Effect of Chromium on Microstructure and Mechanical Properties of Hot-Dip Galvanized Dual-Phase (DP980) Steel

Abstract

1. Introduction

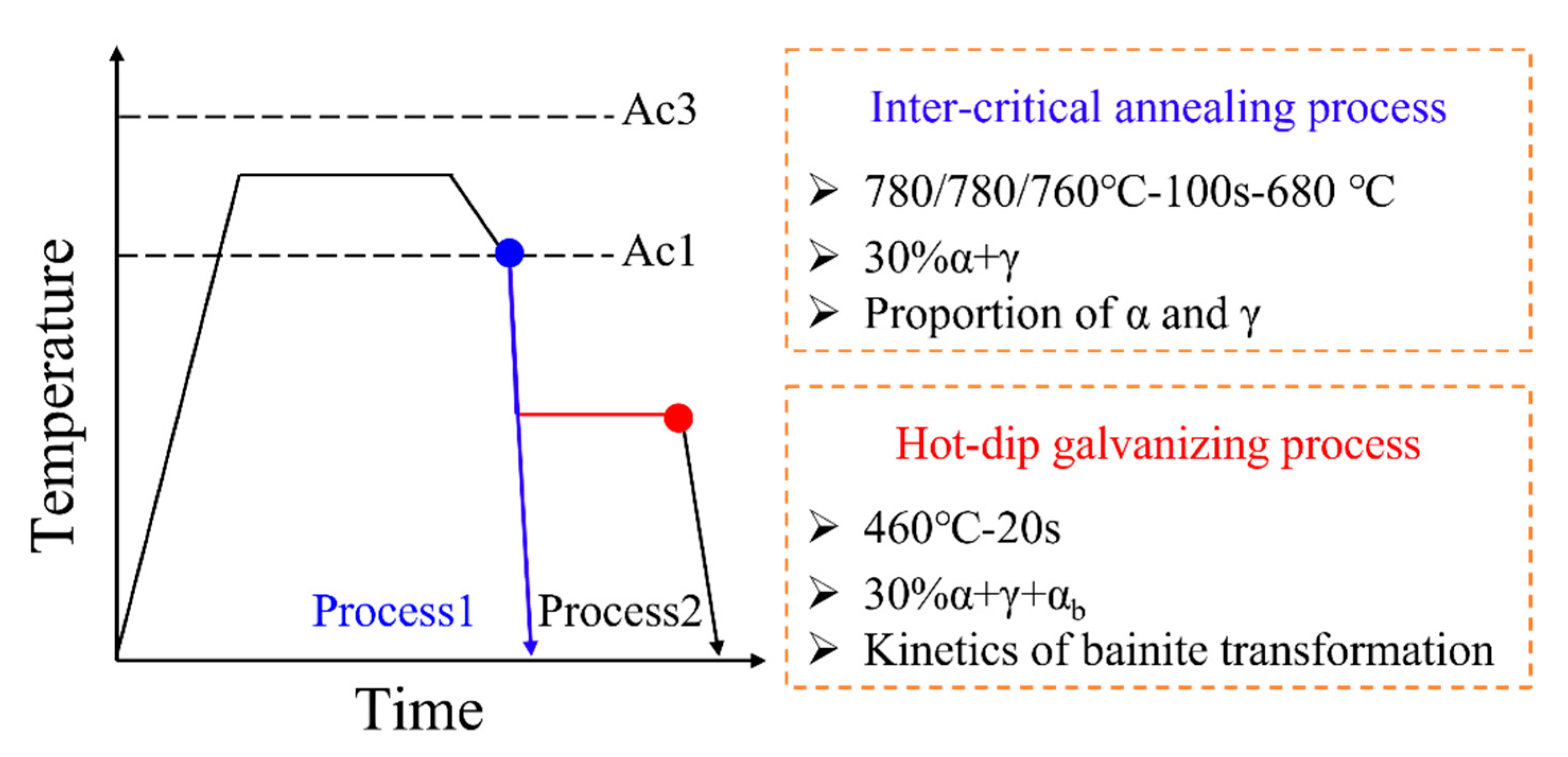

