Abstract

This review analyzes the use of magnetite-based catalysts in various oxidation reactions. It is shown that magnetite-based catalysts are the most promising candidates from the standpoint of easy separation from the reaction zone and reusability. Diverse examples of the use of magnetite-based composites are discussed, including the following reactions: partial oxidation of methane to formaldehyde; the oxidation of cycloalkanes into alcohols and ketones; the oxidation of alkenes and alcohols with the major focus made on benzylic alcohol oxidation; oxidative cracking of alkenes; Fenton-type reactions with H2O2 as a benign oxidant; the removal of dyestuff in water (including wastewater by oxidation); reactions of sulfides and thiols; the oxidation of 5-hydroxymethylfurfural as a platform chemical to 2,5-diformylfuran; the oxidation of D-glucose to D-gluconic acid; and the electrocatalytic oxidation of methanol and ethanol. The most important and best-studied applications of magnetic nanoparticles in the oxidation reactions are believed to be the oxidation of diverse benzylic alcohols and D-glucose, and Fenton-like reactions aiming at the removal of S- and N-compounds from ware and fuels. Magnetic nanocomposites are determined as the materials meeting a range of criteria: (1) they should be magnetic, (2) they contain nanoparticles, and (3) they consist of two (or more) nanocomponents. The core–shell materials with magnetic nanoparticles used as a core or as decorating nanoparticles are discussed in the review. Three main types of magnetic nanocomposites can be distinguished: (1) the systems where the magnetic phase is active in the considered reaction, for instance, Fenton-like oxidation; (2) the systems containing active metal nanoparticles supported onto the magnetic nanoparticles; and (3) materials with magnetic nanoparticles as a core coated with one or two shells (porous or non-porous), with the magnetic nanoparticles being active or not in the title reaction. Magnetic nanoparticles exhibit a number of advantages compared with supported non-magnetic catalysts of oxidation reactions. The advantages include the possibility of separation from the reaction medium (5–10 times) without a significant loss of the activity, their non-toxicity, low cost, and availability, and the easy preparation of these materials. The drawbacks may include the leaching of active components; a decrease in saturation magnetization in comparison with the bulk magnetite; a limited accessibility of active sites due to diffusion through the shells; the complicated composition and structure of the nanomaterials; a decrease in the activity and specific surface area; and a limited number of magnetic compounds with acceptable characteristics. Nevertheless, the advantages of magnetic nanocatalysts stimulate their wide use in liquid-phase oxidation reactions, which will be discussed in the review. Future perspectives on the use of magnetic composites are considered.

1. Introduction

Homogeneous catalysts for liquid-phase oxidation reactions provide enhanced reaction rates and increased yields of the target products. However, the extraction of catalysts from reaction media causes certain difficulties. This launched the design of improved heterogeneous catalysts. The development and synthesis of robust and stable catalysts possessing a high selectivity, as well as reusable ones, has been and remains a significant problem. Such catalysts attract great attention in the design of new approaches aimed at the production of valuable chemicals. Therefore, the attention of researchers is currently focused on the heterogenization of active phases on different porous solid carriers, such as graphene oxide, mesoporous oxides, metal–organic frameworks, carbon nanotubes, zeolites, etc. However, the separation of the catalyst from the reaction media is not a trivial task even in the case of solid catalytic materials. Therefore, magnetic nanoparticles attract growing attention for their application in heterogeneous catalysis due to their characteristic physical and magnetic properties. Magnetic nanoparticles, such as magnetite-based ones, are also of considerable interest because of their low cost and non-toxicity. The use of magnetic materials as catalysts has several advantages, namely, eliminating the need for filtration, centrifugation, or other procedures necessary to separate the catalyst from reaction products [1,2,3,4]. Among magnetic nanoparticles, Fe3O4 is the most widely used carrier for catalysis [1]. It has been established that unprotected magnetic nanoparticles are unstable, susceptible to oxidation, and prone to rapid aggregation in liquid and aggressive media during catalytic transformations, which leads to the deterioration of magnetic properties, and a decrease in their catalytic activity and dispersion [4]. In this regard, it becomes necessary to create composites to protect magnetite nanoparticles [5]. Due to their advantages, such as high dispersion, and nanoscale and magnetic properties, a high catalytic activity of catalysts based on magnetic particles is achieved [6], in particular, with the use of magnetite [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30].

The goal of the present review is to evaluate the possibilities of using magnetite nanoparticles in catalytic oxidation processes, as well as the influence of the structure and preparation methods on their catalytic properties. The publications from the last five years are mainly discussed with a focus on the papers where the extraction of a catalyst from the reaction mixture using a magnetic field (a magnet) is used, and the exact structure of magnetite in the nanostructured catalytic materials is established. The structure of the review is based on the oxidation of different compounds and classes of compounds, starting with methane.

2. Partial Oxidation of Methane

The global problem in gas processing is the efficient direct conversion of methane into valuable chemicals. Magnetically separable nanocatalysts Me-Fe3O4 (Me-Pd, Ag) have been developed containing 1–3 wt.% Pd, which showed remarkable activity in the partial oxidation of methane at temperatures up to 200 °C [2]. It has been shown that the oxidation of methane at 200 °C for the tested catalysts leads to formaldehyde as the target product at a selectivity over 74% and CO2 as the only detected by-product. The bimetallic catalyst 3%AgPd-Fe3O4 demonstrated higher activity compared to the monometallic catalysts Pd-Fe3O4. The selectivity towards formaldehyde increased, while the Pd content increased to reach a maximum of more than 97% in the case of the monometallic system 3%Pd-Fe3O4 and the bimetallic material 3%AgPd-Fe3O4 at 200 °C. The temperature increase to 250 °C results in some increase in the methane conversion, whereas the selectivity to the partial oxidation product decreases for the monometallic Pd-Fe3O4 catalysts, i.e., there is no inverse dependence of the conversion versus the selectivity. Remarkably, the selectivity to formaldehyde remains high and practically does not change in the range from 200 to 250 °C in the case of a bimetallic catalyst 3%AgPd-Fe3O4, which provides the formaldehyde space–time yield of 43 g CH2O kgcat−1 h−1 with a turnover frequency (TOF) of 24.7 h−1. The nanocomposites studied proved promising for further research in the field of the partial oxidation of methane in the gas phase at reduced reaction temperatures compared to the data reported to date for other catalysts [2].

3. Oxidation of Cycloalkanes

The functionalization of C–H bonds, namely via mild oxidation of cycloalkanes C5–C8 to the alcohols and ketones using tert-butylhydroperoxide (TBHP) as an oxidant at 50–70 °C in an acetonitrile medium, provides the yield up to 15% based on a cycloalkane; TON = 335, with the magnetic nanocomposite catalyst Fe3O4@mSiO2@Cu4 being the most active and selective [3]. The catalyst was obtained by supporting a tetranuclear copper (2+) complex [Cu4(µ4-O){N(CH2CH2O)3}4(BOH)4][BF4]2 (Cu4 catalyst) supported on a core–shell nanoparticles with a core formed by Fe3O4 nanoparticles and a shell formed by mesoporous silicon dioxide with radially arranged channels. The resulting hybrid material behaves as a magnetically separable nanocatalyst. In the presence of this catalyst, the oxidation of cyclohexanol results in the cyclohexanone formation with a yield of ~25% (TON = 570). The Fe3O4@mSiO2@Cu4 system can be used five times without any noticeable decrease in the activity. In the case of the oxidation of various alkanes and naphthenes (methylcyclohexane, adamantane, cis- and trans-1,2-dimethylcyclohexane, n-hexane, n-heptane, n-octane), the regio- and stereoselectivity have been studied, and a comparison was made with homogeneous catalysts containing a Cu4 complex. In particular, the increased selectivity values found in the case of methylcyclohexane and adamantane oxidation in the presence of Fe3O4@mSiO2@Cu4 suggest that reactions can proceed in the hydrophobic sites of the nanocatalyst [3].

The development of highly efficient catalysts for cyclohexane oxidation to valuable products, including cyclohexanol and cyclohexanone, is of great industrial importance. Graphene oxide (GO) in combination with composites of Fe3O4 and Ag nanoparticles (GO-Ag and GO-Fe3O4) has been studied with the goal of revealing the synergy between Ag and Fe3O4 nanoparticles in the photocatalytic oxidation of cyclohexane [4]. A comparison of thermal and photothermal processes has shown that an increase in the temperature contributed to the conversion efficiency, but the selectivity for the cyclohexanol and cyclohexanone mixture lower than 50% was reached at an elevated temperature (140 °C). An increased selectivity and milder conditions were achieved in the photothermal process compared with thermal catalysis. Silver nanoparticles play a more important role in photocatalysis compared to the thermal process, whereas thermocatalysis is enhanced by Fe3O4 nanoparticles. At 1.5 MPa with dry air as an oxidant in the presence of GO-Ag and GO-Fe3O4 nanoparticles, a 6.6% cyclohexane conversion was achieved, while the selectivity to the cyclohexanol and cyclohexanone mixture was over 98%. In addition, there was no apparent decrease in catalytic activity over five cycles. The approach of photothermal interaction in cyclohexane oxidation on GO-Ag and GO-Fe3O4 nanoparticles provides a novel approach to the selective oxidation of saturated C–H bonds and the development of highly efficient catalysts [4].

Magnetite nanoparticles coated with silicon dioxide containing a first-row transition metal (Fe3O4@SiO2-M2+, where M = Mn2+, Co2+, Cu2+, Zn2+) have been used as catalysts for partial cyclohexane oxidation with hydrogen peroxide to cyclohexanol and cyclohexanone. The particle size was determined to be equal to 22 and 31 nm for Fe3O4 and Fe3O4@SiO2, respectively, i.e., the silica shell around the magnetite core was about 9 nm. After supporting a transition metal, the size of the particles increased to 24–35 nm. The data on saturation magnetization for the studied samples were missing; therefore, it is not possible to reveal the dependence of the saturation magnetization on the size of the composite nanoparticles in the range of the studied transition metal ions (Mn2+, Co2+, Cu2+, Zn2+). It was established that the reaction occurs under mild conditions with microwave heating without the use of a solvent to produce water as the only by-product. The maximum results were achieved when Fe3O4@SiO2-Mn2+ and Fe3O4@SiO2-Co2+ were used as catalysts, with the yield of the target products of 24% and 21%, respectively, at 2 h (80 °C). For the Mn-containing particles, a positive effect of microwave heating during the reaction was demonstrated, compared with conventional thermal heating. It took one hour to complete the reaction under microwave conditions, whereas the process occurred after at least 6 h under conventional thermal heating. Overall, the initial catalyst activity decreased in the order Cu2+ > Co2+ > Mn2+ > Zn2+. The catalysts can be easily isolated from the reaction medium using a magnet, and when recycled, they practically do not lose activity for five cycles [5].

