Annihilation and Generation of Dislocations by Irradiation by Ions and Electrons in Strontium Titanate Single Crystal

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

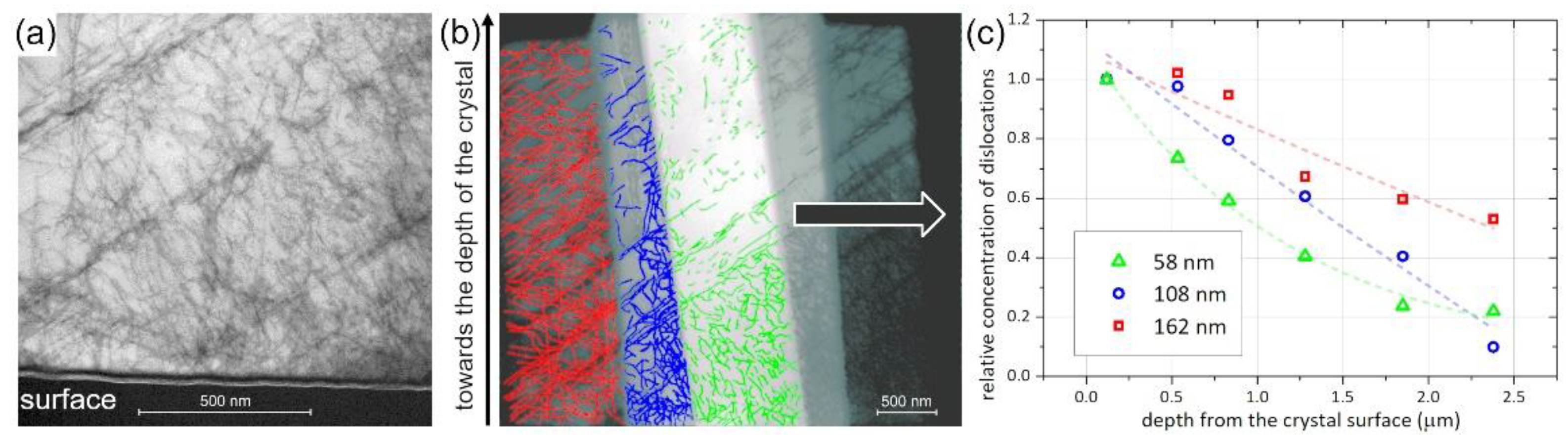

- The first approach focused on ion bombardment during lamella preparation and its influence on the dislocation concentration. The STEM observation allowed us to directly observe defect structure along the (110) direction and measure a dislocation concentration as a function of the sample thickness and depth from the crystal surface. It allowed us to observe the annihilation of dislocations in the surface region of the STO crystal.

