Experimental Study of Reaming Sizes on Fatigue Life of Cold-Expanded 7050-T7451 Aluminum Alloy

Abstract

1. Introduction

2. Materials and Methods

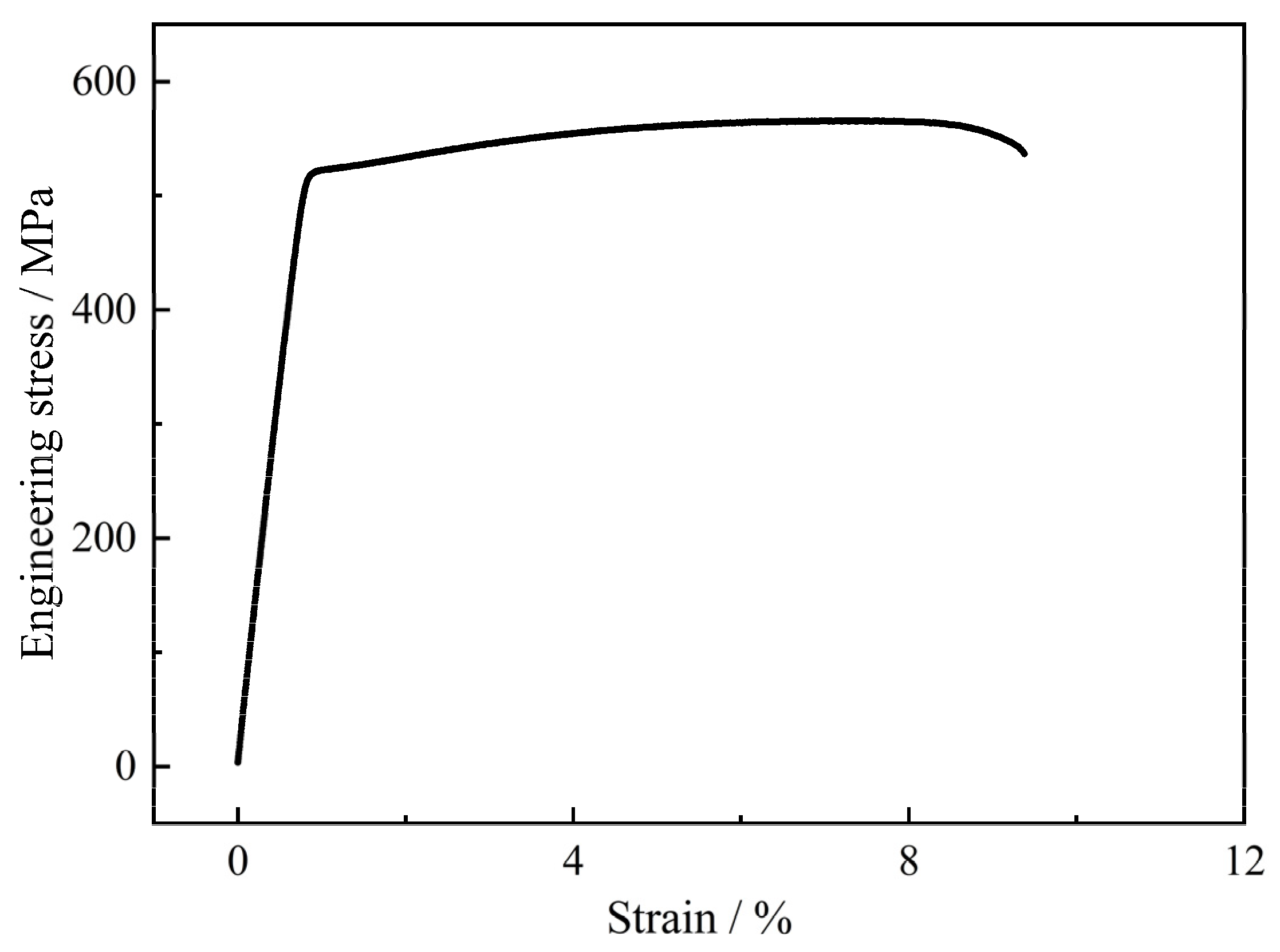