4. Oxidation of Alkenes and Alcohols

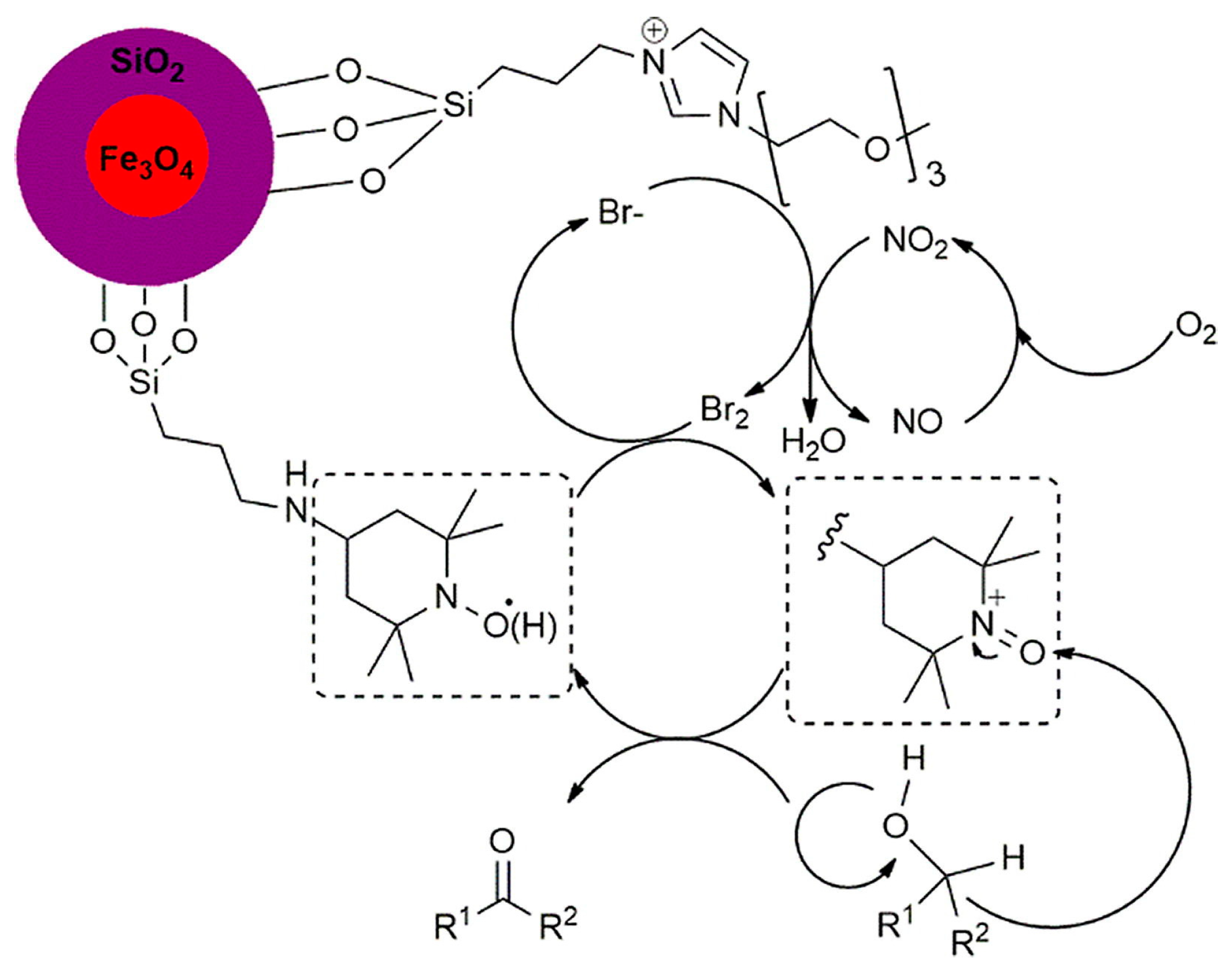

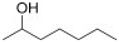

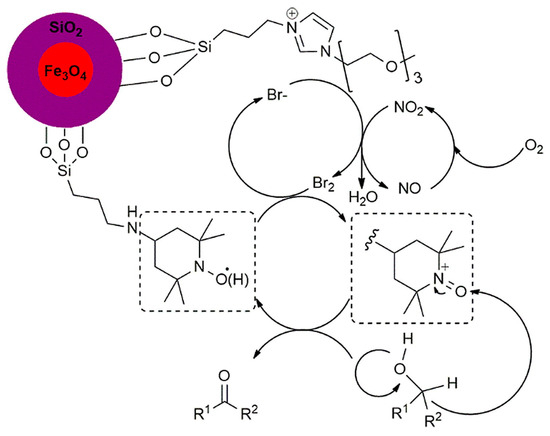

The oxidation of alcohols to the corresponding carbonyl compounds is of significant importance in organic syntheses, fine chemical syntheses, and the pharmaceutical industry. Of special interest are the systems that can be used in aqueous media, which is in line with the principles of “green” chemistry. Therefore, the paper by Karimi et al. [6] caught our attention as an example of a rather complicated nanocomposite consisting of four components, each component playing its own role in alcohol oxidation. The nanocomposite included the following: 2,2,6,6-Tetramethylpiperidine-N-oxyl (TEMPO), component 1, which is the active phase in the metal-free oxidation reaction, and was deposited on magnetic nanoparticles Fe3O4@SiO2, components 2 and 3, respectively, serving as a magnetic core (Fe3O4) and a hydrophilic shell (SiO2), which was further modified with an ionic liquid (imidazolium bromide containing triethylene glycol groups), with component 4 acting as a hydrophilic linker between the SiO2 shell of the magnetic nanoparticle and the TEMPO as the active site. The composite Fe3O4@SiO2 nanoparticles were prepared by the microemulsion method in the reverse water-in-oil micelles of sodium dodecylbenzene sulfonate as a surfactant. Unfortunately, the size of the nanoparticles was not disclosed in the paper; therefore, it is difficult to compare the data obtained with the results presented for other systems reported in the literature. The thus designed (MNS-TEG-IL-TEMPO-Br) composite was used as a magnetically separable water-dispersible bifunctional catalyst in the oxidation of alcohols in water under metal-free aerobic conditions [6]. The catalyst has demonstrated excellent double-controlled selectivity in the partial oxidation of primary alcohols to aldehydes or carboxylic acids by appropriately choosing the solvent and reaction time, as well as outstanding recycling characteristics due to the “double separation strategy”. It has been shown that the change in the reaction solvent in combination with the interaction of imidazolium bromide and TEMPO in the synthesized catalyst allows the regulation of the selectivity and overall performance of the catalyst, perhaps by means of a synergistic relay mechanism (Figure 1). The high stability of the nanocomposites in water allowed their recyclization with magnetic separation fourteen times in aqueous solutions and five times in acetonitrile solutions.

Figure 1.

The proposed mechanism of the oxidation of alcohols with oxygen using MNS-TEG-IL-TEMPO-Br. Reproduced with permission from [6].

It has been shown that the studied systems consist of triple redox pairs such as NO/NO2, Br2/Br−, and TEMPO+/TEMPOH acting synergistically, thereby facilitating the transfer of electrons from an alcohol to O2 molecules. These studies allowed the authors to propose a mechanism of synergetic relay.

One more, very simple, catalytic system was proposed for the oxidation of alcohols consisting of Fe3O4@SiO2 core–shell particles modified with a K2CO3-glycerol deep eutectic solvent that was grafted onto the surface of the core–shell particles by covalent bonds [31]. The authors stress the “green” nature of the composite containing only “green” environmentally friendly components.

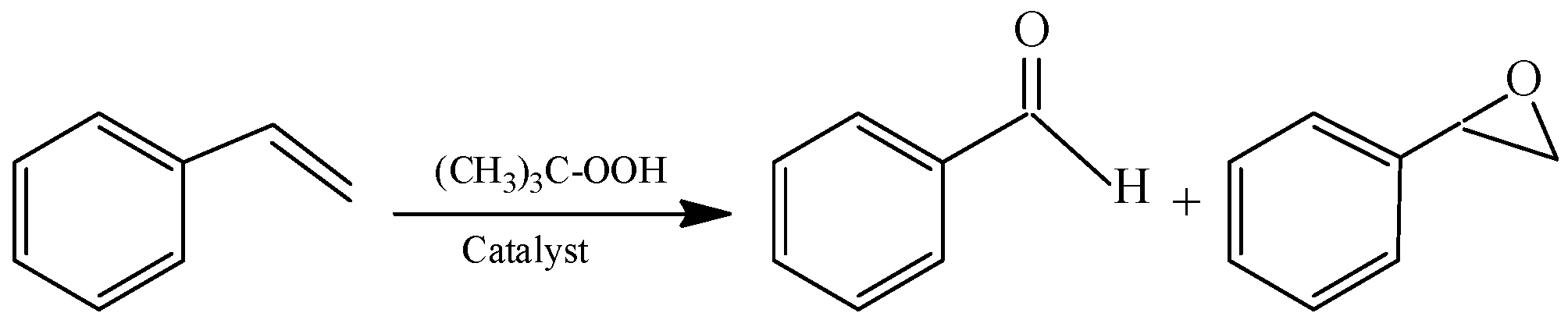

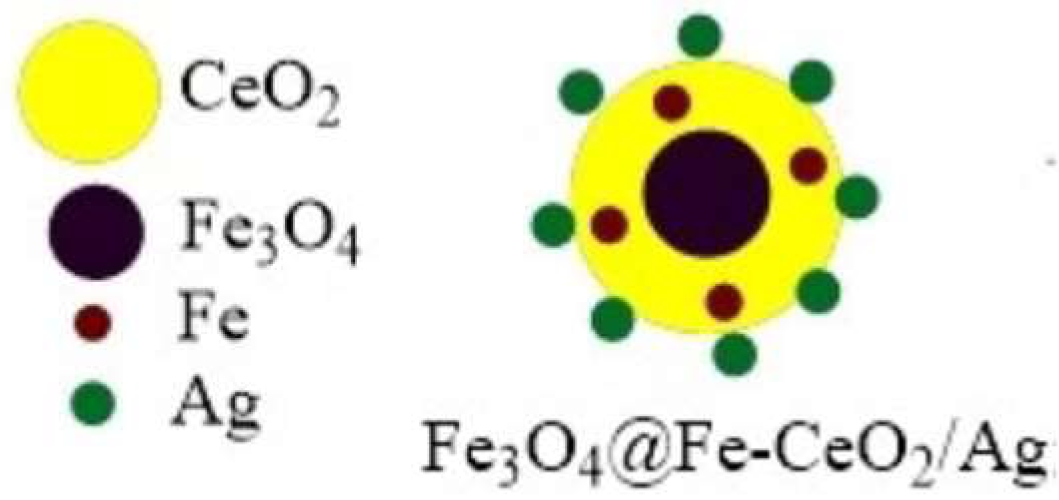

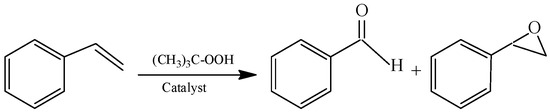

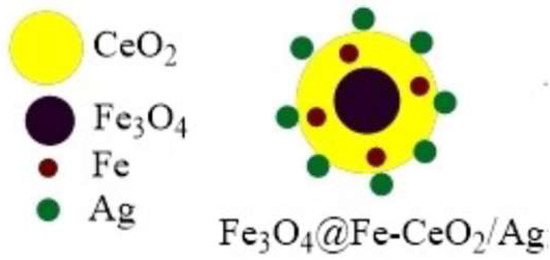

For the oxidation of alkenes (Figure 2), a nanocatalyst based on a triple composite material Fe3O4@Fe-CeO2 decorated with silver again containing four components, all of them inorganic, was synthesized and characterized using a simple and environmentally friendly co-deposition method using NaOH as a precipitating agent and water as a “green” solvent under rather mild reaction conditions without the use of additional additives, toxic solvents, surfactants, or templates [7]. Using high-resolution TEM, it was shown that a composite with a core–shell structure was formed, where Fe3O4 was coated with spherical particles of cerium oxide, resulting in the formation of Fe3O4@Fe-CeO2 decorated with silver nanoparticles (Figure 3).

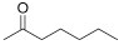

Figure 2.

The oxidation reaction of styrene to benzaldehyde and 2-phenyloxyrane.

Figure 3.

Fe3O4@Fe-CeO2/Ag nanocatalyst.

A comparison of the catalytic properties of Fe3O4@Fe-CeO2/Ag with other catalysts such as (NH4)2Ce(NO3)6, AgNO3 and Fe(NO3)3 × 9H2O (providing the styrene conversion of 43%, 47%, and 68% with selectivity for benzaldehyde of 88%, 83%, and 73%, respectively) showed that the composite nanocatalyst Fe3O4@Fe-CeO2/Ag ensures a 100% styrene conversion with the selectivity as high as 95% toward benzaldehyde and the selectivity to the side product, 2–phenyloxirane, about 5%. As is known, the oxidative transformation of alkenes into aldehydes using tert-butylhydroperoxide (TBHP) as an oxidant is accompanied by a radical mechanism (Figure 3). Similarly, in the presence of the Fe3O4@Fe-CeO2/Ag nanocatalyst, TBHP dissociates to form tert-butoxy and tert-butyl peroxide radicals. During the reaction, styrene reacts with the tert-butyl peroxide radical and, after the completion of the two-stage process, benzaldehyde is formed. The catalyst was used in four cycles with only a negligible decrease in the activity. The authors did not present, however, any data on the size of the composite nanoparticles, nor the size of the core. The only information available in the paper is related to the size of CeO2 particles in the composition of the nanocomposite. The authors did not discuss the localization of dissociated TBHP molecules or the nature of the species present in the composite that are responsible for the dissociation. It is noteworthy that such inorganic nanocomposite particles should not be stable enough in aqueous solutions; therefore, the reaction was performed in an organic media and with the use of TBHP as an oxidant, while no experiments with hydrogen peroxide were carried out for comparison.

Copper-based catalysts are widely used for the selective oxidation of oxygenated organic compounds [8]. A solid catalyst based on a copper(II) complex with a Schiff base covalently immobilized on the surface of Fe3O4 nanoparticles coated with silica (Fe3O4@ SiO2-Schiff base-Cu(II) has been studied [9]. The catalytic properties of Fe3O4@ SiO2-Schiff base-Cu(II) have been studied in the partial oxidation of diverse alkenes (cyclooctene, cyclohexene, styrene, α-methylstyrene, and norbornene) and alcohols (benzylic alcohol, 3-methoxybenzylic alcohol, 3-chlorobenzylic alcohol, benzhydrol, and n-butanol) with TBHP as an oxidizer. The catalyst was especially effective in norbornene and benzylic alcohol oxidation to produce epoxydinorbornene and benzoic acid with a selectivity of 100 and 87%, respectively. Other advantages of this catalyst were simple magnetic extraction from the reaction vessel and repeated use with no significant loss of the catalyst activity.

Similar systems based on a Schiff-base Cu(II) complex grafted onto the surface of Fe3O4@SiO2 nanoparticles prepared by the interaction with 3-aminopropyltrimethoxysilane were tested in the oxidation of styrene, cyclohexene, and benzylic alcohol with a high selectivity towards oxidation products—styrene oxide, 2-cyclohexene-1-one, and benzoic acid—reaching 88%, 100%, and 100%, respectively [32].

Vanadium complexes are also known in art as active catalysts for olefin oxidation. Magnetic composites containing oxovanadium hydrazone on Fe3O4@SiO2 have been shown to reveal a high activity in the oxidation of olefins of different nature (norbornene, styrene, α-methylstyrene, cyclooctene, cyclohexene) by tert-butyl hydroperoxide [33]. The heterogeneous catalyst was characterized by higher TON compared to the homogeneous complex and could be separated. In the case of norbornene oxidation, the conversion was as high as 99% with an 84% selectivity towards norbornene epoxide.

Another interesting system was reported by Mondal et al. [34], who investigated the oxidation of ethanol to the aldehyde using a Cu(II) complex immobilized on the surface of magnetite modified with isonicotinic acid. The high efficiency and stability of the copper complex were achieved by using specially designed pyridyliminophenol ligands to form surface Schiff-base complexes. Hydrogen peroxide was used as an oxidizing agent in an aqueous media. Up to five cycles were used to demonstrate good stability of the catalyst and the absence of leaching of the active complex from the surface.