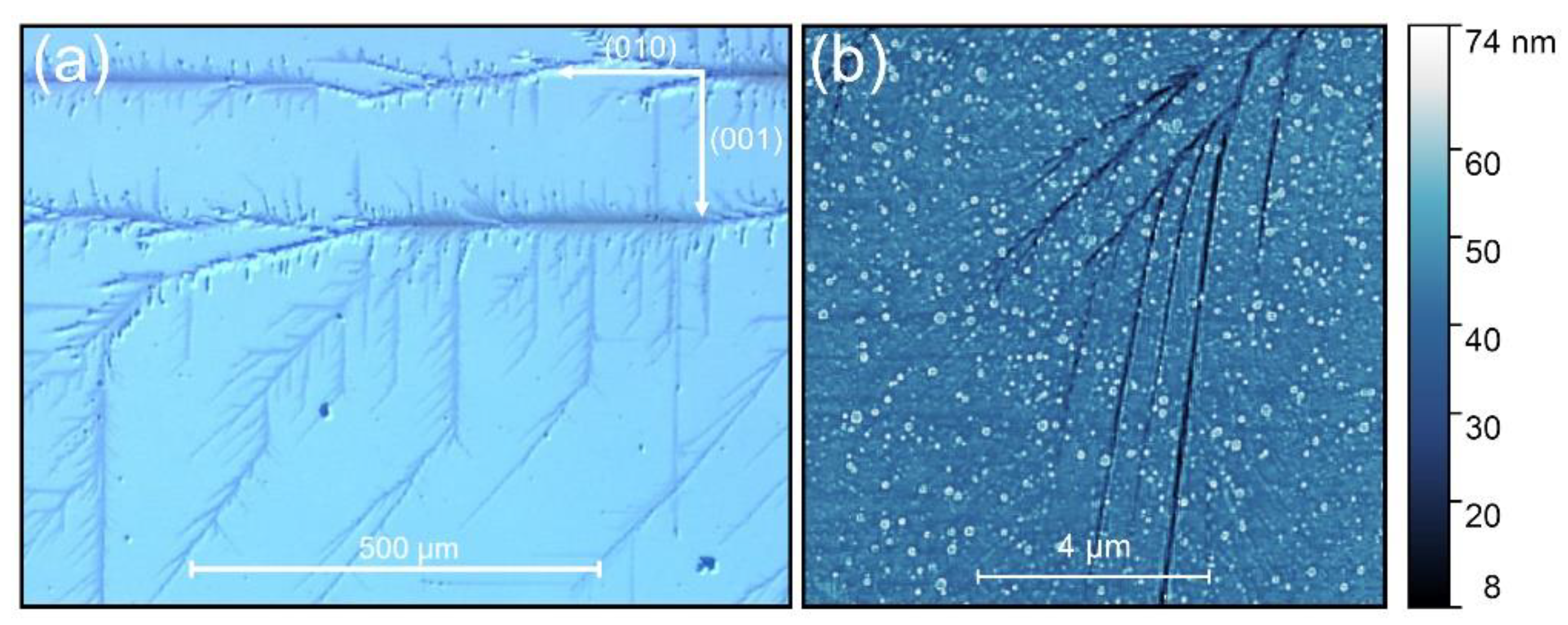

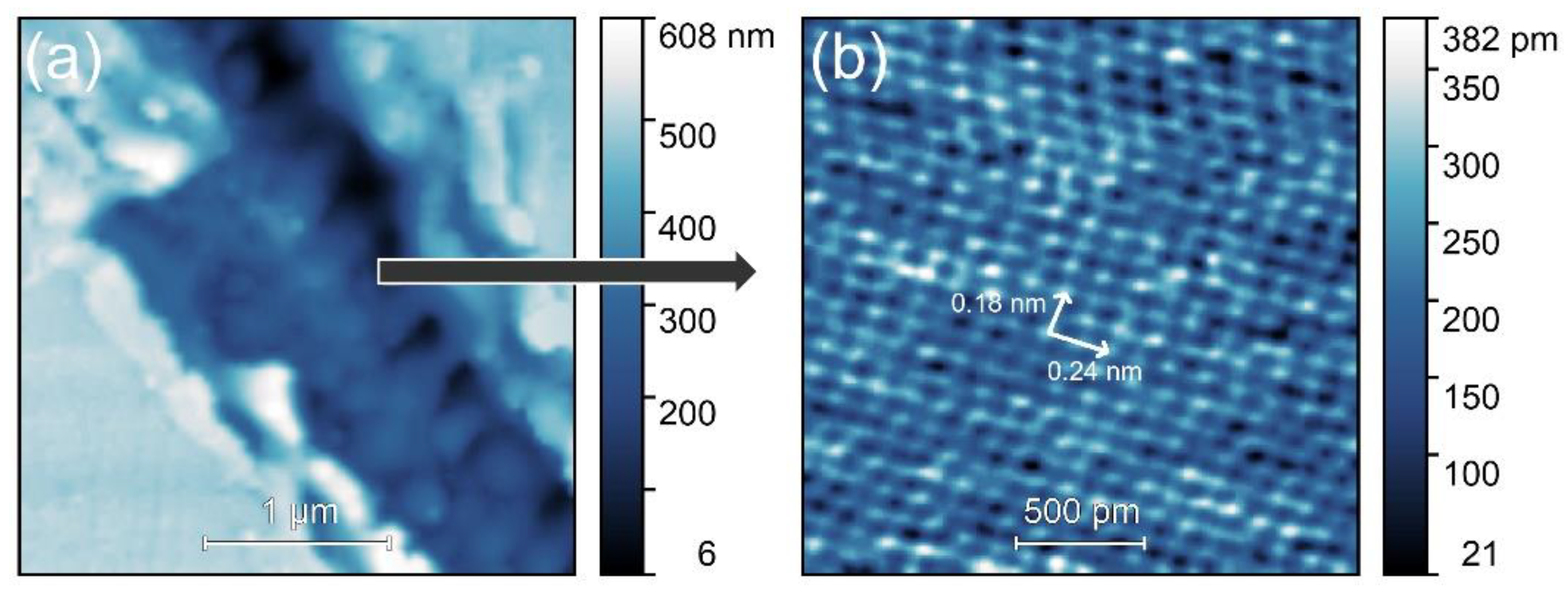

- The second approach implemented electron irradiation from a high-voltage source. It led to the formation of visible patterns along (010), (001), and (011) directions, which are typical for electro-degradation and resistive switching on the STO crystal surface. Such patterns mirror the arrangement of the extended defects found in the crystal, which can be investigated by optical and atomic force microscopy. It allowed us, in turn, to observe the generation and movement of dislocations in the measured sample.

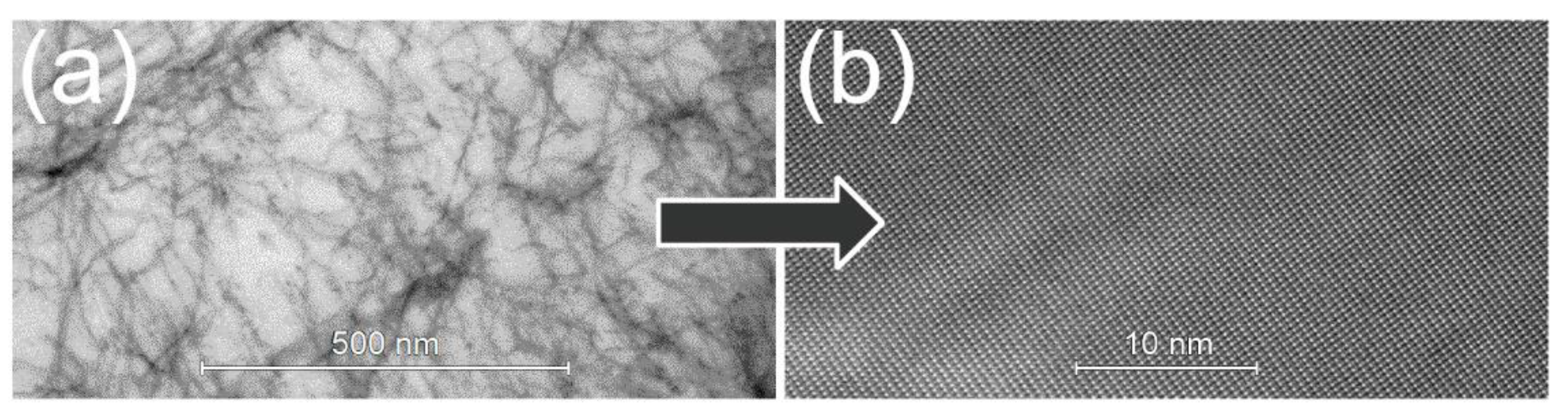

3.1. Decrease of Dislocation Density in an STO Lamella Induced by Thinning with the Focused Ion Beam

- Ion implantation—The calculations of the penetration range of Ga ions into the STO matrix were done by the SRIM/TRIM software [24]. The calculations for the grazing angle and 2 keV (final step of the thinning) beam gave a 2.5 Å penetration range, roughly half of the unit cell of the STO. This effect would be much more prominent in the FIB milling technique, where Ga accumulation can cause the formation of new phases [25]. However, this is not the case, and due to the short penetration depth, we can assume that the ion implantation will not influence the defect concentration much.

