The Effect of Annealing Treatment on the Microstructure and Texture of a Cold-Rolled TiNiFe Shape Memory Alloy Tube

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

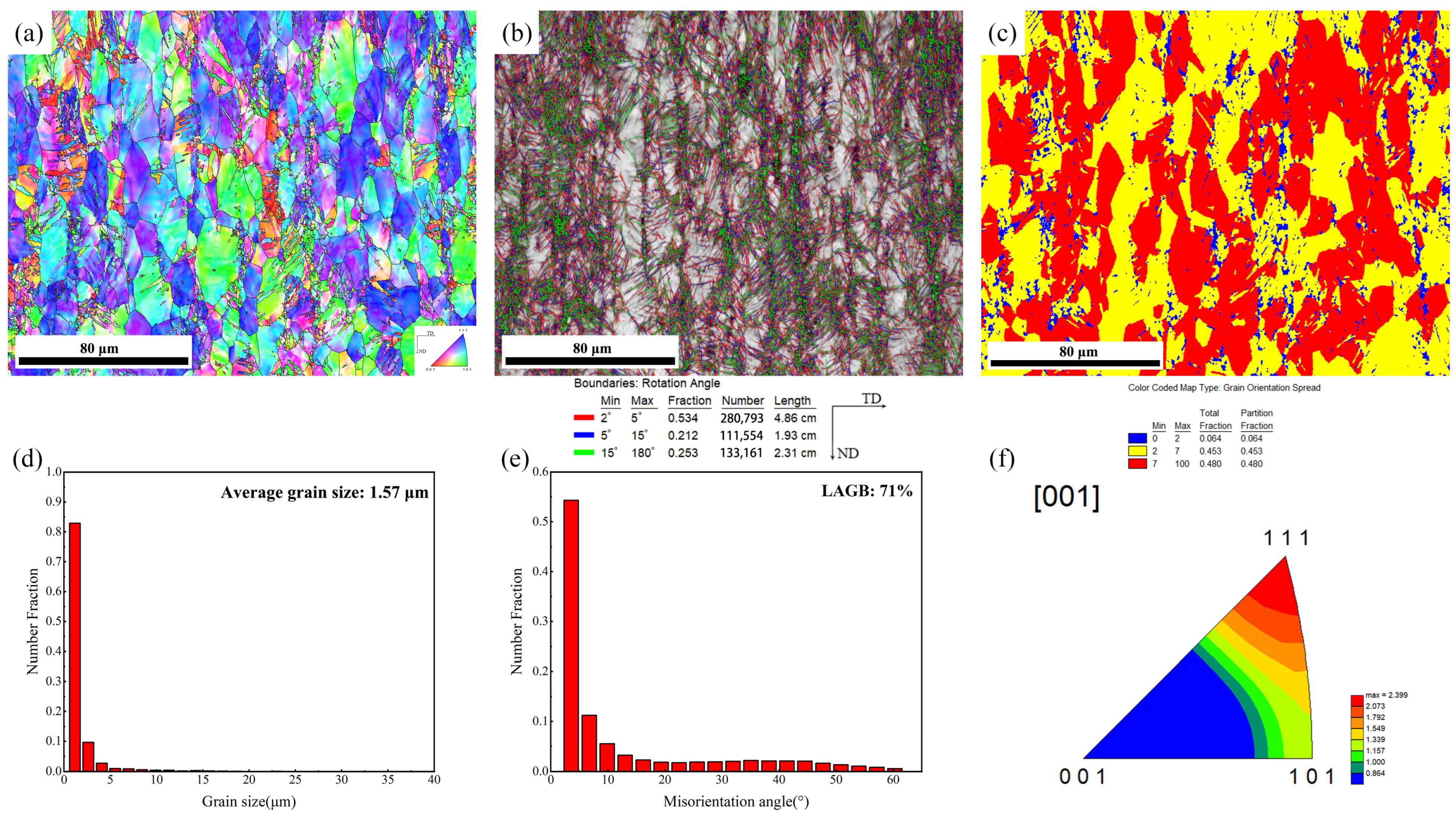

3.1. Microstructure of Cold-Rolled TiNiFe SMA Tube

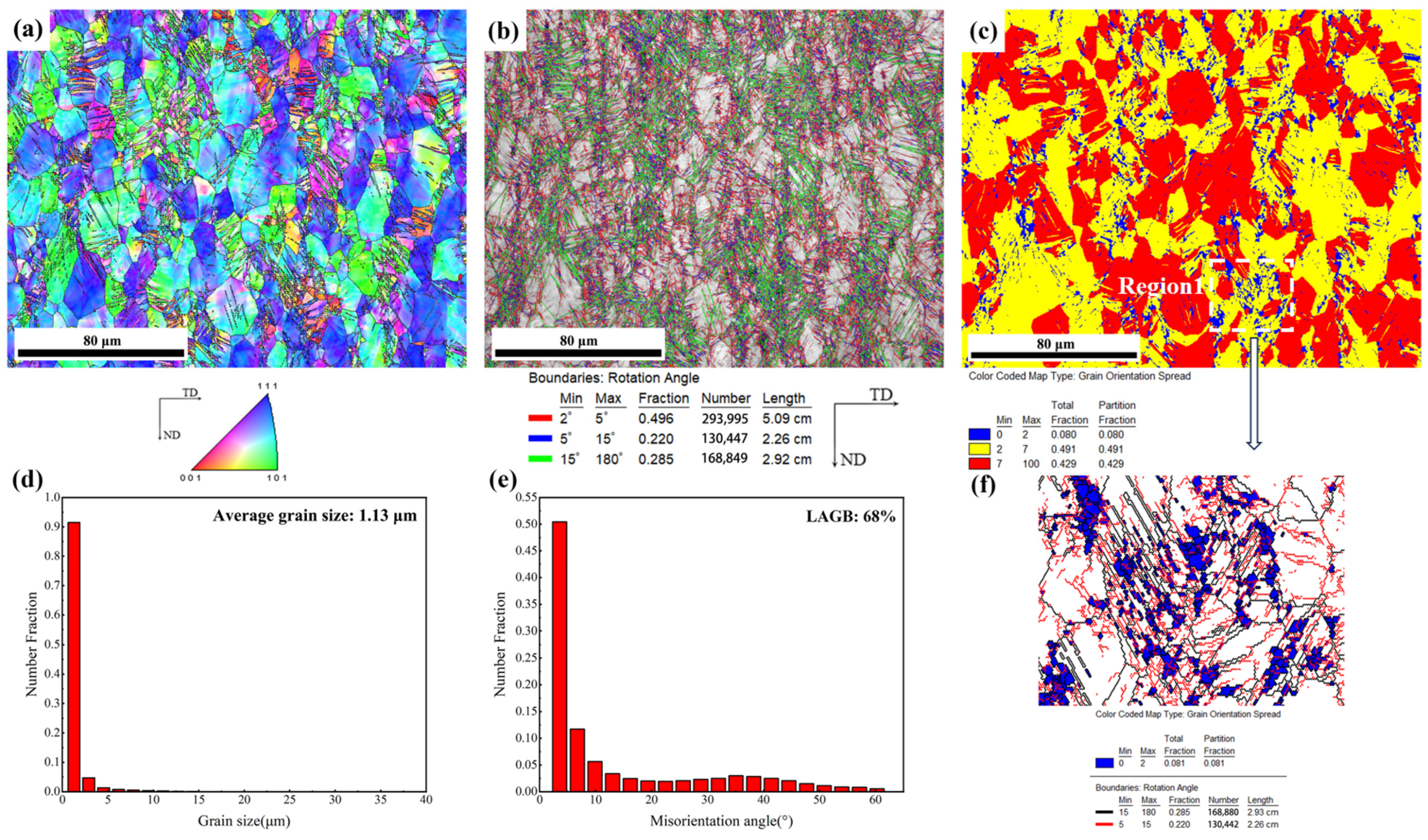

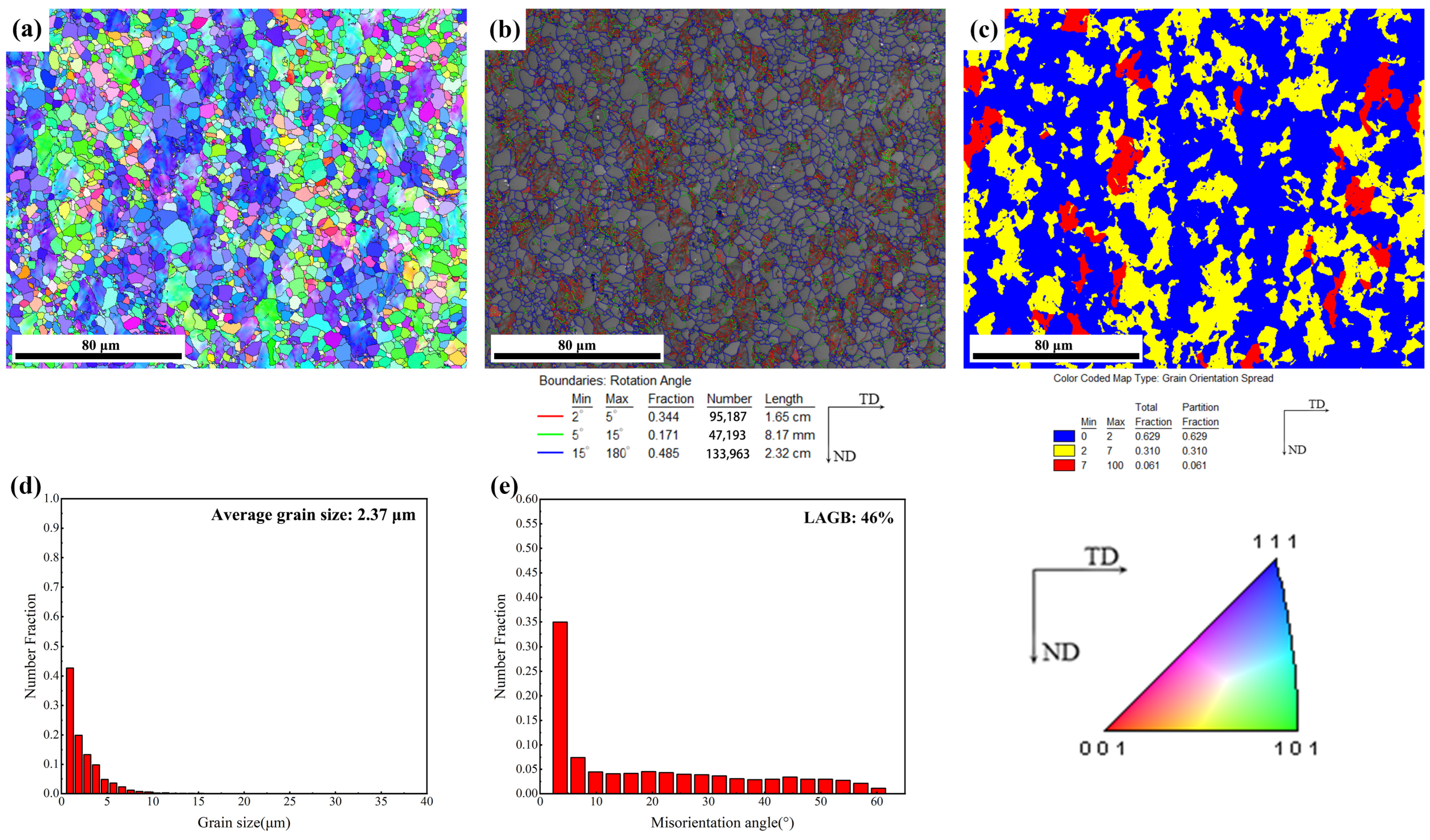

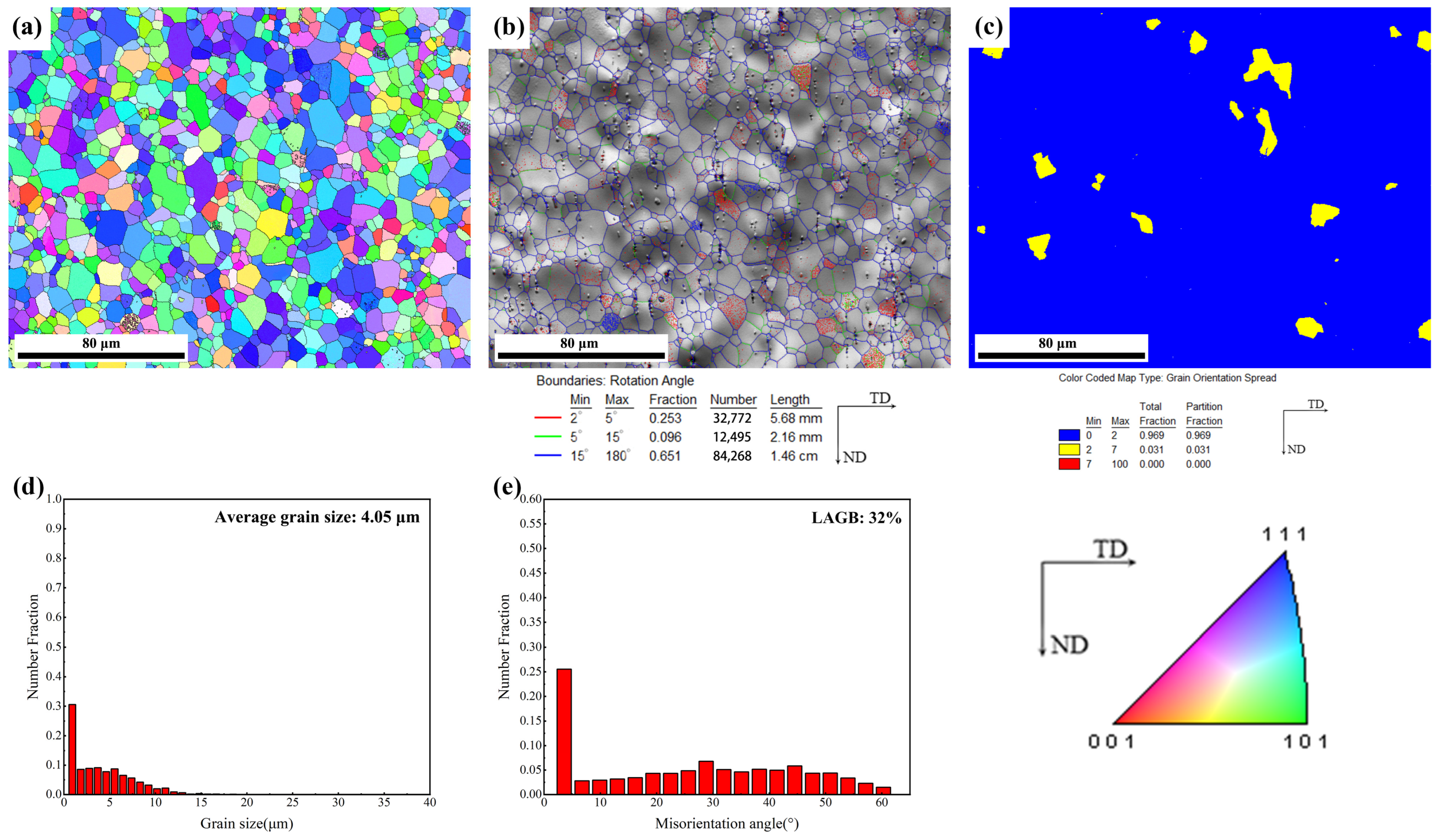

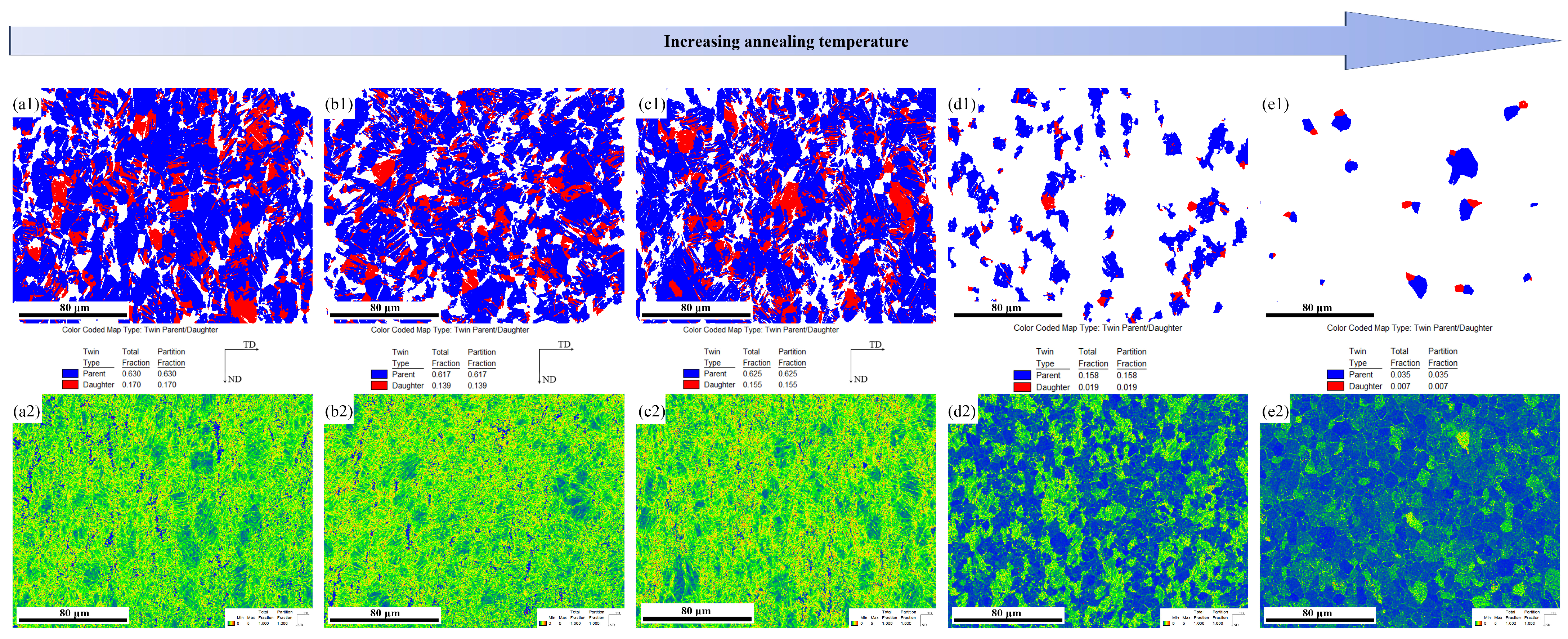

3.2. Microstructure Evolution of Alloy Tube Annealed at Different Temperatures

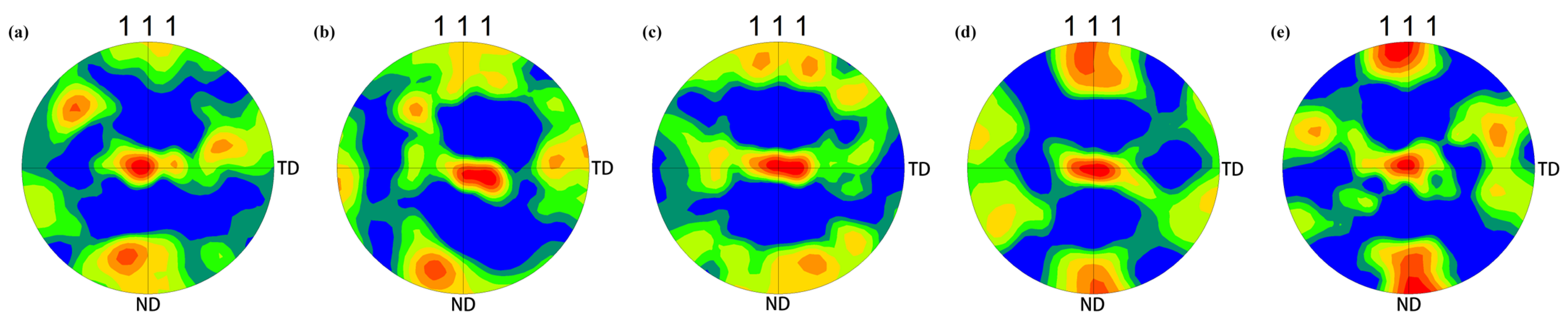

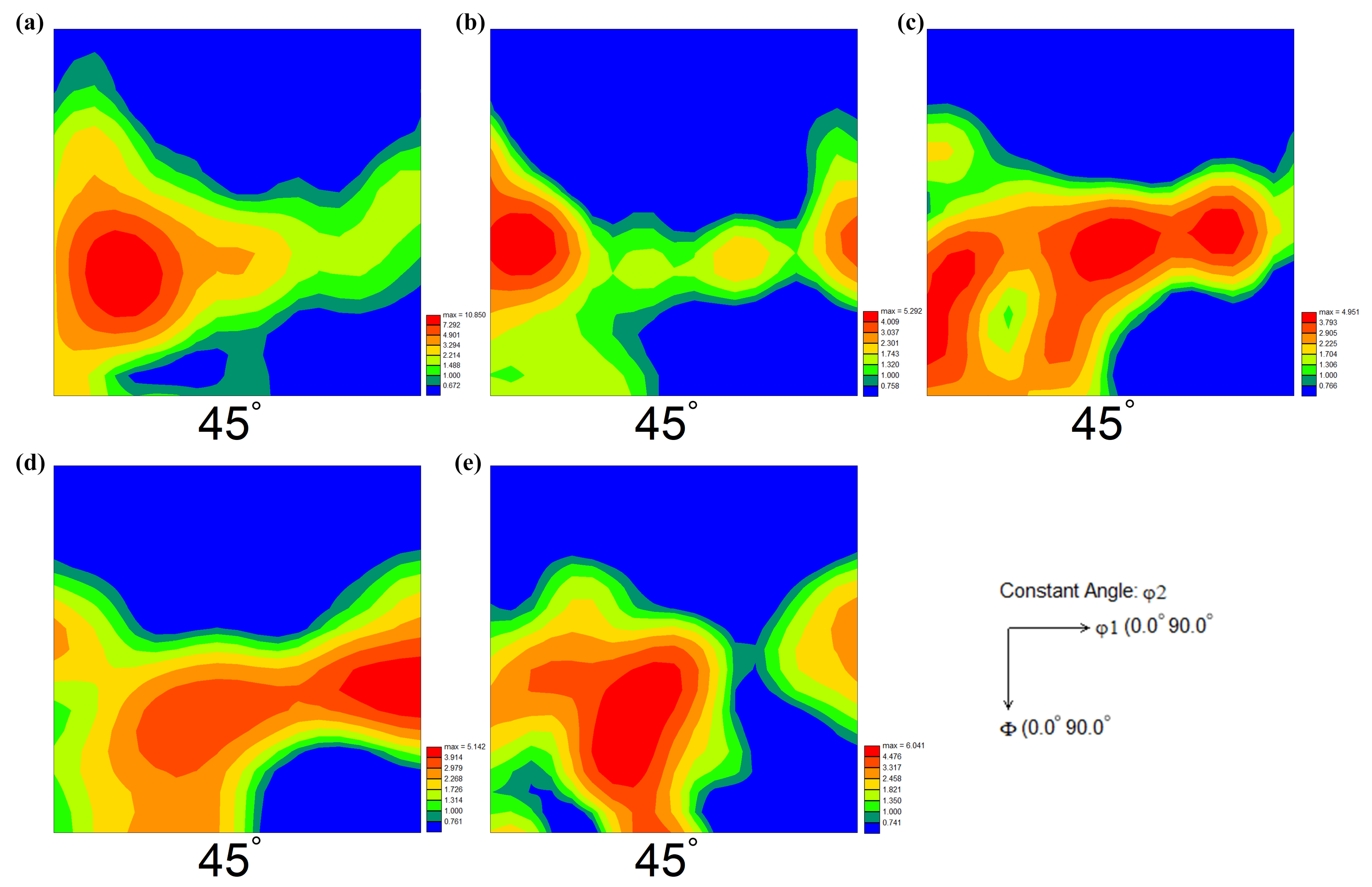

