High Energy Storage Performance in Pb1−xLax(Hf0.45Sn0.55)0.995O3 Antiferroelectric Ceramics

Abstract

:1. Introduction

2. Experimental Procedures

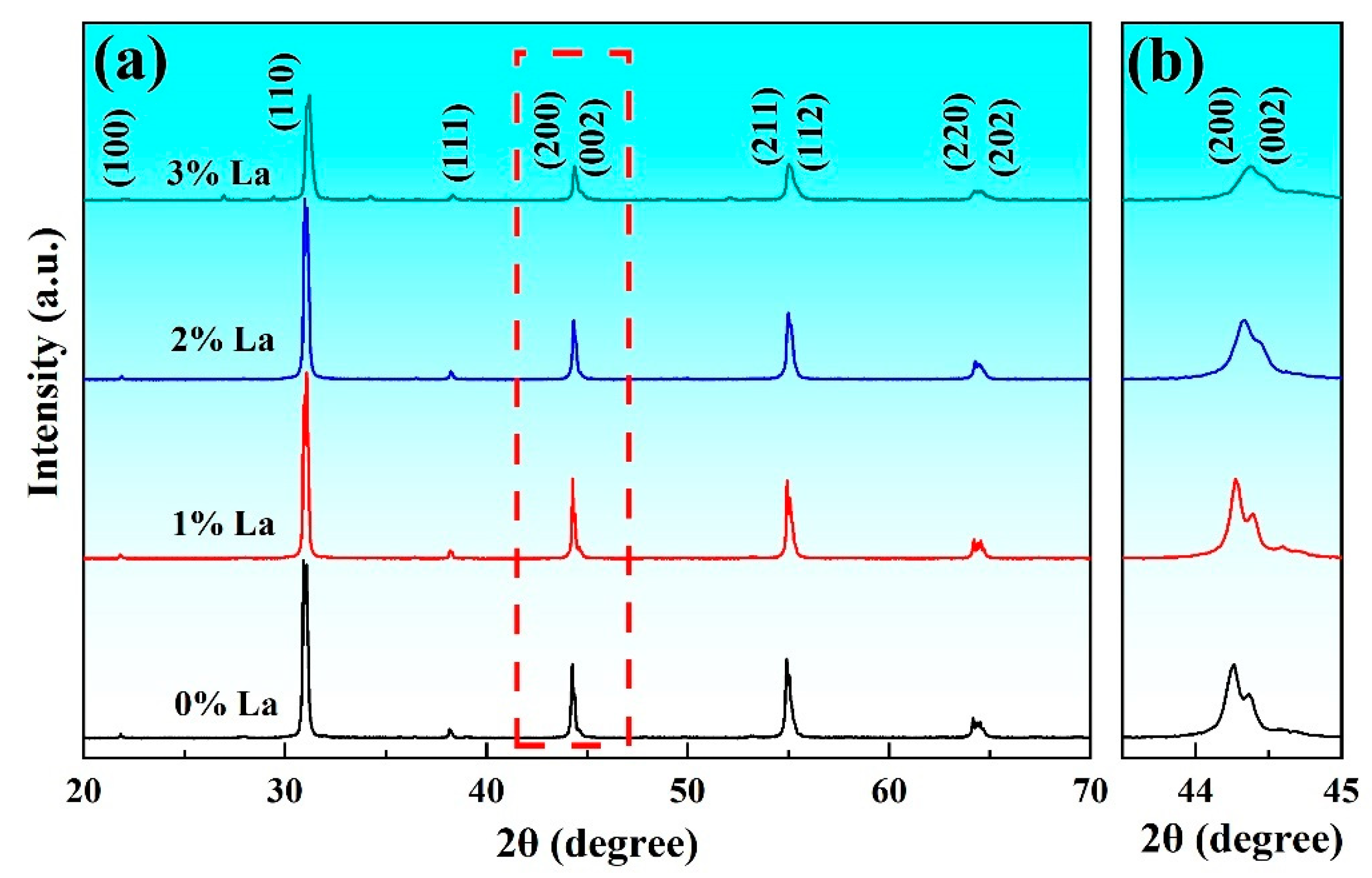

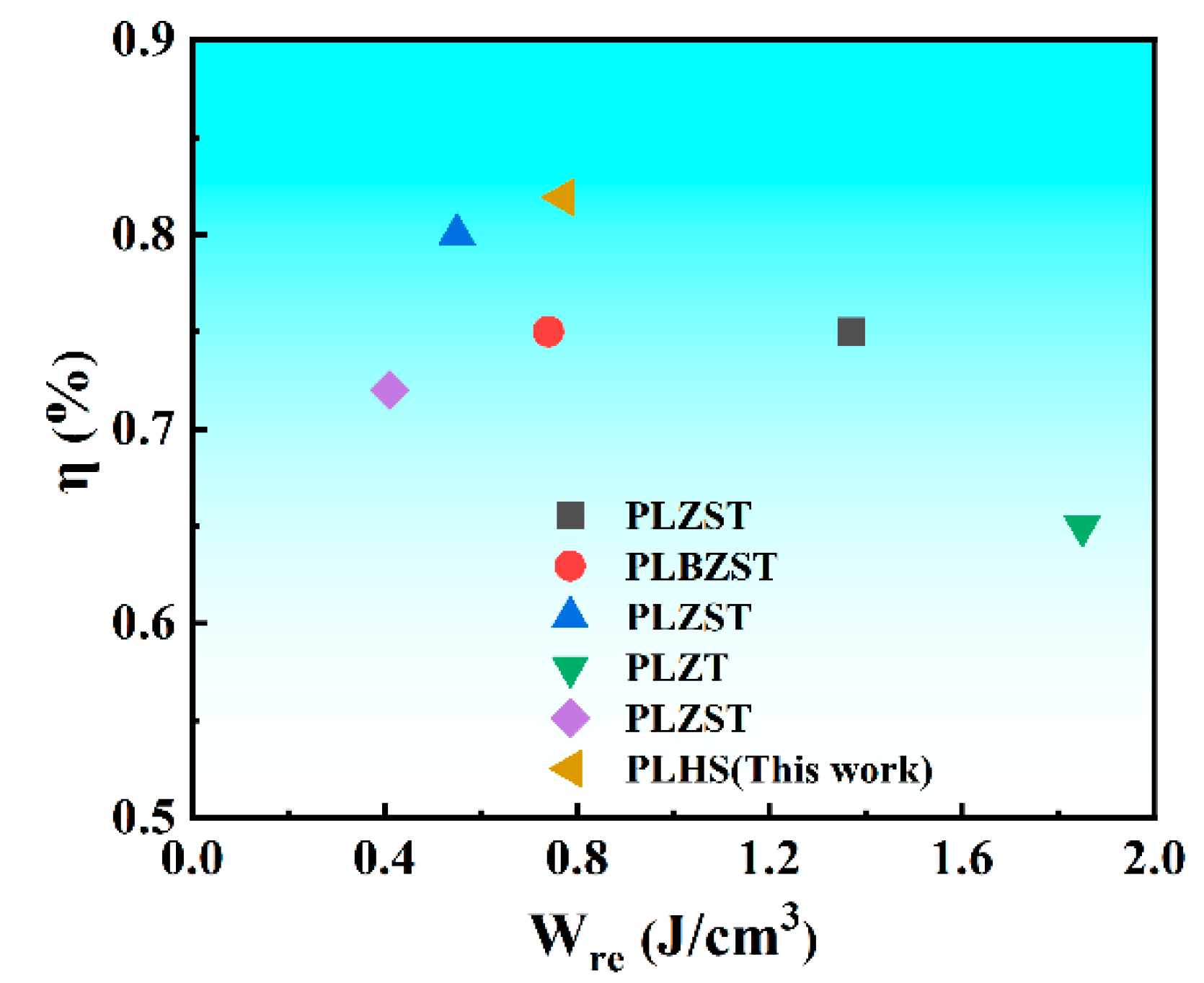

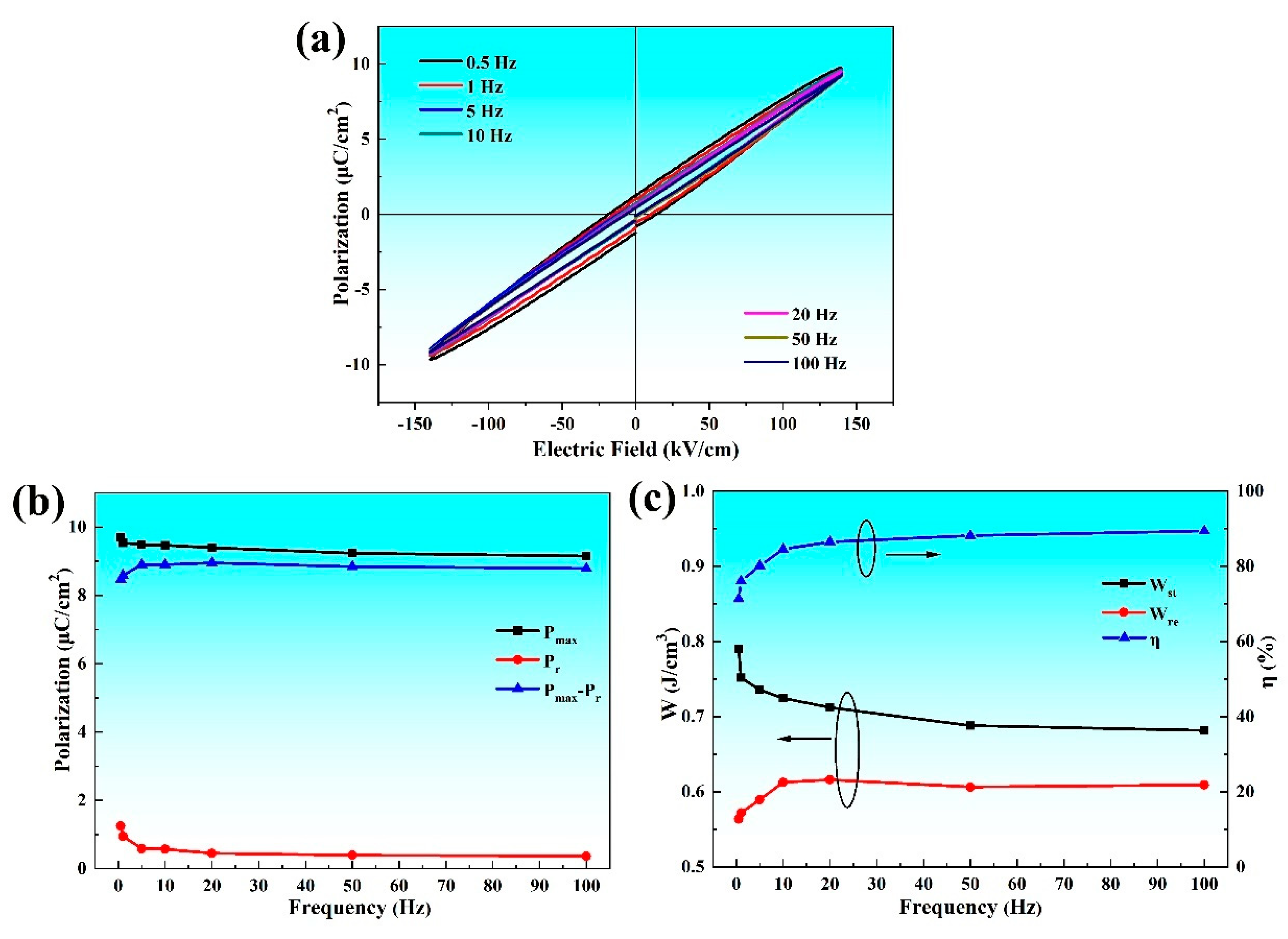

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Lu, T.; Ye, J.; Wang, G.; Dong, X.; Withers, R.; Liu, Y. Antiferroelectrics for energy storage applications: A review. Adv. Mater. Technol. 2018, 3, 1800111. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for high-energy density capacitors: Current status and future perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Yang, T.; Zhang, S.J. Ultrahigh energy-storage density in antiferroelectric ceramics with field-induced multiphase transitions. Adv. Funct. Mater. 2019, 29, 1807321. [Google Scholar] [CrossRef]

- Shirane, G.; Sawaguchi, E.; Takagi, Y. Dielectric properties of lead zirconate. Phys. Rev. J. Arch. 1951, 84, 476. [Google Scholar] [CrossRef]

- Shirane, G.; Sawaguchi, E.; Takeda, A. On the phase transition in lead zirconate. Phys. Rev. J. Arch. 1950, 80, 485. [Google Scholar] [CrossRef]

