Abstract

Ag2MoO4 crystals were prepared by a precipitation method by mixing parent solutions of silver nitrate and sodium molybdate. The effects of experimental parameters such as temperature, concentration, and pH were studied. The samples were found to be crystalline, pure, and monophasic in all cases, except in the case of very low pH. The precipitation leads to the formation of the cubic phase β and no secondary phase is present within the limits of detection of XRD and Raman spectroscopy. However, in some cases, at high temperature and high pH, silver oxide nanoparticles form on the surfaces of the crystals, which create a fluorescence background in the Raman spectra, which is otherwise absent. Analyses with the electron microscope have highlighted that the most common crystalline shape is octahedral, which is the most prevalent at low temperatures and pH around 7, but others are also possible, in particular at high temperatures. No growth occurs after precipitation, so crystals with different appearances form at the same time.

1. Introduction

Ag2MoO4 is an interesting semiconductor, with a band gap around 3.30 eV [1,2], depending on the polymorph, and it has recently been attracting a lot of interest for its excellent properties, that can find applications in many fields. It has a high electrical conductivity [3], exhibits photoluminescence [3,4], suggesting a possible use as a sensor, it has been claimed that it could be use as supercapacitor [5], it is an excellent catalyst for many organic reactions [6,7,8], and it has shown good antimicrobial capabilities [2,9,10]. These aspects are also combined with very low toxicity [9] and excellent ease of chemical synthesis [1,3].

This material has been synthesized by many different routes, including solid-state reactions, classical or microwave-assisted hydrothermal methods, and sonochemical processes [3]. However, considering its high insolubility in water, (pKs = 11.6), one of the most practical ways to obtain it is through a controlled precipitation process. When distinct solutions containing Ag+ and MoO42− ions, respectively (for instance a solution of AgNO3 and one of Na2MoO4), are mixed, microcrystals of the desired phase are rapidly formed, which can be easily recovered using traditional methods, such as simple filtration.

Precipitation is in general an efficient chemical method for the preparation of many materials, such as oxides, halides, phosphates, and others and allows, if operating conditions are correct, to obtain high purity, crystalline, and good quality phases [10]. It is also possible in certain cases to induce a desired level of doping in the crystals or even to obtain phases with an intermediate composition between pure compounds. By changing the nature of the solvent, in terms of pH, concentration, ionic strength, etc., or parameters such as temperature or pressure, it is possible to obtain preferential crystallization of a specific polymorph, not necessarily the most thermodynamically stable one. For example, it is possible to prepare pure calcite or aragonite, two polymorphs of calcium carbonate, or a mixture of the two, changing the temperature at which the precipitation occurs [11].

In the case of Ag2MoO4, precipitation leads to the formation of the β phase that is cubic, with cell parameter a = 9.3130 Å, space group F d −3 m [1,2], and it belongs to the spinel group, A2BX4, being a rare combination of monovalent and hexavalent cations.

Chemical-physical properties of Ag2MoO4 prepared by the precipitation route have been largely studied and well described in the scientific literature, because of the importance of this material. However, some aspects of crystal growth itself have not been studied extensively.

It is well known that, in general, parameters such as temperature, concentration, pH, and others play an important role in the formation of crystals, with regard to their average size and distribution, shape (i.e., the specific geometric form that a crystal takes based on its internal cell symmetry, such as cubes, prisms, or pyramids, that a crystal can exhibit based on its internal atomic arrangement), and crystalline habits, which representsthe geometric appearance of an individual crystal or aggregate of crystals, and that could be acicular, tabular, or striated, which is determined by length, width, and numbers of crystal faces [10,12,13]. It can be expected that factors affecting crystal growth in Ag2MoO4 could lead to changes in the final appearance of crystals.

The present work aims to study the formation and growth of crystals of this material, prepared with a simple precipitation method. The formation of crystals by precipitation is a simple and direct method, which does not require a sophisticated apparatus with a very rigorous control of conditions, as in hydrothermal or sonochemical methods, and can often do without particular or harmful solvents. For this reason, it makes sense to investigate the effects of experimental conditions on the growth of crystalline particles. Parameters such as temperature, pH, concentration, or ionic strength can be expected to play an important role. In many systems, it is actually observed that by changing them the crystals that form can be very different. And this, despite the fact that, in an aqueous solution, obviously the range in which they can vary is narrow. In this specific case, however, these correlations have not so far been thoroughly investigated and this work aims to provide useful and new information in this regard. Ag2MoO4 crystals have been obtained by many methods, but how conditions influence their formation has not been systematically studied and this work has the aim of studying the correlation between the crystals that form and the experimental parameters that can be easily set.

2. Experimental Section

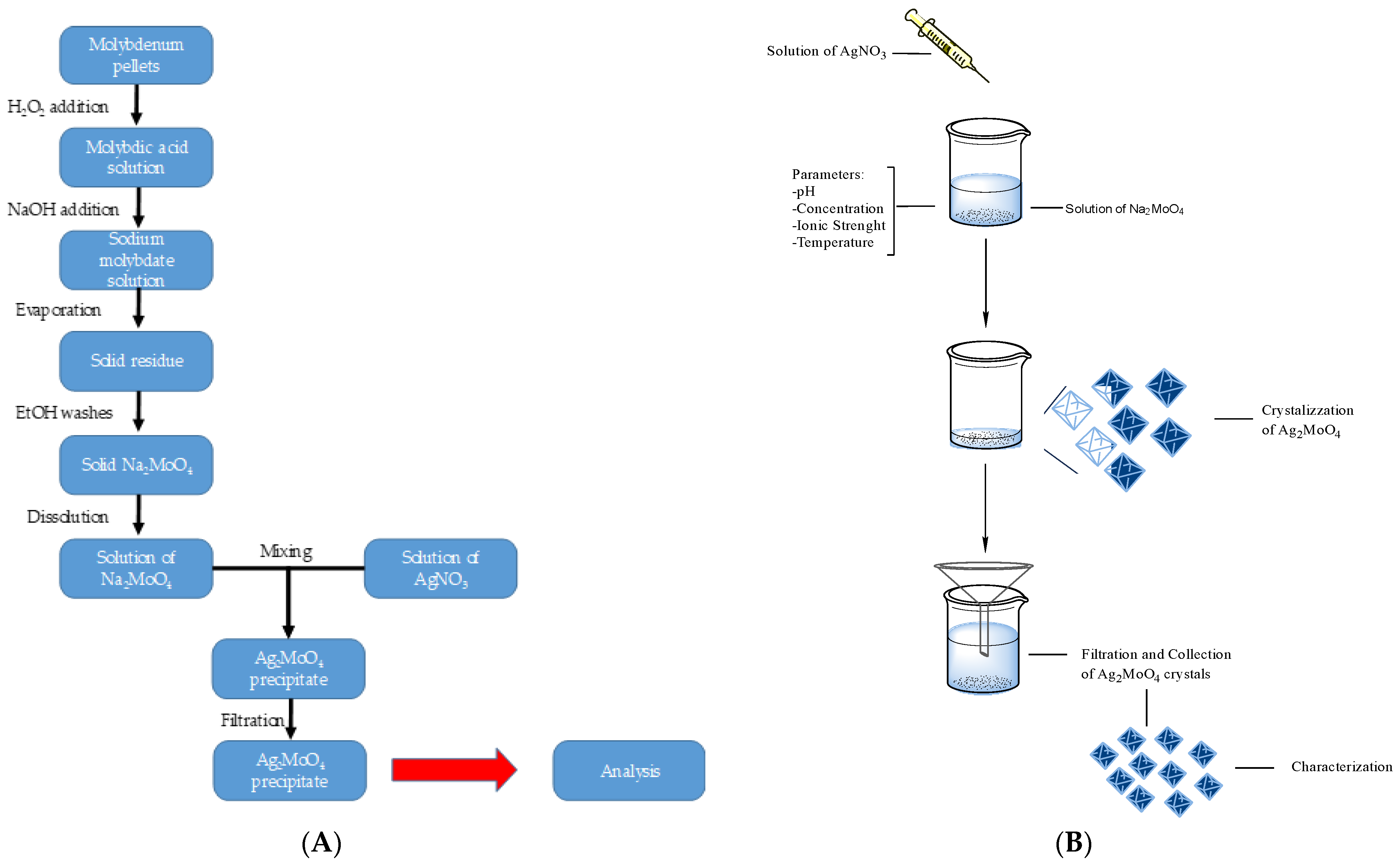

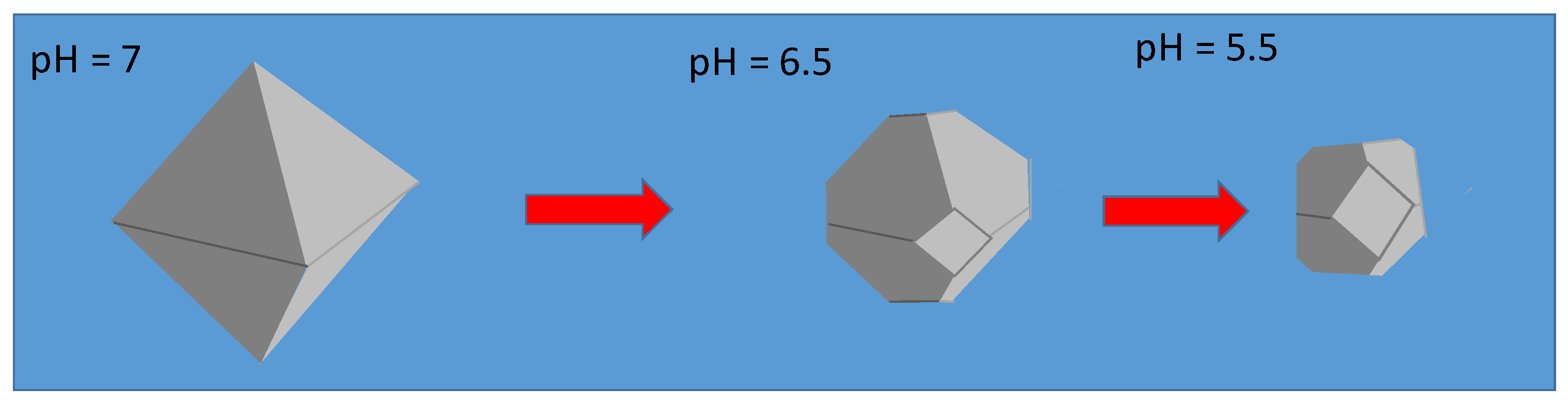

Crystals of Ag2MoO4 were prepared by the precipitation route by mixing liquid solution of AgNO3 (Carlo Erba Reagents, Milano, Italy, purity 99.8%) and Na2MoO4 under different conditions. In turn, Na2MoO4 was prepared from metallic Mo (Luoyang Combat Tungsten & Molybdenum Material Co., Ltd. (Luoyang, China), purity = 99.9%) by reaction with H2O2 35% (Carlo Erba Reagents), according to [14,15]. Solid Molybdenum reacts quickly with hydrogen peroxide, leading to a clear solution of molybdic acid (H2MoO4). Raising pH, by NaOH 1M (PanReac AppliChem Itw Reagents, Darmstadt, Germany) additions up to at least 12/13, the sodium molybdate solution was obtained. It was dried to eliminate the solvent and the solid residue was subsequently washed numerous times with ethanol to eliminate the excess of NaOH. The final purity of this compound was verified by Raman spectroscopy and X-ray diffractometry. Once Na2MoO4 was prepared, it was dissolved again in pure de-ionized water (resistivity 18.2 MOhm cm−1) that was obtained from a Milli-Q Advantage A10 water purification system (Millipore, Bedford, MA, USA) and precipitation was achieved under different operating conditions. Figure 1A shows a flowchart of the process and Figure 1B shows the experimental set-up. The experiments were conducted by slowly adding the AgNO3 solution to the Na2MoO4 solution, changing the parameters from time to time. The two stock solutions were first held at the same temperature before mixing.

