Revisiting the Crystallography of {225}γ Martensite: How EBSD Can Help to Solve Long-Standing Controversy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Prediction of the PTMC for an LIS on

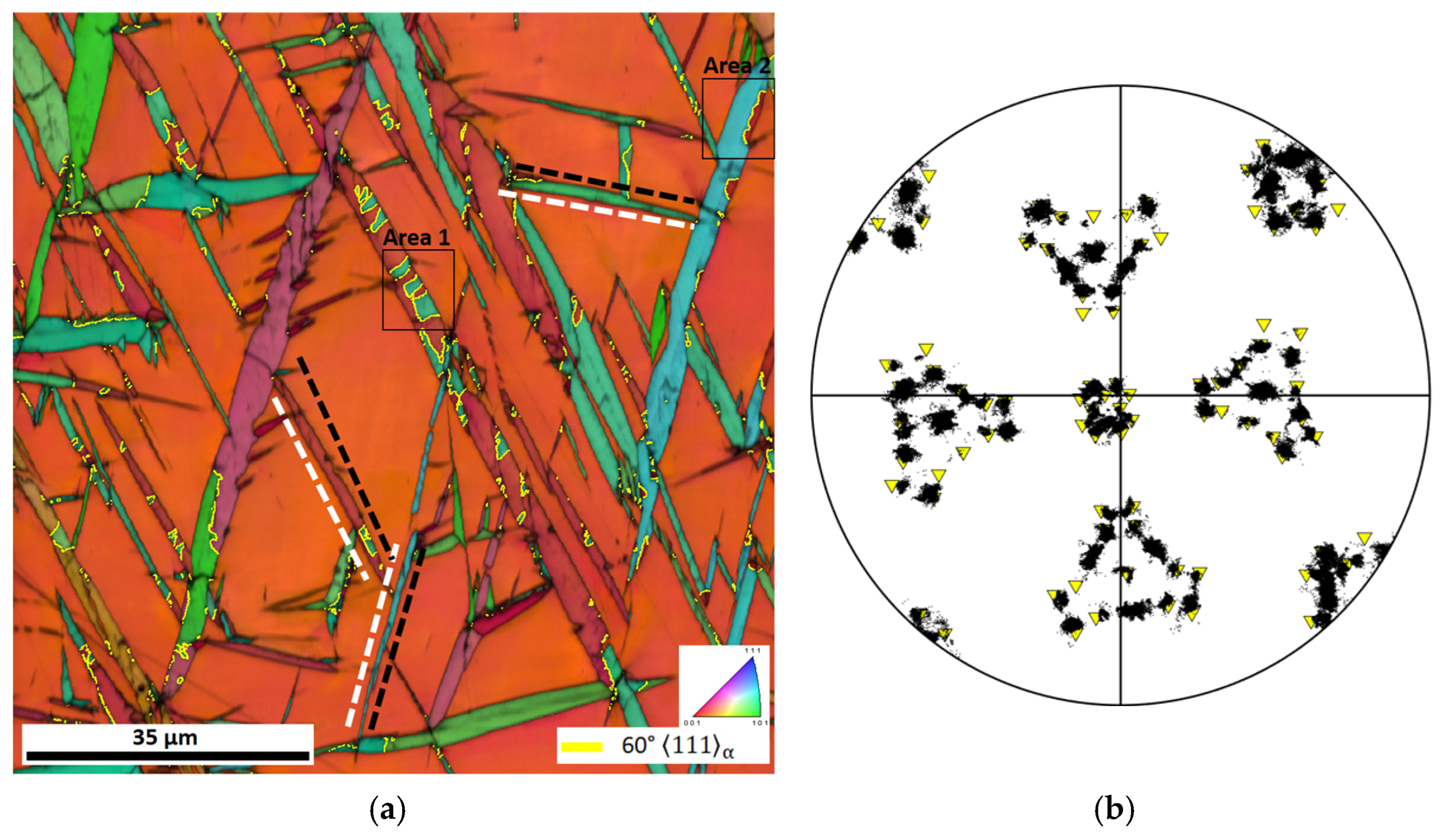

3.2. The OR and HP of Fully Grown Plates

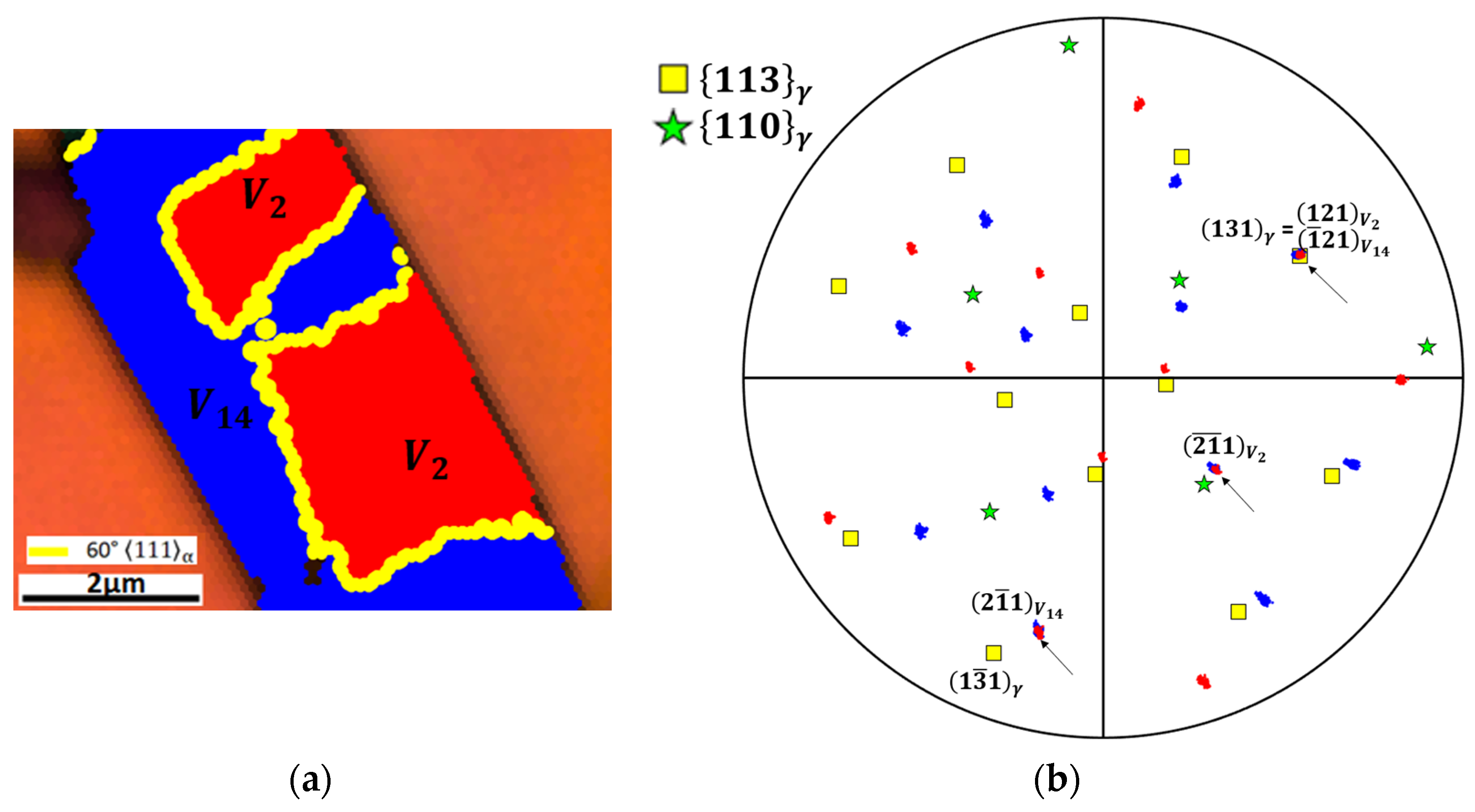

3.3. Local Misorientation Analysis at the Scale of the Transformation Twins

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raabe, D.; Sun, B.; Kwiatkowski Da Silva, A.; Gault, B.; Yen, H.-W.; Sedighiani, K.; Thoudden Sukumar, P.; Souza Filho, I.R.; Katnagallu, S.; Jägle, E.; et al. Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels. Met. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Vermeij, T.; Mornout, C.J.A.; Rezazadeh, V.; Hoefnagels, J.P.M. Martensite Plasticity and Damage Competition in Dual-Phase Steel: A Micromechanical Experimental–Numerical Study. Acta Mater. 2023, 254, 119020. [Google Scholar] [CrossRef]

- Park, H.S.; Kwon, O.-H.; Baskin, J.S.; Barwick, B.; Zewail, A.H. Direct Observation of Martensitic Phase-Transformation Dynamics in Iron by 4D Single-Pulse Electron Microscopy. Nano Lett. 2009, 9, 3954–3962. [Google Scholar] [CrossRef] [PubMed]