- Viehland, D. Transmission electron microscopy study of high-Zr-content lead zirconate titanate. Phys. Rev. B 1995, 52, 778–791. [Google Scholar] [CrossRef]

- Shirane, G.; Pepinsky, R. Phase Transitions in Antiferroelectric PbHfO3. Phys. Rev. 1953, 91, 812–815. [Google Scholar] [CrossRef]

- Kania, A.; Roleder, K.; Kugel, G.; Fontana, M.D. Raman scattering, central peak and phase transitions in AgNbO3. J. Phys. C Solid State Phys. 1986, 19, 9. [Google Scholar] [CrossRef]

- Yashima, M.; Matsuyama, S.; Sano, R.; Itoh, M.; Tsuda, K.; Fu, D. Structure of Ferroelectric Silver Niobate AgNbO3. Chem. Mater. 2011, 23, 1643–1645. [Google Scholar] [CrossRef]

- Mishra, S.K.; Choudhury, N.; Chaplot, S.L.; Krishna, P.S.R.; Mittal, R. Competing antiferroelectric and ferroelectric interactions inNaNbO3: Neutron diffraction and theoretical studies. Phys. Rev. B 2007, 76, 024110. [Google Scholar] [CrossRef]

- Saito, T.; Adachi, H.; Wada, T.; Adachi, H. Pulsed-laser deposition of ferroelectric NaNbO3 thin films. Jpn. J. Appl. Phys. 2005, 44, 6969–6972. [Google Scholar] [CrossRef]

- Koruza, J.; Groszewicz, P.; Breitzke, H.; Buntkowsky, G.; Rojac, T.; Malič, B. Grain-size-induced ferroelectricity in NaNbO3. Acta Mater. 2017, 126, 77–85. [Google Scholar] [CrossRef]

- Shuvaeva, V.A.; Antipin, M.Y.; Lindeman, R.S.V.; Fesenko, O.E.; Smotrakov, V.G.; Struchkov, Y.T. Crystal structure of the electric-fieldinduced ferroelectric phase of NaNbO3. Ferroelectrics 2011, 141, 307–311. [Google Scholar] [CrossRef]

- Beppu, K.; Shimasaki, T.; Fujii, I.; Imai, T.; Adachi, H.; Wada, T. Energy storage properties of antiferroelectric 0.92 NaNbO3-0.08 SrZrO3 film on (001) SrTiO3 substrate. Phys. Lett. A 2020, 384, 126690. [Google Scholar] [CrossRef]

- Luo, B.; Dong, H.; Wang, D.; Jin, K. Large recoverable energy density with excellent thermal stability in Mn-modified NaNbO3-CaZrO3 lead-free thin films. J. Am. Ceram. Soc. 2018, 101, 3460–3467. [Google Scholar] [CrossRef]

- Tian, Y.; Jin, L.; Zhang, H.; Xu, Z.; Wei, X.; Politova, E.D.; Stefanovich, S.Y.; Tarakina, N.V.; Abrahams, I.; Yan, H. High energy density in silver niobate ceramics. J. Mater. Chem. A 2016, 4, 17279–17287. [Google Scholar] [CrossRef]

- Wang, J.; Wan, X.; Rao, Y.; Zhao, L.; Zhu, K. Hydrothermal synthesized AgNbO3 powders: Leading to greatly improved electric breakdown strength in ceramics. J. Eur. Ceram. Soc. 2020, 40, 5589–5596. [Google Scholar] [CrossRef]

- Rashid, M.; Mahmood, Q.; Babar, F.; Ramay, S.M.; Mahmood, A. Study of mechanical, electronic and optical properties of PbZrO3 and PbHfO3; DFT approach. Mater. Res. Express 2019, 6, 066311. [Google Scholar] [CrossRef]

- Xu, R.; Zhu, Q.; Xu, Z.; Feng, Y.; Wei, X. High energy and power density achieved in Pb0.94La0.04HfO3 antiferroelectric ceramics with multiple phase transition. Appl. Phys. Lett. 2022, 120, 052904. [Google Scholar] [CrossRef]

- Hu, J.; Li, W.; Tang, X.; Shen, Z.; Wang, K.; Zhang, Y.; Zhang, S.; Jiang, Y.; Guo, X. Enhancement of energy storage density and efficiency of PbHfO3 doped with La antiferroelectric thin films. ACS Appl. Energy Mater. 2022, 6, 120–126. [Google Scholar] [CrossRef]