Zamani et al. used a combination of cobalt(II)-containing metalloporphyrin encapsulated in the UiO-66 metal-organic framework with Fe3O4 [35]. Olefins and allylic alcohols can be effectively oxidized with tert-butyl hydroperoxide with an outstanding efficiency of 95% and a 67% selectivity.

A variety of alcohols were oxidized with air to corresponding aldehydes without noticeable formation of carboxylic acids in the case of primary alcohols using gold-containing catalysts on magnetite coated with carbon [36]. The magnetic catalyst can be recycled 10 times with no loss of activity and remarkable leaching of gold.

5. Benzylic Alcohol Oxidation

Standing alone, but no less important, is the oxidation of aromatic alcohols into aldehydes or carboxylic acids [37]. Magnetite and maghemite obtained by a simple method of co-precipitation from aqueous solutions of divalent and trivalent iron salts were used to activate the oxidation of benzylic alcohols [10]. It was established that aliphatic alcohols are not oxidized by oxygen in the studied conditions. Flow experiments have shown that the same benzaldehyde yield of 8% is achieved in the presence of magnetite or maghemite and without the formation of carboxylic acid at 202–203 °C with an airflow rate of 100 mL/min. The crystal structures of magnetite and maghemite are similar, which allows these oxides to act as mobile oxygen carriers. The reaction mechanism probably involves a radical chain reaction.

A more complicated system based on magnetite on graphene oxide modified with lantana was employed as an efficient and selective catalyst for the oxidation of aromatic alcohols into the corresponding aldehydes with magnetic catalyst separation [38].

The use of hollow porous nanospheres providing good diffusivity of reactants inside the hollow cavity and outside the hollow cavity through micro or mesopores is a promising approach to designing magnetic catalysts with good separation ability and acceptable transport properties for the reactants and products. Zhang et al. proposed using organic hollow porous nanospheres with incorporated Fe3O4 and Pd nanoparticles inside the cavities for the oxidation of alcohols of different natures [39]. The authors used a strategy resembling the ship-in-the-bottle approach that is often used in zeolite catalyst preparation. The prepared nanospheres demonstrated a high specific surface area (about 350 m2/g) and a hierarchical micro/mesoporous structure, as well as an acceptable magnetic response (saturation magnetization of 9 emu/g).

The synthesis of active heterometallic modified (M = Pd, Cu) magnetite (M-Fe3O4) hollow nanospheres (with dimensions of 600–900 nm and with a shell of 50 nm) is reported using a two-stage method: the solvothermal method and calcination [11]. Due to the uniformly dispersed active heterometallic particles in the spherical shell of hollow Fe3O4 nanospheres, the freshly prepared Pd-Fe3O4 material demonstrates outstanding catalytic activity with respect to the reduction of 4-nitrophenol with the TOF value of 145 min−1 and also shows excellent stability and magnetic separation ability. The catalytic efficiency is superior to most similar metal catalysts on the Fe3O4 carrier which have been reported in the literature. In particular, Cu-Fe3O4 showed a five times higher activity in the benzylic alcohol oxidation compared to pure Fe3O4 prepared using the same method. The conversion of 49.66% and remarkable selectivity of 100% were reached in the presence of Cu-Fe3O4, while in the presence of Pd-Fe3O4, the conversion was lower at 19.88%, and the selectivity for benzaldehyde reached 98.95%, whereas in the case of magnetite [12], the corresponding values were 9.99% and 100%, respectively. The work demonstrates that increasing the activity of iron oxides via modification with a heterometal is a promising approach for increasing the productivity of various organic synthesis reactions.

Xu et al. prepared magnetic core–shell Fe3O4@Cu2O and Fe3O4@Cu2O-Cu materials and used them as catalysts for the oxidation of benzylic alcohols with air in the presence of 2,2,6,6-tetramethylpiperidine-N-oxyl and N-methylimidazole [40]. Magnetite nanoparticles were first modified with an aminoacid (L-lysine) to create amino groups at the surface, and then Cu2O was precipitated with ethylene glycol acting as a reductant. By varying the reduction conditions, it was possible to prepare a mixture of Cu(I) and Cu(0) states (the Fe3O4@Cu2O-Cu material). The only products of the oxidation of benzylic alcohols were benzaldehyde derivatives formed with a yield of 100%. The Fe3O4@Cu2O-Cu material demonstrated somewhat better activity and withstood seven cycles of repeated runs.

The authors of [41] proposed using a natural biomolecule, tannic acid, for the stabilization of magnetic particles and supported copper. These materials were successfully tested in the selective oxidation of aliphatic and benzylic alcohols into the corresponding aldehydes and ketones.

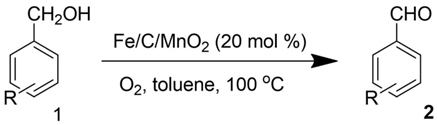

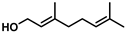

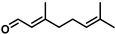

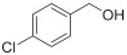

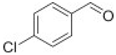

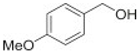

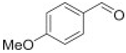

For the controlled oxidation of various benzylic alcohols with O2 molecules, a Fe3O4/C/MnO2 nanocatalyst based on manganese oxide deposited on a magnetic carrier (Fe3O4/C) was prepared [13]. The authors optimized the conditions for the oxidation of p-methoxybenzylic alcohol.

To study the application of catalysts, a number of aromatic alcohols with different structures were oxidized under optimized conditions. The results obtained are summarized in Table 1.

Table 1.

Oxidation of various benzylic alcohols.

Benzylic alcohols bearing electron-donating or electron-acceptor groups were oxidized to the aldehydes with a rather good yield. Aromatic alcohols with electron-donating groups such as –OCH3 and –CH3 were oxidized faster with a good yield (Table 1, entries 2, 4) compared with benzylic alcohols having electron-acceptor groups such as –NO2, –Cl, –F, –Br (Table 1, entries 3, 5, 7). Heteroaromatic compounds, for example, 3-pyridylmethanol, seem to be oxidized under optimized conditions with a moderate yield. Even aromatic secondary alcohols are oxidized to ketones with a satisfactory yield. However, allylic alcohol did not change under reaction conditions (entry 11). It is shown that the catalyst exhibits a high selectivity in the oxidation of benzylic alcohol, using the example of 4-methylthiobenzylic alcohol oxidized to 4-methylsulfinylbenzaldehyde, instead of 4-methylsulfinylbenzylic alcohol. The catalyst can be recycled and used again five times without a loss of efficiency.

Palladium remains the metal with superior activity in the oxidation of aklylarenes and benzylic alcohols. A Pd/PdO/Fe3O4 catalyst based on polymeric graphene quantum dots (PGQD) with magnetic separation showed excellent activity in the oxidation of alkylarenes and alcohols using H2O2 as a benign oxidizer at ambient temperature [15]. It is noteworthy that the polymer-like graphene quantum dots were prepared by heat treatment of citric acid in the presence of sodium hydroxide as the basic catalyst. A comparison of the results of benzylic alcohol oxidation using Pd/PdO/Fe3O4@PGQD showed that the catalyst demonstrates high turnover numbers under very mild conditions. Oxidation at 20 °C and the easy recovery of the catalyst using a magnet are characteristic features of the action of Pd/PdO/Fe3O4@PGQD. It has been demonstrated that the catalyst can be reused five times without a noticeable loss of activity [15]. The saturation magnetization of Fe3O4 and Pd/PdO/Fe3O4@PGQD nanoparticles was found to be 59.11 and 16.24 emu g−1, respectively. The obtained structural data seem to be contradictory: XRD data provide the size of Fe3O4 particles of 23 nm in the composite Pd/PdO/Fe3O4@PGQD, whereas TEM analysis gives the size of the entire composite particle of about 9–14 nm, i.e., at least two times greater than that of Fe3O4 particles. It is noteworthy that there are no papers in the literature where the size effect of magnetic nanoparticles on their catalytic activity/selectivity pattern is studied and the structure–activity relationship is established.

Another example of Pd-catalyzed oxidation of benzylic alcohols to benzaldehyde derivatives is presented in the work by Fekri et al. [42], who used carbene complexes of Pd(II) to catalyze this reaction. Particles with magnetite–silica core and shells and SBA-15 mesoporous silicate were used to immobilize the carbene complexes. Some Pd leaching of about 0.83% was observed in a series of eight repeated runs in the oxidation of benzyl alcohol.

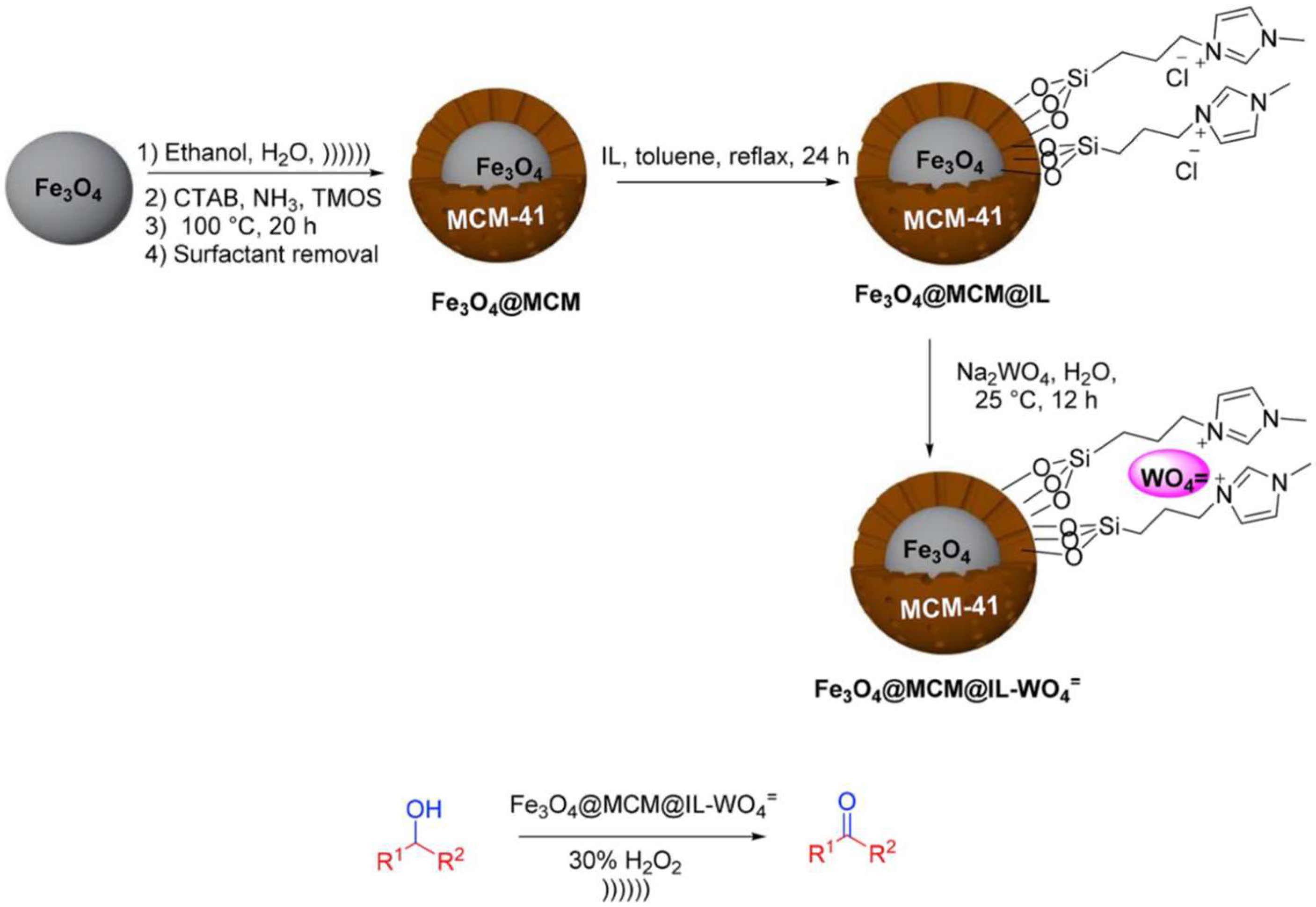

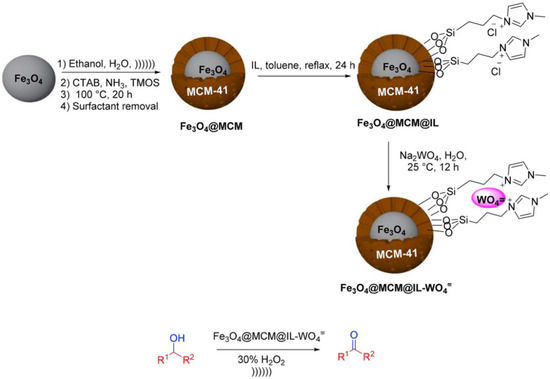

A composite Fe3O4@MMS@IL-WO42− consisting of a tungstate modified with an ionic liquid (IL) deposited on a magnetic mesoporous silicate (MMS) was synthesized and used as a recyclable nanocatalyst in the “green” oxidation of alcohols using hydrogen peroxide as an oxidizer and ultrasound (Figure 4) [16]. It is shown that the corresponding carbonyl products are formed with high yields and selectivity (Table 2).

Figure 4.

The scheme of the preparation of the Fe3O4@MMS@ IL-WO42 nanocatalyst and its use in the oxidation of alcohols. Reproduced with permission from [16].

Table 2.

The oxidation of alcohols with H2O2 as an environmentally acceptable oxidizer on the nanocatalyst Fe3O4@MMS@IL-WO42− under thermal and ultrasonic exposure.