- Shinohara, Y.; Hishida, M.; Tanaka, Y.; Inamura, T. Analysis of Thin-Plate Martensite Microstructure in Steel Focusing on Incompatibility and Its Visualization. Acta Mater. 2023, 259, 119275. [Google Scholar] [CrossRef]

- Shibata, A.; Miyamoto, G.; Morito, S.; Nakamura, A.; Moronaga, T.; Kitano, H.; Gutierrez-Urrutia, I.; Hara, T.; Tsuzaki, K. Substructure and Crystallography of Lath Martensite in As-Quenched Interstitial-Free Steel and Low-Carbon Steel. Acta Mater. 2023, 246, 118675. [Google Scholar] [CrossRef]

- Krauss, G.; Marder, A.R. The Morphology of Martensite in Iron Alloys. Metall. Trans. 1971, 2, 2343–2357. [Google Scholar] [CrossRef]

- Umemoto, M.; Yoshitake, E.; Tamura, I. The Morphology of Martensite in Fe-C, Fe-Ni-C and Fe-Cr-C Alloys. J. Mater. Sci. 1983, 18, 2893–2904. [Google Scholar] [CrossRef]

- Kelly, P.M.; Nutting, J.; Cottrell, A.H. The Martensite Transformation in Carbon Steels. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1997, 259, 45–58. [Google Scholar] [CrossRef]

- Bowles, J.S.; Mackenzie, J.K. The Crystallography of Martensite Transformations III. Face-Centred Cubic to Body-Centred Tetragonal Transformations. Acta Metall. 1954, 2, 224–234. [Google Scholar] [CrossRef]

