The Microstructural Evolution and Mechanical Properties of Boron-Doped Ti35Zr30V10Nb25 Refractory High-Entropy Alloy

Abstract

1. Introduction

2. Experimental Methods

2.1. Materials Preparation

2.2. Microstructural Characterization

2.3. Mechanical Tests

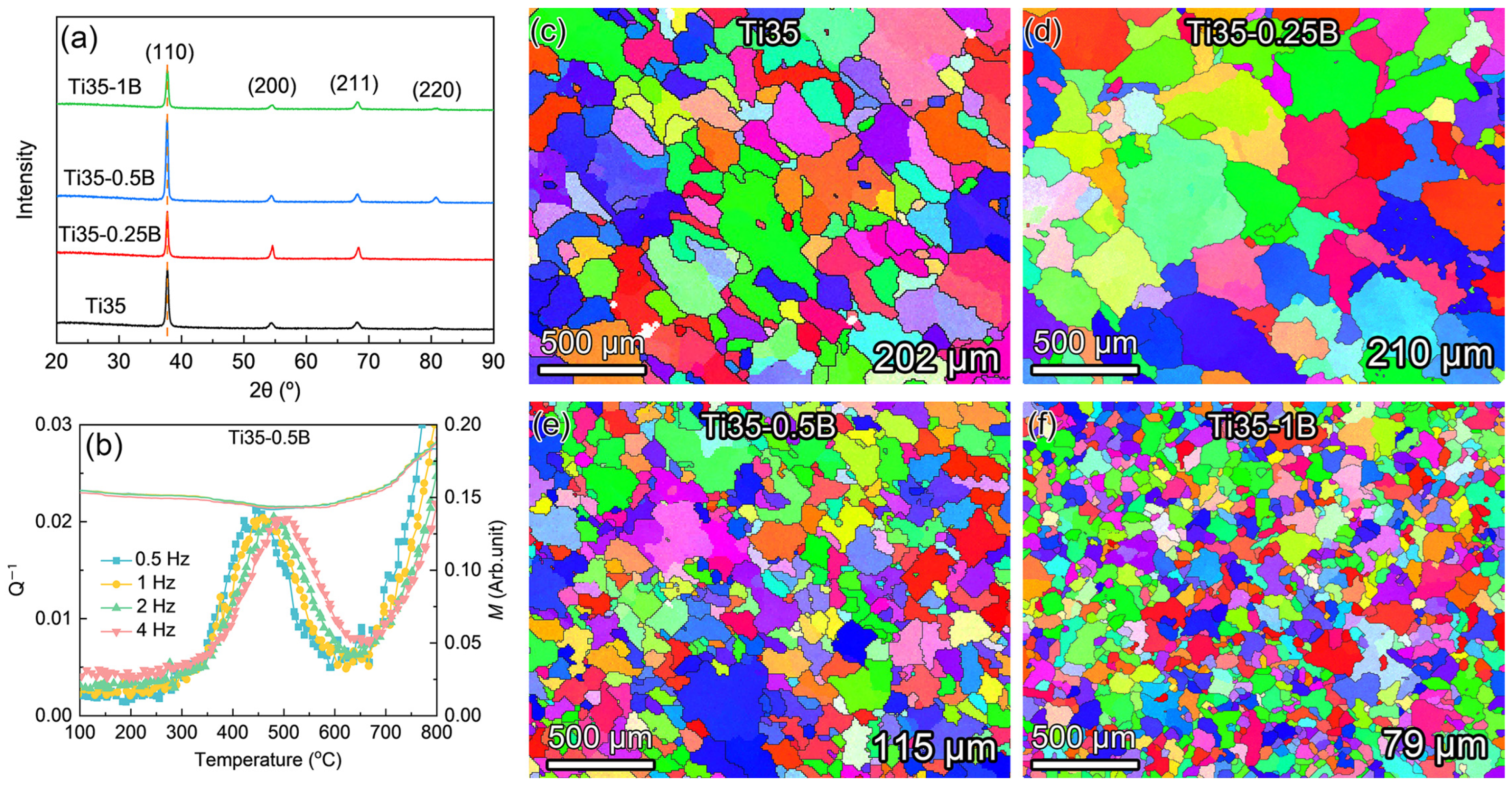

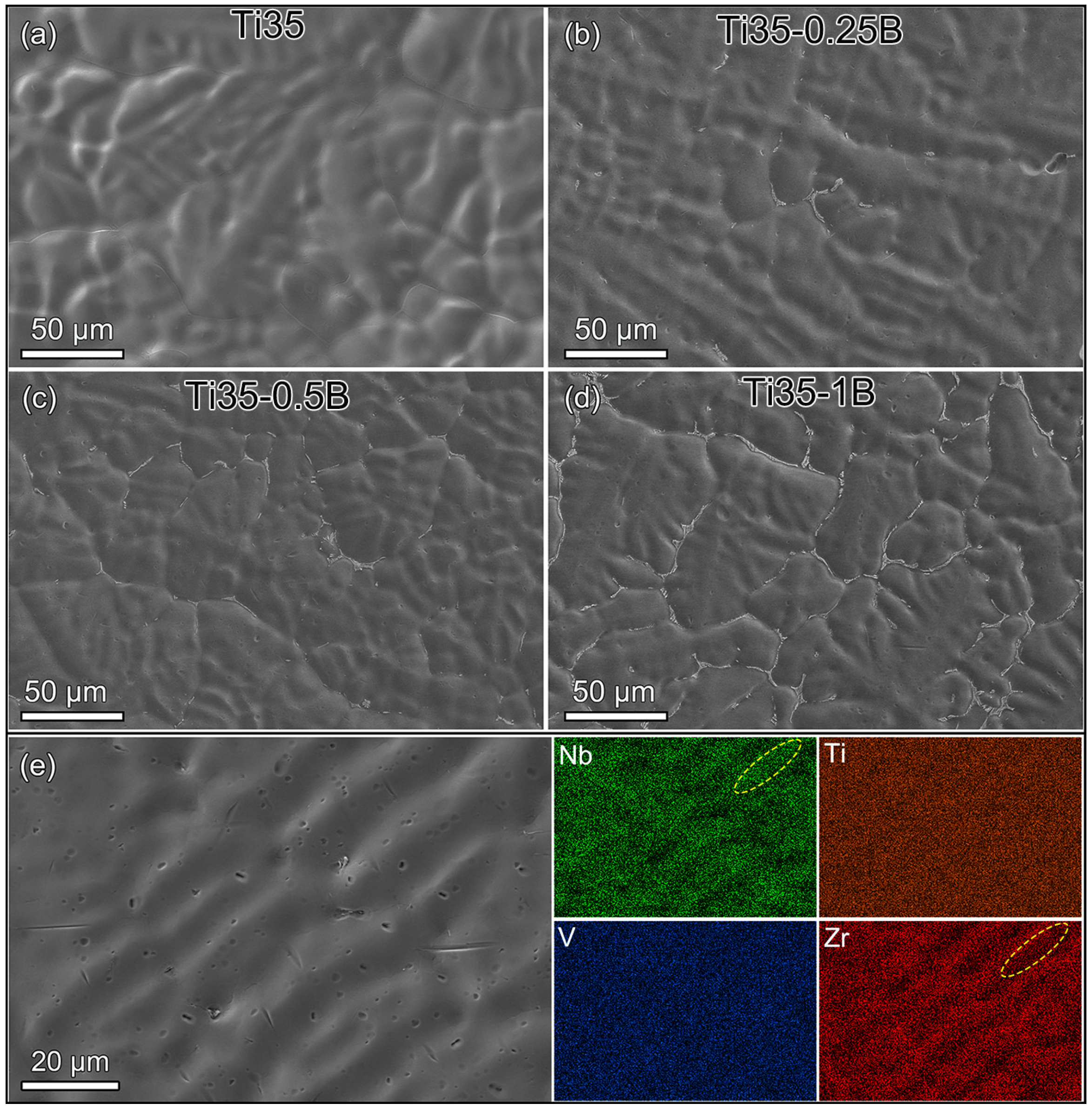

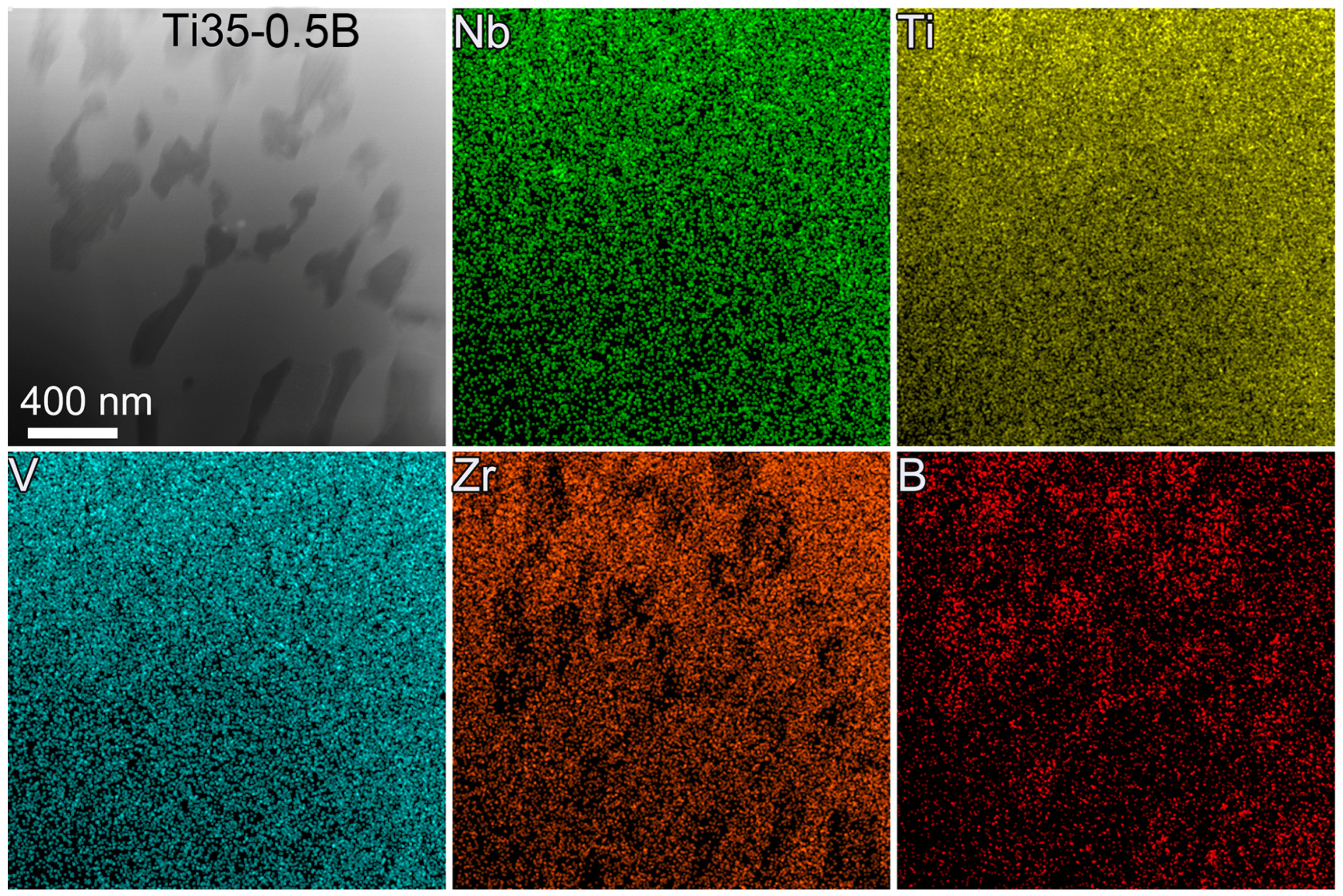

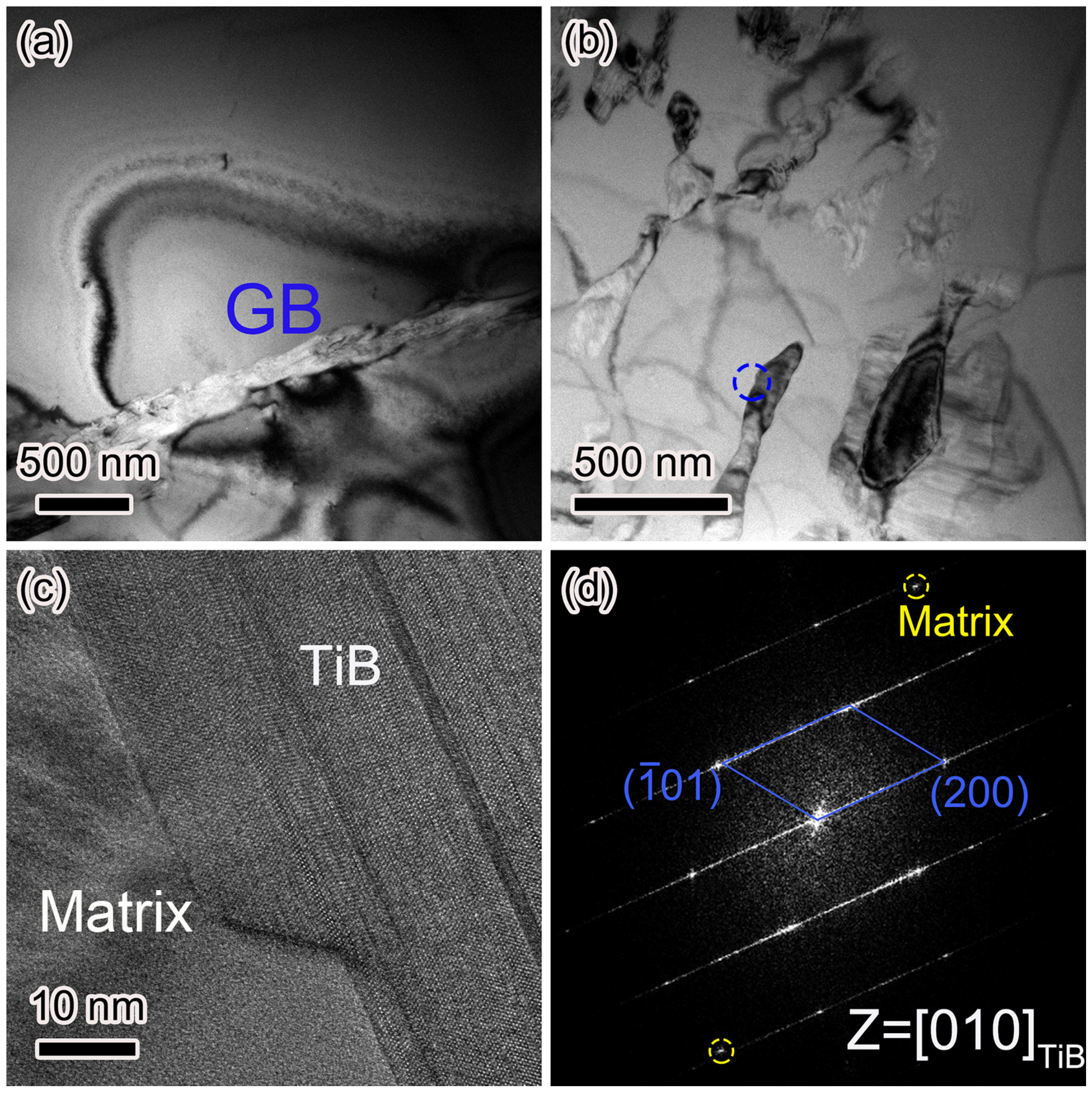

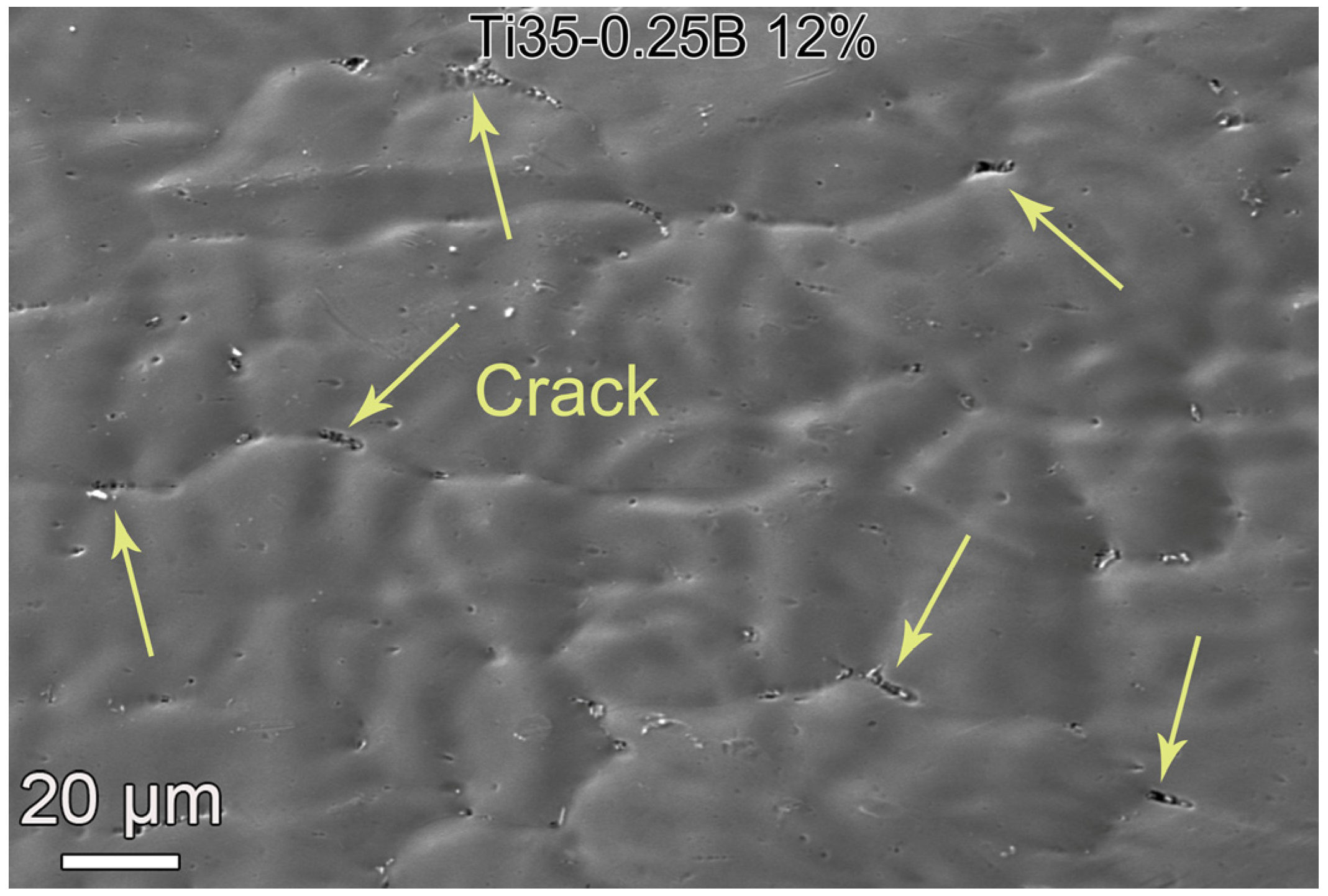