To activate molecular oxygen in the selective oxidation of benzylic alcohol to benzaldehyde, a Fe3O4@C/MnO2 catalyst based on MnO2 nanoplate polymorphs deposited on Fe3O4 nanoparticles coated with carbon with a core–shell structure was obtained using a self-sacrificing template [17]. A high conversion rate was established, and the catalyst was repeatedly used in six cycles without reducing its activity. Table 3 presents a comparison of the known catalysts for the oxidation of benzylic alcohol into benzaldehyde on magnetite-based catalysts.

Table 3.

Oxidation of benzylic alcohols on magnetic catalysts.

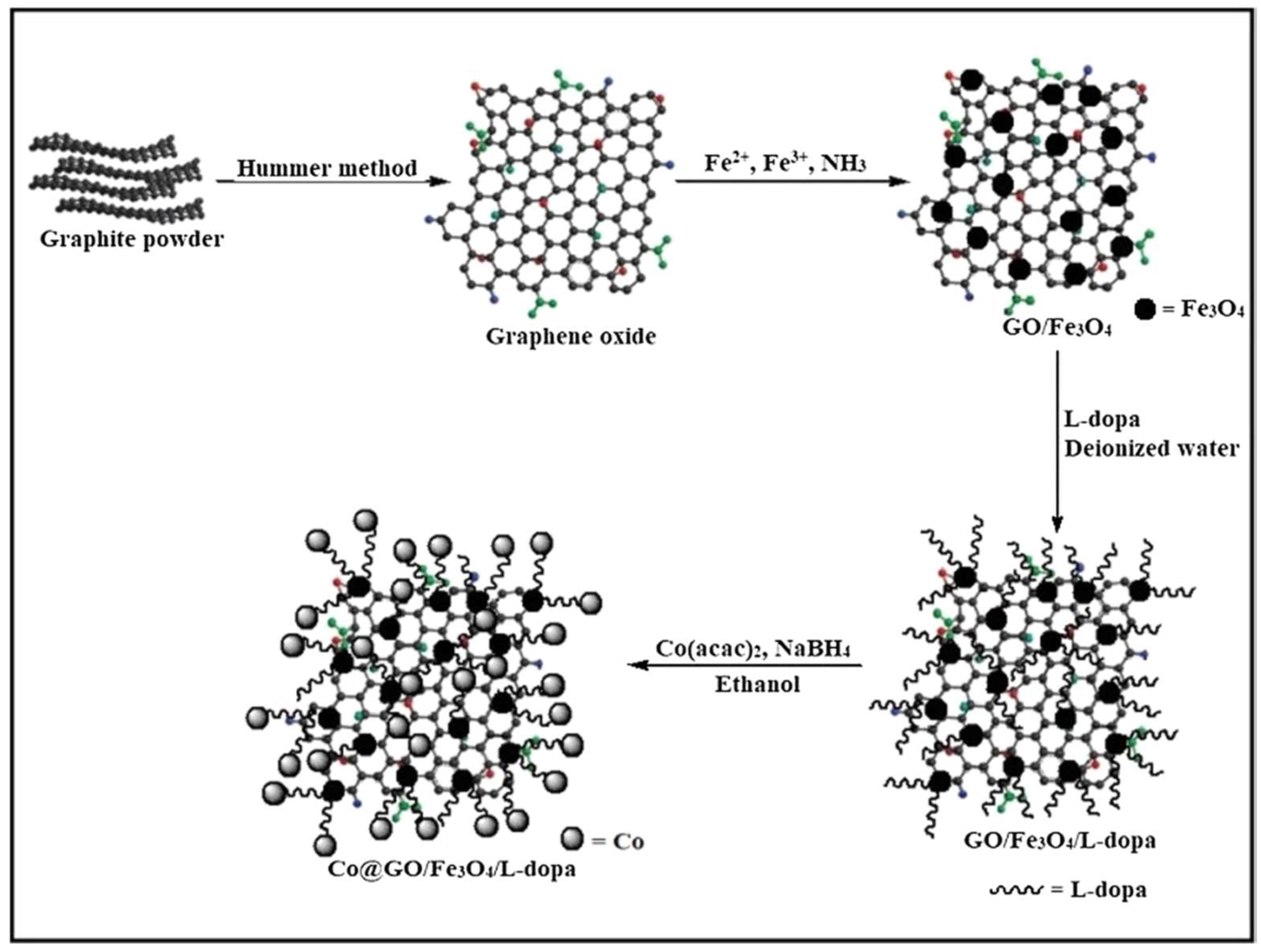

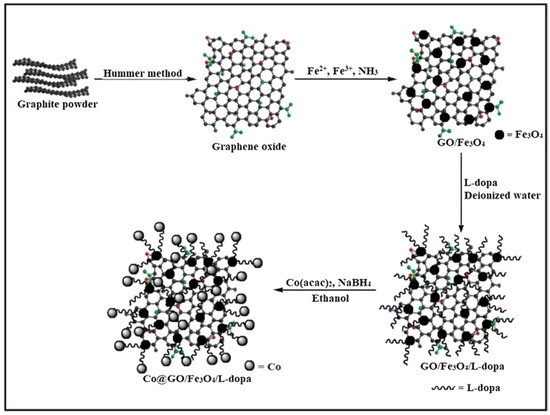

The synthesis of an effective and inexpensive Co@GO/Fe3O4/L-dopa catalyst for Suzuki cross-coupling and selective oxidation reactions, which are usually performed using noble and expensive transition metals, has been reported [18]. Co@GO/Fe3O4/L-dopa was obtained by immobilization of cobalt nanoparticles on a graphene oxide substrate with grafted magnetite functionalized with L-3,4-dihydroxyphenylalanine (L-dopa) (Figure 5). The highest yield of the product in the oxidation of benzylic alcohol reaching 92% was observed with water as a solvent and TBHP as an oxidant, whereas alcohols, acetonitrile or dichloromethane, as solvents and oxygen as an oxidant reduced the yield. However, the authors did not report the size of the nanoparticles obtained and no effect of the particle morphology was studied. The saturation magnetization for the prepared nanoparticles was not high, about 33.5 emu/g, which is related to the presence of a large quantity of non-magnetic components in the particle, including graphene oxide and L-dopa, but the saturation magnetization of the starting magnetite was not reported. Nevertheless, the saturation magnetization value permanently decreases in the order GO/Fe3O4 > GO/Fe3O4/L-dopa > Co@GO/Fe3O4/L-dopa.

Figure 5.

Preparation of Co@GO/Fe3O4/L-dopa. Reproduced with permission from [18].

Graphene oxide is often used as a support due to its outstanding electrical, mechanical, and thermal properties. To simplify the cumbersome process of separating the catalyst from the reaction medium, magnetite nanoparticles are deposited on top of the graphene oxide. After the preparation of magnetic nanoparticles on a graphene oxide substrate, L-dopa is grafted onto Fe3O4 nanoparticles to ensure reliable fixation of cobalt nanoparticles. Then, cobalt(0) nanoparticles are supported on the prepared magnetic substrate (Figure 6). Although the graphene oxide–magnetite composite is quite stable, the disadvantage is the aggregation and loss of active metal nanoparticles via leaching from the catalyst surface.

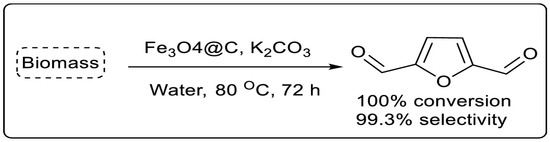

Figure 6.

Conversion of biomass into 2,5-diformylfurane.

A bifunctional Mn-salen complex associated with TEMPO is used as a reducing agent for the in situ production of Fe3O4 nanoparticles by co-deposition [19]. The resulting Mn/TEMPO catalyst doped with Fe3O4 nanoparticles was effective in the selective oxidation of benzylic alcohol to the carbonyl compound (benzaldehyde) or carboxylic acid by changing the type of an oxidizer. Thus, in the presence of ozone as an oxidizer, alcohols are oxidized to acids. In the case of oxygen, carbonyl products are selectively obtained. Mn/TEMPO-doped Fe3O4 exhibits high activity in at least eight consecutive cycles.

Heteropolyacids are often used in selective oxidation, including the oxidation of benzylic alcohols with hydrogen peroxides, but their use faces a problem of separation. A magnetic catalytic system based on Fe3O4 nanoparticles and Keggin-type phosphotungstic acid was prepared and effectively used for the oxidation of benzylic alcohol to benzaldehyde under mild reaction conditions [43].

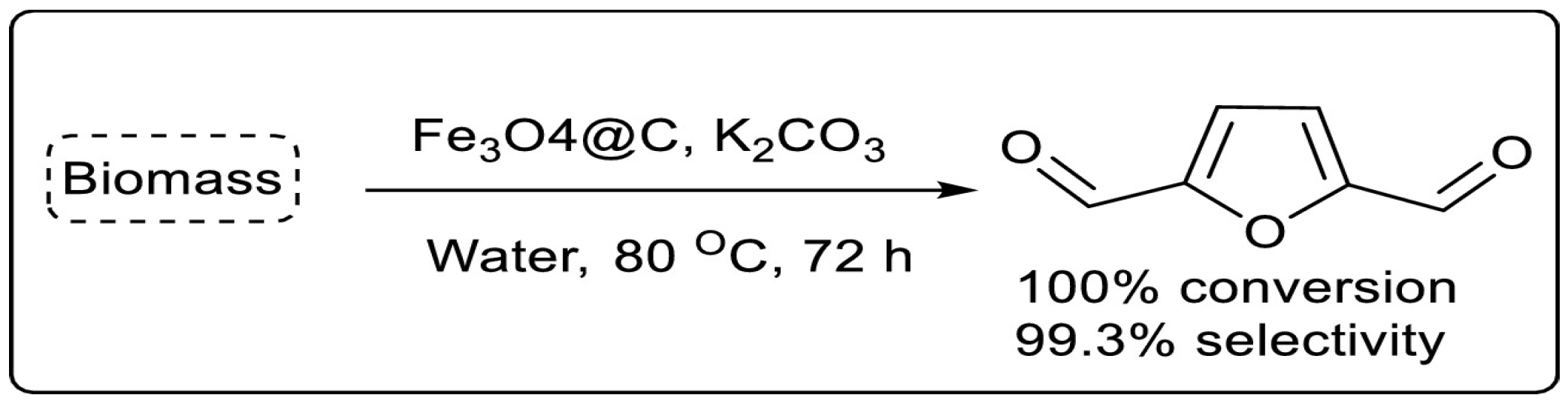

6. Oxidation of 5-Hydroxymethylfurfural to 2,5-Diformylfuran

Fe3O4@C is used in the direct synthesis of 2,5-diformylfuran as a product derived from biomass (using glucose or fructose) with high conversion (100%) through two successive stages, including dehydration and oxidation (Figure 6). Interestingly, candle soot is used as a source of carbon nanoparticles to produce Fe3O4@C, consisting of magnetite with dispersed carbon nanoparticles. It has been shown that Fe3O4@C plays an important role in the dehydration of carbohydrates, unlike non-carbon black Fe3O4 [20].

7. Oxidative Cracking of Alkenes

Selenized magnetite coated with mesoporous silica and with introduced Pd nanoparticles (Pd/SiO2/Fe3O4–Se) has been used for oxidative cracking of alkenes [21]. First, Fe3O4 was treated with NaHSe, and then coated with mesoporous silica and immersed in a PdCl2 solution to load palladium. After heating, Pd nanoparticles deposited on magnetic mesoporous silicon dioxide were obtained (Pd/SiO2/Fe3O4-Se). During catalysis with Pd/SiO2/Fe3O4-Se, 1,1-diphenylethylene can be oxidized with hydrogen peroxide to obtain the desired benzophenone with a yield of 88%. The catalyst may be extracted using a magnet and used again in the next cycle. The catalyst was not deactivated during five reaction cycles, with benzophenone being the only product with yields of 88%, 87%, 89%, 86%, and 85% in five consecutive runs, respectively. The material was also stable and could be stored for more than six months without deactivation.

8. Magnetite in Fenton Reactions

Advanced oxidation processes, which use iron particles and hydrogen peroxide, are an effective method of neutralizing organic pollutants in wastewater [44]. The rate of regeneration of Fe(II) from Fe(III) is known to be the crucial stage of this process, and the application of diverse additional components in the composites aids in controlling this process.

A multifunctional magnetic catalyst, β-cyclodextrin/graphite-like carbon nitride (Fe3O4@β-CD/g-C3N4), has been prepared [22] to remove polychlorinated biphenyls from wastewater. The synthesized Fe3O4@β-CD/g-C3N4 material exhibits excellent catalytic activity, and the decomposition efficiency of six polychlorinated biphenyls reaches 77–98% in 55 min with a pseudo-first-order reaction rate constant varying in the range of 0.027–0.065 min−1. The super-synergy of photodegradation and Fenton oxidation was observed, which was manifested as a 2.1–4.6 times higher efficiency under the conditions of the combined action as compared to only photodegradation or heterogeneous Fenton oxidation. It is noteworthy that the β-CD cavity as an adsorption center can be regenerated in situ. The Fe3O4@β-CD/g-C3N4 catalyst can be used in six cycles without significantly impairing its catalytic performance. The intermediates were determined using GC-MS/MS methods. The products of the final stage of the process are alkanes, aldehyde, ketone, and ester formed as a result of ring opening, dechlorination, and isomerization reactions. Based on the study of trace amounts, it was found that in the decomposition of polychlorinated biphenyls, the main role is played by the OH radical, the secondary role is assigned to O2− radical species, whereas the contribution of singlet oxygen 1O2, holes h± and free electrons e− is even less significant. The catalytic efficiency of the Fe3O4@β-CD/g-C3N4 system in visible light conditions with respect to the decomposition of polychlorinated biphenyls in groundwater and wastewater was 89–100% and 69–92%, respectively; this means that the Fe3O4@β-CD/g-C3N4 material has great perspectives for wastewater treatment [22].