2. Materials and Methods

3. Results and Discussion

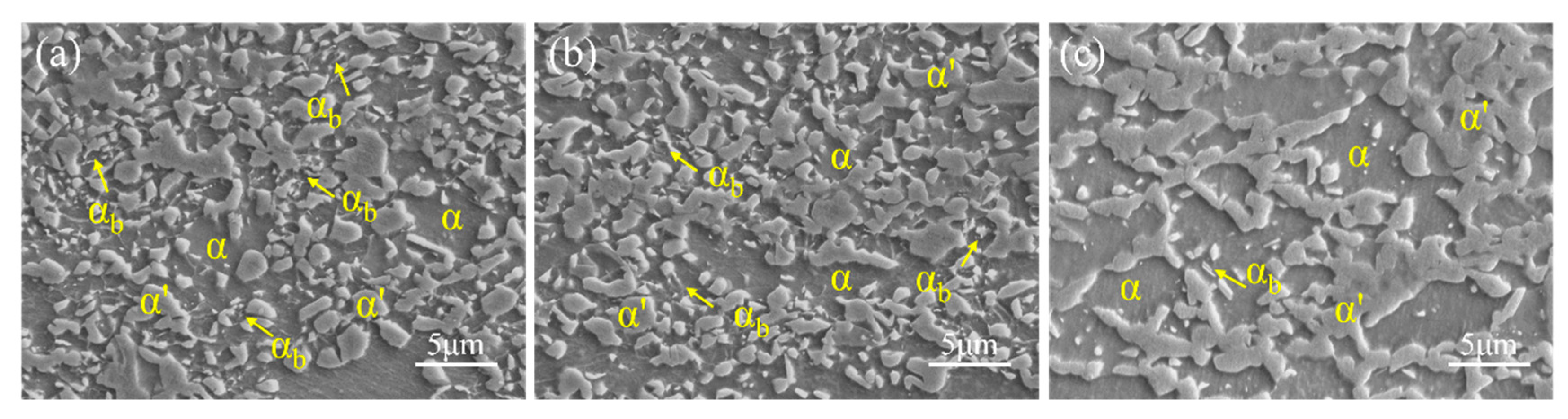

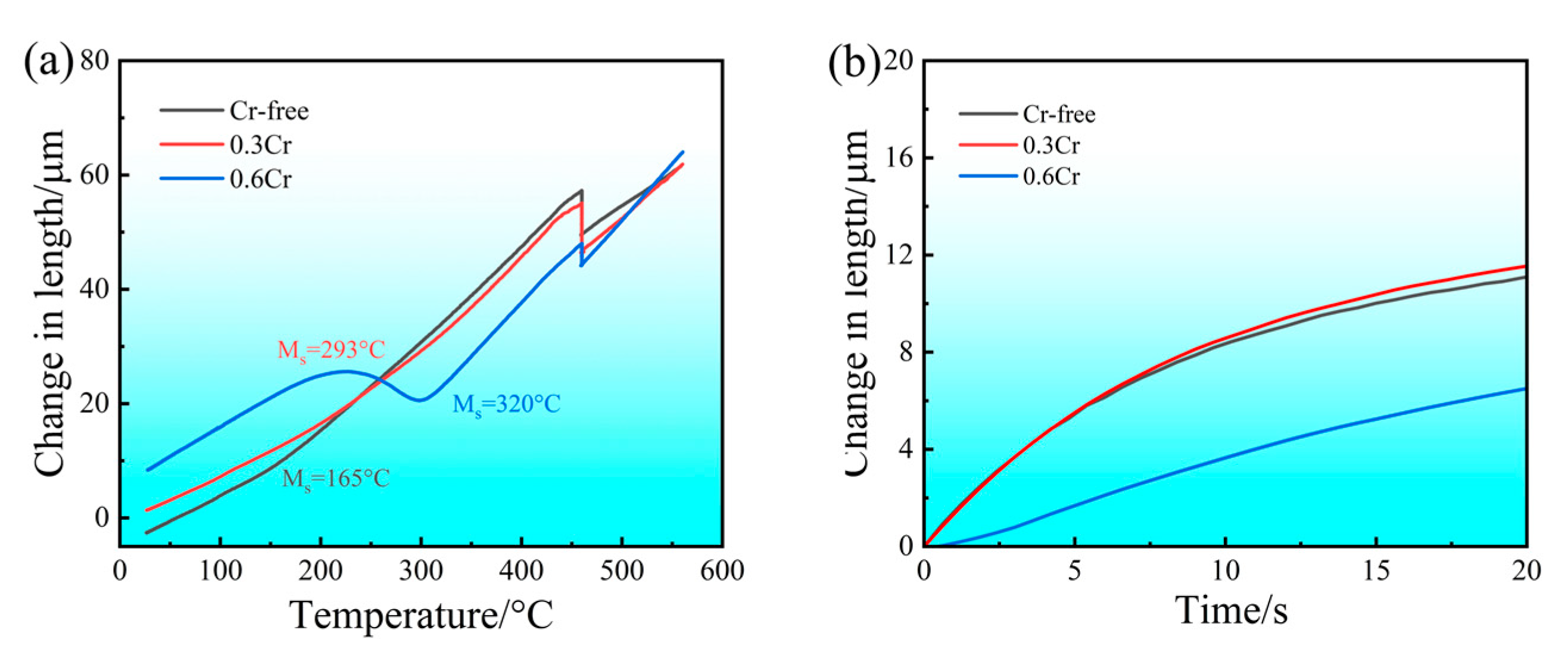

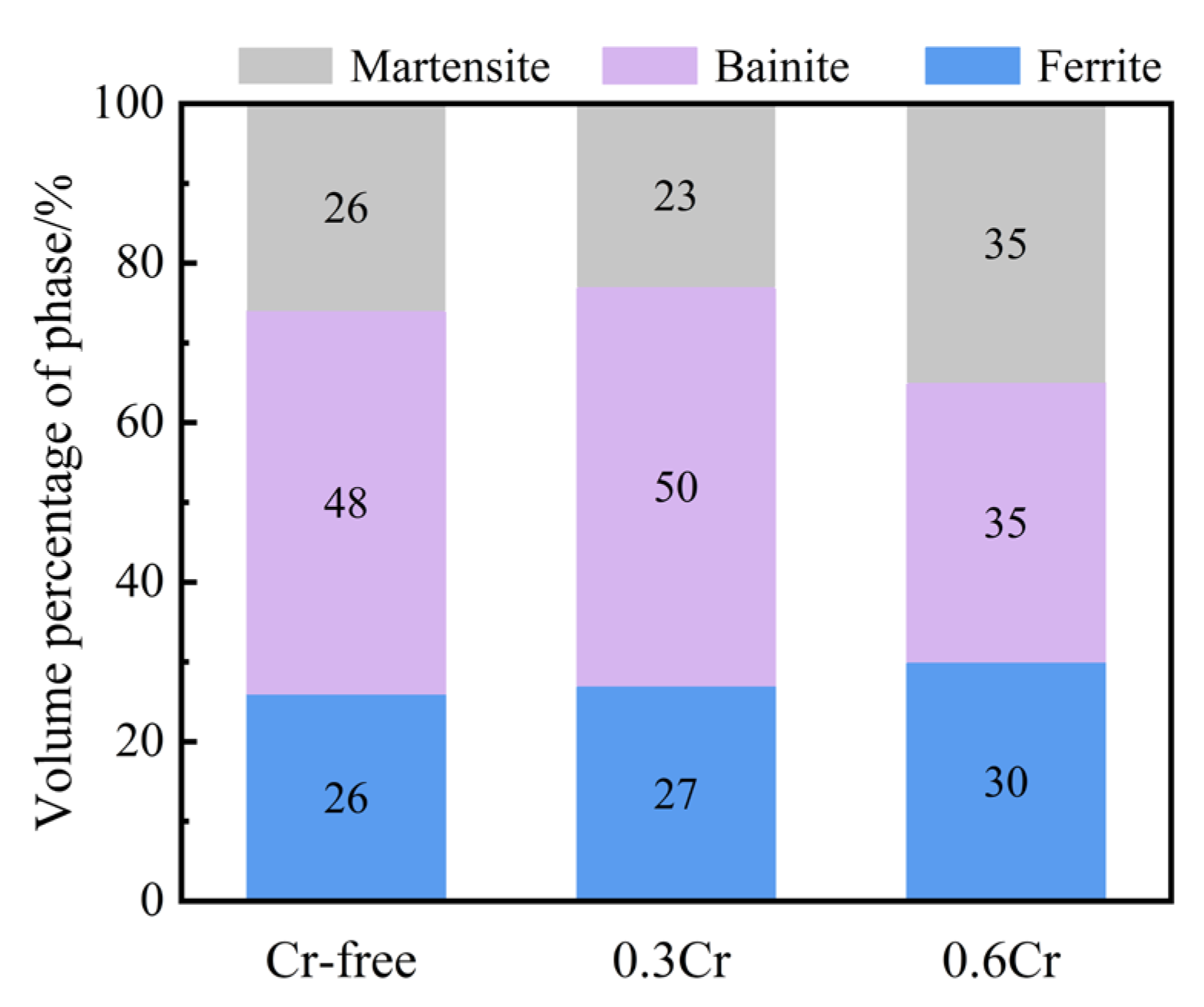