- Ma, C.-H.; Liao, Y.-K.; Zheng, Y.; Zhuang, S.; Lu, S.-C.; Shao, P.-W.; Chen, J.-W.; Lai, Y.-H.; Yu, P.; Hu, J.-M.; et al. Synthesis of a new ferroelectric relaxor based on a combination of antiferroelectric and paraelectric systems. ACS Appl. Mater. Interfaces 2022, 14, 22278–22286. [Google Scholar] [CrossRef]

- Ge, P.-Z.; Tang, X.-G.; Meng, K.; Huang, X.-X.; Li, S.-F.; Liu, Q.-X.; Jiang, Y.-P. Energy storage density and charge–discharge properties of PbHf1−xSnxO3 antiferroelectric ceramics. Chem. Eng. J. 2022, 429, 132540. [Google Scholar] [CrossRef]

- Ge, P.-Z.; Tang, X.-G.; Liu, Q.-X.; Jiang, Y.-P.; Guo, X.-B.J. Superior Energy and Power Density Realized in Pb (Hf1−xTix)O3 System at Low Electric Field. Energy Mater. Adv. 2023, 4, 0025. [Google Scholar] [CrossRef]

- Ge, P.-Z.; Tang, X.-G.; Meng, K.; Huang, X.-X.; Liu, Q.-X.; Jiang, Y.-P.; Gong, W.-P.; Wang, T. Ultrahigh energy storage density and superior discharge power density in a novel antiferroelectric lead hafnate. Mater. Today Phys. 2022, 24, 100681. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.-F.; Zhang, S. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, T.; Yan, S.; Liao, Q.; Dong, X.; Wang, G.; Liu, Y. Large electrocaloric and pyroelectric energy harvesting effect over a broad temperature range via modulating the relaxor behavior in non-relaxor ferroelectrics. J. Mater. Chem. A 2021, 9, 22015–22024. [Google Scholar] [CrossRef]

- Almousa, N.; Issa, S.A.; Salem, M.M.; Darwish, M.A.; Serag, E.N.; Nazrin, S.N.; Zakaly, H.M. Tailoring perovskite ceramics for improved structure, vibrational behaviors and radiation protection: The role of lanthanum in PbTiO3. Opt. Mater. 2024, 152, 115543. [Google Scholar] [CrossRef]

- Wang, S.B.; Zhao, P.F.; Jian, X.D.; Yao, Y.B.; Tao, T.; Liang, B.; Lu, S.G. Large energy storage density and electrocaloric strength of Pb0. 97La0. 02 (Zr0.46−xSn0.54Tix)O3 antiferroelectric thick film ceramics. Scr. Mater. 2022, 210, 114426. [Google Scholar] [CrossRef]

- Ren, P.; Ren, D.; Sun, L.; Yan, F.; Yang, S.; Zhao, G. Grain size tailoring and enhanced energy storage properties of two-step sintered Nd3+-doped AgNbO3. J. Eur. Ceram. Soc. 2020, 40, 4495–4502. [Google Scholar] [CrossRef]

- Luo, N.; Han, K.; Zhuo, F.; Xu, C.; Zhang, G.; Liu, L.; Chen, X.; Hu, C.; Zhou, H.; Wei, Y. Aliovalent A-site engineered AgNbO3 lead-free antiferroelectric ceramics toward superior energy storage density. J. Mater. Chem. A 2019, 7, 14118–14128. [Google Scholar] [CrossRef]

- Mao, S.; Luo, N.; Han, K.; Feng, Q.; Chen, X.; Peng, B.; Liu, L.; Hu, C.; Zhou, H.; Toyohisa, F.; et al. Effect of Lu doping on the structure, electrical properties and energy storage performance of AgNbO3 antiferroelectric ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 7731–7741. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, Y.; Zhao, L.; Lee, K.-Y.; Liu, Q.; Studer, A.; Hinterstein, M.; Zhang, S.; Li, J.-F. Enhanced antiferroelectric phase stability in La-doped AgNbO3: Perspectives from the microstructure to energy storage properties. J. Mater. Chem. A 2019, 7, 2225–2232. [Google Scholar] [CrossRef]