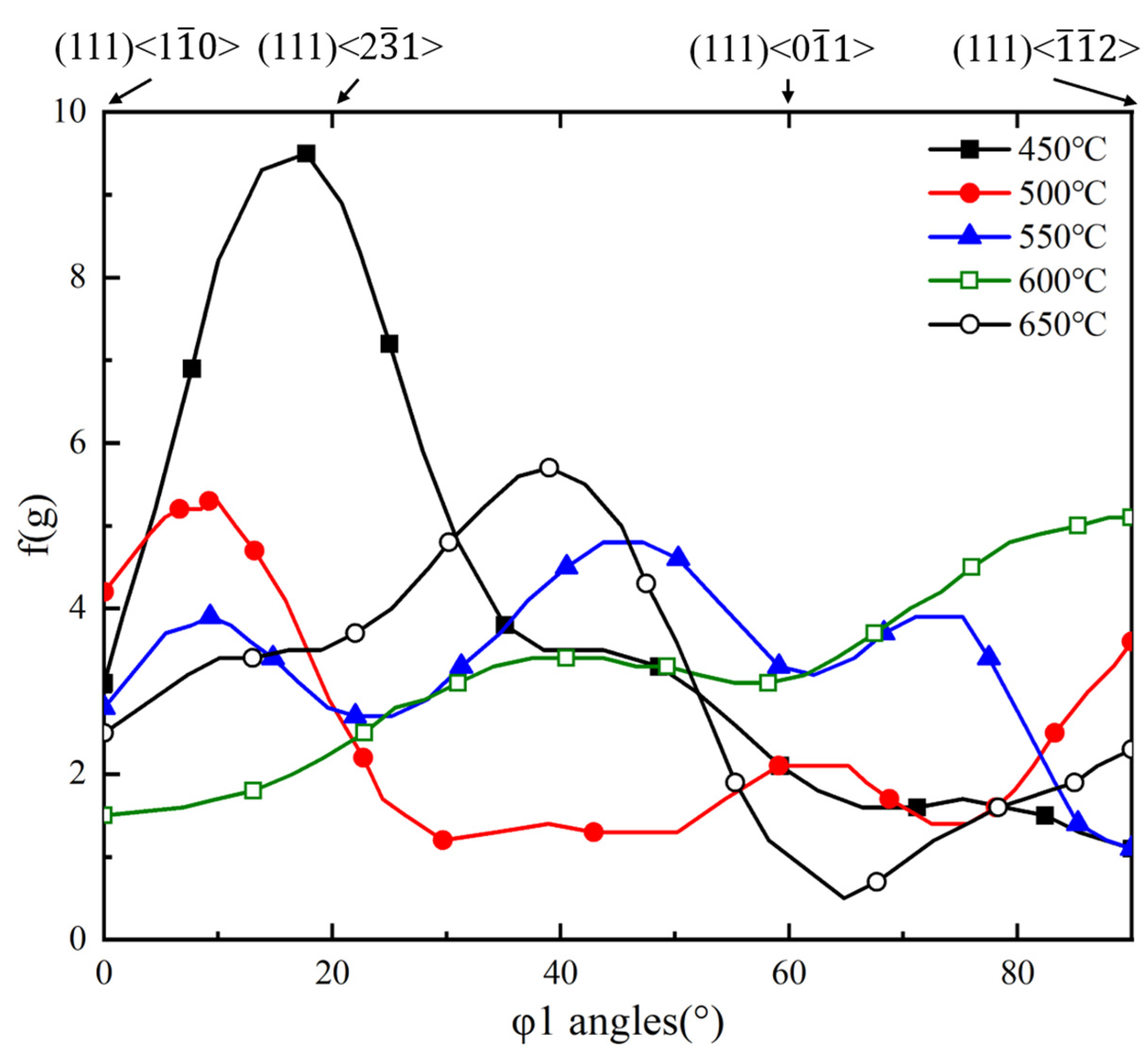

3.3. Texture Evolution of Alloy Tube Annealed at Different Temperatures

4. Conclusions

- With the increase in the annealing temperature, the cold-rolled Ti50Ni47Fe3 alloy tube undergoes a recovery, recrystallization, and grain growth process, and the microstructure changes from long striped grains to equiaxed grains. The recrystallization mainly occurs at 600 °C.

- The main texture of the as-annealed alloy tube is (111)<uvw>, distributed along the γ orientation line. With the increase in the annealing temperature, the orientation density dramatically decreases first and then remains