2.1. Experimental Materials

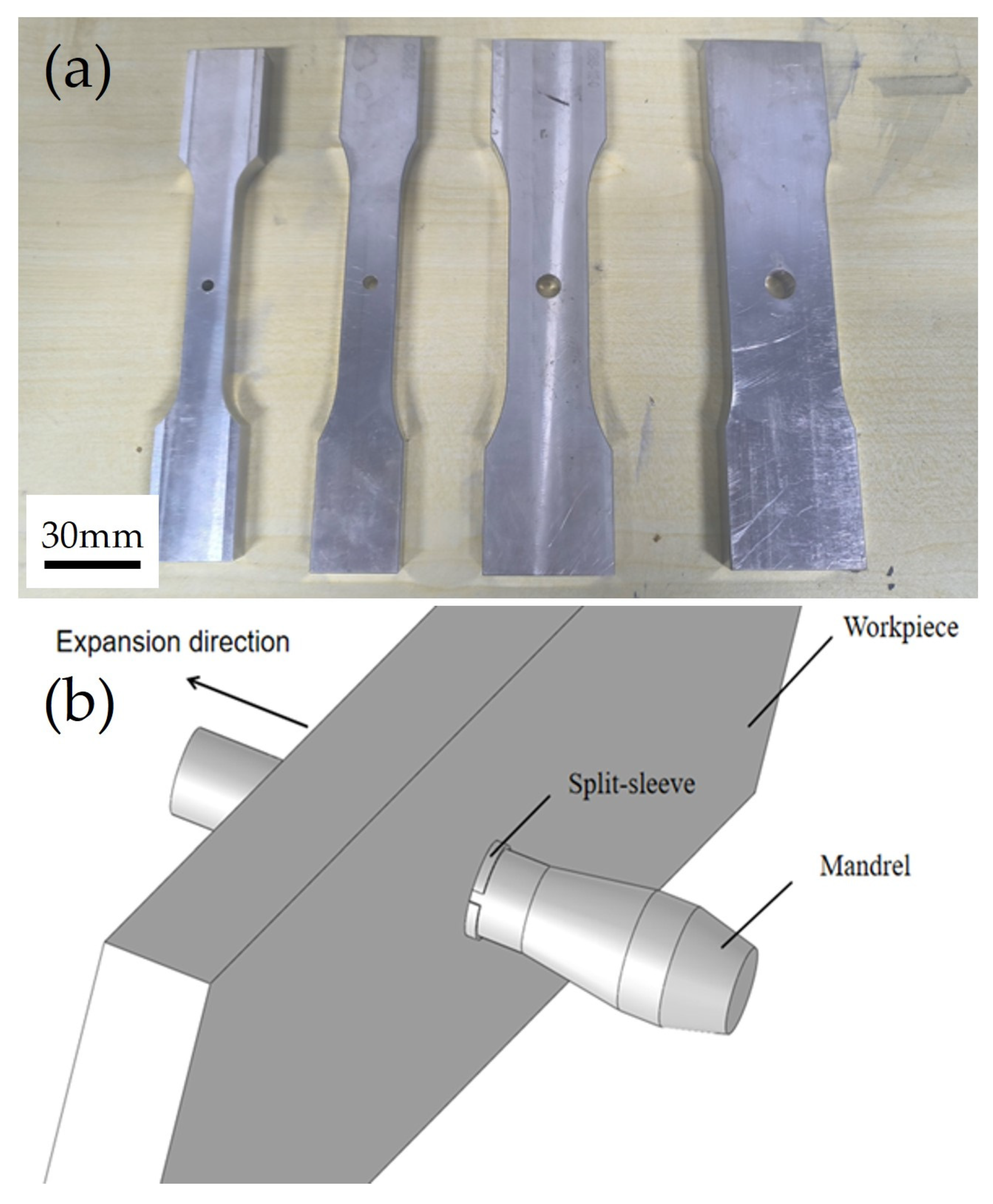

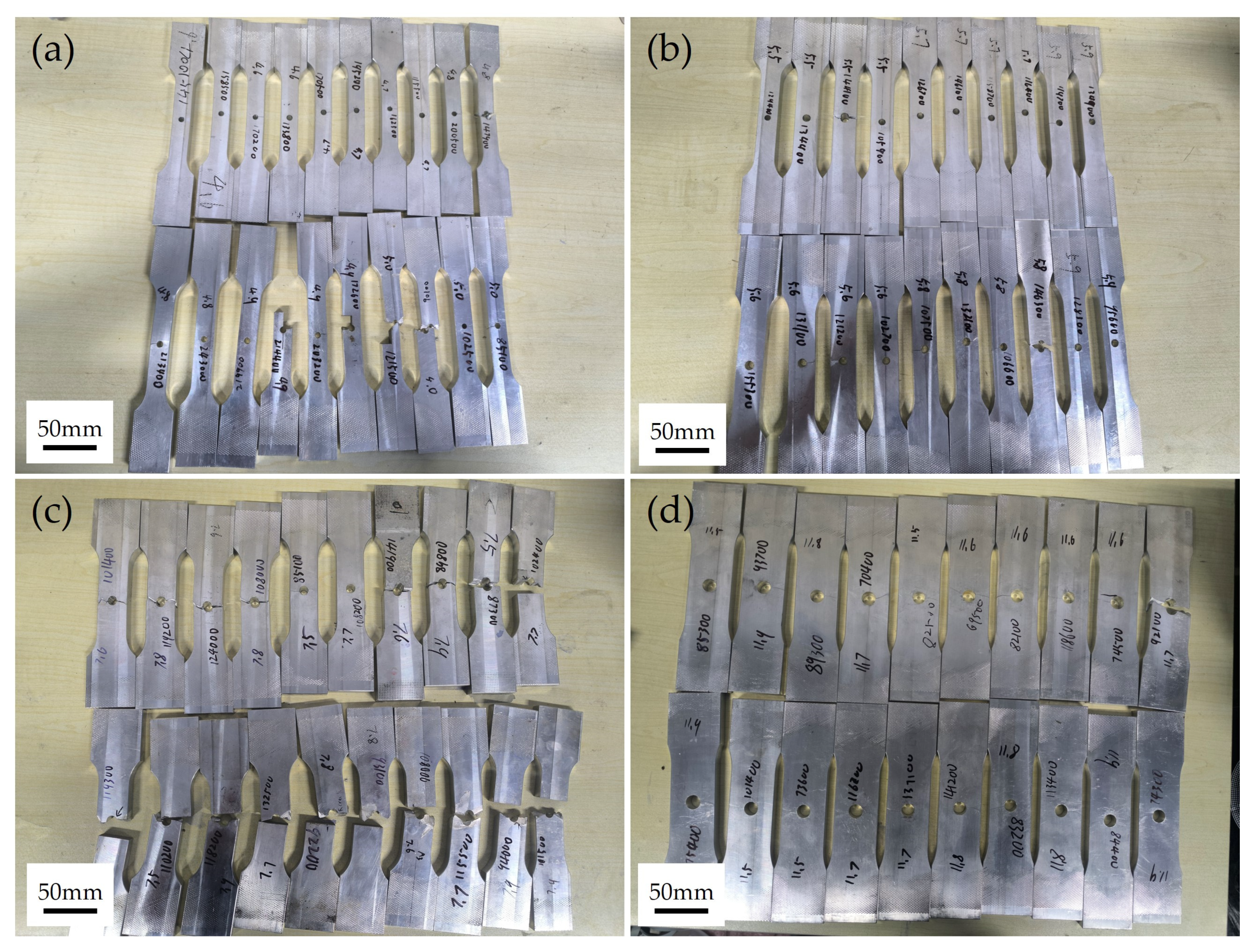

2.2. Fatigue Test

2.3. Characterization

3. Results and Discussion

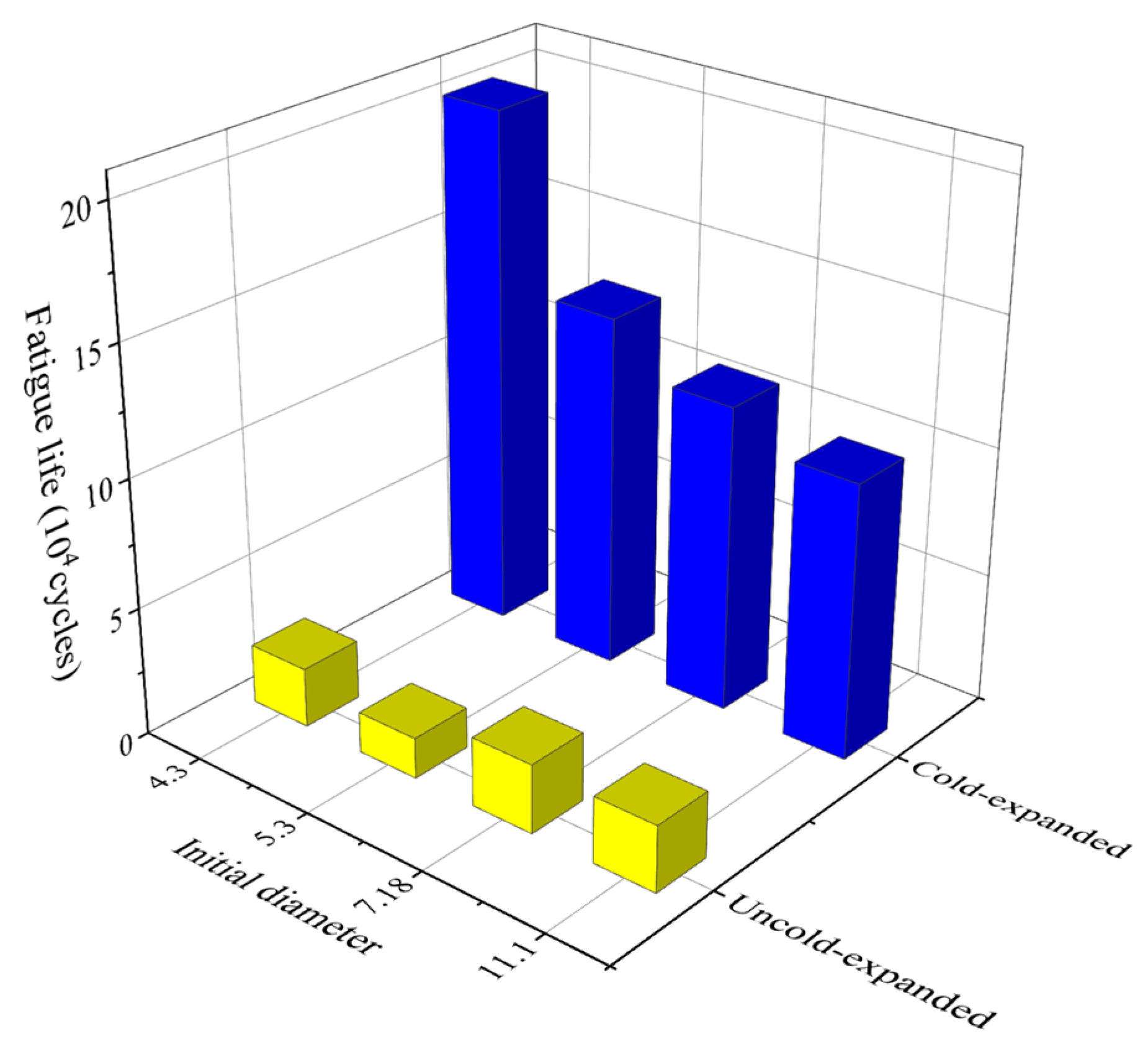