- Gao, J.; Liu, Q.; Dong, J.; Wang, X.; Zhang, S.; Li, J.-F. Local structure heterogeneity in Sm-doped AgNbO3 for improved energy-storage performance. ACS Appl. Mater. Interfaces 2020, 12, 6097–6104. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Nie, H.; Wang, G.; Xu, C.; Liu, N.; Zhou, M.; Cao, F.; Dong, X. Significantly enhanced energy storage performance of rare-earth-modified silver niobate lead-free antiferroelectric ceramics via local chemical pressure tailoring. J. Mater. Chem. C 2019, 7, 1551–1560. [Google Scholar] [CrossRef]

- Wang, X.; Hao, X.; Zhang, Q.; An, S.; Chou, X. Energy-storage performance and pyroelectric energy harvesting effect of PNZST antiferroelectric thin films. J. Mater. Sci. Mater. Electron. 2017, 28, 1438–1448. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.G. Recent progress in relaxor ferroelectrics with perovskite structure. J. Mater. Sci. 2006, 41, 31–52. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Houwman, E.P.; Dekkers, M.; Nguyen, C.T.; Vu, H.N.; Rijnders, G. Research update: Enhanced energy storage density and energy efficiency of epitaxial Pb0.9La0.1(Zr0.52Ti0.48)O3 relaxor-ferroelectric thin-films deposited on silicon by pulsed laser deposition. APL Mater. 2016, 4, 080701. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Peng, W.; Xu, C.; Dong, X.; Cao, F.; Wang, G. Temperature-dependent stability of energy storage properties of Pb0.97La0.02(Zr0.58Sn0.335Ti0.085)O3 antiferroelectric ceramics for pulse power capacitors. Appl. Phys. Lett. 2015, 106, 262901. [Google Scholar] [CrossRef]

- Xu, R.; Xu, Z.; Feng, Y.; He, H.; Tian, J.; Huang, D. Temperature dependence of energy storage in Pb0.90La0.04Ba0.04[(Zr0.7Sn0.3)0.88Ti0.12]O3 antiferroelectric ceramics. J. Am. Ceram. Soc. 2016, 99, 2984–2988. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, X.; Cao, F.; Wang, G.; Dong, X.; Hu, Z.; Du, T. Charge–discharge properties of an antiferroelectric ceramics capacitor under different electric fields. J. Am. Ceram. Soc. 2010, 93, 4015–4017. [Google Scholar] [CrossRef]

- Ciuchi, I.V.; Mitoseriu, L.; Galassi, C. Antiferroelectric to ferroelectric crossover and energy storage properties of (Pb1−xLax)(Zr0.90Ti0.10)1−x/4O3(0.02 ≤ x ≤ 0.04) ceramics. J. Am. Ceram. Soc. 2016, 99, 2382–2387. [Google Scholar] [CrossRef]

- Xu, R.; Xu, Z.; Feng, Y.; Wei, X.; Tian, J.; Huang, D. Polarization of antiferroelectric ceramics for pulse capacitors under transient electric field. J. Appl. Phys. 2016, 119, 224103. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, E.; Yue, L.; Chu, Y.; Sun, C.; Zhao, J.; Zhang, S.; Liu, J.; Zhang, Y.; Zhang, L. High Energy Storage Performance in Pb1−xLax(Hf0.45Sn0.55)0.995O3 Antiferroelectric Ceramics. Crystals 2024, 14, 732. https://doi.org/10.3390/cryst14080732

Wang E, Yue L, Chu Y, Sun C, Zhao J, Zhang S, Liu J, Zhang Y, Zhang L. High Energy Storage Performance in Pb1−xLax(Hf0.45Sn0.55)0.995O3 Antiferroelectric Ceramics. Crystals. 2024; 14(8):732. https://doi.org/10.3390/cryst14080732

Chicago/Turabian StyleWang, Erping, Liqin Yue, Yuanhong Chu, Caixia Sun, Jinyu Zhao, Siyu Zhang, Jiale Liu, Yangyang Zhang, and Ling Zhang. 2024. "High Energy Storage Performance in Pb1−xLax(Hf0.45Sn0.55)0.995O3 Antiferroelectric Ceramics" Crystals 14, no. 8: 732. https://doi.org/10.3390/cryst14080732