3.1. Effect of Cr on Microstructure Evaluation

3.2. Effect of Cr on Mechanical Properties

4. Conclusions

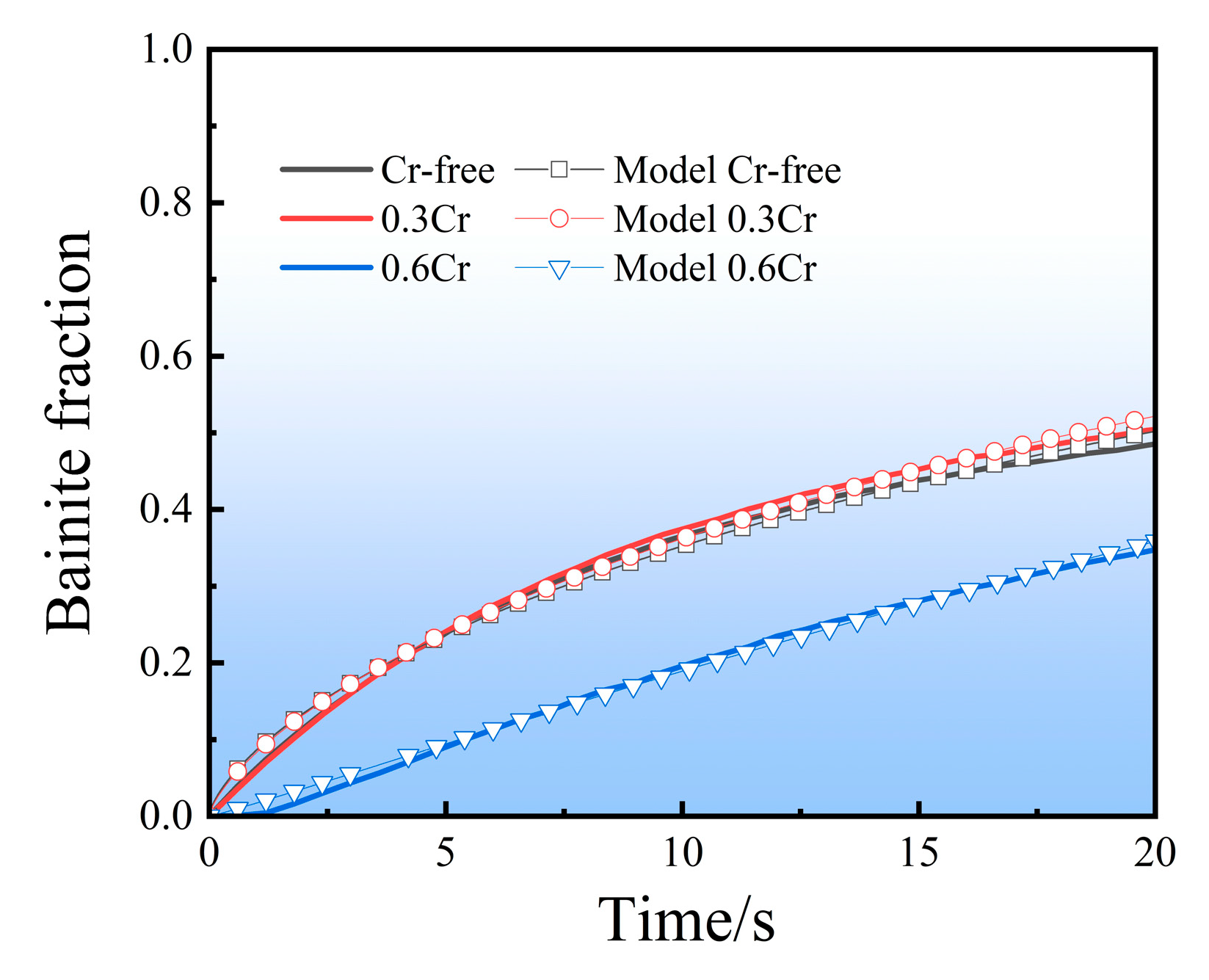

- Compared to Cr-free steel, the bainitic volume fraction of 0.6Cr is significantly decreased. Moreover, Cr delays the incubation time and decreases the rate of the bainitic transformation.