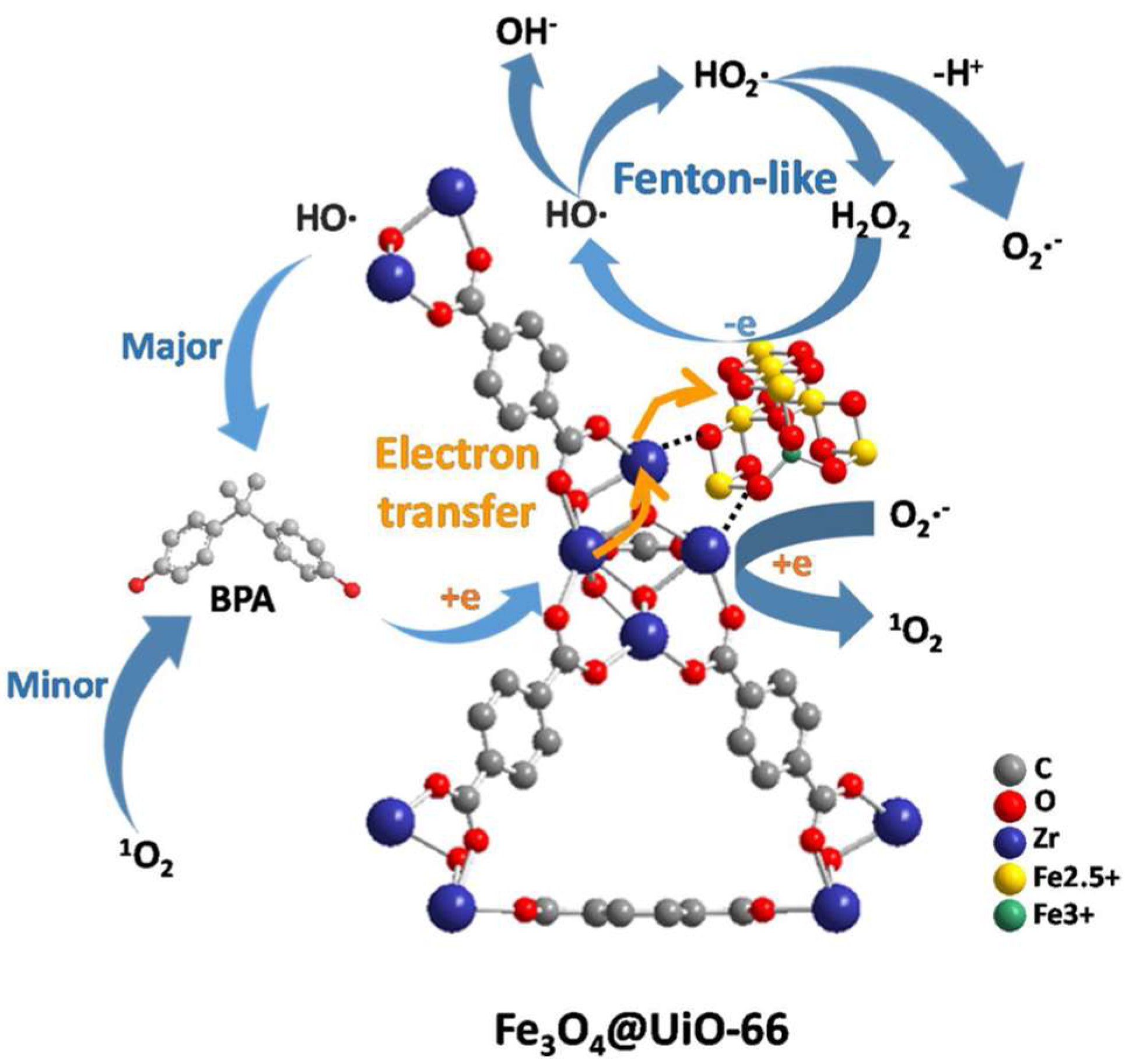

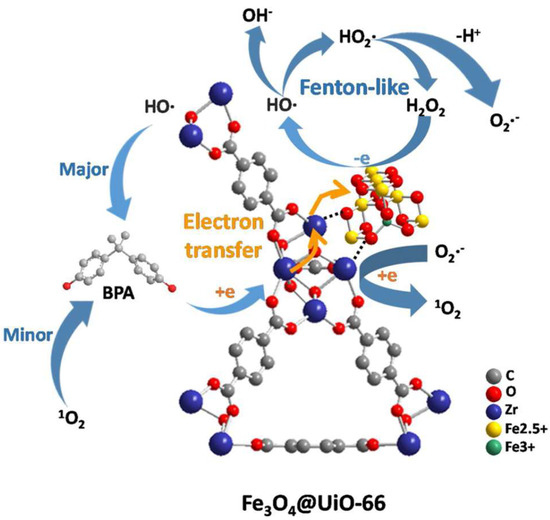

The effects of the synergy or polyfunctionality in magnetic materials are of great interest. The nature and catalytic activity of Fe3O4 nanoparticles deposited on UiO-66 metal-organic framework based on zirconium ions placed in the nods of the framework allow us to take a fresh look at the double active sites of a Fe-Zr type in Fenton-like reactions [23]. It is noteworthy that the Fe3O4 nanoparticles with a size of 14.5 nm are distributed on the surface of UiO-66 particles with a size of 400 nm. No data on saturation magnetization of both naked and supported magnetite nanoparticles were disclosed. Fe3O4 deposited on Zr-MOF UiO-66 was used to study the interaction between the double active sites of the Fe-Zr type in the Fenton process conducted using bisphenol A (BPA) as a model pollutant. The conditions for changing the Fe3O4 content and H2O2 concentration and pH have been optimized. A comparison was made with the traditional H2O2/Fe3O4 system, and almost three times more hydroxyl radicals (HO) were detected in the H2O2/Fe3O4@UIO-66 catalyst at pH = 5. In addition, singlet oxygen 1O2 was identified in the H2O2/Fe3O4@UIO-66 system. The data from the XPS analysis and Moessbauer spectroscopy confirm that the electrons on Fe2+ are directed towards Zr (Figure 7); as a result, Fe2+ loses electrons more easily, which facilitates the reduction of H2O2. However, singlet oxygen species 1O2 were formed when O2− superoxide anions lost electrons at the Zr center; these electrons can be transferred to Fe3+, thereby resulting in an accelerated reduction of Fe3+. These data show that Zr sites can interact with Fe to form double-active sites in Fenton-type reactions.

Figure 7.

The diagram of electron transfer and the formation of active sites between Fe-Zr double active centers. Reproduced with permission from [23].

Thus, a new strategy is proposed for optimizing catalysts with double active centers for Fenton-like processes in water purification.

The reduction of Fe3+ ions to Fe2+ ions in Fenton-type catalysts usually suppresses the catalytic performance. With the goal of improving this process, heterojunctions containing Ni-doped Fe3O4 nanoparticles (0D) and two-dimensional (2D) SnS2 nanosheets were synthesized by a benign method [24]. The composite demonstrated higher photo-Fenton activity in Rhodamine B decomposition than either Ni-doped Fe3O4 or SnS2, or even a mixture of Ni-doped Fe3O4 and SnS2. The composite showed excellent performance in a wide interval of pH ranging from 3.42 to 9.06 in 60 min tests. Interestingly, the composite was active towards dyes of a cationic nature, such as methylene blue, and anionic dyes, such as methyl orange.

A two-stage hydrothermal method has been developed for the preparation of aerogel Fe3O4/reduced graphene oxide (RGO) for use as a reusable heterogeneous Fenton catalyst for the decomposition of methylene blue (MB) [25]. At the first stage of synthesis, a colloidal solution of Fe3O4 was obtained by a hydrothermal method; at the second, graphene oxide hydrogels were prepared by self-assembly and reduced to graphene in the course of the hydrothermal reaction. Thus, zero-dimensional Fe3O4 nanoparticles were supported on graphene oxide due to the effect of colloidal coagulation. The adsorption isotherm and the kinetics of MB decomposition on Fe3O4/RGO nanocomposites showed that the maximum adsorption capacity was 163.83 mg/g, and the adsorption process followed the pseudo-second-order model. It was found that the decomposition efficiency of MB increases with an increase in the initial pH (pH 3–10), i.e., complete decomposition occurs under alkaline conditions within 60 min. The catalytic reaction essentially proceeds at the solid–liquid interface, with increasing pH values; the electrostatic attraction between the cationic molecules of MB and the Fe3O4/RGO surface increases; the adsorption capacity increases, which improves the catalytic performance. The catalyst can be efficiently restored by a magnetic field and has excellent stability after five decomposition cycles.

9. Oxidation of Dyes, Drugs, and Other Organic Pollutants in Water

A fair number of papers describe the use of stabilized magnetite nanoparticles for the degradation of dyes in water [45]. A cheap magnetically separable catalyst was prepared by combining magnetite with montmorillonite clay and used for methylene blue degradation in aqueous solutions with hydrogen peroxide as an oxidant [46]. The use of clay made it possible to enhance the adsorption of methylene blue.

Cu-containing catalysts combined with magnetite nanoparticles are often used in the advanced oxidation of various drugs and other organic pollutants in water. A combination with a metal–organic framework seems to provide beneficial transport of reactants [47]. The combination of graphene oxide, copper benzene dicarboxylate metal–organic framework, and Fe3O4 nanoparticles afforded peroxymonosulfate activation and eventually the high efficiency in the oxidation of ciprofloxacin antibiotic via the formation of hydroxyl and sulfate radicals, with the conversion reaching 98.5% in 24 min, the rate constant being 0.191 min−1.

The catalytic oxidation of methylene blue with hydrogen peroxide was studied using composites based on Fe3O4@Cu/C and Fe3O4@CuO prepared using magnetic metal–organic framework Fe3O4@HKUST-1 with encapsulated Fe3O4 nanoparticles using a sacrificing template [26]. Thus, when calcining Fe3O4@HKUST-1 in different atmospheres (nitrogen or air), Fe3O4@Cu/C and Fe3O4@CuO composites were prepared, respectively. It has been shown that the composites possess not only superparamagnetic properties but also high peroxidase-like activity and stability compared to the precursor. It is assumed that the high peroxidase-mimicking activity of Fe3O4@Cu/C and Fe3O4@CuO is due to the synergistic interaction of Fe3O4 nanoparticles with Cu/C or CuO. A high catalytic activity is attributed to a relatively large specific surface area, a hierarchical pore structure, and the accessibility of internal pores to the reagents.

The catalytic decomposition of methyl orange (MO) in the presence of H2O2 at various pH values and temperatures under the action of hydrophilic Fe3O4 nanoparticles prepared by thermal decomposition of ferrocene has been studied. The stability of the catalyst was evaluated in eight consecutive cycles of decomposition of MO. It was found that the conversion of MO reaches 99% in 3 min. The high activity is explained by the small size and high dispersion of Fe3O4 nanoparticles [27]. The decomposition of methyl orange under the action of hydrogen peroxide was also efficiently catalyzed by the Fe3O4/orange peel composite [48]. The degradation degree was close to 98% (20 min), which did not deteriorate in 10 consecutive cycles. A comparison with Fe3O4 showed the benefits of using the natural products in the composite: the degree of methyl orange decomposition on Fe3O4 was only 62.5%.

One of the recent papers describes a simple inexpensive catalyst for oxidation of days for the treatment of wastewater [49]. Magnetically separable Fe3O4/polyvinylpyrrolidone/polystyrene was used for the removal of azo dye acid red 18 with H2O2 as an oxidant. In the first step, PVP/PS microspheres were prepared by gamma-irradiation of styrene in polyvinylpyrrolidone; then, iron oxide was deposited on the surface of the microspheres. The size of the composite particles was 26 nm. The saturation magnetization was found to be 26.38 emu/g. It is noteworthy that the higher the saturation magnetization, the more efficient catalyst separation is possible. The extent of the dye removal reached 94.4% in 45 min and remained nearly unchanged in six cycles at pH 3. A mixture of different dyes was also tested and was efficiently destroyed.

Another example of the use of magnetic nanoparticles for Fenton-type destruction of azo dyes in water is reported by [50]. Sulfidation of magnetite nanoparticles provided much higher activity in Rhodamin B, as well as MB, MG, and AR-73 decomposition, compared with non-modified Fe3O4 nanoparticles in a broad pH range from 3 to 9.

A three-dimensional foam from reduced graphene oxide (RGO) with deposited Fe3O4 nanoparticles (3D-RGO-Fe3O4) was prepared using a hydrothermal method from graphene oxide (GO) and iron(2+) sulfate as precursors and used as an effective persulfate activator for glyphosate (GLY) degradation [30]. The effect of the Fe3O4 loading, pH, oxidant concentration, temperature, and introduced ions on the GLY degradation efficiency was studied in detail. Physicochemical methods, including scanning electron microscopy, Fourier transform infrared spectroscopy, and X-ray photoelectron spectroscopy, showed that the three-dimensional foam prevents aggregation of Fe3O4 nanoparticles due to in situ uniform formation on GO nanosheets. The addition of Fe is crucial for the activation of the oxidation system. The experimental data showed that the efficiency of GLY decomposition reached 96.8% at the initial concentration of GLY 30 mg L−1, a mass ratio of graphene:Fe3O4 of 1:7, pH of the solution = 4, and a mass of persulfate 48 mg. High temperatures contribute to a significant increase in GLY degradation. In addition, according to the results of repeated tests, the 3D-RGO-Fe3O4 catalyst turned out to be very stable. According to EPR spectroscopy data, the catalytic activation of Na2S2O8 using 3D-RGO- Fe3O4 mainly leads to the formation of OH and SO42− radicals, and the predominant radical is SO42−. It has been shown that 3D-RGO-Fe3O4 exhibits excellent catalytic activity and stability and, accordingly, has good prospects of application for the purification of water contaminated with organophosphorus herbicides.

