High-Temperature (Cu,C)Ba2Ca3Cu4Oy Superconducting Films with Large Irreversible Fields Grown on SrLaAlO4 Substrates by Pulsed Laser Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the (Cu,C)-1234 Target

2.2. Deposition of the (Cu,C)-1234 Films

2.3. Characterization Techniques

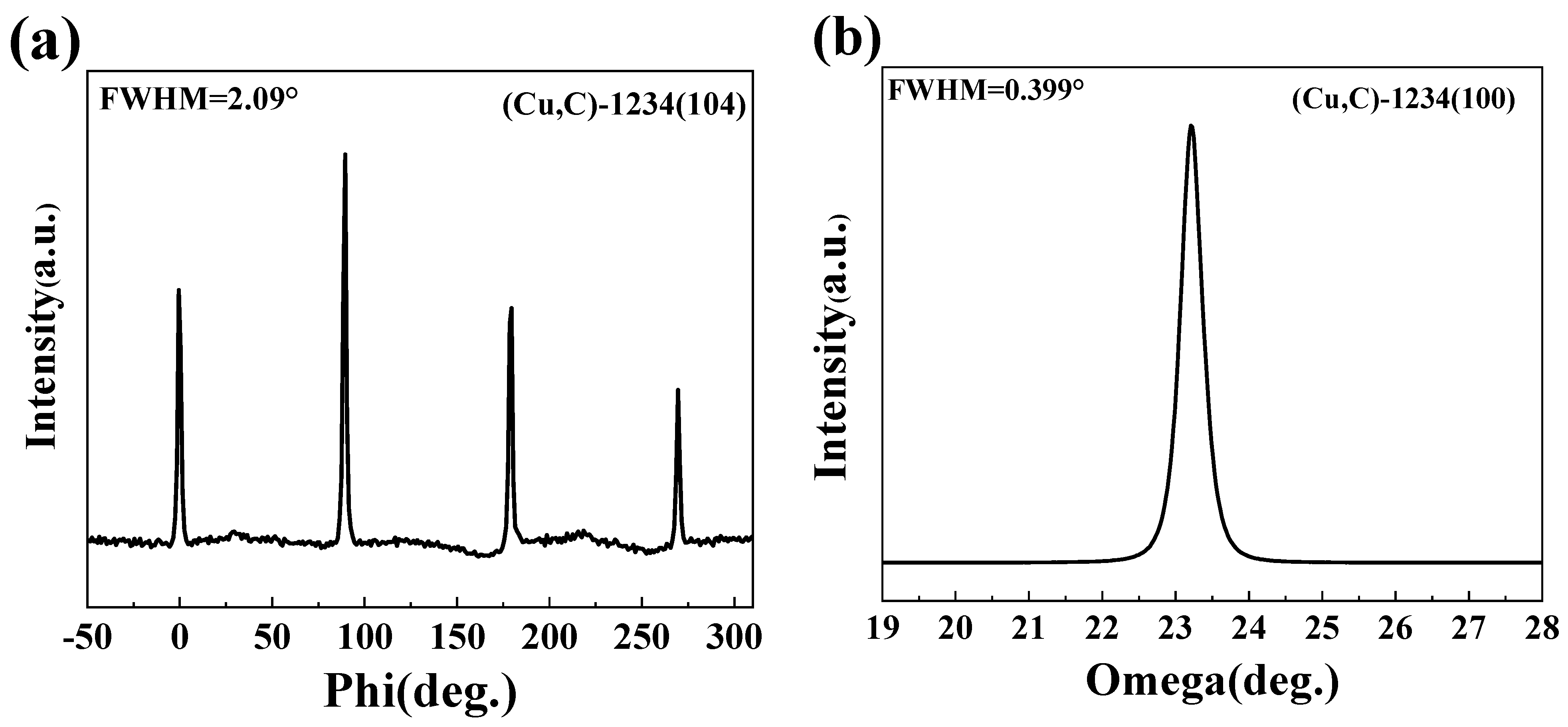

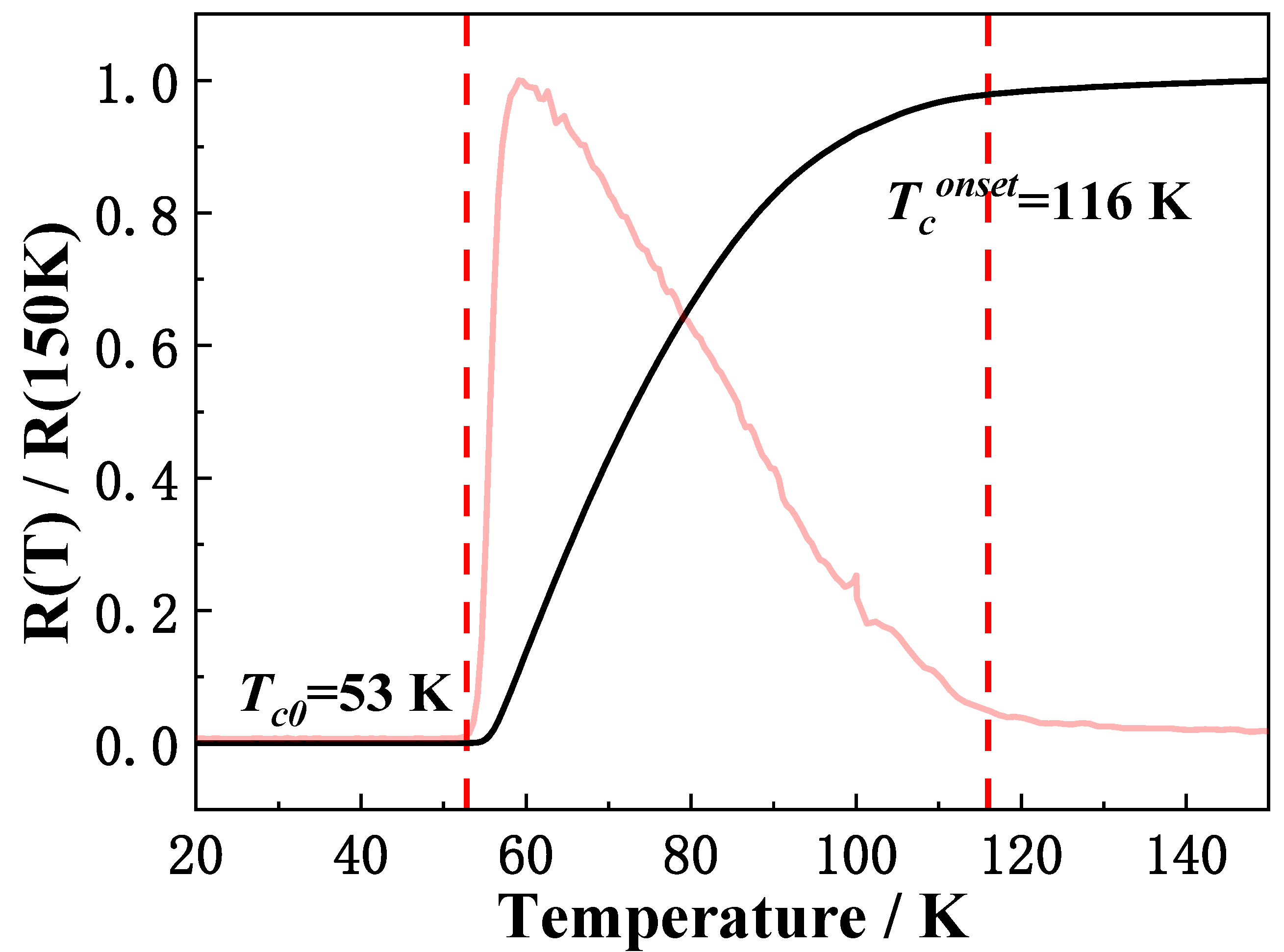

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bondarenko, S.I.; Koverya, V.P.; Krevsun, A.V.; Link, S.I. High-temperature superconductors of the family (RE)Ba2Cu3O7-δ and their application. Low Temp. Phys. 2017, 43, 1125. [Google Scholar] [CrossRef]

- Cai, C.; Chi, C.; Li, M.; Liu, Z.; Lu, Y.; Guo, Y.; Bai, C.; Lu, Q.; Dou, W. Advance and challenge of secondary-generation high- temperature superconducting tapes for high field applications. Sci. Bull. 2019, 64, 827. [Google Scholar] [CrossRef]

- Wang, K.; Hou, Q.; Pal, A.; Wu, H.; Si, J.; Chen, J.; Yu, S.; Chen, Y.; Lv, W.; Ge, J.; et al. Structural and Physical Properties of High-Entropy REBa2Cu3O7-δ Oxide Superconductors. J. Supercond. Novel Magn. 2021, 34, 1379. [Google Scholar] [CrossRef]

- Cai, C.; Li, Z.; Lu, Y. Evolvement and Prospect of Practical Superconducting Materials. Mater. China 2011, 30, 1. [Google Scholar]