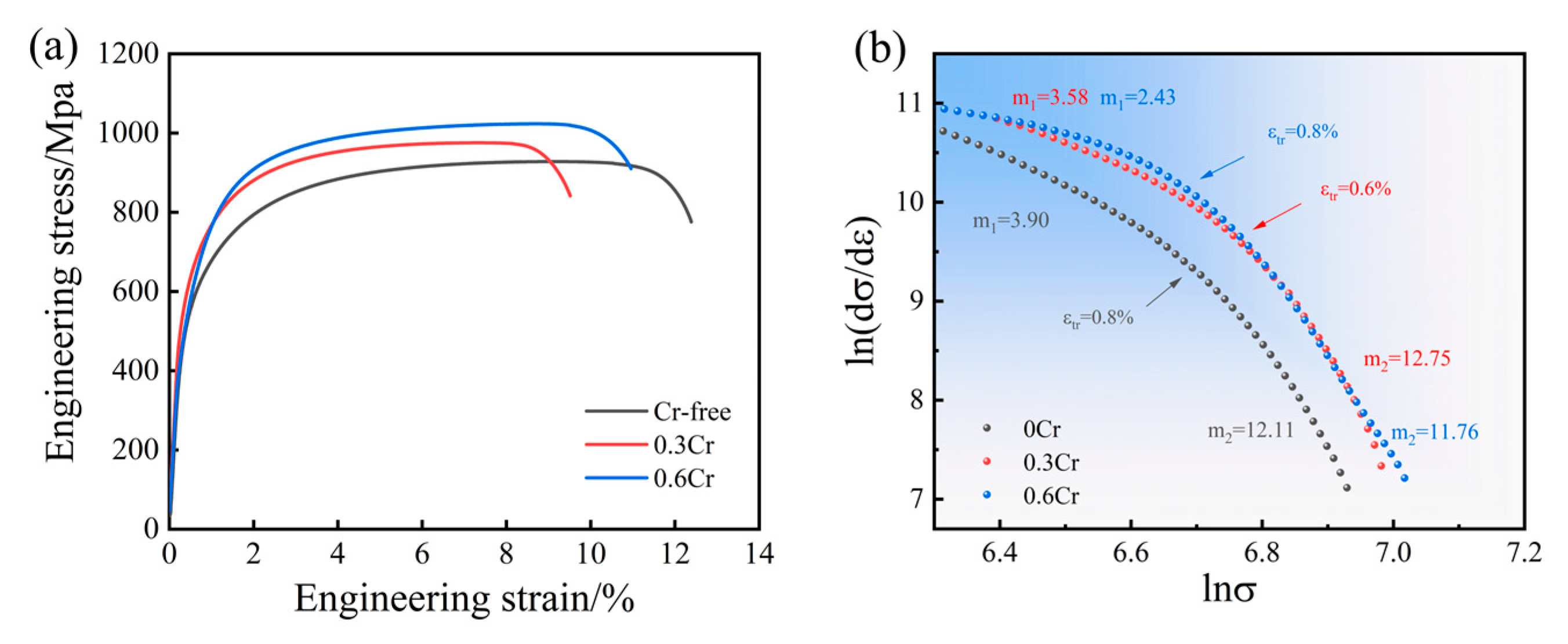

- The tensile strength and yield strength are improved by the addition of 0.6 wt.% Cr without a loss of uniform elongation.

- The mechanical properties of 0.6Cr steel achieve a tensile strength of 1033 MPa and a uniform elongation of 9.1%, which satisfies the requirement of hot-dip galvanized DP980 steel.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.W.; Jiang, Z.Y. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar] [CrossRef]

- Bouaziz, O.; Zurob, H.; Huang, M.X. Driving force and logic of development of advanced high strength steels for automotive applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Park, K.S.; Park, K.T.; Lee, D.L.; Lee, C.S. Effect of heat treatment path on the cold formability of drawn dual-phase steel. Mater. Sci. Eng. A 2007, 449–451, 1135–1138. [Google Scholar] [CrossRef]

- Petit, E.J.; Grosbety, Y.; Aden-Ali, S.; Gilgert, J.; Azari, Z. Microstructure of the coating and mechanical properties of galvanized chromium-rich martensitic steel. Surf. Coat. Technol. 2010, 205, 2404–2411. [Google Scholar] [CrossRef]

- Mintz, B. Hot dip galvanising of transformation induced plasticity and other inter-critically annealed steels. Int. Mater. Rev. 2013, 46, 169–197. [Google Scholar] [CrossRef]