Figure 1.

Synthesis of Ag2MoO4 flow chart (A) and experimental set-up for the Ag2MoO4 precipitation (B).

The reaction between the two parent solutions in the stoichiometric ratio was carried out at different temperatures: 4 °C, 25 °C, 50 °C, and 90 °C. In the case of the highest temperature, the effect of time was also studied: the samples remained in equilibrium with their mother solutions for 10 min, one hour, and two hours. Furthermore, in one case, the sample was immediately cooled with an ice bath. The concentration of the parent solutions was also investigated, changing between [MoO42−] = 0.004 M, 0.02 M and 0.04 M, at 50 °C (always in the ratio Ag: Mo = 2:1).

The effect of pH was investigated by carrying out precipitation at pH = 1, 5.5, 7, 9.5 and 12. The precipitations, when pH was lower than 7, were carried out by adding nitric acid, HNO3, to the AgNO3 solutions before mixing with the molybdate solution, while those with pH higher than 7 were made by adding NaOH to the Na2MoO4 solution. Similarly, the effects of ionic strength were studied by adding 0.001, 0.003, and 0.01 mol of NaNO3 to AgNO3 solutions and carrying out precipitations at 50 °C.

The quality and the purity of the so prepared samples were investigated by Raman spectroscopy, acquiring at room temperature their spectra, by a BWTEK i-Raman plus spectrometer equipped with a 785 nm laser in the range 100–3500 cm−1 with a spectral resolution of 2 cm−1, fixing the measurement parameters such as acquisition time, number of repetitions, and laser energy, in order to maximize the signal to noise ratio. By X-Ray Powder Diffraction (XRPD), investigations were performed to determine the crystalline phases, using a Philips X’Pert PRO 3040/60 diffractometer (Almelo, The Netherlands), operating at 40 kV, 40 mA, with Bragg–Brentano geometry, equipped with a Cu Kα source (1.54178 Å) Ni-filtered, and a curved graphite monochromator. PANalytical High Score software (version 4.1) was utilized for data elaboration.

Samples were analyzed using a FEI Quanta (Hillsboro, OR, USA) Inspect S Scanning Electron Microscope coupled to an Oxford Instruments Xplore microanalysis (Oxfordshire, UK): characterization of the samples, morphology, and composition has been carried out at different magnifications using both secondary electron and backscattered electron detectors at 10 mm working distance, with energy ranging from 10 to 20 KV. The elemental analysis was carried out in the most significant areas of the samples.

3. Results and Discussion

Silver molybdate crystalizes in different polymorphs, among which is the meta-stable tetragonal α—phase [9,16]. Solid-state reactions lead to the almost exclusive formation of this phase. Instead, it has been reported that the precipitation reaction leads to the formation of the stable cubic phase, the so-called β—phase. In these crystalline cells, molybdenum ions are tetrahedrally surrounded by four anions, while the silver ions are octahedrally coordinated by eight oxygen atoms.

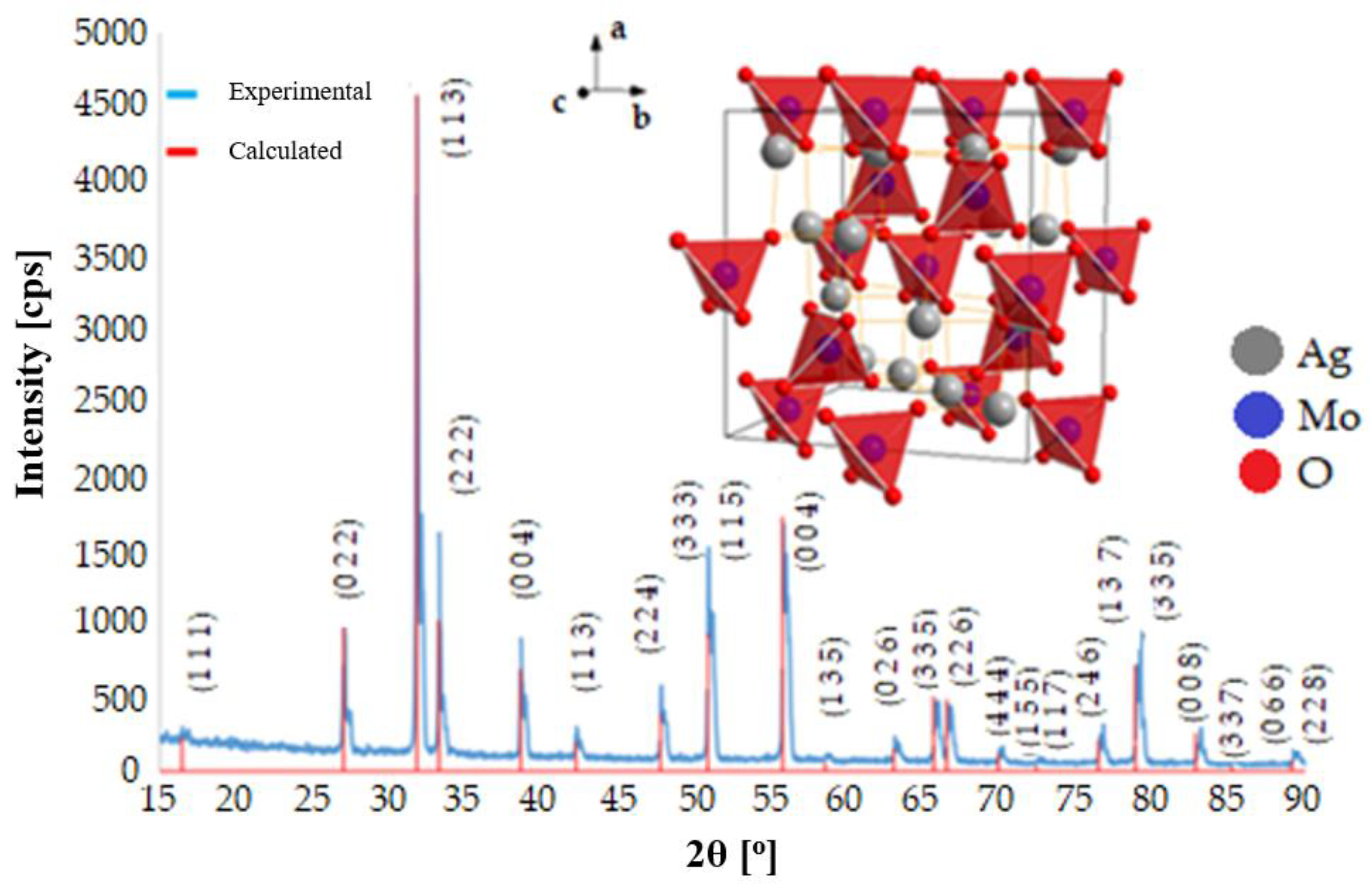

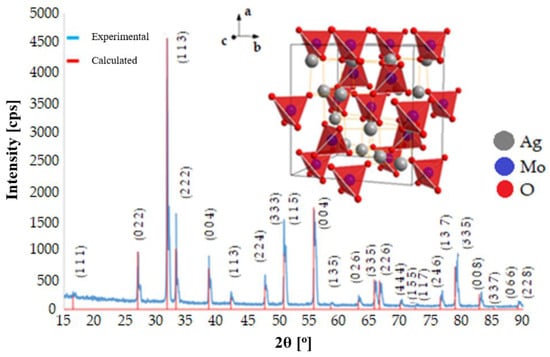

Precipitation is, in general, a very fast process [13] and sometimes it can lead to the formation of amorphous phases: this is often observed for many metallic hydroxides [17] or some aluminosilicates [18]. However, the precipitate of Ag2MoO4 is highly crystalline, as can be observed in Figure 2, which shows the XRD pattern of a sample prepared at pH = 7 and 4 °C. The inset shows the crystal structure of cubic Ag2MoO4, with local coordination around the Mo atoms highlighted.

Figure 2.

XRD patterns of Ag2MoO4 formed by precipitation at 4 °C and pH = 7; theoretical pattern was calculated using the “Diamond version 3.2k” software, also used to draw the crystal structure.

This figure puts in evidence the good quality of the samples prepared using the described method as all peaks can be uniquely attributed only to the pure cubic Ag2MoO4, (ICSD card no. 28891) without evident presence of spurious phases, and it is possible to assign the Miller index to each of them, with relative intensity in good agreement with the calculated values. This is a general finding. Similar curves appear in the diffractograms of other samples prepared by changing experimental conditions. A biphasic system formed only in the case of the lowest pH, and some triclinic Ag2Mo2O7 formed in addition to the intended phase. According to the Pourbaix diagram [19], the ion MoO42− is the main anion in solution only for pH higher than 6; below this value, the ion HMoO4− exists and it becomes prevalent at very low pH. Furthermore, it is worth noting that the chemistry of molybdenum in solution is complex and the Mo2O72− dimer and even more complex polyanions are easily formed, especially in an acidic environment. Hence, it cannot be so unexpected that this further compound forms under these conditions.

The XRD patterns of these samples do not reveal any additional phases. However, in some cases, the morphological and compositional analyses conducted through SEM indicate the presence of small particles rich in silver with nanometric size, as will be discussed later. They are, in mass and volume, well below the detection limit of a normal XRD diffractometer.