3.1. Fatigue Life Behavior

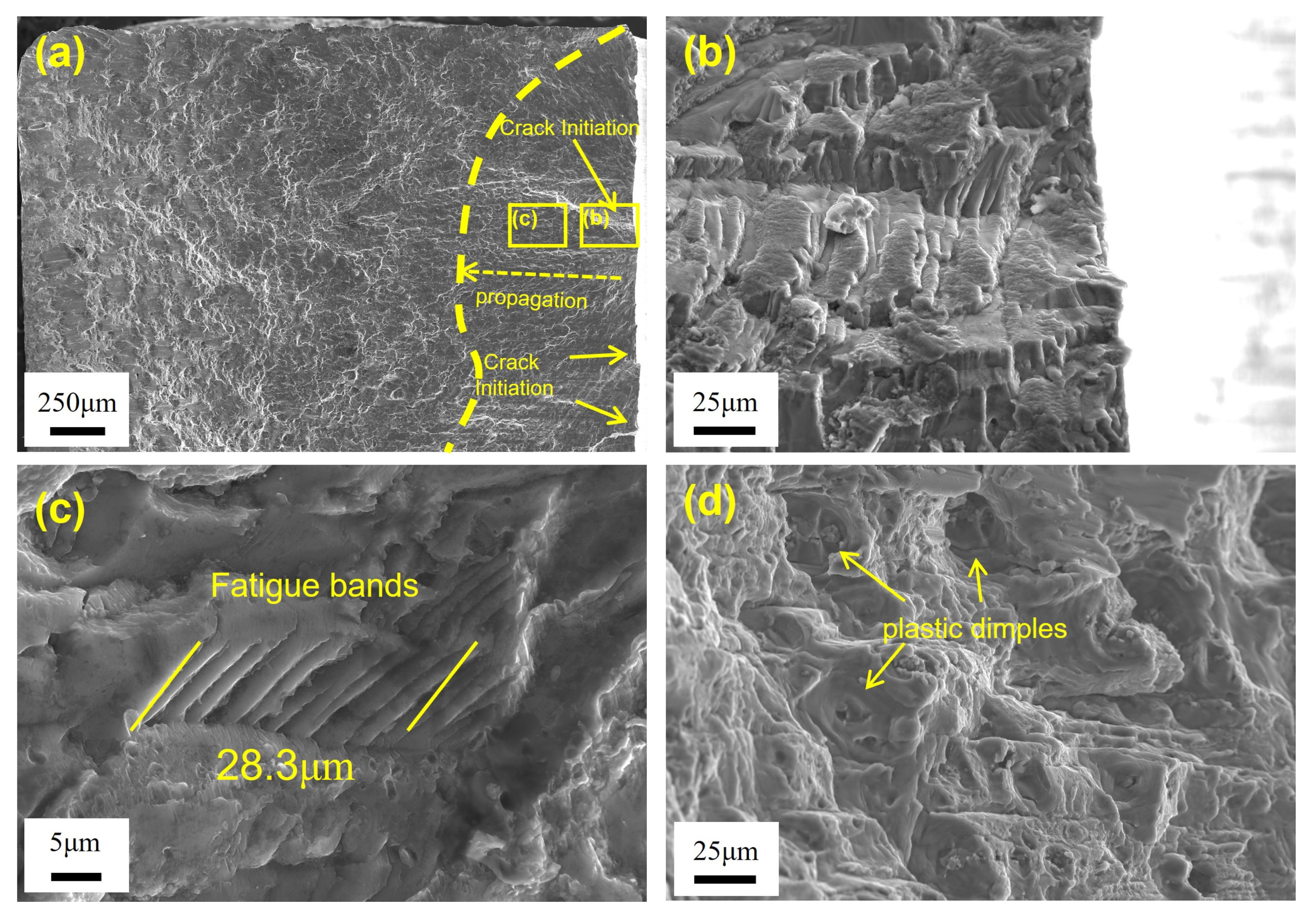

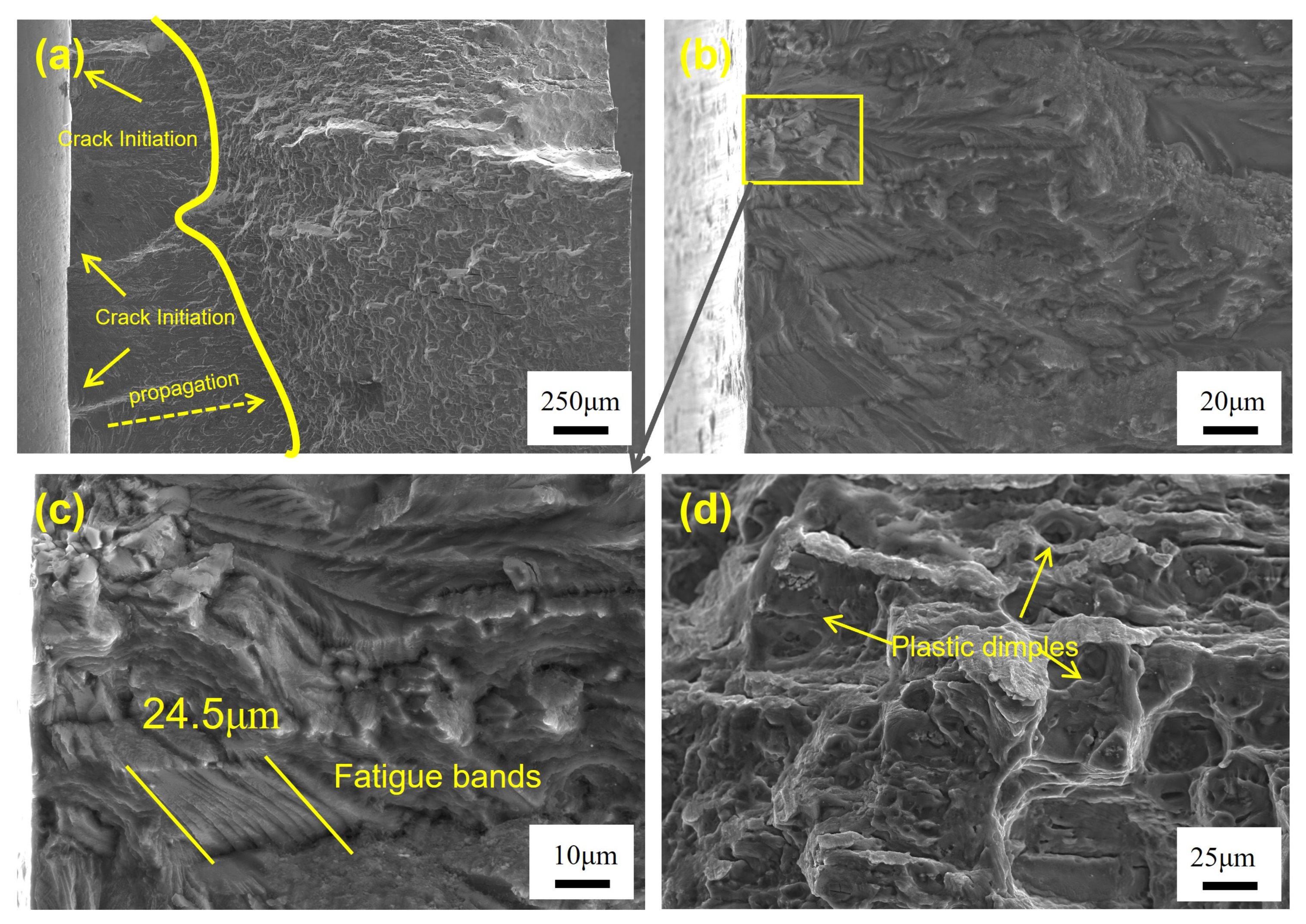

3.2. Observation of Port Morphology

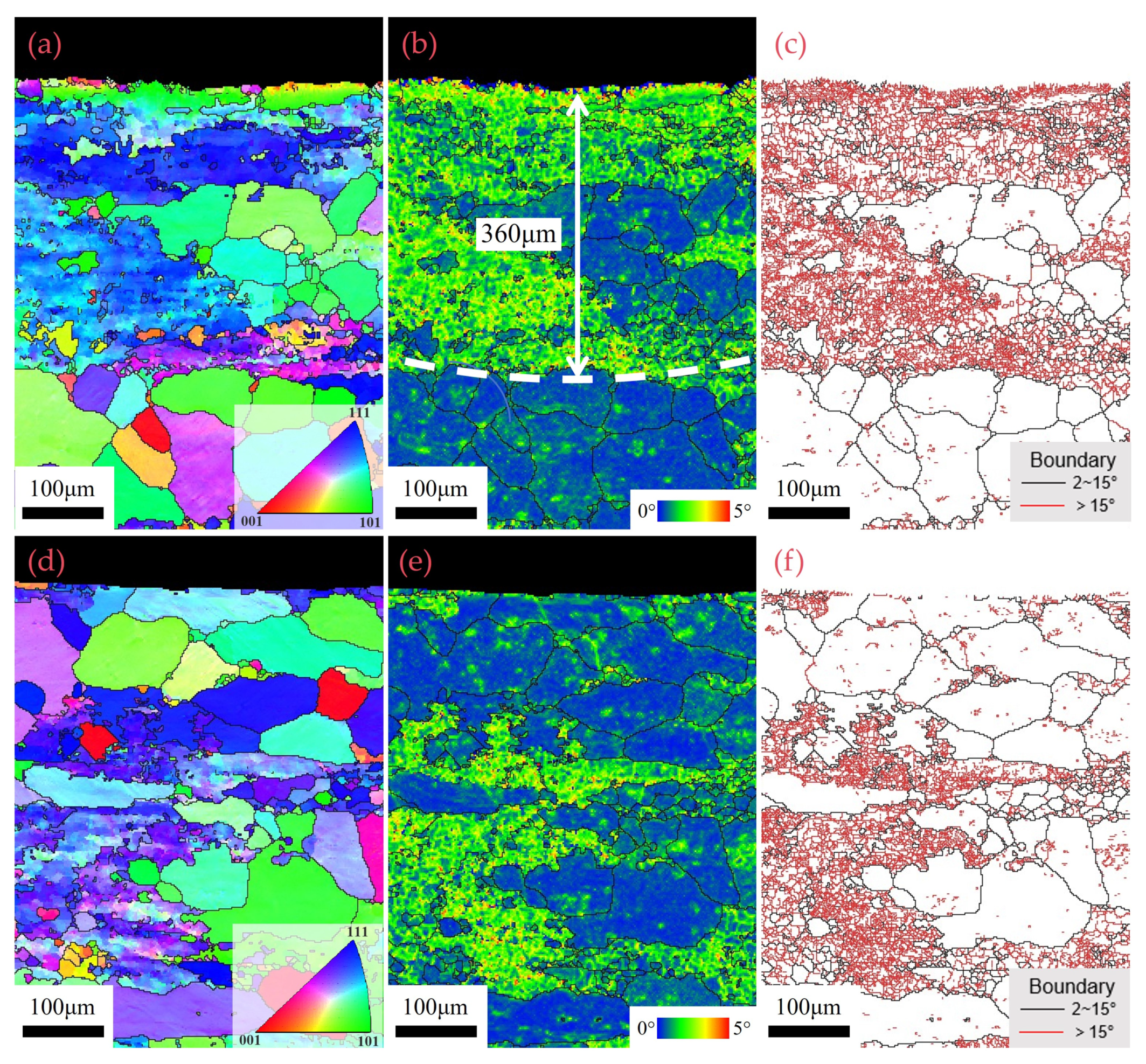