- Pan, E.; Di, H.; Jiang, G.; Bao, C. Effect of Heat Treatment on Microstructures and Mechanical Properties of Hot-Dip Galvanized DP Steels. Acta Met. Sin. Engl. Lett. 2014, 27, 469–475. [Google Scholar] [CrossRef]

- Lin, K.C.; Chu, P.W.; Lin, C.S.; Chen, H.B. Galvanizing and Galvannealing Behavior of CMnSiCr Dual-Phase Steels. Met. Mater. Trans. A. 2013, 44, 2690–2698. [Google Scholar] [CrossRef]

- Fonstein, N.; Jun, H.J.; Huang, G. Effect of bainite on mechanical properties of multiphase ferrite-bainite-martensite steels. Mater. Sci. Technol. 2011, 1, 333–341. [Google Scholar]

- Kumar, A.; Singh, S.B.; Ray, K.K. Influence of bainite/martensite-content on the tensile properties of low carbon dual-phase steels. Mater. Sci. Eng. A 2008, 474, 270–282. [Google Scholar] [CrossRef]

- Schemmann, L.; Zaefferer, S.; Raabe, D.; Friedel, F.; Mattissen, D. Alloying effects on microstructure formation of dual phase steels. Acta Mater. 2015, 95, 386–398. [Google Scholar] [CrossRef]

- Lai, Q.; Bouaziz, O.; Gouné, M.; Perlade, A.; Bréchet, Y.; Pardoen, T. Microstructure refinement of dual-phase steels with 3.5 wt% Mn: Influence on plastic and fracture behavior. Mater. Sci. Eng. A 2015, 638, 78–89. [Google Scholar] [CrossRef]

- Douguet, P.; Da Rosa, G.; Maugis, P.; Drillet, J.; Hoummada, K. Effect of boron segregation on bainite nucleation during isothermal transformation. Scr. Mater. 2022, 207, 114286. [Google Scholar] [CrossRef]