- Ion damage—the thinning process was done under a grazing angle, but still, the ions carry significant mass and energy, which can modify the sample surface deep into the bulk. In principle, the damage done by the FIB is proportional to the range of Ga ion implantation [26]. For a similar case (in terms of energy) of Si crystal, a 2 keV Ga beam used for polishing is able to cause amorphization of 0.5–1.5 nm surface [27]. In our case, the penetration range was equal to 2.5 Å. However, a non-stoichiometric STO is especially susceptible to ion damage [21]. Thus, one can expect that the ion beam caused enough damage to form an amorphous layer of at most a few nm.

- Temperature gradients—the evaluation of the exact temperature gradient is rather difficult, as it depends on the FIB parameters, sample properties (thermal conductivity), and geometry. The available data do not show a significant global temperature change, especially during lamella formation. Some data on limiting FIB damage to soft matter like tissues show significant temperature changes of 250 °C [28]. However, the modeling was done on a material with a significantly worse thermal conductivity coefficient than STO (by a factor of 8). Since the temperature increase is strongly dependent on this parameter, we can estimate that the temperature increase has to be much smaller than in the presented example.

3.2. Increase of Dislocation Density and Its Role in Electrical Pattern Formation Caused by Electron Irradiation from a High-Voltage Source

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peña, M.A.; Fierro, J.L.G. Chemical Structures and Performance of Perovskite Oxides. Chem. Rev. 2001, 101, 1981–2018. [Google Scholar] [CrossRef]

- Pai, Y.-Y.; Tylan-Tyler, A.; Irvin, P.; Levy, J. Physics of SrTiO3-Based Heterostructures and Nanostructures: A Review. Rep. Prog. Phys. 2018, 81, 036503. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Morales, J.C.; Canales-Vázquez, J.; Savaniu, C.; Marrero-López, D.; Zhou, W.; Irvine, J.T.S. Disruption of Extended Defects in Solid Oxide Fuel Cell Anodes for Methane Oxidation. Nature 2006, 439, 568–571. [Google Scholar] [CrossRef]

- Townsend, T.K.; Browning, N.D.; Osterloh, F.E. Nanoscale Strontium Titanate Photocatalysts for Overall Water Splitting. ACS Nano 2012, 6, 7420–7426. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.B.; Tan, Z.H.; Yang, R.; Guo, X. Single Crystalline SrTiO3 as Memristive Model System: From Materials Science to Neurological and Psychological Functions. J. Electroceram. 2017, 39, 210–222. [Google Scholar] [CrossRef]

- Ielmini, D. Resistive Switching Memories Based on Metal Oxides: Mechanisms, Reliability and Scaling. Semicond. Sci. Technol. 2016, 31, 063002. [Google Scholar] [CrossRef]

- Szot, K.; Rodenbücher, C.; Bihlmayer, G.; Speier, W.; Ishikawa, R.; Shibata, N.; Ikuhara, Y. Influence of Dislocations in Transition Metal Oxides on Selected Physical and Chemical Properties. Crystals 2018, 8, 241. [Google Scholar] [CrossRef] [Green Version]

- Du, H.; Jia, C.L.; Mayer, J. Local Crystallographic Shear Structures in: A [201] Extended Mixed Dislocations of SrTiO3 Unraveled by Atomic-Scale Imaging Using Transmission Electron Microscopy and Spectroscopy. Faraday Discuss. 2019, 213, 245–258. [Google Scholar] [CrossRef] [Green Version]