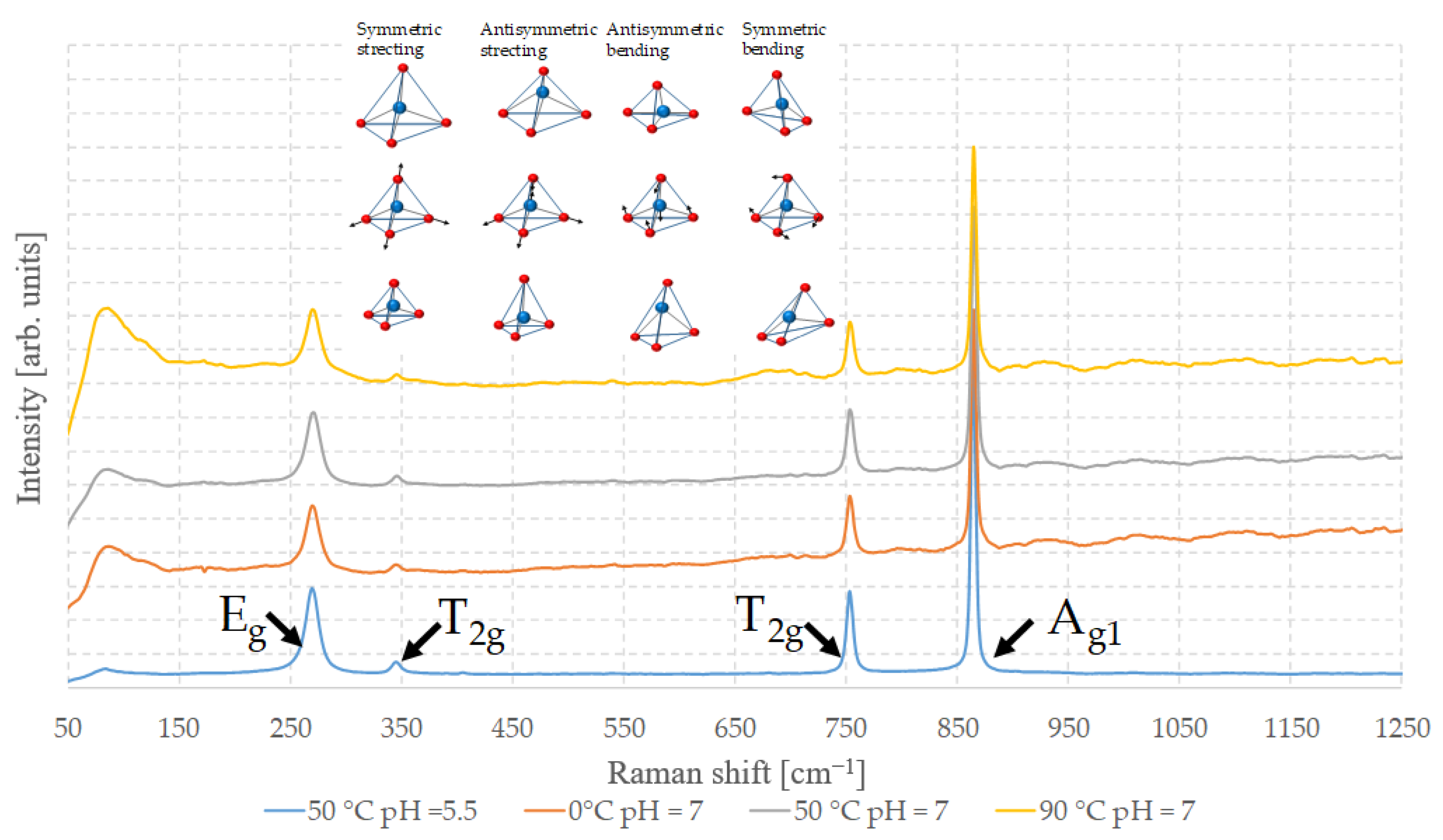

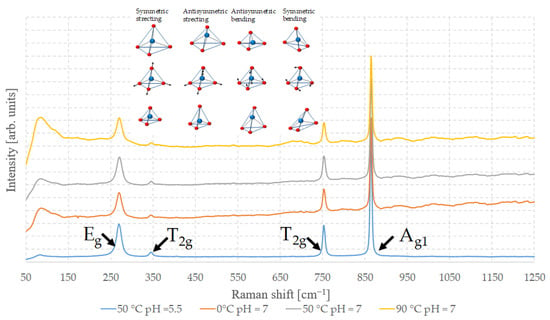

Similar considerations can also be made regarding the Raman analyses that were carried out on the different samples and the results are in good agreement with the X-rays. Due to its crystalline symmetry, the Raman spectra of cubic Ag2MoO4 are present in some bands, due to the characteristic vibrations of the MoO4 units [1,20]. In particular, these bands are symmetric stretching, antisymmetric stretching, antisymmetric bending, and symmetric bending. There is also a band at a low wavenumber due to the collective modes of the entire crystal. Table 1 summarizes the characteristics of these bands.

Table 1.

Assignments of the Raman bands of β—Ag2MoO4 [21].

All these features are observed in all the spectra, as can be observed in Figure 3, which shows the Raman spectra of some samples prepared under different experimental conditions, even if their intensity can change. The inset shows a schematic representation of active Raman vibrational modes. No significant shifts in positions or broadening of bands are evident in any case and this indicates that the particles obtained are crystalline and of comparable quality and purity. Only the sample prepared at pH = 1 exhibits a completely different spectrum, due to its biphasic nature.

Figure 3.

Raman spectra of Ag2MoO4 prepared at 0 °C, 50 °C, 90 °C and pH = 7, and at 50 °C and pH = 5.5.

Nevertheless, in certain samples, a notable contribution of fluorescence is apparent, leading to a deviation in the curves. Overall, it is observed that the fluorescence intensity tends to increase with higher precipitation temperatures, all other factors held constant. The fluorescence in the samples prepared at 4 °C is weaker while it is very evident in the case of the samples prepared at 90 °C. Fluorescence also decreases as pH decreases. The sample prepared at 50 °C and pH = 5.5 is the one with the lowest fluorescence among those considered. The other experimental parameters have no role in this spectral characteristic. This fluorescence does not seem due to the presence of secondary phases or impurities. However, while XRD patterns are normally sensitive to the absolute numbers of phases present in a sample, Raman spectra can be very sensitive to even small numbers of secondary phases, if their scattering response is strong and, in some cases, they can be the main recognizable feature. Often, the fluorescence present in a spectrum can be due to phases present even in very limited quantities. Among the possible candidates in this system, silver or silver oxide nanoparticles or nanostructures should be taken into consideration, because they generate fluorescence [22,23], although their most intense peak falls in a slightly different spectral range. However, the wavelength of the fluorescence peak depends on the average size of these particles [24]. In this case, the increasing fluorescence intensity would be a consequence of the increase in the number of these nanoparticles of the right size.

A clue regarding this possibility can be offered by the morphological analysis of the samples using electron microscopy.