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, F.; Balbus, G.H.; Xu, S.; Su, Y.; Shin, J.; Rottmann, P.F.; Knipling, K.E.; Stinville, J.C.; Mills, L.H.; Senkov, O.N.; et al. Multiplicity of dislocation pathways in a refractory multiprincipal element alloy. Science 2020, 370, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Couzinié, J.P.; Heczko, M.; Mazánová, V.; Senkov, O.N.; Ghazisaeidi, M.; Banerjee, R.; Mills, M.J. High-temperature deformation mechanisms in a BCC+B2 refractory complex concentrated alloy. Acta Mater. 2022, 233, 117995. [Google Scholar] [CrossRef]

- Shi, T.; Su, Z.; Li, J.; Liu, C.; Yang, J.; He, X.; Yun, D.; Peng, Q.; Lu, C. Distinct point defect behaviours in body-centered cubic medium-entropy alloy NbZrTi induced by severe lattice distortion. Acta Mater. 2022, 229, 117806. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Wang, X.G.; Sun, M.; Liu, J.X.; Liu, X.Q.; Ke, Y.B.; Jiang, W.B.; Wang, H.; Fang, Q.F.; Wang, X.P. Effects of vanadium content on the microstructure and tensile properties of NbTiVxZr high-entropy alloys. J. Alloys Compd. 2024, 987, 174227. [Google Scholar] [CrossRef]