3.3. EBSD Analysis

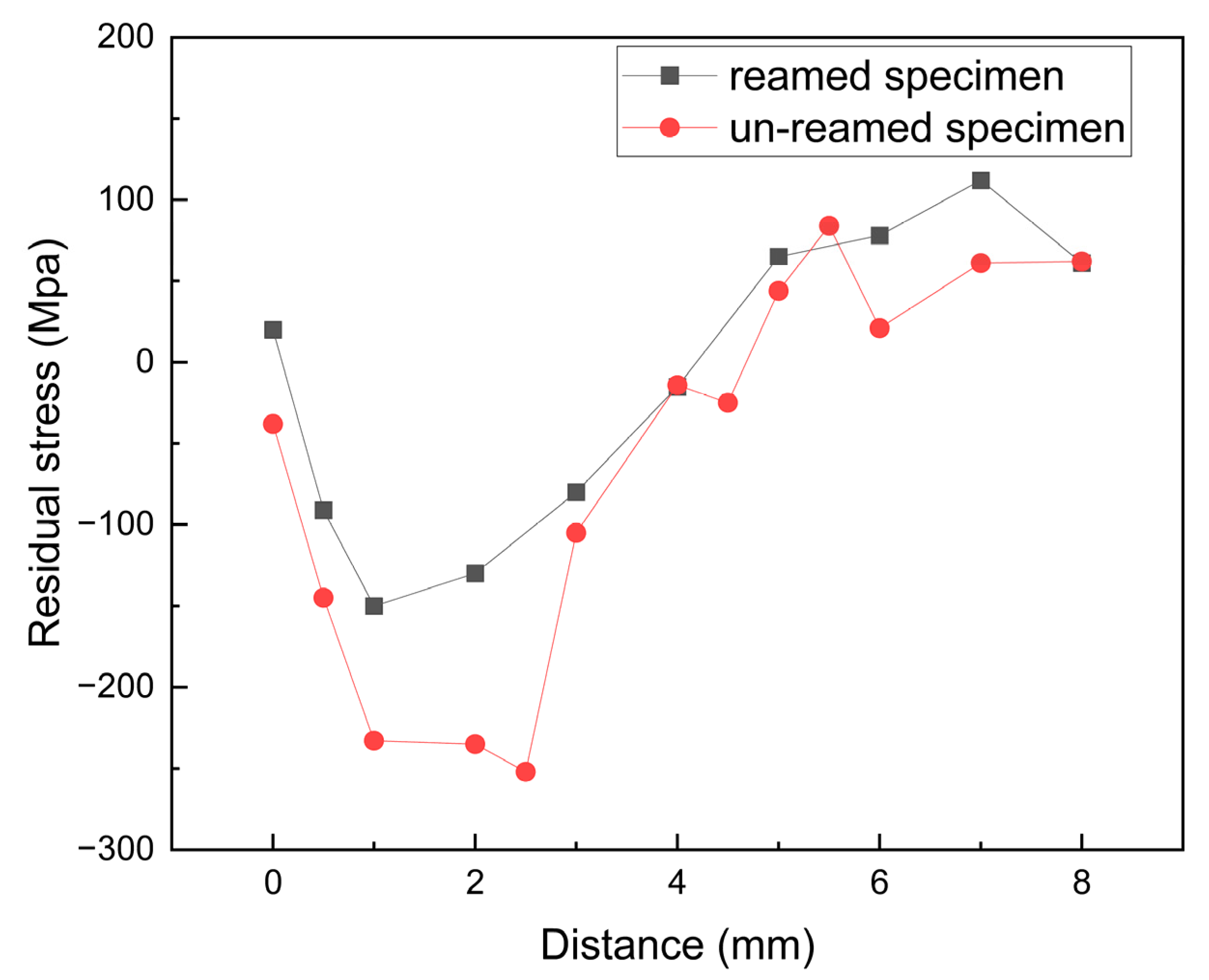

3.4. Residual Stress Analysis

4. Conclusions

- Fatigue testing after approximately 4% cold expansion of plates with four different sizes of perforations showed that fatigue life first increases and then decreases with greater reaming. This conclusion applies to apertures ranging from 4.3 mm to 11.1 mm. The maximum fatigue life was about 4.4 to 8.7 times higher than that of the uncold-expanded plate. Excessive reaming results in a significantly smaller crack extension zone in the fatigue specimen, weakening its ability to withstand fatigue.