- Taylor, M.D.; Choi, K.S.; Sun, X.; Matlock, D.K.; Packard, C.E.; Xu, L.; Barlat, F. Correlations between nanoindentation hardness and macroscopic mechanical properties in DP980 steels. Mater. Sci. Eng. A 2014, 597, 431–439. [Google Scholar] [CrossRef]

- Liu, H.; Li, F.; Shi, W.; Swaminathan, S.; He, Y.; Rohwerder, M.; Li, L. Challenges in hot-dip galvanizing of high strength dual phase steel: Surface selective oxidation and mechanical property degradation. Surf. Coat. Technol. 2012, 206, 3428–3436. [Google Scholar] [CrossRef]

- Wang, L.Y.; Wu, Y.X.; Sun, W.W.; Bréchet, Y.; Brassart, L.; Arlazarov, A.; Hutchinson, C.R. Transitions in the strain hardening behaviour of tempered martensite. Acta Mater. 2021, 221, 117397. [Google Scholar] [CrossRef]

- Xia, Y.; Miyamoto, G.; Yang, Z.G.; Zhang, C.; Furuhara, T. Direct measurement of carbon enrichment in the incomplete bainite transformation in Mo added low carbon steels. Acta Mater. 2015, 91, 10–18. [Google Scholar] [CrossRef]

- Han, Q.H.; Kang, Y.L.; Zhao, X.M.; Lü, C.; Gao, L.F. Microstructure and Properties of Mo Microalloyed Cold Rolled DP1000 Steels. J. Iron Steel Res. Int. 2011, 18, 52–58. [Google Scholar] [CrossRef]

- Han, Y.; Kuang, S.; Liu, Y.S.; Jiang, Y.H.; Liu, G.H. Effect of Chromium on Microstructure and Mechanical Properties of Cold Rolled Hot-dip Galvanizing DP450 Steel. J. Iron Steel Res. Int. 2015, 22, 1055–1061. [Google Scholar] [CrossRef]

- Bracke, L.; Xu, W. Effect of the Cr Content and Coiling Temperature on the Properties of Hot Rolled High Strength Lower Bainitic Steel. ISIJ Int. 2015, 55, 2206–2211. [Google Scholar] [CrossRef]

- Irie, T.; Satoh, S.; Hashiguchi, K.; Takahsahi, I.; Hashimoto, O. Metallurgical Factors Affecting the Formability of Cold-rolled High Strength Steel Sheets. Trans. Iron Steel Inst. Jpn. 1981, 21, 793–801. [Google Scholar] [CrossRef]

- Silva Filho, J.F.D.; Oliveira, C.A.S.D.; Fonstein, N.; Girina, O.; Miranda, F.J.F.; Drumond, J.; Serafim, E.A.; Afonso, C.R.M. Effect of Cr Additions on Ferrite Recrystallization and Austenite Formation in Dual-Phase Steels Heat Treated in the Intercritical Temperature Range. JMR 2016, 19, 258–266. [Google Scholar] [CrossRef]

- Tsai, S.-P.; Su, T.-C.; Yang, J.-R.; Chen, C.-Y.; Wang, Y.-T.; Huang, C.-Y. Effect of Cr and Al additions on the development of interphase-precipitated carbides strengthened dual-phase Ti-bearing steels. Mater. Des. 2017, 119, 319–325. [Google Scholar] [CrossRef]

- Fang, L.; Wood, W.E.; Atterdge, D.G. Identification and range quantification of steel transformation products by transformation kinetics. Met. Mater. Trans. A 1997, 28, 5–14. [Google Scholar] [CrossRef]

- Caballero, F.G.; Santofimia, M.J.; Gracia-Mateo, C. Time-temperature-transformation diagram within the bainitic temperature range in a medium carbon steel. Mater. Trans. 2004, 45, 3272–3281. [Google Scholar] [CrossRef][Green Version]

- Quidort, D.; Breche, Y.J.M. A model of isothermal and non isothermal transformation kinetics of bainite in 0.5% C steels. ISIJ Int. 2002, 42, 1010–1017. [Google Scholar] [CrossRef]