- Wu, Y.D.; Cai, Y.H.; Wang, T.; Si, J.J.; Zhu, J.; Wang, Y.D.; Hui, X.D. A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater. Lett. 2014, 130, 277–280. [Google Scholar] [CrossRef]

- He, M.Y.; Shen, Y.F.; Jia, N.; Liaw, P.K. C and N doping in high-entropy alloys: A pathway to achieve desired strength-ductility synergy. Appl. Mater. Today 2021, 25, 101162. [Google Scholar] [CrossRef]

- Lei, Z.F.; Liu, X.J.; Wu, Y.; Wang, H.; Jiang, S.H.; Wang, S.D.; Hui, X.D.; Wu, Y.D.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered O complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Wang, X.G.; Sun, M.; Liu, X.Q.; Ke, Y.B.; Shi, T.; Liu, J.X.; Jiang, W.B.; Lu, C.Y.; Wang, X.P.; Fang, Q.F. Ultrabroad distribution of multiple anelasticities in O-doped refractory multiprincipal element alloys. Acta Mater. 2024, 271, 119911. [Google Scholar] [CrossRef]

- Son, S.; Lee, J.; Asghari-Rad, P.; Gu, G.H.; Haftlang, F.; Kim, H.S. A facile strengthening method by co-doping boron and nitrogen in CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2022, 846, 143307. [Google Scholar] [CrossRef]

- Pang, J.; Zhang, H.; Zhang, L.; Zhu, Z.; Fu, H.; Li, H.; Wang, A.; Li, Z.; Zhang, H. Simultaneous enhancement of strength and ductility of body-centered cubic TiZrNb multi-principal element alloys via boron-doping. J. Mater. Sci. Technol. 2021, 78, 74–80. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wu, H.H.; Wu, Y.; Huang, H.L.; Zhu, X.Y.; Zhang, Y.J.; Zhu, H.H.; Yuan, X.Y.; Chen, Q.; Wang, S.D.; et al. Solving oxygen embrittlement of refractory high-entropy alloy via grain boundary engineering. Mater. Today 2022, 54, 83–89. [Google Scholar] [CrossRef]