stable. The orientation (111)<110> decreases, and the crystal orientation of the alloy gradually turns to (111)<112>. A series of secondary textures are distributed along the γ orientation line when the alloy is annealed at a lower temperature (450~600 °C).

- A recrystallization texture (111)<112> is formed during the recrystallization process. When the alloy is annealed at 650 °C, <101> and <111> orientation grains appear, which promotes the generation of recrystallization textures and weakens the fiber texture that is formed in the CR process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, W.; Meng, X.L.; Zhao, L.C. Recent development of TiNi-based shape memory alloys. Curr. Opin. Solid State Mater. Sci. 2005, 9, 296–302. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Recent developments in the research of shape memory alloys. Intermetallics 1999, 7, 511–528. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, X.-W.; Wang, K.-S.; Wang, W. Preparation and hot compression deformation of biomedical Ni-Ti alloy. Chin. J. Eng. 2019, 41, 238–245. [Google Scholar] [CrossRef]

- Huo, X.; Chen, P.; Lahkar, S.; Jin, M.; Han, X.; Song, Y.; Wang, X. Occurrence of the R-phase with increased stability induced by low temperature precipitate-free aging in a Ni50.9Ti49.1 alloy. Acta Mater. 2022, 227, 117688. [Google Scholar] [CrossRef]

- Yu, H.; Qiu, Y.; Young, M.L. Influence of Ni4Ti3 precipitate on pseudoelasticity of austenitic NiTi shape memory alloys deformed at high strain rate. Mater. Sci. Eng. A 2021, 804, 140753. [Google Scholar] [CrossRef]

- Rao, W.-F.; Wuttig, M.; Khachaturyan, A.G. Giant Nonhysteretic Responses of Two-Phase Nanostructured Alloys. Phys. Rev. Lett. 2011, 106, 105703. [Google Scholar] [CrossRef]

- Yang, R.; Ma, W.; Wang, C.; Wang, T.-M.; Wang, Q.-H. Effect of hot rolling on microstructure and tribology behaviors of Ti−50.8Ni alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 967–979. [Google Scholar] [CrossRef]

- Nii, Y.; Arima, T.-h.; Kim, H.Y.; Miyazaki, S. Effect of randomness on ferroelastic transitions: Disorder-induced hysteresis loop rounding in Ti-Nb-O martensitic alloy. Phys. Rev. B 2010, 82, 214104. [Google Scholar] [CrossRef]

- Sharifi, E.M.; Karimzadeh, F.; Kermanpur, A. The effect of cold rolling and annealing on microstructure and tensile properties of the nanostructured Ni50Ti50 shape memory alloy. Mater. Sci. Eng. A 2014, 607, 33–37. [Google Scholar] [CrossRef]