- Cold expansion forms a dense grain structure around the hole, creating a crystal refinement layer of approximately 20 μm. Because the height of the convex ridge is much greater than its depth, the reaming process removes this crystal refinement layer.

- A plastic deformation layer forms at the hole wall, constraining residual stresses in the deeper layers. The reaming process disrupts this plastic layer, releasing the residual stresses. The extent of this effect depends on the reaming depth. Proper assessment of the plastic deformation layer’s depth, formed by cold expansion, is crucial in determining the optimal reaming amount.

- Reaming the cold-expanded plate reduces radial residual stresses around the hole by up to 102 MPa compared to the unreamed plate, due to the loss of stress restraint by the innermost plastic layer. This reduction in residual stresses also decreases the fatigue resistance of the cold-expanded split-sleeve.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H. Riveting Sequence Study of Horizontal Stabilizer Assembly Using Finite-Element Analysis and Riveting Equivalent Unit. J. Aerosp. Eng. 2014, 27, 04014040. [Google Scholar] [CrossRef]

- Liu, J.T.; Zhao, A.A.; Ke, Z.Z.; Zhu, Z.D.; Bi, Y.B. Influence of Rivet Diameter and Pitch on the Fatigue Performance of Riveted Lap Joints Based on Stress Distribution Analysis. Materials 2020, 13, 3625. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.W.; Xi, J.J.; Zheng, K.L.; Shi, Z.S.; Lin, J.G.; Nikbin, K.; Duan, S.H.; Wang, B.W. A review on solid riveting techniques in aircraft assembling. Manuf. Rev. 2020, 7, 40. [Google Scholar] [CrossRef]

- Wang, Q.T.; Li, B.B.; Zheng, Y.M.; Chen, X. Effects of Stress Amplitude and Cold Expansion Strengthening on the Fatigue Property of TC4 Titanium Alloy. J. Mater. Eng. Perform. 2023, 10, 1–10. [Google Scholar] [CrossRef]

- Pitt, S.; Jones, R.J.E.F.A. Multiple-site and widespread fatigue damage in aging aircraft. Eng. Fail. Anal. 1997, 4, 237–257. [Google Scholar] [CrossRef]

- Kumar, S.A.; Babu, N.C.M. Influence of Induced Residual Stresses on Fatigue Performance of Cold Expanded Fastener Holes. In Proceedings of the 5th International Conference on Materials Processing and Characterization (ICMPC), Gokaraju Rangaraju Institution of Engineering & Technology, Hyderabad, India, 12–13 March 2016; pp. 2397–2402. [Google Scholar]

- Masserey, B.; Fromme, P. In-situ monitoring of fatigue crack growth using high frequency guided waves. NDT E Int. 2015, 71, 1–7. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.Q.; Song, Q.H.; Wan, Y.; Ren, X.P. A Modified Johnson-Cook Constitutive Model and Its Application to High Speed Machining of 7050-T7451 Aluminum Alloy. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 011012. [Google Scholar] [CrossRef]

- Chakherlou, T.N.; Vogwell, J. The effect of cold expansion on improving the fatigue life of fastener holes. Eng. Fail. Anal. 2003, 10, 13–24. [Google Scholar] [CrossRef]

- Andrew, D.L.; Clark, P.N.; Hoeppner, D.W. Investigation of cold expansion of short edge margin holes with pre-existing cracks in 2024-T351 aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 406–416. [Google Scholar] [CrossRef]

- Liu, J.; Shao, X.J.; Liu, Y.S.; Yue, Z.F. Effect of cold expansion on fatigue performance of open holes. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 477, 271–276. [Google Scholar] [CrossRef]

- Yan, W.Z.; Wang, Y.W.; Liang, S.J.; Huo, S.H. Study on the Residual Stress Distribution of Bi-Directional Cold Expansion Process Performed on Open Holes. J. Press. Vessel Technol. Trans. ASME 2023, 145, 041501. [Google Scholar] [CrossRef]

- Lin, Z.L.; Bai, Q.S.; Wang, H.F.; Wu, B.Q.; Li, W.S. Research on the Residual Stress Field of a Compression Bushing-Lug Plate in Cold Expansion Strengthening. Appl. Sci. 2023, 13, 11694. [Google Scholar] [CrossRef]

- Liu, Y.S.; Shao, X.J.; Liu, J.; Yue, Z.F. Finite element method and experimental investigation on the residual stress fields and fatigue performance of cold expansion hole. Mater. Des. 2010, 31, 1208–1215. [Google Scholar] [CrossRef]

- Liu, Y.S.; Liu, J.; Shao, X.J. Study on the Residual Stress Fields, Surface Quality, and Fatigue Performance of Cold Expansion Hole. Mater. Manuf. Process. 2011, 26, 294–303. [Google Scholar] [CrossRef]