- Gao, P.; Yang, S.; Ishikawa, R.; Li, N.; Feng, B.; Kumamoto, A.; Shibata, N.; Yu, P.; Ikuhara, Y. Atomic-Scale Measurement of Flexoelectric Polarization at SrTiO3 Dislocations. Phys. Rev. Lett. 2018, 120, 267601. [Google Scholar] [CrossRef]

- Shimada, T.; Masuda, K.; Hagiwara, Y.; Ozaki, N.; Xu, T.; Wang, J.; Kitamura, T. Ferroic Dislocations in Paraelectric SrTiO3. Phys. Rev. B 2021, 103, L060101. [Google Scholar] [CrossRef]

- Szot, K.; Speier, W.; Bihlmayer, G.; Waser, R. Switching the Electrical Resistance of Individual Dislocations in Single-Crystalline SrTiO3. Nat. Mater. 2006, 5, 312–320. [Google Scholar] [CrossRef]

- Szot, K.; Bihlmayer, G.; Speier, W. Nature of the Resistive Switching Phenomena in TiO2 and SrTiO3: Origin of the Reversible Insulator—Metal Transition, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2014; Volume 65, ISBN 9780128001752. [Google Scholar]

- Rodenbücher, C.; Bihlmayer, G.; Korte, C.; Szot, K. Gliding of Conducting Dislocations in SrTiO3 at Room Temperature: Why Oxygen Vacancies Are Strongly Bound to the Cores of Dislocations. APL Mater. 2023, 11, 021108. [Google Scholar] [CrossRef]

- Adepalli, K.K.; Yang, J.; Maier, J.; Tuller, H.L.; Yildiz, B. Tunable Oxygen Diffusion and Electronic Conduction in SrTiO3 by Dislocation-Induced Space Charge Fields. Adv. Funct. Mater. 2017, 27, 1700243. [Google Scholar] [CrossRef]

- Javaid, F.; Stukowski, A.; Durst, K. 3D Dislocation Structure Evolution in Strontium Titanate: Spherical Indentation Experiments and MD Simulations. J. Am. Ceram. Soc. 2017, 100, 1134–1145. [Google Scholar] [CrossRef]

- Kamaladasa, R.J.; Jiang, W.; Picard, Y.N. Imaging Dislocations in Single-Crystal SrTiO3 Substrates by Electron Channeling. J. Electron. Mater. 2011, 40, 2222–2227. [Google Scholar] [CrossRef]

- Wrana, D.; Rodenbücher, C.; Jany, B.R.; Kryshtal, O.; Cempura, G.; Kruk, A.; Indyka, P.; Szot, K.; Krok, F. A Bottom-up Process of Self-Formation of Highly Conductive Titanium Oxide (TiO) Nanowires on Reduced SrTiO3. Nanoscale 2019, 11, 89–97. [Google Scholar] [CrossRef] [PubMed]

- Rodenbücher, C.; Menzel, S.; Wrana, D.; Gensch, T.; Korte, C.; Krok, F.; Szot, K. Current Channeling along Extended Defects during Electroreduction of SrTiO3. Sci. Rep. 2019, 9, 2502. [Google Scholar] [CrossRef] [Green Version]

- Hirel, P.; Carrez, P.; Cordier, P. From Glissile to Sessile: Effect of Temperature on (110) Dislocations in Perovskite Materials. Scr. Mater. 2016, 120, 67–70. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Zhu, Y.; Shapiro, S. Structural Defects and the Origin of the Second Length Scale in SrTiO3. Phys. Rev. Lett. 1998, 80, 2370–2373. [Google Scholar] [CrossRef]

- Won, J.; Vernon, L.J.; Karakuscu, A.; Dickerson, R.M.; Cologna, M.; Raj, R.; Wang, Y.; Yoo, S.J.; Lee, S.H.; Misra, A.; et al. The Role of Non-Stoichiometric Defects in Radiation Damage Evolution of SrTiO3. J. Mater. Chem. A 2013, 1, 9235–9245. [Google Scholar] [CrossRef]