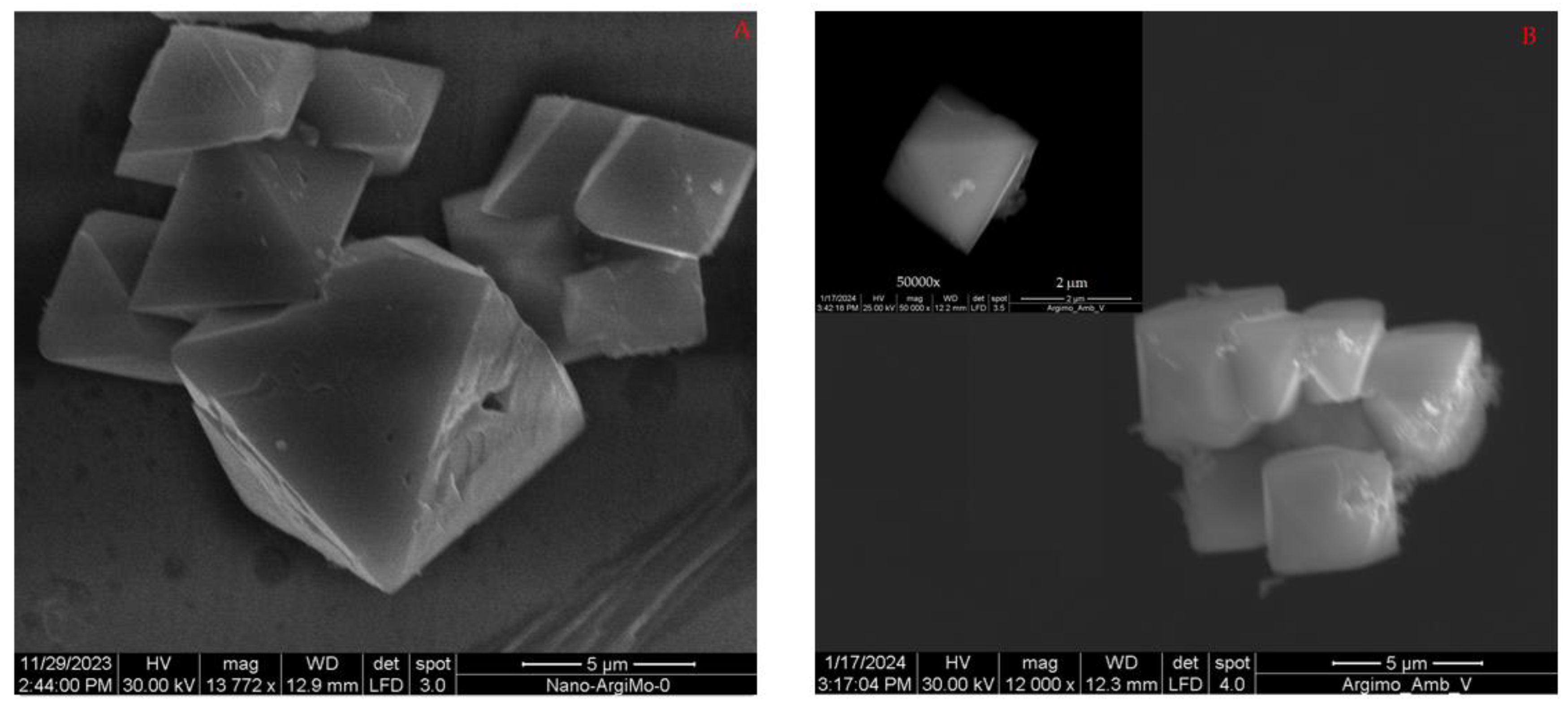

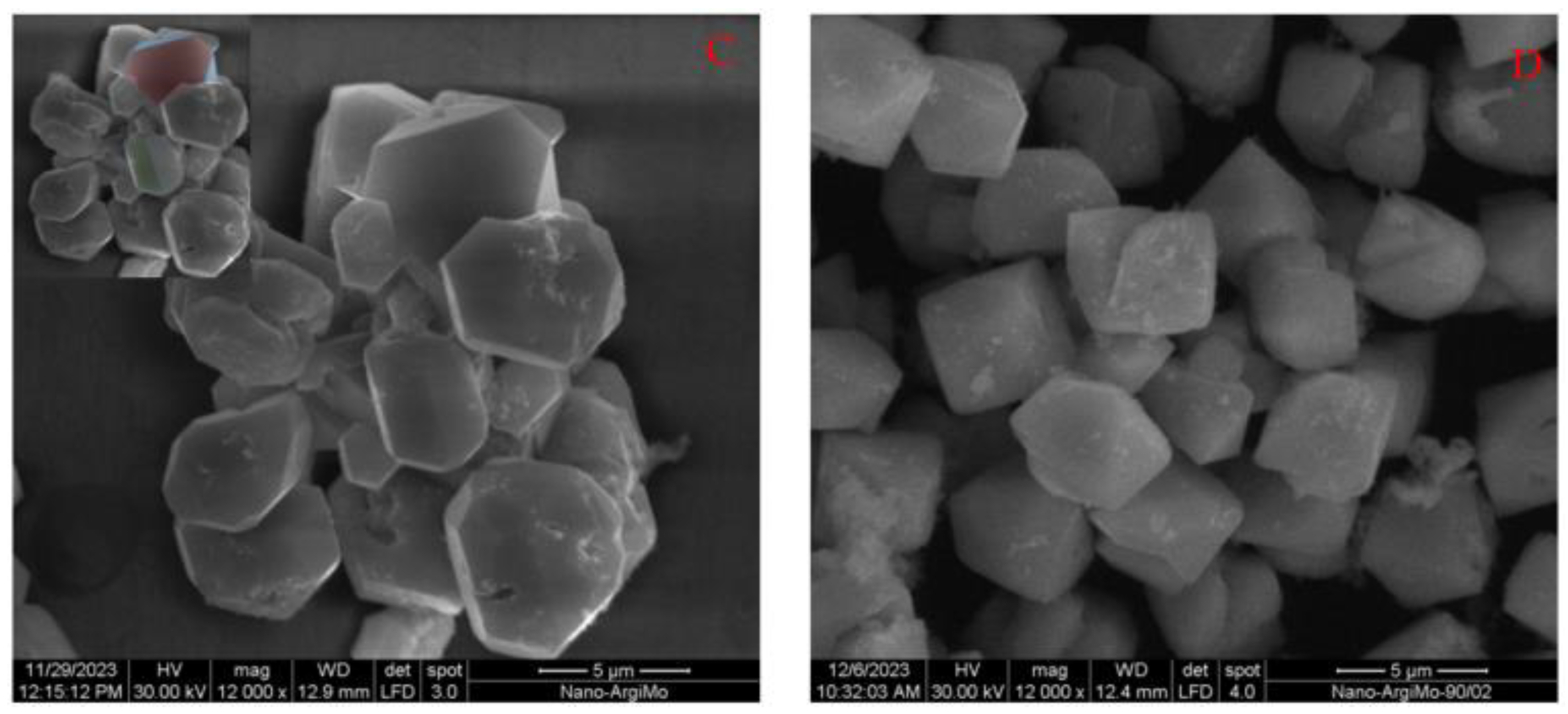

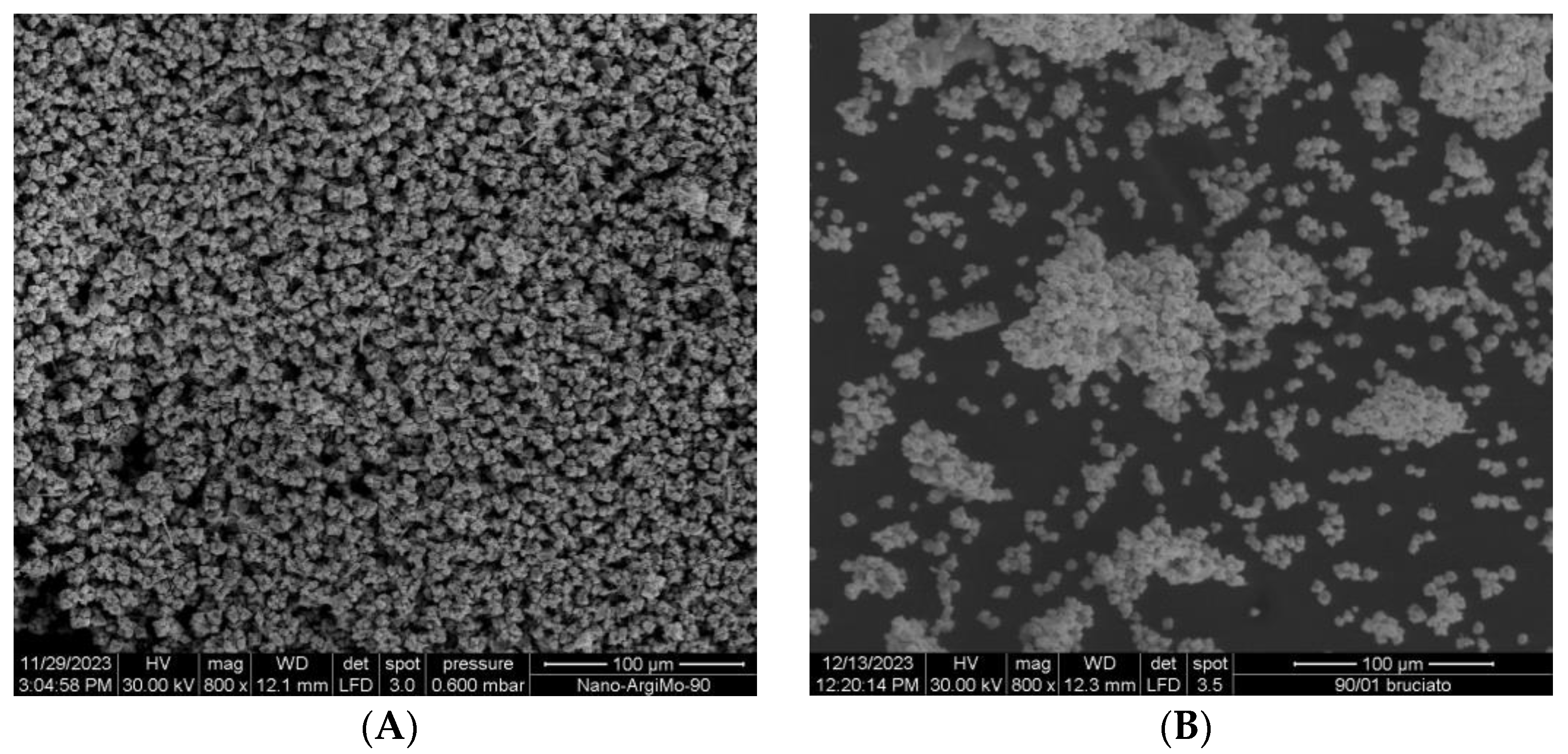

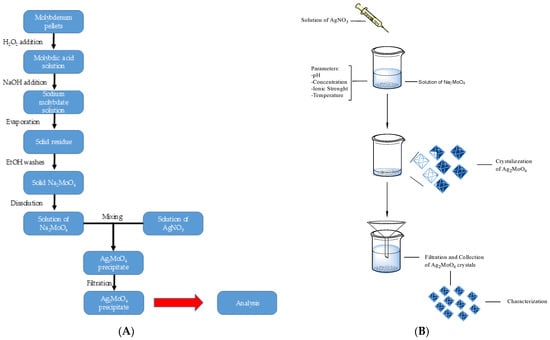

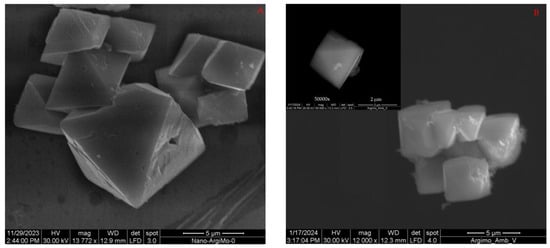

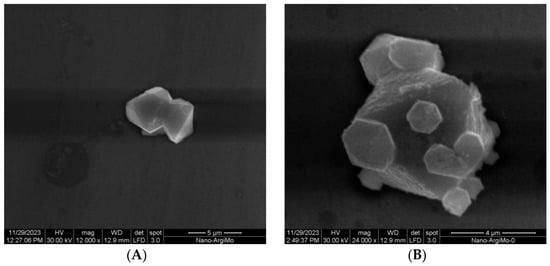

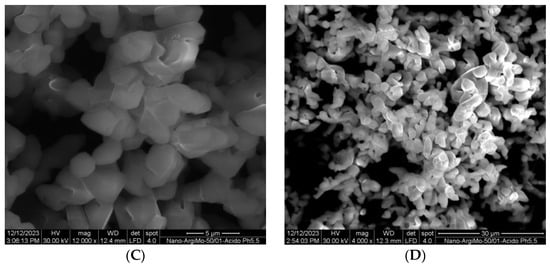

According to what has been found by the other techniques, in all cases the particles formed by precipitation are crystalline and their most common shape is octahedral (as can be seen in Figure 4A, which shows some crystals formed at 4 °C and pH = 7). The faces of these crystals belong to the {100} family and the average size of these crystals is a few microns. This can be seen in Figure 4B, which shows crystals formed at room temperature and with the other conditions constant (in the inset, an isolated crystal from the same batch at higher magnification, shown in order to better highlight its characteristics), in Figure 4C, which shows crystals formed at 50 °C (the insert is designed as a guide for the eyes, to highlight the different faces), and in Figure 4D, which shows crystals formed at 90 °C at the same pH and concentration.

Figure 4.

SEM images of Ag2MoO4 crystals prepared at pH = 7 at 4 °C (A); at room temperature (B); at 50 °C (C) and at 90 °C (D).

In general, once the experimental conditions have been fixed, the free particles have very constant morphologies and dimensions. This is also valid for the other cases, i.e., the free crystals have a very uniform size, regardless of the conditions used for precipitation. The only exception is the samples made at very low pH.

Although it is possible that smaller, nanosized particles may be lost during filtration, the absence of particles much larger than others should also be noted. This indicates that the size distribution curve of crystalline particles is narrow and, in this case, the most common one is a few microns. Often, precipitation can lead to the formation of very small particles, much below a micron, especially in the case of salts or very insoluble compounds; however, it is not uncommon that larger crystals form depending on the chemical nature of the compound and on the nucleation and growth rates of crystalline particles, and on which of the two factors is prevalent and faster [25].

Although it is difficult to follow the kinetics of precipitation, in the case of Ag2MoO4, it seems that most of the crystalline nuclei form rapidly at the same time and that they grow at uniform rates, leading to crystals of fairly constant size.