- Wechsler, M.; Lieberman, D.; Read, T. The Martensite Transformation. Trans. AIME 1953, 197, 1503–1521. [Google Scholar]

- Krauklis, P.; Bowles, J.S. The Direct Measurement of Length Changes in the (225) Martensite Habit Plane. Acta Metall. 1969, 17, 997–1004. [Google Scholar] [CrossRef]

- Dunne, D.P.; Bowles, J.S. Measurement of the Shape Strain for the (225) and (259) Martensitic Transformations. Acta Metall. 1969, 17, 201–212. [Google Scholar] [CrossRef]

- Bowles, J.S.; Mackenzie, J.K. The Crystallography of the (225)F-Transformation in Steels. Acta Metall. 1962, 10, 625–636. [Google Scholar] [CrossRef]

- Ross, N.D.H.; Crocker, A.G. A Generalized Theory of Martensite Crystallography and Its Application to Transformations in Steels. Acta Metall. 1970, 18, 405–418. [Google Scholar] [CrossRef]

- Acton, A.F.; Bevis, M. A Generalised Martensite Crystallography Theory. Mater. Sci. Eng. 1969, 5, 19–29. [Google Scholar] [CrossRef]

- Dunne, D.P.; Wayman, C.M. The Crystallography of Ferrous Martensites. Met. Trans. 1971, 2, 2327–2341. [Google Scholar] [CrossRef]