- Seol, J.B.; Bae, J.W.; Li, Z.; Han, J.C.; Kim, J.G.; Raabe, D.; Kim, H.S. Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 2018, 151, 366–376. [Google Scholar] [CrossRef]

- Jia, Y.; Zhang, L.; Li, P.; Ma, X.; Xu, L.; Wu, S.; Jia, Y.; Wang, G. Microstructure and Mechanical Properties of Nb–Ti–V–Zr Refractory Medium-Entropy Alloys. Front. Mater. 2020, 7, 00172. [Google Scholar] [CrossRef]

- King, D.J.M.; Cheung, S.T.Y.; Humphry-Baker, S.A.; Parkin, C.; Couet, A.; Cortie, M.B.; Lumpkin, G.R.; Middleburgh, S.C.; Knowles, A.J. High temperature, low neutron cross-section high-entropy alloys in the Nb-Ti-V-Zr system. Acta Mater. 2019, 166, 435–446. [Google Scholar] [CrossRef]

- Liu, C.; Cui, J.Z.; Cheng, Z.Y.; Zhang, B.Z.; Zhang, S.Y.; Ding, J.; Yu, R.; Ma, E. Direct Observation of Oxygen Atoms Taking Tetrahedral Interstitial Sites in Medium-Entropy Body-Centered-Cubic Solutions. Adv Mater. 2023, 35, 2209941. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Jiang, W.; Ke, Y.; Ge, B.; Wang, X.; Fang, Q. Tetragonal dipole dominated Zener relaxation in BCC-structured Fe-17at%Ga single crystals. Acta Mater. 2023, 258, 119245. [Google Scholar] [CrossRef]

- Sun, M.; Liu, X.Q.; Jiang, W.B.; Lei, Y.W.; Ke, J.G.; Liu, R.; Wang, X.P.; Wu, X.B.; Fang, Q.F.; Liu, C.S. Grain boundary relaxation behavior and phase stability of AlCrTiVx (x = 0, 0.5 and 1) high-entropy alloys. Scr. Mater. 2021, 204, 114144. [Google Scholar] [CrossRef]

- Choi, W.S.; Lee, J.; De Cooman, B.C. Internal-friction analysis of dislocation–interstitial carbon interactions in press-hardened 22MnB5 steel. Mater. Sci. Eng. A 2015, 639, 439–447. [Google Scholar] [CrossRef]

- Almeida, L.; Niemeyer, T.; Pires, K.; Grandini, C.; Pintao, C.; Florencio, O. Anelastic relaxation processes due oxygen in Nb–3.1 at.% Ti alloys. Mater. Sci. Eng. A 2004, 370, 96–99. [Google Scholar] [CrossRef]

- Lei, Z.F.; Wu, Y.; He, J.Y.; Liu, X.J.; Wang, H.; Jiang, S.H.; Gu, L.; Zhang, Q.H.; Gault, B.; Raabe, D.; et al. Snoek-type damping performance in strong and ductile high-entropy alloys. Sci. Adv. 2020, 6, eaba7802. [Google Scholar] [CrossRef]

- Shvindlerman, L.S.; Jannot, E.; Gottstein, G. On precipitation-controlled grain size in the presence of solute segregation. Acta Mater. 2007, 55, 3397–3401. [Google Scholar] [CrossRef]

- Sun, L.; Cao, J.; Li, L.; Li, J.; Wang, J. Boron-induced microstructure evolution and mechanical properties of in situ Ti-based bulk metallic glass composites. Intermetallics 2024, 165, 108156. [Google Scholar] [CrossRef]