The persulfate method of oxidation of drugs present in water was used by Zhang et al. [51]. The active species were assumed to be the SO42− radical, which is able to oxidize organic compounds, such as tetracycline, in an aqueous solution. Fe3O4 is supposed to act as an activator of persulfate, but the process is limited by the transition of Fe2+ to Fe3+. Therefore, the authors proposed to use Mo4+ in the molybdenum sulfide composition as a reducing agent preventing the above process. Using the developed rationale, the authors succeeded in reaching the removal efficiency of 91.8% for 20 mg·L−1 tetracycline water solution. The tetracycline molecules are converted by the reactions of hydroxylation, ketylation of the dimethylamino group, and breaking of C-N bonds.

The removal of tetracycline in wastewater was also effectuated by using magnetic Fe3O4–N-doped carbon sphere composites with peroxymonosulfate activation [52]. The materials were prepared by pyrolysis of chitosan–iron complexes. The synergistic effect was achieved by enhanced electron transport in the electroconducting material. The most important factor for magnetic separation was the value of the saturation magnetization, which was as high as 56 emu/g. The authors studied the effect of the process inhibition by anions present in wastewater and found the following order of the decreasing activity: Cl− > NO3− > SO42− > CH3COO− > HCO3−. Singlet oxygen was proposed as a key active species in this process, i.e., a non-radical mechanism is believed to predominate.

A combination of cellulose, carbon nanotubes, and magnetite turned out to be active in the removal of bisphenol A via an “enhanced non-radical oxidation” occurring in an alkaline-urea system with peroxydisulfate activated on the magnetite particles [53]. A 100% removal of bisphenol A in water was easily achieved with the possibility of magnetic separation of the catalyst without any iron leaching in the course of the advanced oxidation process.

The removal of phenol derivatives, namely tetrabromobisphenol A, was demonstrated for magnetic Fe3O4@ZIF-67 composites containing zeolite-like imidazolate framework ZIF-67 with activation of peroxymonosulfate [54]. It is noteworthy that the rate constant for the composite was about 2000 times higher than that for the Fe3O4 nanoparticles with peroxymonosulfate. Virtually the same composite was reported for the decomposition of ciprofloxacin in wastewater via an advanced oxidation process [55].

Cobalt-magnetite on hydroxyapatite core–shell nanoparticles revealed outstanding performance in the advanced oxidation process based on the use of persulfate anions and generation of sulfate radicals [56]. The degradation of a sulfanilamide drug as a representative of the class of antibiotics was studied using the developed nanocomposites. The concentration of sulfanilamide in water was reduced by 94% within 5 min. OH and SO42− radicals as well as singlet oxygen were revealed by the EPR method, which contributes mainly to the radical mechanism of the entire process. No significant Co or Fe leaching was found during the catalyst testing in the cyclic mode.

Another group of authors studied the oxidation of sulfonamides in water by molecular dynamics selection and mechanism analysis [57]. The selective recognition process was efficiently used to design the active centers for the advanced oxidation process.

As has already been mentioned, covalent organic frameworks (COFs) and metal–organic frameworks (MOFs) attract growing attention as matrices or components of magnetic nanocomposites because of their unique porosity, high adsorption capacity, and good stability of water or organic solvents. Therefore, composites based on a combination of magnetic materials with COFs or MOFs are intensively explored in the processes of the oxidation of dyes, drugs, and other organic pollutants in aqueous solutions. An efficient composite containing COF (TpMA) and magnetite has been designed [58]. The catalyst was prepared by ball milling and tested in methyl orange oxidation with hydrogen peroxide in water solutions with an efficiency of 88% within 40 min. It is noteworthy that the activity of the thus-prepared nanocomposite was 4–12 times higher than the activities of the individual components or their mechanical mixture.

Aniline removal in water has also been the focus of research [59]. Ferromagnetic Fe(II)-nano-Fe3O4@PAC composites supported onto powdered activated carbon (PAC) turned out to be an active catalyst with hydrogen peroxide as an oxidant providing an efficiency of 91.2% (30 min). A mixed homogenous/heterogeneous Fenton-like mechanism is proposed to explain the observed reaction kinetics.

Apart from iron-containing particles, Ni or Co-containing particles have been efficiently used as magnetic nanocatalysts for the removal of naproxene in water by using peroxymonosulfate as an oxidant [60]. NiCo-layered double hydroxides (Fe3O4@NiCo) removed 83.9% of naproxene in 20 min and withstood five cycles of recyclization.

10. Catalysis of Sulfide Oxidation

The oxidation of sulfur-containing compounds is of great importance for both organic syntheses and desulfurization of fuels [61,62].

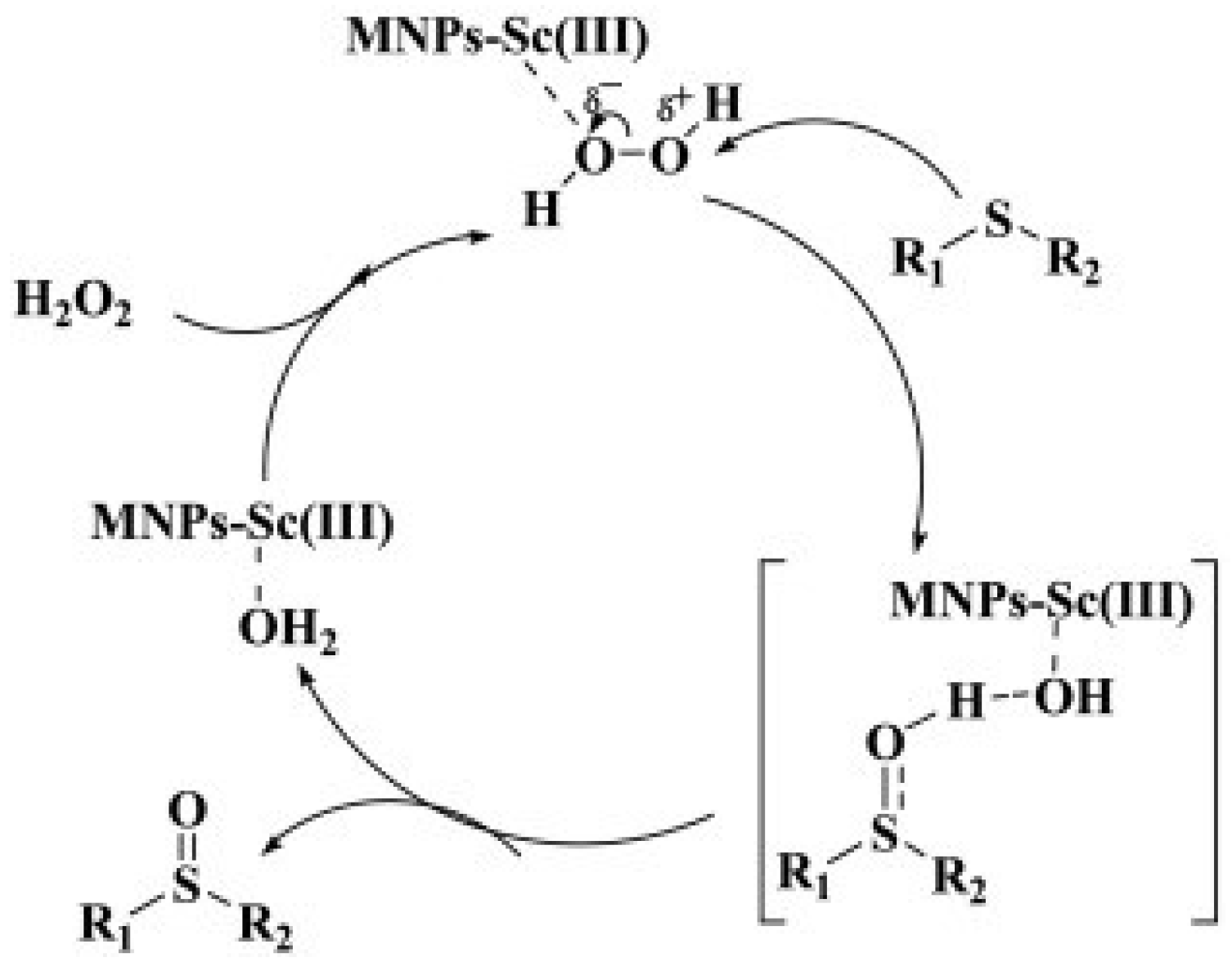

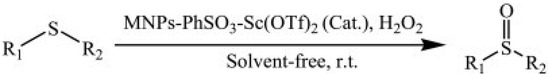

A scandium(III)-based catalyst (MNSPs-PhSO4-Sc(OTf)) has been developed for the oxidation of sulfides to sulfoxides; the catalytic system was synthesized by immobilization of scandium triflate onto magnetic nanoparticles functionalized with sodium benzenesulfonate [28]. To find optimal reaction conditions, the effect of various amounts of a catalyst and hydrogen peroxide on the process of oxidation of methylphenyl sulfide as a model compound in the absence of a solvent at 20 °C was studied (Figure 8). The average size of the composite nanoparticle was smaller than 22 nm.

Figure 8.

The oxidation of methylphenyl sulfide on the catalyst MNSPs-PhSO4-Sc(OTf).

The catalyst showed excellent activity, and products with yields from 90 to 98% were obtained in a short reaction time using H2O2 as a benign oxidizer. The system also combined the benefits of homogeneous Sc(III)-containing catalysts (high activity and reproducibility) and those of heterogeneous materials (simple procedure of separation and outstanding reusability, 15 cycles), making it a promising candidate for practical and large-scale application.

A possible reaction mechanism is proposed (Figure 9), where it is assumed that scandium (III) polarizes the O–O bond in H2O2 to form an intermediate for the transfer of reactive oxygen and then the transfer of oxygen to sulfide.

Figure 9.

The mechanism of sulfide oxidation on a Sc-based catalyst. Reproduced with permission from [28].