- Yu, C.; Aoun, B.; Cui, L.; Liu, Y.; Yang, H.; Jiang, X.; Cai, S.; Jiang, D.; Liu, Z.; Brown, D.E.; et al. Synchrotron high energy X-ray diffraction study of microstructure evolution of severely cold drawn NiTi wire during annealing. Acta Mater. 2016, 115, 35–44. [Google Scholar] [CrossRef]

- Shahmir, H.; Nili-Ahmadabadi, M.; Huang, Y.; Myun Jung, J.; Seop Kim, H.; Langdon, T.G. Shape memory effect in nanocrystalline NiTi alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 626, 203–206. [Google Scholar] [CrossRef]

- Jiang, S.; Hu, L.; Zhang, Y.; Liang, Y. Nanocrystallization and amorphization of NiTi shape memory alloy under severe plastic deformation based on local canning compression. J. Non-Cryst. Solids 2013, 367, 23–29. [Google Scholar] [CrossRef]

- Liang, Y.; Jiang, S.; Zhang, Y.; Hu, L.; Zhao, C. Microstructure evolution and deformation mechanism of NiTiFe shape memory alloy based on plane strain compression and subsequent annealing. Mater. Chem. Phys. 2018, 215, 112–120. [Google Scholar] [CrossRef]

- Cui, B.; Yao, J.; Wu, Y.; Cai, W. Effect of cold rolling ratio on the microstructure and recovery properties of Ti-Ni-Nb-Co shape memory alloys. J. Alloys Compd. 2019, 772, 728–734. [Google Scholar] [CrossRef]

- Liang, Q.; Zhao, S.; Liang, C.; Zhao, T.; Wang, D.; Ding, X.; Li, S.; Wang, Y.; Zheng, Y.; Ren, X.; et al. Strain states and unique properties in cold-rolled TiNi shape memory alloys. Acta Mater. 2022, 231, 117890. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Song, C.; Valiev, R.Z.; Mukherjee, A.K. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing. Mater. Sci. Eng. A 2003, 339, 159–165. [Google Scholar] [CrossRef]

- Ishida, A.; Sato, M. Microstructure and shape memory behaviour of annealed Ti51.5Ni(48.5-x)Cux (x = 6.5–20.9) thin films. Philos. Mag. 2007, 87, 5523–5538. [Google Scholar] [CrossRef]

- Lee, H.-C.; Shen, J.-J.; Chang, Y.-T.; Wu, C.-T.; Chen, C.-H. Evolutions of superelasticity and elastocaloric effect of Ti50Ni48Fe2 and aged-hardened Ni-rich Ti49.2Ni49.3Fe1.5 shape memory alloys under cyclic compressive deformation. J. Alloys Compd. 2022, 893, 162352. [Google Scholar] [CrossRef]

- Li, P.; Jia, Y.; Wang, Y.; Li, Q.; Meng, F.; He, Z. Effect of Fe Addition on Microstructure and Mechanical Properties of As-cast Ti49Ni51 Alloy. Materials 2019, 12, 3114. [Google Scholar] [CrossRef]

- Liu, S.; Hui, S.; Li, Y.; Song, X.; Yu, Y.; Ye, W. Equivalent Heat Treatments and Mechanical Properties in Cold-Rolled TiNiFe Shape-Memory Alloys. Materials 2023, 16, 7395. [Google Scholar] [CrossRef]

- Tu, C.-H.; Wu, S.-K.; Lin, C.; Huang, B.-Y. A study on two R-phase transformations in intermediate temperature aged Ni-rich TiNiFe-based shape memory alloys. Intermetallics 2021, 132, 107123. [Google Scholar] [CrossRef]

- Lai, Y.-C.; Wu, S.-K. A Study on Phase Transformation Exhibited in Ti49±xNi49∓xFe2 (x = 0 to 1) Shape Memory Alloys. Metall. Mater. Trans. A 2021, 52, 4636–4648. [Google Scholar] [CrossRef]

- Wang, T.; Guo, F.; Ai, T.; Li, Y. Superelastic stability of nanocrystalline Ni47Ti50Fe3 shape memory alloy. J. Mater. Res. Technol. 2023, 24, 3048–3054. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Guan, H.; Yang, Z.; Zhang, Y.; Gu, Q.; Yang, J. Degradation of recovery properties after heat treatment in hot-forged NiTiFe alloy. J. Alloys Compd. 2022, 928, 167171. [Google Scholar] [CrossRef]

- Kuranova, N.; Pushin, A.; Pushin, V.; Uksusnikov, A.; Kourov, N. Formation of nanostructured states in ternary TiNiFe-based shape memory alloys during megaplastic deformation and subsequent heat treatment. Tech. Phys. 2014, 59, 685–691. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Zhang, Y.; Yang, Z.; Gu, Q.; Wang, X.; Zhang, Y.; Yang, J. Cryogenic temperature deformation behavior and shape memory mechanism of NiTiFe alloy. Intermetallics 2023, 162, 107997. [Google Scholar] [CrossRef]