- Hofmann, F.; Tarleton, E.; Harder, R.J.; Phillips, N.W.; Ma, P.W.; Clark, J.N.; Robinson, I.K.; Abbey, B.; Liu, W.; Beck, C.E. 3D Lattice Distortions and Defect Structures in Ion-Implanted Nano-Crystals. Sci. Rep. 2017, 7, 45993. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hanlon, S.M.; Persaud, S.Y.; Long, F.; Korinek, A.; Daymond, M.R. A Solution to FIB Induced Artefact Hydrides in Zr Alloys. J. Nucl. Mater. 2019, 515, 122–134. [Google Scholar] [CrossRef]

- Ziegler, J.F. Srim-2003. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2004, 219–220, 1027–1036. [Google Scholar] [CrossRef] [Green Version]

- Casey, J.D.; Phaneuf, M.; Chandler, C.; Megorden, M.; Noll, K.E.; Schuman, R.; Gannon, T.J.; Krechmer, A.; Monforte, D.; Antoniou, N.; et al. Copper Device Editing: Strategy for Focused Ion Beam Milling of Copper. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2002, 20, 2682. [Google Scholar] [CrossRef]

- Mayer, J.; Giannuzzi, L.A.; Kamino, T.; Michael, J. TEM Sample Preparation and FIB-Induced Damage. MRS Bull. 2007, 32, 400–407. [Google Scholar] [CrossRef] [Green Version]

- Giannuzzi, L.A.; Geurts, R.; Ringnalda, J. 2 KeV Ga+ FIB Milling for Reducing Amorphous Damage in Silicon. Microsc. Microanal. 2005, 11, 828–829. [Google Scholar] [CrossRef] [Green Version]

- Wolff, A.; Klingner, N.; Thompson, W.; Zhou, Y.; Lin, J.; Peng, Y.Y.; Ramshaw, J.A.M.; Xiao, Y. Modelling of Focused Ion Beam Induced Increases in Sample Temperature: A Case Study of Heat Damage in Biological Samples. J. Microsc. 2018, 272, 47–59. [Google Scholar] [CrossRef]

- Takahashi, Y. Two Hundred Years of Lichtenberg Figures. J. Electrostat. 1979, 6, 1–13. [Google Scholar] [CrossRef]

- Wojtyniak, M.; Szot, K.; Wrzalik, R.; Rodenbücher, C.; Roth, G.; Waser, R. Electro-Degradation and Resistive Switching of Fe-Doped SrTiO3 Single Crystal. J. Appl. Phys. 2013, 113, 083713. [Google Scholar] [CrossRef]

- Armstrong, M.D.; Lan, K.W.; Guo, Y.; Perry, N.H. Dislocation-Mediated Conductivity in Oxides: Progress, Challenges, and Opportunities. ACS Nano 2021, 15, 9211–9221. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wojtyniak, M.; Rodenbücher, C.; Jany, B.R.; Cempura, G.; Kruk, A.; Krok, F.; Szot, K. Annihilation and Generation of Dislocations by Irradiation by Ions and Electrons in Strontium Titanate Single Crystal. Crystals 2023, 13, 1259. https://doi.org/10.3390/cryst13081259

Wojtyniak M, Rodenbücher C, Jany BR, Cempura G, Kruk A, Krok F, Szot K. Annihilation and Generation of Dislocations by Irradiation by Ions and Electrons in Strontium Titanate Single Crystal. Crystals. 2023; 13(8):1259. https://doi.org/10.3390/cryst13081259

Chicago/Turabian StyleWojtyniak, Marcin, Christian Rodenbücher, Benedykt R. Jany, Grzegorz Cempura, Adam Kruk, Franciszek Krok, and Krzysztof Szot. 2023. "Annihilation and Generation of Dislocations by Irradiation by Ions and Electrons in Strontium Titanate Single Crystal" Crystals 13, no. 8: 1259. https://doi.org/10.3390/cryst13081259