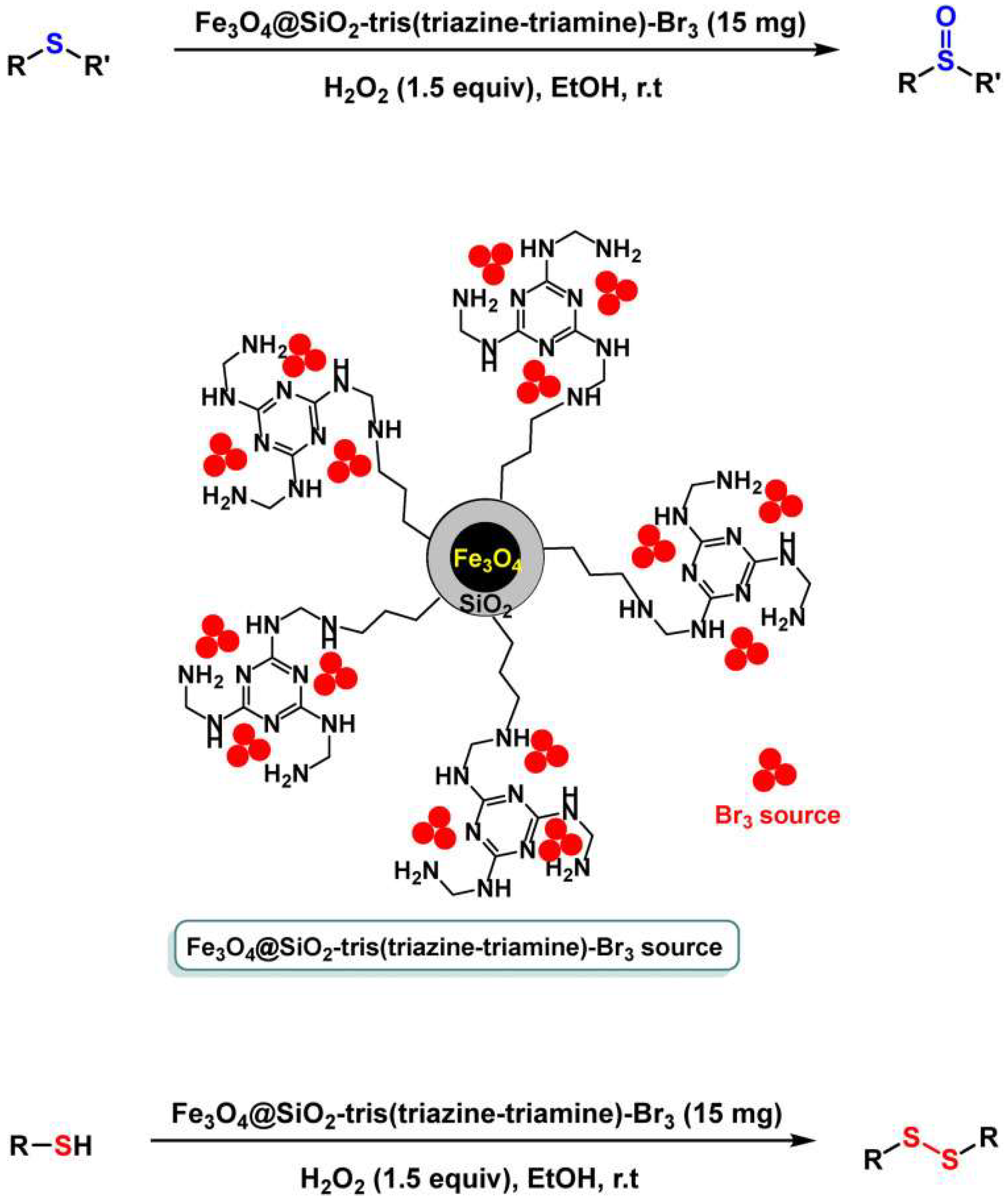

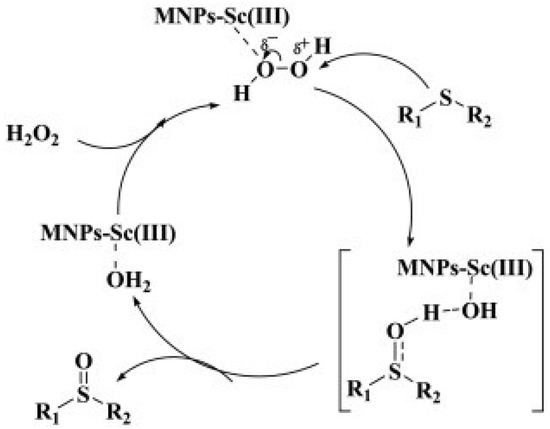

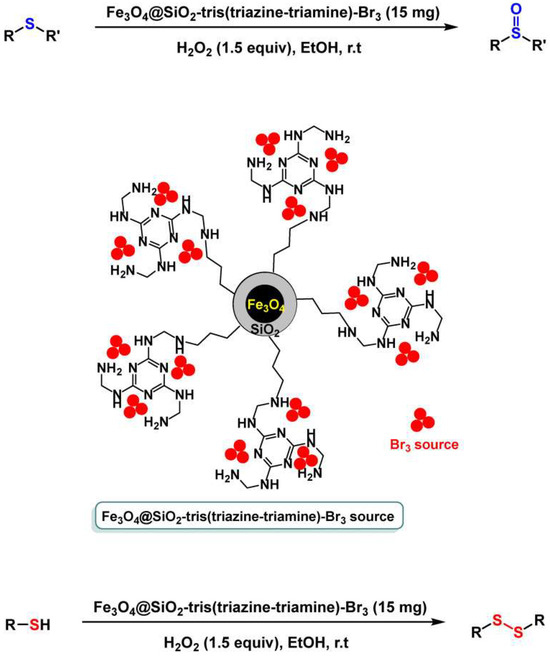

For the oxidation of sulfides into sulfoxides and oxidative coupling of thiols, a regenerable catalyst was designed with tribromide placed on the surface of magnetite covered with silicon dioxide, which was in turn functionalized with N2,N4,N6-tris(aminomethyl)-1,3,5-triazine-2,4,6-triamine (Fe3O4@SiO2-tris(triazine-triamine)-Br3) [29]. The catalyst has been repeatedly used in the oxidation of disulfides with hydrogen peroxide as an environmentally friendly oxidizer. The analysis by scanning and transmission electron microscopy confirmed that the typical thickness of the silica shell is about 20 nm. It has been shown that the Fe3O4@SiO2-tris(triazine-triamide)-Br3 catalyst can be easily extracted by simple magnetic separation and used six times with no deterioration of the catalytic performance (Figure 10).

Figure 10.

Fe3O4@SiO2-tris(triazine-triamide)-Br3 catalyst and its activity towards the oxidation of sulfides. Reproduced with permission from [29].

Apart from magnetite, mixed metal oxides of the iron triad can be used as magnetically separable catalysts. One of the examples is a CoFe2O4@aminoglycol/Gd composite [63]. The composite contains 2-amino-2-methyl-1,3-propanediol as an aminoglycol tethered to the surface of the magnetic CoFe2O4 material. The catalyst has been tested six times in the oxidation of sulfides in an aqueous medium under mild conditions with consequent magnetic separation of the catalyst.

Heteropolyacids are known as efficient catalysts of the desulfurization of fuel, but they are not easily recyclable unless supported on a solid carrier, and even in this case, their stability may be insufficient for practical application. Li et al. proposed a combination of four components in one composite to assure magnetic separation, catalytic activity, stability, and the preservation of leaching: Fe3O4, mesoporous SiO2 (MCM-41), heteropolyacid, and APES as a linker between mesoporous silica and heteropoly acid [64]. Air was used to oxidize dibenzothiphene, and the catalyst exhibited a 100% conversion within 90 min of testing in each of the eight runs.

11. Oxidation of D-Glucose

D-glucose oxidation leads to the production of important products in biotechnology—D-gluconic acid and its salts. The oxidation of D-glucose is carried out using an enzyme of the oxidoreductase class, glucose oxidase. However, the use of native forms of enzymes is difficult and economically unprofitable. The solution to these problems is the immobilization of enzymes in various organic and inorganic media.

The process of D-glucose oxidation to D-gluconic acid in the presence of magnetically separable biocatalysts based on glucose oxidase has been studied [65]. New biocatalysts have been synthesized by the covalent binding of glucose oxidase to the initial and magnetically separated mesoporous oxides of silicon, aluminum, and zirconium. To obtain magnetically separable carriers, silicon oxide and aluminum oxide are used, with magnetic nanoparticles being synthesized in the pores of these oxides due to the thermal decomposition of iron nitrate. Glucose oxidase is then covalently bound using glutaraldehyde to the surface of carriers pre-functionalized with amino groups using 3-aminopropyltriethoxysilane. A low-temperature nitrogen adsorption study for silicon, aluminum, and zirconium oxides has shown that they belong to mesoporous materials with a pore size of 4–8 nm. Transmission electron microscopy and X-ray diffraction data have shown that magnetite nanoparticles are formed in the pores (size of the nanoparticles: 4–8 nm) and at the junctions of pores (size: 12–13 nm). The magnetization curves confirm that the obtained Fe3O4 nanoparticles, regardless of the nature of the oxide, have superparamagnetic properties. For magnetically separable biocatalysts, it is found that the inclusion of magnetite nanoparticles increases the relative activity by 7–10%, which is due to the correlation between the glucose oxidase activity and the enzyme-like activity of Fe3O4. Magnetically separable biocatalysts Fe3O4-SiO2-GOx, Fe3O4-Al2O3-GOx, and Fe3O4-ZrO2-GOx show 95%, 93%, and 98% activity of the native enzyme in the oxidation of D-glucose, respectively. Kinetic parameters are calculated, and it is demonstrated that the greatest affinity of the substrate and the enzyme is observed for the Fe3O4-ZrO2-GOx biocatalyst. The stability of glucose oxidase immobilized on magnetically separable mesoporous oxides during the D-glucose oxidation to D-gluconic acid has been studied. In 10 consecutive cycles, the best magnetically separable biocatalyst Fe3O4-ZrO2-GOx loses no more than 7% of its activity, which is explained by the high abrasion resistance of ZrO2. The high enzymatic activity of biocatalysts in a wide range of pH and temperature makes them promising for practical use. The most efficient performance was obtained for the immobilized enzyme for the Fe3O4-SiO2-GOx sample (Km = 118 mM, Vmax = 152 µm/min).

Authors from the same team [66] reported on the activity of the biocatalysts based on magnetite nanoparticles covered with a thin layer (0.9 nm) of chitosan that has been cross-linked by sodium tripolyphosphate. Glucose oxidase was tethered to the carrier by the reaction with N-hydroxysuccinimide and carbodiimide. Using the approach developed in this work, the authors succeeded in increasing the yield of D-gluconic acid. The formation of a chemical bond with the biocatalyst preserves the catalyst from leaching.

12. Other Oxidation Reactions

For the electrocatalytic oxidation of methanol and ethanol, the catalysts ZnO, ZnO-MWCNT, and ZnO-MWCNT@Fe3O4 were designed and prepared by the hydrothermal method, and their structure and morphology were established using various physico-chemical methods [67]. It was shown that the addition of multi-walled carbon nanotubes decorated with Fe3O4 into the zinc oxide structure creates active oxidation centers and increases the conductivity and specific surface area of the catalyst. The synergistic effects of placing the catalyst components on top of each other increase the ability of ZnO-MWCNT@Fe3O4 to oxidize methanol and ethanol, and outstanding stability is maintained for 500 cycles during the methanol oxidation process.

An interesting application of a magnetic nanocatalyst based on iron hematite–magnetite composite supported on mesoporous SBA-15 synthesized by using silica from cogon grass was reported by Kulawong et al. [68]. They studied phenol hydroxylation with hydrogen peroxide to produce a mixture of two dihydroxybenzenes, catechol, and hydroquinone; heterogeneous iron-containing catalysts are known to have been active in this reaction. The Fe2O3–Fe3O4/SBA-15 composite demonstrated the highest conversion achieving 88% and the hydroquinone selectivity of 46%, which is higher compared to single-phase catalysts Fe2O3/SBA-15 and Fe3O4/SBA-15. Only the catalysts containing the Fe3O4 particles can be used with magnetic separation of the catalyst from the reaction mixture, with up to four cycles of recyclization without any loss of activity. However, in the case of the Fe3O4/SBA-15 system, the authors observed iron leaching and a partial decrease in activity.

13. A Critical Analysis of the Use of Magnetic Nanoparticles in Oxidation Reactions: Advantages and Disadvantages

Naturally, magnetic nanoparticles can be used in gas-phase reactions as well, although there is no need for magnetic separation in this case. Therefore, most examples of the use of magnetic materials in catalysis with further magnetic extraction of the catalyst from the reaction media are related to liquid-phase reactions. Most of them proceed under mild conditions (T, P), and there are many examples of the use of such nanocatalysts in aqueous solutions/suspension as a “green” approach to catalysis. There are no ideal catalysts, and magnetic catalysts are no exception; they are characterized by definite advantages but have also certain drawbacks. The benefits and limitations of magnetic nanocatalysts are summarized in Table 4.

Table 4.

Advantages and limitations of magnetic nanocatalysts.

Some of the advantages listed in Table 4 are questionable; therefore, we put a question mark next to them. We need to distinguish the magnetic nanoparticles themselves in the composition of the nanocomposite and the particles of the composite containing such magnetic nanoparticles. Even the possibility of separation from the reaction medium several times (5–10 times) without losing the activity may be realized for a limited number of magnetic nanocomposites. In most cases, the authors declare the stability or a small decrease of the activity only for 3–6 runs. To the best of our knowledge, there are no papers demonstrating recyclization in more than 10 cycles.

The claimed low toxicity or non-toxicity of magnetic nanocomposites may not be so low. Indeed, Fe3O4 nanoparticles are conventionally non-toxic, but the composite nanoparticles may contain Pd, Cu, and some organic molecules as ligands that are considered rather toxic. The cost of Fe3O4 as a chemical is very low, but the cost of Fe3O4 nanoparticles is about two orders higher, not to mention the cost of composite nanoparticles, which may include very expensive components such as Pd or organic ligands. Even the availability of nanocomposite nanoparticles is doubtful. The Fe3O4 nanoparticles can be prepared and are available, but the nanoparticles of a composite are a design product with limited stability and availability in the market. Finally, the easiness and simplicity of preparation evoke some doubts because the examples of one-step syntheses are very rare, which means that the synthesis of composite nanoparticles includes usually 2–4 stages with intermediate treatments, separation, washing, drying, solvent evaporation, etc. The composite nanoparticles in most cases represent multiple core–shell spherical particles with Fe3O4 nanoparticles used as a core or outer shell or placed inside cavities, as in the case of hollow materials. Thus, the preparation of such nanocomposites seems easy, but may not be “green” in terms of the use of solvents and energy consumption. It should be noted that microwave heating reduces the latter, and its efficiency has been demonstrated in several cases [69], such as the sonochemical treatment.

Turning to limitations, we should stress that leaching of active components has been reported in a fair number of cases of the use of Pd and Cu-containing magnetic nanocatalysts; iron leaching was even observed. The decrease in saturation magnetization may result in almost complete loss of the possibility of magnetic separation. Indeed, Fe3O4 nanoparticles themselves are characterized by rather high values of saturation magnetization ranging from 70 to about 90–95 emu/g. When the shell is built over the Fe3O4 nanoparticles, their magnetic properties are quenched because the shells are usually diamagnetic, i.e., they dilute the magnetic material and make it less acceptable to extraction with an external magnet. In some cases considered in this review, the saturation magnetization of the composite nanoparticles decreases to 10–15 emu/g or even 2 emu/g, which is not acceptable. The limited accessibility of active sites is not a rare case because the layer-by-layer construction of the composite nanoparticles creates additional diffusion constraints, especially when the nanocomposites contain from three to four levels of complexity. Now we have arrived at the complicated composition and structure of the nanocomposites: most of them appear to be tailor-made materials; the choice of the components is made on the basis of significant experimentation and optimization. Last but not least is the issue of the limited number of magnetic compounds with acceptable characteristics. Magnetite (Fe3O4) is nigh on perfect: it is cheap, highly magnetic, available, and non-toxic. However, other magnetic materials may not quite satisfy at least one or even all of these criteria.

The magnetic properties of materials depend on their chemical composition, morphology, size of particles, and the presence of linked diamagnetic (or other type) components [70,71,72,73,74]. It should be noted that we failed to find any papers in the literature where the size effect of magnetic nanoparticles on their catalytic activity/selectivity pattern in oxidation reactions is studied and a structure–activity relationship is found. Some data on the size effect on the magnetic properties of iron-containing materials are presented in the review by Kolhatkar [68], but they are very contradictory.