- Li, Q.; Suenaga, M.; Kaneko, T.; Sato, K.; Simmon, C. Collapse of irreversible field of superconducting Bi2Sr2Ca2Cu3O10+δ/Ag tapes with columnar defects. Appl. Phys. Lett. 1997, 71, 1561. [Google Scholar] [CrossRef]

- Clayton, N.; Musolino, N.; Giannini, E.; Garnier, V.; Flükiger, R. Growth and superconducting properties of Bi2Sr2Ca2Cu3O10 single crystals. Supercond. Sci. Technol. 2004, 17, S563. [Google Scholar] [CrossRef]

- Liu, J.; Cheng, J.; Wang, Q. Analysis and enhancement of cooling system of high-speed permanent magnet motor based on computational fluid dynamics. Adv. Technol. Electral. Eng. Energy 2017, 36, 1. [Google Scholar]

- Dadras, S.; Falahati, S.; Dehghani, S. Effects of graphene oxide doping on the structural and superconducting properties of YBa2Cu3O7−δ. Phys. C 2018, 548, 65. [Google Scholar] [CrossRef]

- Palau, A.; Valles, F.; Rouco, V.; Coll, M.; Li, Z.; Pop, C.; Mundet, B.; Gazquez, J.; Guzman, R.; Gutierrez, J.; et al. Disentangling vortex pinning landscape in chemical solution deposited superconducting YBa2Cu3O7−x films and nanocomposites. Sci. Technol. 2018, 31, 034004. [Google Scholar]

- Johnson, C.L.; Bording, J.K.; Zhu, Y. Structural inhomogeneity and twinning in YBa2Cu3O7−δ superconductors: High-resolution transmission electron microscopy measurements. Phys. Rev. B 2008, 78, 14517. [Google Scholar] [CrossRef]

- Shimakawa, Y.; Jorgensen, J.D.; Hinks, D.G.; Shaked, H.; Hitterman, R.L.; Izumi, F.; Kawashima, T.; Takayama-Muromachi, E.; Kamiyama, T. Crystal structure of (Cu,C)Ba2Ca3Cu4O11+δ(Tc = 117 K) by neutron-powder-diffraction analysis. Phys. Rev. B 1994, 50, 16008. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, W.; Zhu, X.; Zhao, H.; Hu, Z.; He, C.; Wen, H. Unprecedented high irreversibility line in the nontoxic cuprate superconductor (Cu,C)Ba2Ca3Cu4O11+δ. Sci. Adv. 2018, 4, eaau0192. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Ming, X.; Si, J.; Zhu, X.; Wang, J.; Wen, H. Characterization of the (Cu,C)Ba2Ca3Cu4O11+δ single crystals grown under high pressure. Supercond. Sci. Technol. 2021, 35, 025004. [Google Scholar] [CrossRef]

- He, C.; Ming, X.; Lin, R.; Fan, X.; Song, D.; Ge, B.; Wen, H. Key factor for low anisotropy and high irreversibility field in (Cu,C)Ba2Ca3Cu4O11+δ. Mater. Today Phys. 2022, 29, 100913. [Google Scholar] [CrossRef]

- Allen, J.L.; Mercey, B.; Prellier, W.; Hamet, J.F.; Hervieu, M.; Raveau, B. The first superconducting thin film oxycarbonates coherent intergrowth of several members of a new structural series (CaCuO2)m(Ba2CuO2CO3)n. Phys. C 1995, 241, 158. [Google Scholar] [CrossRef]

- Prellier, W.; Allen, J.L.; Prouteau, C.; Simon, C.; Mercey, B. Irreversibility line and critical current densities of an oxycarbonate thin film Ba2Ca3Cu4CO3O8. Supercond. Sci. Technol. 1995, 8, 361. [Google Scholar] [CrossRef]

- Hervieu, M.; Mercey, B.; Prellier, W.; Allen, J.L.; Hamet, J.F.; Raveau, B. Microstructure of superconducting copper oxycarbonate thin films of the Ba–Ca–Cu–C–O system. J. Mater. Chem. 1996, 6, 165. [Google Scholar] [CrossRef]

- Prellier, W.; Tebano, A.; Allen, J.L.; Mercey, B.; Hamet, J.F.; Hervieu, M.; Raveau, B. High Tc superconducting oxycarbonate thin films grown by laser ablation: Promising new materials. Phys. C 1997, 282, 647. [Google Scholar] [CrossRef]