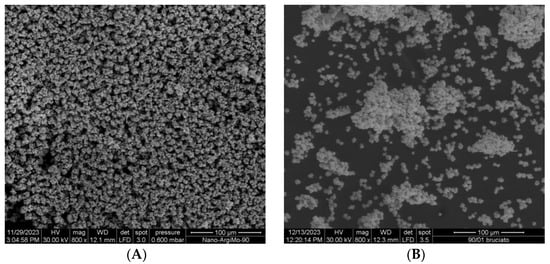

The temperature, but in general also the other factors considered in this work, seems to have little importance on the final dimensions of the crystals. It is worth noting that there is no evidence of growth, either through coarsening or other mechanisms. No meaningful changes were observed in the average size, aspect, or habit of the crystals in samples left in contact with mother waters at 90 °C for 1 and 2 h compared to the sample prepared at the same temperature and immediately quenched after precipitation. This lack of significant alterations is evident in Figure 5A,B. This indicates that once precipitation has taken place, no further change or evolution of the crystals occurs and that all the characteristics of the crystals and their morphology are due to what happens in the moment of formation itself.

Figure 5.

SEM images of Ag2MoO4 crystals prepared at pH = 7 at 90 °C quenched immediately after the precipitation (A) and after being in contact at this temperature for 2 h (B).

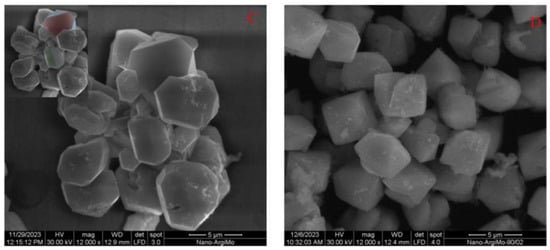

While temperature does not appear to play a role in the average dimensions, which seem to be only slightly smaller at 90 °C compared to 4 °C, it does significantly influence crystal morphology and habit. In fact, at low temperatures, crystals are mostly octahedral and the other shapes are rare; increasing the temperature increases the number of truncated octahedral crystals, and at 90 °C, there are also many prismatic bipyramidal crystals which are rarer at 4 °C and even 50 °C. In some cases, aggregates of particles or twinnings of crystals with similar size form and sometimes smaller secondary crystals can be observed on the faces of the main crystals. Figure 6 shows a case of crystal twinning formed at 25 °C (A) and smaller crystals formed over the main larger crystals (B) at 4 °C.

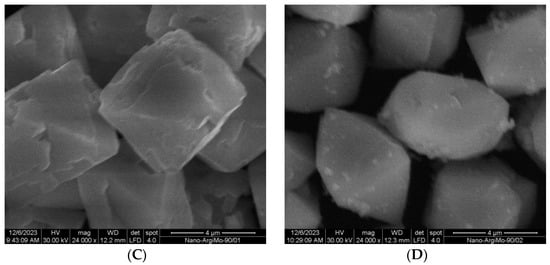

Figure 6.

SEM images of Ag2MoO4 crystals prepared at pH = 7: at 25 °C showing a case of twinning (A); some secondary crystals grown on larger ones at 4 °C (B); evidence of terraces and corrosion marks on crystals formed at 90 °C (C); secondary particles grown on the surfaces of main crystals formed at 90 °C (D).

Although these phenomena can occur at every temperature, they become more frequent as it increases. Indeed, crystal faces are normally very smooth and regular at low temperatures, but terraces and some signs of corrosion are present at higher temperatures (Figure 6C). Another effect related to temperature is the appearance of small particles, with a size of a few tens of nanometers or less, that can be observed on the surface of the crystals (Figure 6D). Again, these small particles become more frequent at high temperatures. In fact, the crystals precipitated at 4 °C are very clean, while they are common at 90 °C. When isolated, these small particles have a spheroidal appearance, but they tend to aggregate and form filaments of particles or bi-dimensional structures as their number increases. These particles are also present in the samples prepared at pH higher than 7 and when the ionic strength increases. Even though it is difficult to analyze them independently of the substrate and a contribution deriving from the underlying crystals is always present, since they are very small, the chemical analysis carried out on them has shown that they are rich in silver and, on the contrary, they have a very low molybdenum content. It must be considered that the diameter of the electron beam spot has a diameter comparable to or greater than that of these particles and that they are also very thin. Only very specific surface analysis techniques could determine the exact chemical composition of these objects; however, the experimental difficulties would not be negligible.

Table 2 shows the average EDX compositional analysis performed on many areas and points shown on clean crystal surfaces and on these particles. EDX shows that the crystalline particles have a composition very close to the nominal one. For instance, the sample prepared at 50 °C, pH = 7, and initial [MoO42−] concentration = 0.04 M has measured average composition, is normalized to silver, and is equal to Ag2Mo0.91O6.0, which is close to the expected one and in good agreement with XRD and Raman results; in all the other cases, similar compositions are found. The atomic percentage of oxygen is unexpectedly high, but this can be justified by the experimental error since this element is much lighter than the other two which, due to their position in the periodic table, are much more similar to each other. Light elements are difficult to quantify by EDS.

Table 2.

Average experimental composition determined by EDX analysis of Ag2MoO4 crystals and of secondary particles.

The Ag2O—MoO3 phase diagram [26] shows that Ag2MoO4 is the most silver-rich intermediate phase, so concerning the nature of these particles, the most likely candidates are silver oxide, Ag2O, silver hydroxide, AgOH, or metallic silver. Hydrogen cannot be measured by this technique, so it is not possible to directly discriminate between the first two compounds. Other compounds such as silver carbonate, for instance, are unlikely.

However, considering that all the processes were carried out in an oxidizing environment or in any case in the presence of oxygen, it seems more realistic that these are oxide or hydroxide nanoparticles rather than pure metal. It is worth noting that Ag2O is relatively stable and begins to decompose only at temperatures much higher than 200 °C [27]. The presence of these small silver-rich particles could justify the fluorescence observed in the Raman spectra as it is stronger the higher their number is.

The shape and morphology of the crystals depend little on the ionic strength of the solutions and their concentration, at least under the experimental conditions considered here, but by increasing this parameter, the average size of the crystals decreases, albeit slightly.

The pH has, on the contrary, a greater influence, if lower than 7. The samples prepared at pH = 9.5 and 12 are, in terms of size distribution and crystal shape, very similar to those made at pH = 7, with a higher concentration of silver-rich particles on the surface.

