yang, H., Cheng, S., Tan, H., Qiao, G., Chen, Q., Xu, J., Yuan, L., Wang, X., & Yang, L. (2023). High-Temperature Piezoelectric Response and Thermal Stability of BiGaO3 Modified BiFeO3–BaTiO3 Lead-Free Piezoelectric Ceramics. Crystals, 13(7), 1026. https://doi.org/10.3390/cryst13071026