- Calestani, G.; Migliori, A.; Spreitzer, U.; Hauser, S.; Fuchs, M.; Barowski, H.; Schauer, T.; Assmann, W.; Range, K.J.; Varlashkin, A.; et al. Ba-Ca–Cu oxycarbonate thin films, prepared by pulsed laser deposition: Structure, growth mechanism and superconducting properties. Phys. C 1999, 312, 225. [Google Scholar] [CrossRef]

- Duan, T.; Hao, J.; Chu, H.; Li, B.; Dai, Y.; Wen, H. Existence of carbonate clusters and its relationship with critical temperature in superconducting (Cu,C)Ba2Ca3Cu4Oy films. Phys. C 2020, 573, 1353646. [Google Scholar] [CrossRef]

- Duan, T.; Hao, J.; Chu, H.; Wen, H. Preparation and superconducting properties of the (Cu,C)Ba2Ca3Cu4O11+y films with zero-resistance transition temperature of 96 K. Supercond. Sci. Technol. 2020, 33, 025009. [Google Scholar] [CrossRef]

- Adachi, H.; Sakai, M.; Satoh, T.; Setsune, K. Epitaxial Growth and Properties of (CO3) Stabilised BaCuO2 Superconducting Thin Films. In Proceedings of the 8th International Symposium on Superconductivity VIII. Advances in Superconductivity VIII, Hamamatsu, Japan, 30 October–2 November 1996; p. 955. [Google Scholar]

- Shibata, H.; Karimoto, S.; Tsukada, A.; Makimoto, T. Growth of (Cu,C)Ba2Ca(n−1)CunOy thin films by molecular-beam epitaxy. Phys. C 2006, 445, 862. [Google Scholar] [CrossRef]

- Shibata, H.; Karimoto, S.; Tsukada, A.; Makimoto, T. Thin film growth of (Cu,C)Ba2Ca(n−1)CunOy(n=1–4) superconductor by molecular beam epitaxy. J. Crys. Growth 2007, 301, 684–686. [Google Scholar] [CrossRef]

- Shi, W.; Shi, J.; Sun, J.; Yao, W.; Qi, Z. Influence of substrate temperature on the orientation of YBa2Cu3O7 films. Appl. Phys. Lett. 1990, 5, 822. [Google Scholar] [CrossRef]

- De, R.; Augustine, S.; Das, B.; Sikdar, M.K.; Ranjan, M.; Sahoo, P.K.; Haque, S.M.; Prathap, C.; Rao, K.D. Influence of in-situ substrate temperature on anisotropic behaviour of glancing angle grown nickel nanocolumns. Appl. Phys. A 2024, 130, 126. [Google Scholar] [CrossRef]

| Method | Film Types | Substrate | Tconset (K) | Tc0 (K) | References |

|---|---|---|---|---|---|

| PLD | Ba2Ca3Cu4CO3O8 | LaAlO3(l00) | 80–100 | 58 | [15,16,17] |

| Ba2Ca3Cu4O8CO3 | 110 | 75 | [18] | ||

| (Cu,C)-1234 | 115 | 78 | [19] | ||

| (Cu,C)-1234 | 118 | 96 | [20,21] | ||

| Sputtering | Ba2CuO2(CO3) | SrTiO3(00l) | 40-50 | 4.2 | [22] |

| MBE | (Cu,C)-1234 | NdGaO3(l00) | 105 | 55 | [23,24] |

| SrLaGaO4(00l) | 90 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, Z.; Zhu, P.; He, J.; Cai, C. High-Temperature (Cu,C)Ba2Ca3Cu4Oy Superconducting Films with Large Irreversible Fields Grown on SrLaAlO4 Substrates by Pulsed Laser Deposition. Crystals 2024, 14, 514. https://doi.org/10.3390/cryst14060514

Li Y, Liu Z, Zhu P, He J, Cai C. High-Temperature (Cu,C)Ba2Ca3Cu4Oy Superconducting Films with Large Irreversible Fields Grown on SrLaAlO4 Substrates by Pulsed Laser Deposition. Crystals. 2024; 14(6):514. https://doi.org/10.3390/cryst14060514

Chicago/Turabian StyleLi, Yugang, Zhiyong Liu, Ping Zhu, Jinyu He, and Chuanbing Cai. 2024. "High-Temperature (Cu,C)Ba2Ca3Cu4Oy Superconducting Films with Large Irreversible Fields Grown on SrLaAlO4 Substrates by Pulsed Laser Deposition" Crystals 14, no. 6: 514. https://doi.org/10.3390/cryst14060514