One has to distinguish between ferromagnetic materials and superparamagnetic materials. The latter are characterized by zero saturation magnetization in the absence of an external magnetic field; this behavior is found only in nanoparticles. Superparamagnetism is especially important in catalytic applications; the superparamagnetic nanoparticles show no magnetic properties after the removal of the external field and therefore have no attraction between each other, thereby minimizing their aggregation.

14. Challenges and Future Perspectives

The following conclusions can be drawn from the above analysis of the recent literature data on the use of magnetite nanoparticles in diverse nanocomposites in catalytic applications:

- (1)

- Magnetite itself usually demonstrates poor catalytic properties, except for Fenton-like reactions, the oxidation of benzylic alcohols, and advanced oxidation processes. In most cases, magnetite is used in nanocomposites as a catalyst carrier due to its unique magnetic properties, which allow its quick separation from the reaction medium.

- (2)

- Various organic ligands and polymers are used to functionalize and protect magnetite, including biomolecules and “green” molecules derived from natural products.

- (3)

- Studies of the structure of magnetite-based nanocomposites have shown that they have a core–shell structure. The specific surface area and adsorption properties of the carrier play an important role in the effectiveness of magnetite-based nanocomposites in catalysis.

Significant progress has been made in the development of magnetically separable catalysts; however, further work is needed to discover other new applications for these catalysts.

Thus, by varying the methods of preparation of these catalysts, and using surface studies and theoretical studies of the mechanisms of processes, it will be possible to develop new highly stable and selective catalysts in the future.

Future activities, as we may predict, may be focused on the following issues:

- Search for new magnetite-based composites with a core–shell structure with enhanced performances in diverse catalytic applications, including the reactions discussed in this mini-review;

- Extension of the areas of the application of magnetic nanomaterials based on magnetite and the like in new catalytic reactions, such as biomass valorization and waste processing into value-added products, including plastic waste; hydrogen storage in the form of liquid organic hydrogen carriers based on reversible hydrogenation-dehydrogenation processes; and carbon dioxide utilization via its conversion into organic carbonates, carboxylic acids, alcohols, etc. under catalytic, photocatalytic and electrocatalytic conditions, just to mention a few hot topics;

- Improvement of the stability of magnetic nanocomposites to prevent leaching and decomposition of the composite structure;

- Design of magnetic materials with increased magnetization, since the nanoparticles and composites are known to exhibit lower magnetization saturation (below 70–90 emu/g) than bulk magnetite;

- Development of novel inexpensive magnetic nanoparticles, different from iron-based magnetite or maghemite materials, perhaps spinel-like MeFe2O4 materials, with better stability and compatibility in the composition of composites, including prevention of leaching;

- Further development of the strategy of functionalization of composite nanoparticles by adjusting the nature of the modifying ligands to the nature of the reaction media/solvent; the TEG-tagged (triethyleneglycol) strategy [6] or similarly designed ligands seem to be a promising and valuable approach for the catalytic applications in aqueous solutions, which combines the benefits of homogeneous, heterogeneous and magnetically separable systems;

- Revealing the effect of the size of nanoparticles, their morphology, and the role of these factors in catalytic applications (not only oxidation reactions), which would be beneficial for the tailor-made design of magnetic nanocomposites;

- The use of magnetic fluids, such as magnetic ionic liquids, as carriers for catalytically active phases or sites, which may pave a new way for future research.

Author Contributions

Conceptualization, S.I.P. and L.M.K.; methodology and formal analysis, E.G.C., R.I.J. and O.N.B.; writing—original draft preparation, S.I.P., O.N.B. and L.M.K.; writing—review and editing, L.M.K.; funding acquisition, L.M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Russian Science Foundation (grant no. 23-73-30007).

Data Availability Statement

Data are available upon request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kustov, L.M.; Kostyukhin, E.M.; Korneeva, E.Y.; Kustov, A.L. Microwave synthesis of nanosized iron-containing oxide particles and their physicochemical properties. Russ. Chem. Bull. 2023, 72, 583–601. [Google Scholar] [CrossRef]

- Martínez-Navarro, B.; Sanchis, R.; Asedegbega-Nieto, E.; Solsona, B.; Ivars-Barceló, F. (Ag)Pd-Fe3O4 Nanocomposites as Novel Catalysts for Methane Partial Oxidation at Low Temperature. Nanomaterials 2020, 10, 988. [Google Scholar] [CrossRef] [PubMed]

- Kirillova, M.V.; Santos, C.I.M.; Wu, W.; Tang, Y.; Kirillov, A.M. Mild oxidative C−H functionalization of alkanes and alcohols using a magnetic core-shell Fe3O4@mSiO2@Cu4 nanocatalyst. J. Molec. Catal. A Chem. 2017, 426, 343–349. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, J.; Wang, H.; Yang, C.; Cheng, H.; Deng, Y.; Cheng, L.; Fang, Y. Photothermal oxidation of cyclohexane by graphene oxide-based composites with high selectivity to KA oil. Molec. Catal. 2020, 493, 111103. [Google Scholar] [CrossRef]

- Martins, N.M.R.; Pombeiro, A.J.L.; Martins, L.M. Green oxidation of cyclohexane catalyzed by recyclable magnetic transition-metal silica coated nanoparticles. Catal. Commun. 2019, 125, 15–20. [Google Scholar] [CrossRef]

- Karimi, B.; Ghaffari, B.; Hojatollah Vali, H. Synergistic catalysis within core-shell Fe3O4@SiO2 functionalized with triethylene glycol (TEG)-imidazolium ionic liquid and tetramethylpiperidine N-oxyl (TEMPO) boosting selective aerobic oxidation of alcohols. J. Colloid Interface Sci. 2021, 589, 474–485. [Google Scholar] [CrossRef]

- Ghosh, T.; Choudhary, N.; Mobin, S.M. Design and Synthesis of Silver Decorated Fe3O4@Fe Doped CeO2 Core-Shell Ternary Composite as Highly Efficient Nanocatalyst for Selective Oxidation of Alkenes. ChemistrySelect 2020, 5, 9601–9606. [Google Scholar] [CrossRef]

- Ghosh, T.; Chandra, P.; Mohammad, A.; Mobin, S.M. Benign approach for methyl-esterification of oxygenated organic compounds using TBHP as methylating and oxidizing agent. Appl. Catal. B 2018, 226, 278–288. [Google Scholar] [CrossRef]

- Sarkheil, M.; Lashanizadegan, M. Copper(II) Schiff Base Complex Immobilized on Superparamagnetic Fe3O4@SiO2 as a Magnetically Separable Nanocatalyst for Oxidation of Alkenes and Alcohols. Appl. Organomet. Chem. 2017, 31, e3726. [Google Scholar] [CrossRef]

- Mingalev, P.G.; Lisichkin, G.V. Magghemite as a catalyst for alcohol oxidation with air. Neftekhim 2020, 60, 341–346. [Google Scholar]

- Wen, L.; Wang, D.; Xi, J.; Tian, F.; Liu, P.; Bai, Z.W. Heterometal modified Fe3O4 hollow nanospheres as efficient catalysts for organic transformations. J. Catal. 2022, 413, 779–785. [Google Scholar] [CrossRef]

- Xiong, L.; Chen, R.; Chen, F. One-step solvothermal synthesis of Al-promoted Fe3O4 magnetic catalysts for the selective oxidation of benzyl alcohol to benzaldehyde with H2O2 in water. RSC Adv. 2016, 6, 101048–101060. [Google Scholar] [CrossRef]

- Prathibha, E.; Rangasamy, R.; Sridhar, A.; Lakshmi, K. Synthesis and Characterization of Fe3O4/Carbon Dot Supported MnO2 nanoparticles for the Controlled Oxidation of Benzyl Alcohols. ChemistrySelect 2020, 5, 988–993. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, X.; Yan, Y.; Zhou, J.; Zhang, W.; Tai, X. Bimetallic Gold-Silver Nanoparticles Supported on Zeolitic Imidazolate Framework-8 as Highly Active Heterogenous Catalysts for Selective Oxidation of Benzyl Alcohol into Benzaldehyde. Polymers 2018, 10, 1089. [Google Scholar] [CrossRef]

- Keshipour, S.; Al-Azmi, A. Synthesis and catalytic application of Pd/PdO/Fe3O4@polymer-like graphene quantum dots. Appl. Organometal. Chem. 2019, 34, e5311. [Google Scholar] [CrossRef]

- Norouzi, M.; Elhamifar, D. Ionic liquid-modified magnetic mesoporous silica supported tungstate: A powerful and magnetically recoverable nanocatalyst. Compos. Part B 2019, 176, 107308. Available online: https://www.sciencedirect.com/science/article/pii/S1359836818342458 (accessed on 17 November 2024). [CrossRef]

- Bakhtiarzadeh, Z.; Rouhani, S.; Karimi, Z.; Rostamnia, S.; Msagati, T.A.M.; Kim, D.; Jang, H.W.; Ramakrishna, S.; Varma, R.S.; Shokouhimehr, M. Hydrothermal self-sacrificing growth of polymorphous MnO2 on magnetic porous—Carbon (Fe3O4@Cg/MnO2): A sustainable nanostructured catalyst for activation of molecular oxygen. Molec. Catal. 2021, 509, 111603. [Google Scholar] [CrossRef]

- Sharma, H.; Sharma, S.; Sharma, C.; Paul, S.; Clark, J.H. Magnetically recoverable graphene oxide supported Co@Fe3O4/L-dopa for C-C cross-coupling and oxidation reactions in aqueous medium. Molec. Catal. 2019, 469, 27–39. [Google Scholar] [CrossRef]

- Ansari, S.A.; Alameri, A.A.; Pradhan, R.; Jabbar, S.H.; Jalil, A.T.; Zabibah, R.S.; Kazemnejadi, M. Unsymmetric bi-functional Mn-salen complex bearing TEMPO and Mn-complex for the synthesis of magnetic Mn/TEMPO-doped Fe3O4 NPs: A simple catalyst (magnetic oxidant) for selective oxidation of alcohols. Res. Chem. Intermed. 2023, 49, 399–422. [Google Scholar] [CrossRef]

- Jaiswal, R.; Ranganath, K.W.S. Carbon Nanoparticles on Magnetite: A New Heterogeneous Catalyst for the Oxidation of 5-Hydroxymethylfurfural (5-HMF) to 2,5-Diformylfuran (DFF). J. Inorg Organometal. Polym. Mater. 2021, 31, 4504–4511. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, W.; Zeng, L.; Zhang, F.; Liu, J. Selenium-directed synthesis of Pd nanoparticles on mesoporous silica-coated Fe3O4: An efficient magnetic catalyst for oxidative alkene cracking. Catal. Commun. 2020, 142, 106031. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Zhang, X.; Wang, S.; Xia, Z.; Zeng, G.; Ding, J.; Ren, N. Construction of Fe3O4@β-CD/g-C3N4 nanocomposite catalyst for degradation of PCBs in wastewater through photodegradation and heterogeneous Fenton oxidation. Chem. Eng. J. 2022, 429, 132445. [Google Scholar] [CrossRef]

- Yin, Y.; Ren, Y.; Lu, J.; Zhang, W.; Shan, C.; Hua, M.; Lv, L.; Pan, B. The nature and catalytic reactivity of UiO-66 supported Fe3O4 nanoparticles provide new insights into Fe-Zr dual active centers in Fenton-like reactions. Appl. Catal. B 2021, 286, 119943. [Google Scholar] [CrossRef]

- Zhang, A.; Zhu, L.; Nan, Z. Ni-doped Fe3O4 nanoparticles coupled with SnS2 nanosheets as 0D/2D heterogeneous catalyst for photo-Fenton reaction. Mater. Chem. Phys. 2019, 224, 156–168. [Google Scholar] [CrossRef]

- Zhang, F.; Xue, X.; Huang, X.; Yang, H. Adsorption and heterogeneous Fenton catalytic performance for magnetic Fe3O4/reduced graphene oxide aerogel. J. Mater. Sci. 2020, 55, 15695–15708. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Zhang, L.; Ma, L.; Li, Y.; Zhong, C. Fe3O4@Cu/C and Fe3O4@CuO Composites Derived from Magnetic Metal-Organic Frameworks Fe3O4@HKUST-1 with Improved Peroxidase-Like Catalytic Activity. Catal. Lett. 2020, 150, 815–825. [Google Scholar] [CrossRef]

- Jia, X.; Chen, X.; Liu, Y.; Zhang, B.; Zhang, H.; Zhang, Q. Hydrophilic Fe3O4 nanoparticles prepared by ferrocene as high-efficiency heterogeneous Fenton catalyst for the degradation of methylorange. Appl. Organometal. Chem. 2019, 33, e4826. [Google Scholar] [CrossRef]

- Khaledian, D.; Rostami, A.; Rouhani, S. Magnetic core-shell nanoparticle-supported Sc (III): A novel and robust Lewis acid nanocatalyst for the selective oxidation of sulfides to sulfoxides by H2O2 under solvent-free conditions. Catal. Commun. 2019, 124, 46–50. [Google Scholar] [CrossRef]

- Abdalkareem, J.S.; Mohsen, A.M.; Hussien, M.; Catalan Opulencia, M.J.; Majdi, A.; Tillaeva, G.U.; Kadhim, M.M.; Yasin, G. Tribromide immobilized on surface of magnetic nanoparticles modified tris(triazine-triamine): A versatile and highly active catalyst for oxidation of sulfides and oxidative coupling of thiols. Phosphorus Sulfur Silicon Relat. Elem. 2023, 198, 92–101. [Google Scholar] [CrossRef]