- Laplanche, G.; Kazuch, A.; Eggeler, G. Processing of NiTi shape memory sheets—Microstructural heterogeneity and evolution of texture. J. Alloys Compd. 2015, 651, 333–339. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Song, X.; Yu, Y.; Ye, W.; Hui, S. Microstructures and Mechanical Properties of Annealed Ti50Ni47Fe3 Shape Memory Alloy. Crystals 2023, 13, 706. [Google Scholar] [CrossRef]

- Chen, Y.; Li, A.; Ma, Z.; Wang, T.; Liu, Y.; Yu, K.; Yang, F.; Jiang, D.; Zhao, K.; Yang, H.; et al. Step-wise R phase transformation rendering high-stability two-way shape memory effect of a NiTiFe-Nb nanowire composite. Acta Mater. 2021, 219, 117258. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Tang, M.; Yan, B.; Yu, J.; Zhao, C. Mechanisms for influence of post-deformation annealing on microstructure of NiTiFe shape memory alloy processed by local canning compression. J. Mater. Process. Technol. 2021, 291, 116998. [Google Scholar] [CrossRef]

- Zhou, D.-D.; Zeng, W.-D.; Xu, J.-W.; Luo, D.-C.; Li, H. Evolution of Microstructure and Texture in Cold-Rolled Ti Tube under Annealing. Chin. J. Rare Met. 2019, 43, 470–475. [Google Scholar] [CrossRef]

- Chang, S.H.; Wu, S.K. Textures in cold-rolled and annealed Ti50Ni50 shape memory alloy. Scr. Mater. 2004, 50, 937–941. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Rui, S.-S.; Han, Q.-N.; Wang, X.; Li, S.; Ma, X.; Su, Y.; Cai, Z.; Du, D.; Shi, H.-J. Correlations between two EBSD-based metrics Kernel Average Misorientation and Image Quality on indicating dislocations of near-failure low alloy steels induced by tensile and cyclic deformations. Mater. Today Commun. 2021, 27, 102445. [Google Scholar] [CrossRef]

- Inoue, H.; Miwa, N.; Inakazu, N. Texture and shape memory strain in TiNi alloy sheets. Acta Mater. 1996, 44, 4825–4834. [Google Scholar] [CrossRef]

- Mao, S.C.; Han, X.D.; Luo, J.F.; Zhang, Z. Microstructure and texture evolution of ultra-thin TiNi hot-rolled sheets studied by automated EBSD. Mater. Lett. 2005, 59, 3567–3571. [Google Scholar] [CrossRef]

- Zhao, H.; Rama, S.C.; Barber, G.C.; Wang, Z.; Wang, X. Experimental study of deep drawability of hot rolled IF steel. J. Mater. Process. Technol. 2002, 128, 73–79. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J.; Hook, R.E. Cold rolling and annealing textures in low carbon and extra low carbon steels. Int. Mater. Rev. 1994, 39, 129–172. [Google Scholar] [CrossRef]

- Inagaki, H. Nucleation of a {111} Recrystallized Grain at the Grain Boundary of Cold Rolled Polycrystalline Iron. Trans. Jpn. Inst. Met. 1987, 28, 251–263. [Google Scholar] [CrossRef]

| Element | Fe | Ni | C | O | Ti |

|---|---|---|---|---|---|

| Content (wt.%) | 3.27 | 52.16 | 0.0028 | <0.002 | Bal. |

| Annealing Temperature (°C) | 450 | 500 | 550 | 600 | 650 |

|---|---|---|---|---|---|

| Microhardness (HV5) | 284.4 | 268.9 | 251.8 | 223.4 | 226.3 |

| 289.2 | 267.4 | 253.4 | 225.2 | 225.2 | |

| 284.4 | 264.9 | 254.4 | 227.4 | 228.7 | |

| 278.5 | 264.9 | 250.5 | 228.0 | 229.1 | |

| 283.4 | 264.9 | 252.1 | 228.3 | 227.3 | |

| Average microhardness (HV5) | 284.0 | 266.2 | 252.4 | 226.5 | 227.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, J.; Song, X.; Li, Y.; Liu, S.; Yu, Y.; Ye, W.; Hui, S. The Effect of Annealing Treatment on the Microstructure and Texture of a Cold-Rolled TiNiFe Shape Memory Alloy Tube. Crystals 2024, 14, 274. https://doi.org/10.3390/cryst14030274

Wen J, Song X, Li Y, Liu S, Yu Y, Ye W, Hui S. The Effect of Annealing Treatment on the Microstructure and Texture of a Cold-Rolled TiNiFe Shape Memory Alloy Tube. Crystals. 2024; 14(3):274. https://doi.org/10.3390/cryst14030274

Chicago/Turabian StyleWen, Jianxian, Xiaoyun Song, Yanfeng Li, Shuwei Liu, Yang Yu, Wenjun Ye, and Songxiao Hui. 2024. "The Effect of Annealing Treatment on the Microstructure and Texture of a Cold-Rolled TiNiFe Shape Memory Alloy Tube" Crystals 14, no. 3: 274. https://doi.org/10.3390/cryst14030274

APA StyleWen, J., Song, X., Li, Y., Liu, S., Yu, Y., Ye, W., & Hui, S. (2024). The Effect of Annealing Treatment on the Microstructure and Texture of a Cold-Rolled TiNiFe Shape Memory Alloy Tube. Crystals, 14(3), 274. https://doi.org/10.3390/cryst14030274