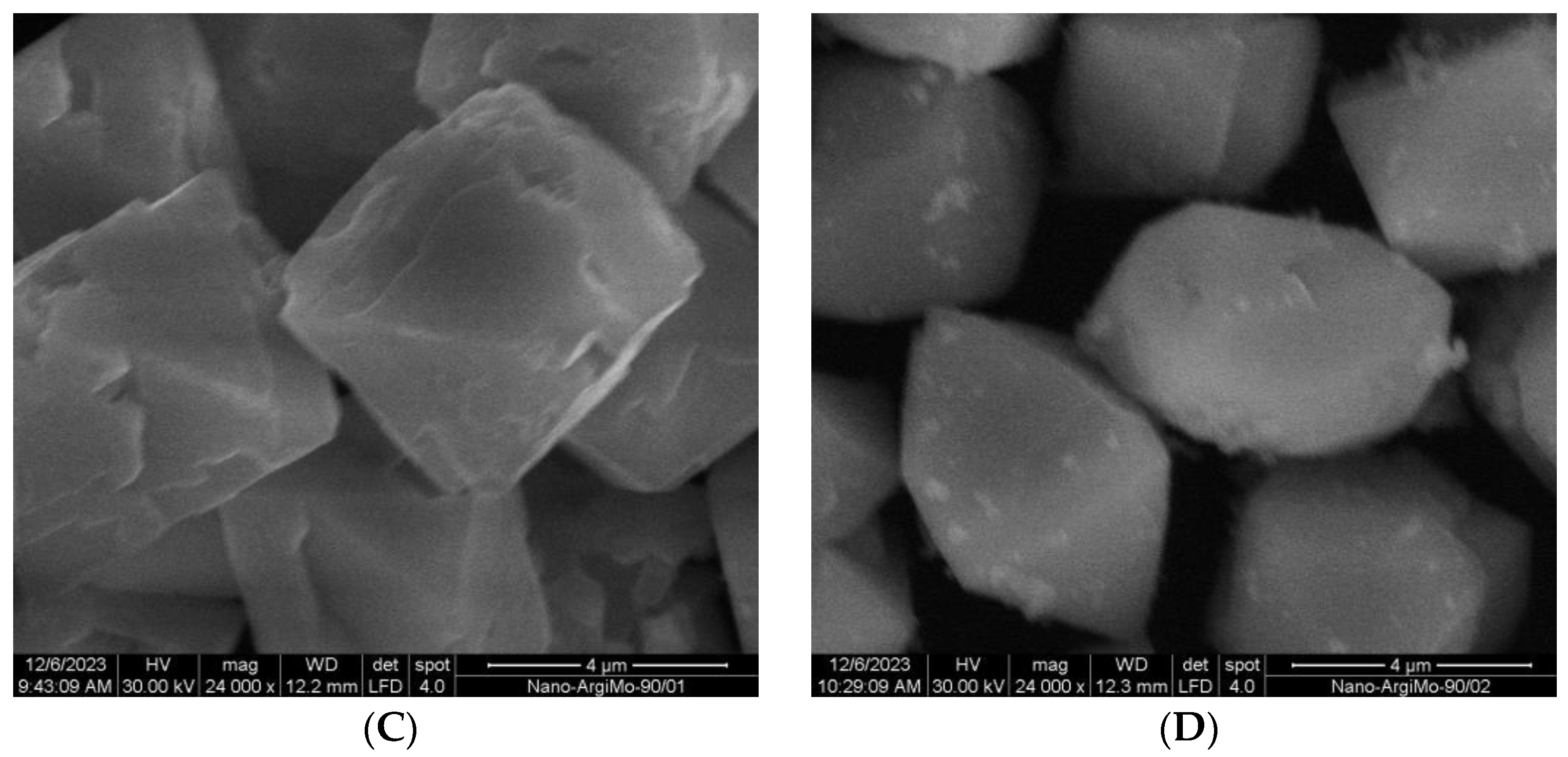

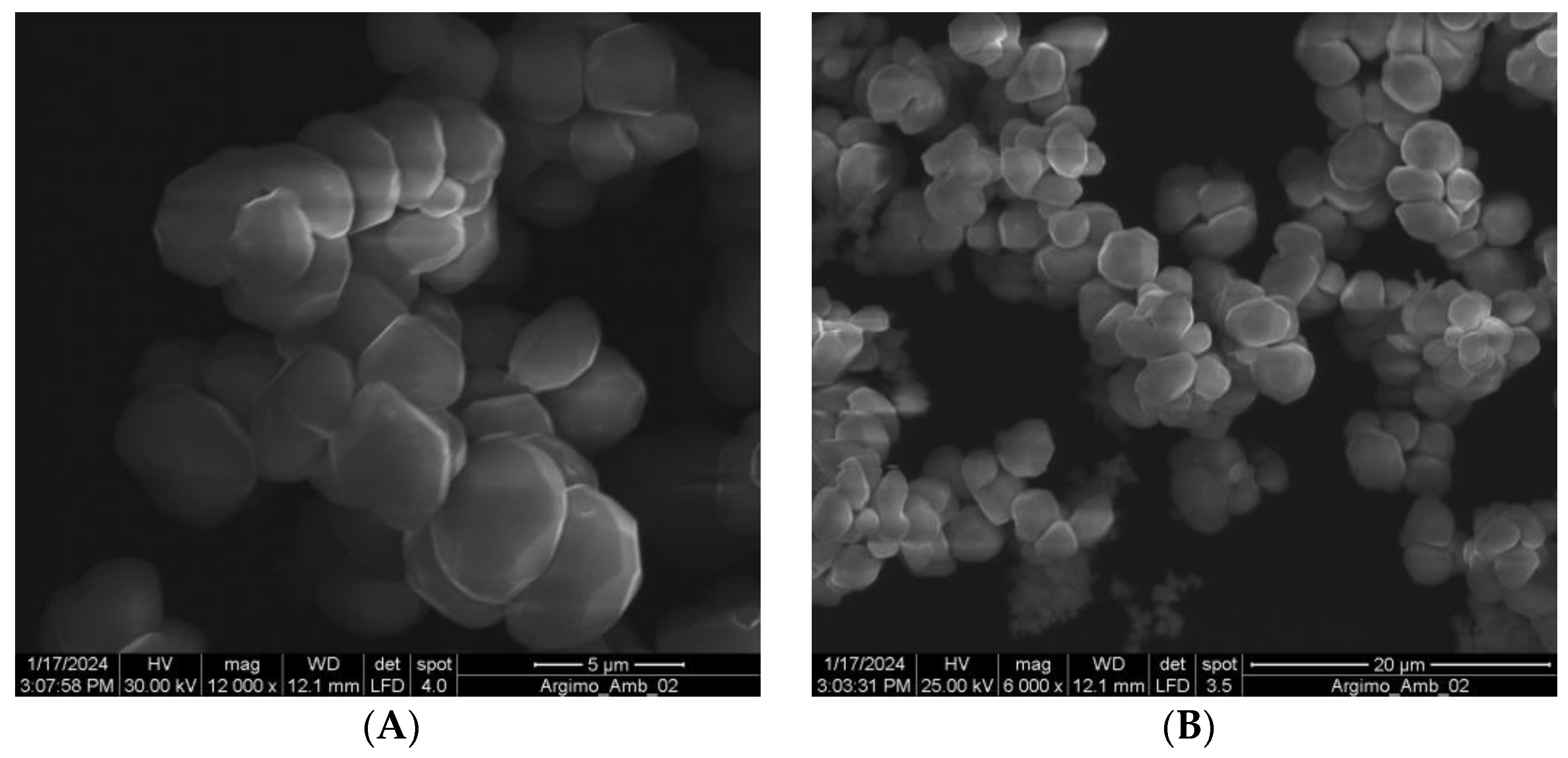

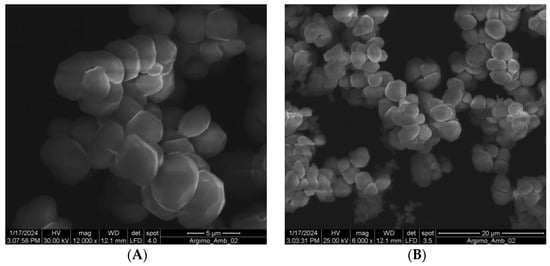

Figure 7 shows crystals that precipitated with pH = 6.5 (A, B) and 5.5 (C, D), respectively, at different magnifications. In this case, the appearance of the crystals is very different. Octahedral crystals and, in general, isolated crystals have disappeared or at least are very rare. Instead, in their place are common aggregates of rather irregularly shaped crystals. These crystals are, in both cases, smaller than the crystals precipitated at higher pH; the lower the pH, the smaller in average size they are and, apparently, they are a little more rounded at pH = 6.5 and somewhat more elongated at pH = 5.5. These crystals are characterized by a greater number of crystal faces compared to those precipitated at higher pH; they do not belong to the {100} family, which is difficult to recognize. It is worth noting that for these samples, nanosized particles are completely absent. The Raman spectra of this sample do not show any fluorescence or drift, providing reasonable confirmation for the hypothesis that these small particles contribute to the spectral feature observed in the other samples.

Figure 7.

SEM images of Ag2MoO4 crystals prepared at pH = 6.5 (A,B) and 5.5 (C,D) at 25 °C at different magnifications.

4. Discussion

The crystalline habit, the type of faces, the morphology, the size, and the average dimensions, as well as the polymorph type of the crystals obtained by precipitation depend on the chemical-physical parameters (temperature, pH, concentration, and above all, the chemical nature of the solvent) of the mother solutions, because they change factors such as the free energy of the crystal faces, the viscosity of the medium, and the diffusion coefficients as well as the supersaturation. One of the most important factors is the chemical nature of the solvent. Crystals obtained from different liquids can vary significantly.

In the case of Ag2MoO4 crystals, however, there is only a limited but still observable variation and SEM analyses showed that there is no evolution of the crystals after they are formed. This implies that the factors ruling precipitation in this case do not change in a wide range. In the case of precipitation from aqueous solutions, it must, however, be considered that the external experimental parameters cannot change in ranges too wide. While the pH can indeed be set from very acidic to very basic, and this allows the effects to be fully studied, the temperature is obviously limited between freezing and boiling and the two limits should be excluded because they induce perturbations that are too large. As regards concentration and ionic strength, the upper possible limit is that of maximum solubility (which for many compounds is often limited). However, the experimental study with diluted solutions is easier and allows us to avoid phenomena such as excessive variations in viscosity and diffusion factors.

Precipitation is the process that results in the formation of a solid from a supersaturated solution. Its main difference from crystallization is the rate at which it occurs. In both cases the same steps are necessary: formation of a supersaturated solution, nucleation, and growth. The critical parameter is supersaturation, which is the excess amount of solute compared to the saturation concentration. Being metastable, a single-phase, supersaturated system evolves towards a two-phase system: solid precipitate and saturated solution [27].

While crystallization is a slow, quasi-equilibrium process, precipitation is very fast and practically out of equilibrium. Precipitation starts typically at high supersaturation levels, where nucleation occurs quickly. Very often the former process leads to large single crystals, whereas the second one leads to small nano or microparticles. Both are controlled by thermodynamics; however, in the case of precipitation, kinetic factors are also crucial.

When two parent solutions of a very insoluble compound are put in contact, locally, supersaturation conditions are created almost instantly and the system is forced to become biphasic, i.e., the separation of a solid from the liquid occurs. Due to the rapidity of the phenomenon, macroscopically there are no variations in the external parameters and it can be considered isothermal.

In such conditions, supersaturation is expected to be very high, leading the system into a regime where nucleation dominates crystal growth. Nanocrystals or particles form immediately and the growth of large crystals does not take place. Precipitation is primarily governed by nucleation. When there are many nuclei, they cannot grow, resulting in uniform particles. The thermodynamic data as a function of these external factors are precisely known only for a few systems, and more importantly, in the case of very insoluble compounds, locally the system reaches and exceeds the critical conditions very easily. In this case, a phenomenological approach is very useful to know the macroscopic effects of parameters that can be established experimentally. Although it is difficult to know a priori whether the change in one of these parameters or possibly a combination of several of them can determine a change in the precipitated crystals, it can be established which are more significant than others in ruling the precipitation process. In the case of the precipitation of Ag2MoO4, the crystals obtained are quite similar to each other in most cases and under most experimental conditions taken into consideration. This is in good agreement with the very low solubility of this compound in water: crystals form rapidly, but do not evolve long after they have precipitated. Some parameters such as temperature or pH induce more variation in the crystals, likely in the moment they form. Other parameters such as ionic strength have a very small influence.

Changing more than one parameter in the same moment may lead to some difference in the precipitation process and in the crystals; however, in this case it would be difficult to separate and analyze the contribution of each of them and draw general conclusions.

Concentration and above all ionic strength, at least in the range considered in this work, seem to have quite little influence on the precipitation and the general characteristics of the crystals. This is not a trivial observation because, in many cases, the morphology and crystalline habit of precipitates can change as a function of such factors. Depending on the microscopic mechanism, higher concentrations of reagents generally lead to a higher concentration of nuclei and often to higher liquid viscosity. In turn, they favor the growth of smaller crystals, because the nucleation rate can be higher than the growth rate. As illustrated by SEM images, the average size of crystals grown from the solution with the highest concentration is only slightly smaller than that of crystals formed from a more diluted solution, with no apparent changes in the shape of the particles.

Temperature and pH are more important parameters and while their effect on the crystal dimensions is limited, this is not the case concerning the crystal aspect. This leads to particles of uniform size and the presence of crystals significantly larger than the others was not observed, i.e., no growth by coarsening or other mechanisms occurred. This also can imply that crystals with different crystalline shapes form at the same time. The octahedral shape is the most common together with the truncated one, the other forms being less common. Their relative abundance is likely determined, for purely statistical reasons, by the relative rates at which they form, as it can be stated that the formation of crystals with different morphologies is a competitive process. It should be taken into consideration that only a few small crystals nucleate and grow on the surface of the main crystals. They have a mainly octahedral shape, and this indicates that they are the most stable and, from a kinetic point of view, those that form first. The speed of formation of a certain crystalline shape depends on the surface energy of its faces, and in this case, it can be assumed that the most favorable are those corresponding to the {100}. Interestingly, the faces of crystals formed at higher temperatures appear more corroded or damaged than the same at low temperatures.

Although there is not much thermodynamic data available regarding the solubility of molybdates in water as a function of temperature, it can be assumed that Ag2MoO4 is slightly more soluble at high temperatures than at low temperatures. This is observed in numerous analogous systems, such as many chromates [28]. In this case, it could be argued that precipitation is slightly slower as the temperature increases, and this can also allow the formation of crystals with different and less favorable crystalline habits. Slightly higher solubility implies moderately lower supersaturation and, based on general considerations regarding classical nucleation theory [29], this corresponds to slightly larger critical radii. This may justify a slower precipitation rate and, therefore, even crystals with less favored shapes have time to form and grow. The higher solubility can also justify the corroded appearance of the crystals obtained at high temperatures. At 90 °C, there are many terraces, surface defects, and corrosion marks, or anyway, some etch pitch and dissolution steps, on the surfaces of many crystals. In fact, dissolution is a phenomenon concurrent with the growth and if a crystal that has formed encounters an area with a concentration gradient, it may partially redissolve. This seems to be more favorable when the solubility is higher.