- Baur, A.P.; Cayron, C.; Logé, R.E. {225}γ Habit Planes in Martensitic Steels: From the PTMC to a Continuous Model. Sci. Rep. 2017, 7, 40938. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, K.; Oka, M.; Wayman, C.M. Transmission Electron Microscopy Studies of {225}f Martensite in an Fe-8%Cr-1%C Alloy. Acta Metall. 1971, 19, 1–6. [Google Scholar] [CrossRef]

- Sandvik, B.P.J.; Wayman, C.M. The Substructure of (252)f Martensite Formed in an Fe- 8Cr- 1 C Alloy. Metall. Trans. A 1983, 14, 2455–2468. [Google Scholar] [CrossRef]

- Morton, A.J.; Wayman, C.M. Theoretical and Experimental Aspects of the “(225)” Austenite-Martensite Transformation in Iron Alloys. Acta Metall. 1966, 14, 1567–1581. [Google Scholar] [CrossRef]

- Ahlers, M. On the Theory of “{225}” Martensite. Scr. Metall. 1968, 2, 529–534. [Google Scholar] [CrossRef]

- Sandvik, B.P.J.; Wayman, C.M. Some Crystallographic Characteristics of the (252)f Martensite Transformation in Fe-Alloys. Metall. Trans. A 1983, 14, 2469–2477. [Google Scholar] [CrossRef]

- Muddle, B.C.; Krauklis, P.; Bowles, J.S. The Shape Strain of the (225)F Martensite Transformation. Acta Metall. 1976, 24, 371–380. [Google Scholar] [CrossRef]

- Gu, X.-F.; Furuhara, T.; Zhang, W.-Z. PTCLaB: Free and Open-Source Software for Calculating Phase Transformation Crystallography. J. Appl. Crystallogr. 2016, 49, 1099–1106. [Google Scholar] [CrossRef]

- Xu, C.Q.; Cao, X.M.; Li, G.J. (225)A Martensite Transformation and Kurdjumow-Sachs Mechanism. MSF 2008, 575–578, 924–929. [Google Scholar]

- Malet, L.; Godet, S. On the Relation between Orientation Relationships Predicted by the Phenomenological Theory and Internal Twins in Plate Martensite. Scr. Mater. 2015, 102, 83–86. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The Morphology and Crystallography of Lath Martensite in Fe-C Alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Qi, L.; Khachaturyan, A.G.; Morris, J.W. The Microstructure of Dislocated Martensitic Steel: Theory. Acta Mater. 2014, 76, 23–39. [Google Scholar] [CrossRef]

- Bate, P.; Hutchinson, B. The Effect of Elastic Interactions between Displacive Transformations on Textures in Steels. Acta Mater. 2000, 48, 3183–3192. [Google Scholar] [CrossRef]

- Kundu, S.; Bhadeshia, H.K.D.H. Crystallographic Texture and Intervening Transformations. Scr. Mater. 2007, 57, 869–872. [Google Scholar] [CrossRef]

| Sol. 1 | Sol. 2 | Sol. 3 | Sol. 4 | |

|---|---|---|---|---|

| HP | ||||

| SD | ||||

| OR | 1.3° from KS | 9.9° from KS | 1° from KS | 7.5° from KS |

| MSD | 1.53 | 1.53 | 0.28 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malet, L.; Godet, S. Revisiting the Crystallography of {225}γ Martensite: How EBSD Can Help to Solve Long-Standing Controversy. Crystals 2024, 14, 287. https://doi.org/10.3390/cryst14030287

Malet L, Godet S. Revisiting the Crystallography of {225}γ Martensite: How EBSD Can Help to Solve Long-Standing Controversy. Crystals. 2024; 14(3):287. https://doi.org/10.3390/cryst14030287

Chicago/Turabian StyleMalet, Loïc, and Stéphane Godet. 2024. "Revisiting the Crystallography of {225}γ Martensite: How EBSD Can Help to Solve Long-Standing Controversy" Crystals 14, no. 3: 287. https://doi.org/10.3390/cryst14030287