- Hupper, T.; Endo, S.; Ishikawa, N. Effect of volume fraction of constituent phases on the stress-strain relationship of dual-phase steels. ISIJ Int. 1999, 39, 288. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Prahl, U.; Bleck, W. Transformation-Induced, Geometrically Necessary, Dislocation-Based Flow Curve Modeling of Dual-Phase Steels: Effect of Grain Size. Met. Mater. Trans. A 2012, 43, 3850–3869. [Google Scholar] [CrossRef]

- Zhang, J.; Di, H.; Deng, Y.; Misra, R.D.K. Effect of martensite morphology and volume fraction on strain hardening and fracture behavior of martensite–ferrite dual phase steel. Mater. Sci. Eng. A 2015, 627, 230–240. [Google Scholar] [CrossRef]

- Xiong, Z.P.; Kostryzhev, A.G.; Stanford, N.E.; Pereloma, E.V. Microstructures and mechanical properties of dual phase steel produced by laboratory simulated strip casting. Mater. Des. 2015, 88, 537–549. [Google Scholar] [CrossRef]

- Hung, T.T.; Gou, R.B.; Dan, W.J.; Zhang, W.G. Strain-hardening behaviors of dual phase steels with microstructure features. Mater. Sci. Eng. A 2016, 672, 88–97. [Google Scholar] [CrossRef]

| Alloys | C | Si | Mn | Al | Nb | Ti | B | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Cr-free | 0.09 | 0.36 | 2.29 | 0.02 | 0.03 | 0.03 | 0.0020 | --- | Bal. |

| 0.3Cr | 0.09 | 0.35 | 2.35 | 0.05 | 0.02 | 0.05 | 0.0020 | 0.32 | Bal. |

| 0.6Cr | 0.08 | 0.43 | 2.30 | 0.03 | 0.02 | 0.02 | 0.0017 | 0.61 | Bal. |

| Alloys | n | k | R |

|---|---|---|---|

| Cr-free | 0.83 | 0.11 | 0.99 |

| 0.3Cr | 0.79 | 0.12 | 0.99 |

| 0.6Cr | 1.16 | 0.02 | 0.99 |

| Alloys | YS/MPa | TS/MPa | TEL/% | UEL/% | YS/TS |

|---|---|---|---|---|---|

| Cr-free | 545 | 910 | 12.3 | 8.7 | 0.60 |

| 0.3Cr | 623 | 980 | 10.0 | 6.7 | 0.63 |

| 0.6Cr | 592 | 1033 | 11.2 | 9.1 | 0.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Liang, J.; Yang, D.; Hu, Z.; Xu, X.; Gu, X.; Xie, G. Effect of Chromium on Microstructure and Mechanical Properties of Hot-Dip Galvanized Dual-Phase (DP980) Steel. Crystals 2023, 13, 1287. https://doi.org/10.3390/cryst13081287

Chen X, Liang J, Yang D, Hu Z, Xu X, Gu X, Xie G. Effect of Chromium on Microstructure and Mechanical Properties of Hot-Dip Galvanized Dual-Phase (DP980) Steel. Crystals. 2023; 13(8):1287. https://doi.org/10.3390/cryst13081287

Chicago/Turabian StyleChen, Xuefei, Jiawei Liang, Dapeng Yang, Zhiping Hu, Xin Xu, Xingli Gu, and Guangming Xie. 2023. "Effect of Chromium on Microstructure and Mechanical Properties of Hot-Dip Galvanized Dual-Phase (DP980) Steel" Crystals 13, no. 8: 1287. https://doi.org/10.3390/cryst13081287

APA StyleChen, X., Liang, J., Yang, D., Hu, Z., Xu, X., Gu, X., & Xie, G. (2023). Effect of Chromium on Microstructure and Mechanical Properties of Hot-Dip Galvanized Dual-Phase (DP980) Steel. Crystals, 13(8), 1287. https://doi.org/10.3390/cryst13081287