Even at low temperatures, a crystal can accidentally move in an area with a local concentration gradient and undergo the same phenomenon of superficial dissolution, but it seems that they are on average a little more stable and, thus, crystal faces are smooth. The octahedral shape is the preferential one, both from a thermodynamic and kinetic point of view. However, increasing temperature makes it possible to have other crystalline forms. Since the crystals do not appear to change their appearance after they are formed, because there is no evidence of evolution either in the shapes or in the average dimensions, the abundance of these different shapes is due to the different speed with which they form.

It is more difficult to offer a justification regarding the different morphology of the crystals formed at acid pH. In this case, the possibility of partial secondary digestion, because of the acidic environment itself, cannot be ruled out. It should be kept in mind that this is the sample with the lowest concentration of silver-rich nanoparticles. In general, pH is an important parameter for those systems where acid–basic equilibria take place [30]. According to reference [17], reaction

occurs at about pH = 6, which is very close to the pH used in this work. Thus, it can be expected that it can be a critical parameter for this system. Higher pH does not seem to lead to important differences, because in this case, the process takes place very far from the range to which the basic acid equilibrium occurs. The only important phenomenon occurring in this case is the presence of more secondary particles on the surfaces of crystals.

MoO42− + H+ → HMoO4−

At pH = 6.5 or 5.5, the concentration of MoO42− ions is a little different from that theoretically expected, because of the presence of other Mo-based anions. The precipitation of Ag2MoO4 perturbs the equilibrium and therefore it can wait for the crystals that are formed to be subject to partial dissolution. According to this hypothesis, the average size seems to be smaller than what is found at higher pH and becomes smaller as the systems become more acidic. The precipitate is crystalline, as shown by the analyses carried out; in particular, Raman spectroscopy and morphological analyses show the presence of crystalline faces, different from what is observed at higher pH. Their appearance and smaller size suggest that they are partly dissolved by the solution after forming. The crystals obtained from precipitation under these conditions show crystalline faces not observed in the other cases.

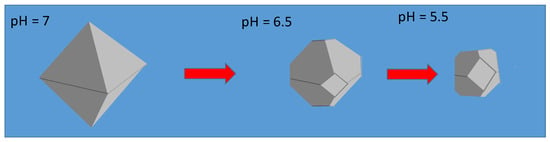

The dissolution process leads to a reduction in crystal size, accompanied by shape evolution according to the crystal habit. The morphologies of the dissolving crystals can be very different from the initial shape, but a dissolving crystal can attain a steady-state shape [31]. It has been suggested that faces in the dissolution shape are derived by cutting off the corners of the equilibrium form [32] and, often, the faces in the growth shape transform to vertices in the dissolution shape and vertices in growth become faces in dissolution [33], and dissolution shape is dominated by the faster-moving facets [34]. Crystals can show varying growth and dissolution rates in different crystallographic directions.

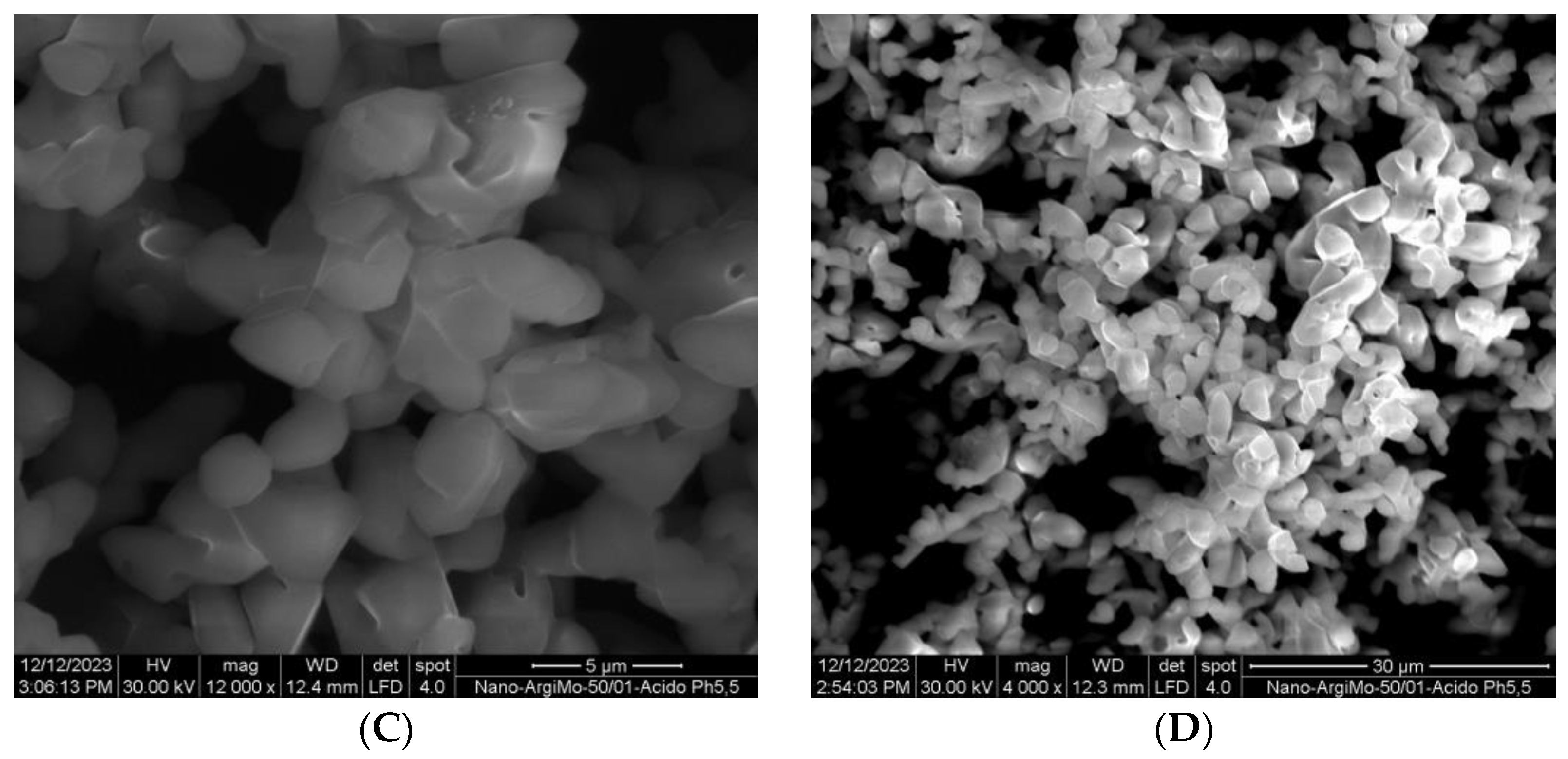

For these reasons, a new crystalline morphology appears. Figure 8 shows a schematic representation of the process.

Figure 8.

Schematic representation of the evolution of crystal shape as a function of pH.

However, the processes of precipitation and dissolution should not necessarily be thought of as consecutive in time, but rather as parallel. Since the conditions of the growth solution are different, the equilibrium morphology is different.

In any way, these samples are of good quality and the secondary particles are absent; this may suggest that they are suitable for measures of chemical physical properties or for the biological activity of this material.

Regarding the silver-rich nanoparticles that can be observed on the surfaces of the crystals, they are more numerous at basic pH and in samples made at high temperatures, suggesting that they derive from some kind of secondary reactions. At pH higher than 8, silver hydroxide, AgOH, is formed following the reaction AgNO3 + NaOH → AgOH + NaNO3.

Silver hydroxide is rather insoluble in water. Thus, it could be thought that it forms and precipitates on the surface of Ag2MoO4, with an increasing concentration as pH increases. It decomposes quickly into silver oxide, Ag2O, because of unfavorable free energy [35]. It seems likely that the particles present on the surface of the crystals are therefore made either from silver hydroxide or from silver oxide which forms from the first one at a later time.

Concentration seems to influence, albeit modestly, on the size of the crystals. The temperature, on the other hand, seems to determine the morphology of the crystals. The pH has an effect similar to that of temperature although for a specific range, beyond which it is much less important. Ionic strength, finally, does not seem to play a role in the process.

Table 3 summarizes the effects of these parameters on crystals formed by precipitation.

Table 3.

Effects of chemical—physical factors on cubic Ag2MoO4 crystals (Cs = crystal shape, Oc = octahedral, To = truncated octahedral, Dp = dipyramid prismatic, Ir = irregular; Fa = face aspect, Sm = smooth, Co = corrosion marks; Anp = Ag-rich nanoparticle).

In principle, it is possible to control the formation of microcrystals of Ag2MoO4 crystals acting on these factors. Some findings are interesting, such as the role of pH as well as the fact that temperature has little role in crystal sizes. It is worth noting also that precipitation can lead to crystals with different shapes and the formation of secondary nanoparticles whose concentration can be controlled. Other effects, such as the one due to the concentration of the precursors, are less surprising, even if it could be a little unexpected that the variations are small.

5. Conclusions

The aim of this work is to study the effects of chemical-physical parameters on the formation of Ag2MoO4 crystals, by precipitation from solutions. Parameters such as concentration, temperature, and pH wield considerable significance in this process, influencing the distinction between amorphous and crystalline precipitates, determining various polymorphic forms, and governing crystalline size and morphology. Accordingly, it would be reasonable to anticipate their significant role even in the case of this oxide. Indeed, these factors bring about alterations in the crystals that take shape.

The morphology changes by varying parameters such as temperature or pH. As can be observed by SEM analysis, at low temperatures, crystals with an octahedral and truncated octahedral shape are much more abundant, while at higher temperatures, crystals of different shapes also become common. At low pH, crystals have irregular shape. Nanoparticles rich in silver form on the crystal’s face when the temperature and pH are high, whereas they are rare at low temperatures and lower pH. Eventually, they are completely absent from the acid environment. Thus, it is possible to control their number and it is possible to obtain high-quality crystals, which can be used for various purposes.