- Juan, C.C.; Tsai, M.H.; Tsai, C.W.; Hsu, W.L.; Lin, C.M.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining. Mater. Lett. 2016, 184, 200–203. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Zhang, X.; Wang, J.; Wu, M.; Shu, D.; Tang, H.; Sun, B. The effects of interstitial oxygen on mechanical properties of TiZrNb medium-entropy alloy over a wide temperature range. J. Alloys Compd. 2024, 989, 174394. [Google Scholar] [CrossRef]

- Wang, S.; Shu, D.; Shi, P.; Zhang, X.; Mao, B.; Wang, D.; Liaw, P.K.; Sun, B. TiZrHfNb refractory high-entropy alloys with twinning-induced plasticity. J. Mater. Sci. Technol. 2024, 187, 72–85. [Google Scholar] [CrossRef]

- Ma, E.; Wu, X. Tailoring heterogeneities in high-entropy alloys to promote strength–ductility synergy. Nat. Commun. 2019, 10, 5623. [Google Scholar] [CrossRef]

- Lilensten, L.; Couzinié, J.P.; Perrière, L.; Hocini, A.; Keller, C.; Dirras, G.; Guillot, I. Study of a bcc multi-principal element alloy: Tensile and simple shear properties and underlying deformation mechanisms. Acta Mater. 2018, 142, 131–141. [Google Scholar] [CrossRef]

- Qin, S.; Yang, M.; Jiang, P.; Wang, J.; Wu, X.; Zhou, H.; Yuan, F. Designing structures with combined gradients of grain size and precipitation in high entropy alloys for simultaneous improvement of strength and ductility. Acta Mater. 2022, 230, 117847. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, X.G.; Jiang, Z.Q.; Chen, M.; Sun, M.; Zhang, X.F. Phase transition and mechanical performance evolution in TiVZr-Nbx alloys. J. Alloys Compd. 2023, 937, 168458. [Google Scholar] [CrossRef]

- Bu, Y.; Wu, Y.; Lei, Z.; Yuan, X.; Wu, H.; Feng, X.; Liu, J.; Ding, J.; Lu, Y.; Wang, H.; et al. Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys. Mater. Today 2021, 46, 28–34. [Google Scholar] [CrossRef]

- He, F.; Chen, D.; Han, B.; Wu, Q.F.; Wang, Z.J.; Wei, S.L.; Wei, D.X.; Wang, J.C.; Liu, C.T.; Kai, J.J. Design of D022 superlattice with superior strengthening effect in high entropy alloys. Acta. Mater. 2019, 167, 275–286. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Sun, M.; Liu, J.; Liu, X.; Jiang, W.; Wang, X.; Fang, Q. The Microstructural Evolution and Mechanical Properties of Boron-Doped Ti35Zr30V10Nb25 Refractory High-Entropy Alloy. Crystals 2024, 14, 1029. https://doi.org/10.3390/cryst14121029

Wang X, Sun M, Liu J, Liu X, Jiang W, Wang X, Fang Q. The Microstructural Evolution and Mechanical Properties of Boron-Doped Ti35Zr30V10Nb25 Refractory High-Entropy Alloy. Crystals. 2024; 14(12):1029. https://doi.org/10.3390/cryst14121029

Chicago/Turabian StyleWang, Xinggang, Meng Sun, Jiaxin Liu, Xueqing Liu, Weibin Jiang, Xianping Wang, and Qianfeng Fang. 2024. "The Microstructural Evolution and Mechanical Properties of Boron-Doped Ti35Zr30V10Nb25 Refractory High-Entropy Alloy" Crystals 14, no. 12: 1029. https://doi.org/10.3390/cryst14121029

APA StyleWang, X., Sun, M., Liu, J., Liu, X., Jiang, W., Wang, X., & Fang, Q. (2024). The Microstructural Evolution and Mechanical Properties of Boron-Doped Ti35Zr30V10Nb25 Refractory High-Entropy Alloy. Crystals, 14(12), 1029. https://doi.org/10.3390/cryst14121029