Author Contributions

Conceptualization, S.C. and A.U.; methodology, A.U.; validation, S.B.; investigation, S.C., A.G., G.M. and S.B.; writing—original draft preparation, A.U.; writing—review and editing, S.C. and A.U. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gouveia, A.F.; Sczancoski, J.C.; Ferrer, M.M.; Lima, A.S.; Santos, M.R.M.C.; Li, M.S.; Santos, R.S.; Longo, E.; Cavalcante, L.S. Experimental and Theoretical Investigations of Electronic Structure and Photoluminescence Properties of β-Ag2MoO4 Microcrystals. Inorg. Chem. 2014, 53, 5589–5599. [Google Scholar] [CrossRef]

- Fabbro, M.; Foggi, C.; Santos, L.; Gracia, L.; Perrin, A.; Perrin, C.; Vergani, C.; Machado, A.; Andres, J.; Cordoncillo, E.; et al. Synthesis, antifungal evaluation and optical properties of silver molybdate microcrystals in different solvents: A combined experimental and theoretical study. Dalton Trans. 2016, 45, 10736–10743. [Google Scholar] [CrossRef]

- Lopes, F.H.P.; Noleto, L.F.G.; Vieira, V.E.M.; de Sousa, P.B.; Jucá, A.C.S.; Oliveira, Y.L.; Costa, K.R.B.S.; Almeida, M.A.P.; Gouveia, A.F. Experimental and Theoretical Correlation of Modulated Architectures of β-Ag2MoO4 Microcrystals: Effect of Different Synthesis Routes on the Morphology, Optical, Colorimetric, and Photocatalytic Properties. J. Inorg. Organomet. Polym. Mater. 2023, 33, 424–450. [Google Scholar] [CrossRef]

- Xu, C.; Chen, Y.; Xie, X.; Yan, K.; Si, Y.; Zhang, M.; Yan, Q. Construction of Ag SPR-promoted Z-scheme Ag2MoO4/CuBi2O4 composites with enhanced photocatalytic performance. J. Mater. Sci. Mater. Electron. 2020, 31, 8151–8164. [Google Scholar] [CrossRef]

- Safartoobi, A.; Mazloom, J.; Ghodsi, F.E. Silver/molybdenum metal-organic framework derived Ag2MoO4 nanoparticles as a novel electrode for high-performance supercapacitor. J. Energy Storage 2023, 68, 107818. [Google Scholar] [CrossRef]

- Della Rocca, D.G.; Peralta, R.M.; Peralta, R.A.; de Fatima Peralta Muniz Moreira, R. Recent development on Ag2MoO4-based advanced oxidation processes: A review. React. Kinet. Mech. Catal. 2021, 132, 1–35. [Google Scholar] [CrossRef]

- Abinaya, M.; Rajakumaran, R.; Chen, S.M.; Karthik, R.; Muthuraj, V. In Situ Synthesis, Characterization, and Catalytic Performance of Polypyrrole Polymer-Incorporated Ag2MoO4 Nanocomposite for Detection and Degradation of Environmental Pollutants and Pharmaceutical Drugs. ACS Appl. Mater. Interfaces 2019, 11, 38321–38335. [Google Scholar] [CrossRef]

- Kumar, J.V.; Karthik, R.; Chen, S.M.; Muthuraj, V.; Karuppiah, C. Fabrication of potato-like silver molybdate microstructures for photocatalytic degradation of chronic toxicity ciprofloxacin and highly selective electrochemical detection of H2O2. Sci. Rep. 2016, 6, 34149. [Google Scholar] [CrossRef]

- De Foggi, C.C.; De Oliveira, R.C.; Assis, M.; Fabbro, M.T.; Mastelaro, V.R.; Vergani, C.E.; Gracia, L.; Andrés, J.; Longo, E.; Machado, A.L. Unveiling the role of β-Ag2MoO4 microcrystals to the improvement of antibacterial activity. Mater. Sci. Eng. C 2020, 111, 110765. [Google Scholar] [CrossRef]

- Oliveira, C.A.; Volanti, D.P.; Nogueira, A.E.; Zamperini, C.A.; Vergani, C.E.; Longo, E. Well-designed β-Ag2MoO4 crystals with photocatalytic and antibacterial activity. Mater. Des. 2017, 115, 73–81. [Google Scholar] [CrossRef]

- Marchal, P.; David, R.; Klein, J.P.; Villermaux, J. Crystallization and precipitation engineering—I. An efficient method for solving population balance in crystallization with agglomeration. Chem. Eng. Sci. 1988, 43, 59–67. [Google Scholar] [CrossRef]

- Simone, E.; Klapwijk, A.R.; Wilson, C.C.; Nagy, Z.K. Investigation of the Evolution of Crystal Size and Shape during Temperature Cycling and in the Presence of a Polymeric Additive Using Combined Process Analytical Technologies. Cryst. Growth Des. 2017, 17, 1695–1706. [Google Scholar] [CrossRef]

- Mersmann, A. Crystallization and precipitation. Chem. Eng. Process. Process Intensif. 1999, 38, 345–353. [Google Scholar] [CrossRef]

- Wray, J.L.; Daniels, F. Precipitation of Calcite and Aragonite. J. Am. Chem. Soc. 1957, 79, 2031–2034. [Google Scholar] [CrossRef]

- Cicconi, F.; Ubaldini, A.; Fiore, A.; Rizzo, A.; Cataldo, S.; Agostini, P.; Pietropaolo, A.; Salvi, S.; Cuzzola, V.; on behalf of the SRF Collaboration. Dissolution of Molybdenum in Hydrogen Peroxide: A Thermodynamic, Kinetic and Microscopic Study of a Green Process for 99mTc Production. Molecules 2023, 28, 2090. [Google Scholar] [CrossRef]

- Ubaldini, A.; Cicconi, F.; Rizzo, A.; Salvi, S.; Cuzzola, V.; Gennerini, F.; Bruni, S.; Marghella, G.; Gessi, A.; Falsini, N. Preparation and Characterization of Isostructural Na2MoO4 and Na2WO4 and a Study of the Composition of Their Mixed System. Molecules 2023, 28, 6602. [Google Scholar] [CrossRef]

- Beltrán, A.; Gracia, L.; Longo, E.; Andrés, J. First-Principles Study of Pressure-Induced Phase Transitions and Electronic Properties of Ag2MoO4. J. Phys. Chem. C 2014, 118, 3724–3732. [Google Scholar] [CrossRef]

- Balayeva, O.O.; Azizov, A.A.; Muradov, M.B.; Alosmanov, R.M.; Eyvazova, G.M.; Mammadyarova, S.J. Cobalt chromium-layered double hydroxide, α- and β- Co(OH)2 and amorphous Cr(OH)3: Synthesis, modification and characterization. Heliyon 2019, 5, e02725. [Google Scholar] [CrossRef]

- Wada, K.; Kubo, H. Precipitation of amorphous aluminosilicates from solutions containing monomeric silica and aluminium ions. J. Soil Sci. 1975, 26, 100–111. [Google Scholar] [CrossRef]

- Nixon, D.M. Molybdenum 1991. Coord. Chem. Rev. 1994, 134, 1–90. [Google Scholar] [CrossRef]

- Moura, J.V.B.; da Silva Filho, J.G.; Freire, P.T.C.; Luz-Lima, C.; Pinheiro, G.S.; Viana, B.C.; Mendes Filho, J.; Souza-Filho, A.G.; Saraiva, G.D. Phonon properties of β-Ag2MoO4: Raman spectroscopy and ab initio calculations. Vib. Spectrosc. 2016, 86, 97–102. [Google Scholar] [CrossRef]

- Fabbro, M.T.; Saliby, C.; Rios, L.R.; La Porta, F.A.; Gracia, L.; Li, M.S.; Andrés, J.; Santos, L.P.S.; Longo, E. Identifying and rationalizing the morphological, structural, and optical properties of β-Ag2MoO4 microcrystals, and the formation process of Ag nanoparticles on their surfaces: Combining experimental data and first-principles calculations. Sci. Technol. Adv. Mater. 2015, 16, 065002. [Google Scholar] [CrossRef]

- Peyser, L.A.; Vinson, A.E.; Bartko, A.P.; Dickson, R.M. Photoactivated fluorescence from individual silver nanoclusters. Science 2001, 291, 103–106. [Google Scholar] [CrossRef] [PubMed]

- Kayed, K. The luminescence properties of individual silver nanoparticles in Ag/Ag2O composites synthesized by oxygen plasma treatment of silver thin films. J. Lumin. 2021, 237, 118163. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, F.; Ma, L.; Yang, J.; Yang, J.; Xiang, H. Prediction of the Crystal Size Distribution for Reactive Crystallization of Barium Carbonate under Growth and Nucleation Mechanisms. Cryst. Growth Des. 2019, 19, 3616–3625. [Google Scholar] [CrossRef]

- Waterhouse, G.; Bowmaker, G.; Metson, J. The thermal decomposition of silver (I,III) oxide: A combined XRD, FT-IR and Raman spectroscopic study. Phys. Chem. Chem. Phys. 2001, 3, 3838–3845. [Google Scholar] [CrossRef]

- Doremus, R.H. Precipitation and Crystal Growth from Solution. Croat. Chem. Acta 1970, 42, 293–298. [Google Scholar]

- Christov, C.; Ivanova, K.; Velikova, S.; Tanev, S. Thermodynamic study of aqueous sodium and potassium chloride and chromate systems at the temperature 298.15 K. J. Chem. Thermodyn. 2002, 34, 987–994. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, Y.; Tang, W. Molecular Mechanism of Organic Crystal Nucleation: A Perspective of Solution Chemistry and Polymorphism. Crystals 2022, 12, 980. [Google Scholar] [CrossRef]

- Link, F.J.; Heng, J.Y.Y. Unraveling the Impact of pH on the Crystallization of Pharmaceutical Proteins: A Case Study of Human Insulin. Cryst. Growth Des. 2022, 22, 3024–3033. [Google Scholar] [CrossRef]

- Prajapati, N.; Späth, M.; Knecht, L.; Selzer, M.; Nestler, B. Quantitative Phase-Field Modeling of Faceted Crystal Dissolution Processes. Cryst. Growth Des. 2021, 21, 3266–3279. [Google Scholar] [CrossRef]

- Lacmann, R.; Franke, W.; Heimann, R. The dissolution forms of single crystal spheres: I. Theory for the molecular-kinetics interpretation. J. Cryst. Growth 1974, 26, 107–116. [Google Scholar] [CrossRef]

- Moore, M. On the shapes of dissolved crystals. Mineral. Mag. 1986, 50, 331–332. [Google Scholar] [CrossRef]

- Snyder, R.C.; Doherty, M.F. Faceted crystal shape evolution during dissolution or growth. AIChE J. 2007, 53, 1337–1348. [Google Scholar] [CrossRef]

- Liu, Q.; Li, M.; Zeng, Q.; Wu, X. Synthesis and kinetics of micron-scale silver(I) oxide via efficient chemical precipitation process. Mater. Res. Express 2019, 6, 115539. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).