- Dey, M.K. Finite Element Parametric Investigation on the Residual Stresses Induced by Split Sleeve Cold Expansion Process; Washington State University: Washington, DC, USA, 2021. [Google Scholar]

- Karabin, M.E.; Barlat, F.; Schultz, R.W. Numerical and experimental study of the cold expansion process in 7085 plate using a modified split sleeve. J. Mater. Process. Technol. 2007, 189, 45–57. [Google Scholar] [CrossRef]

- Lv, Y.; Dong, M.E.; Zhang, T.; Wang, C.K.; Hou, B.; Li, C.F. Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy. Materials 2023, 16, 1109. [Google Scholar] [CrossRef]

- Nigrelli, V.; Pasta, S. Finite-element simulation of residual stress induced by split-sleeve cold-expansion process of holes. J. Mater. Process. Technol. 2008, 205, 290–296. [Google Scholar] [CrossRef]

- Guan, D.; Sun, Q. Numerical Simulation of the Cold Expansion and Residual Stress Relaxation for Aluminum Alloy 7050. In Proceedings of the International Conference on Applied Mechanics, Materials and Manufacturing (ICAMMM 2011), Shenzhen, China, 18–20 November 2011; pp. 1656–1661. [Google Scholar]

- Özdemir, A.T. Experimental assessment of the redistribution of 3D residual stresses during early fatigue at split-sleeve cold expanded reamed A/C fastener holes. Sci. Iran. 2018, 25, 1153–1168. [Google Scholar] [CrossRef]

- Barlat, F.; Karabin, M.E.; Schultz, R.W. A modified split sleeve for the cold expansion process and application to 7085 plate. In Proceedings of the 10th ESAFORM Conference on Material Forming, Zaragoza, Spain, 18–20 April 2007; pp. 343–348. [Google Scholar]

- Huang, Y.J.; Guan, Z.D.; Li, Z.S.; Liu, F.Q.; He, Y.M.; Dan, H. An Numerical Investigation on the Effect of the Combination of Cold Expansion and Interference Fitting on Fatigue Life Improvement of a 7075-T6 Aluminum Alloy Single Plate. In Proceedings of the 8th International Conference on Mechanical and Aerospace Engineering (ICMAE), Prague, Czech Republic, 22–25 July 2017; pp. 632–638. [Google Scholar]

- Yan, W.Z.; Wang, X.S.; Gao, H.S.; Yue, Z.F. Effect of split sleeve cold expansion on cracking behaviors of titanium alloy TC4 holes. Eng. Fract. Mech. 2012, 88, 79–89. [Google Scholar] [CrossRef]

- Li, Q.; Xue, Q.C.; Hu, Q.S.; Song, T.; Wang, Y.H.; Li, S.Y. Cold Expansion Strengthening of 7050 Aluminum Alloy Hole: Structure, Residual Stress, and Fatigue Life. Int. J. Aerosp. Eng. 2022, 2022, 4057898. [Google Scholar] [CrossRef]

- Wang, C.G.; Zou, F.; Zhou, E.T.; Fan, Z.L.; Ge, E.D.; An, Q.L.; Ming, W.W.; Chen, M. Effect of split sleeve cold expansion on microstructure and fatigue performance of 7075-T6 aluminum alloy holes. Int. J. Fatigue 2023, 167, 107339. [Google Scholar] [CrossRef]

- Yang, K.; Chen, X.H.; Lv, X.M.; Ding, F.; Dang, B.; Li, F.K.; Wei, D.B.; Zhang, P.Z. Effect of split-sleeve cold hole expansion on the fatigue performance of an additive manufactured TC18 alloy. J. Mater. Res. 2023, 12, 841–852. [Google Scholar] [CrossRef]

- Li, K.S.; Wang, R.Z.; Zhang, X.C.; Yao, S.L.; Cheng, L.Y.; Lei, X.L.; Tu, S.T. Process-performance-prediction integration for fatigue life improvement technologies: An implementation in cold expansion of hole structures. Int. J. Fatigue 2023, 170, 107507. [Google Scholar] [CrossRef]

- Liu, K.Y.; Yang, X.S.; Zhou, L.; Li, M.; Zhu, W.J. Numerical investigation of the effect of hole reaming on fatigue life by cold expansion. Trans. Can. Soc. Mech. Eng. 2022, 46, 400–411. [Google Scholar] [CrossRef]

- Lacombe, A.; Landon, Y.; Paredes, M.; Chirol, C.; Benaben, A. Numerical simulation of the reaming process in aluminium 2024-t351-analysis of the evolution of the material stress state. Dyna 2019, 94, 215–220. [Google Scholar] [CrossRef]

- HB/Z 170-2005; Cold Expansion Process for Hole of Aircraft Metal Part. Commission of Science, Technology and Industry for National Defence: Beijing, China, 2005.

- GB/T 3280-2015; Cold Rolled Stainless Steel Plate, Sheet and Strip. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2015.

- Jamali, A.; Ma, A.X.; Llorca, J. Influence of grain size and grain boundary misorientation on the fatigue crack initiation mechanisms of textured AZ31 Mg alloy. Scr. Mater. 2022, 207, 114304. [Google Scholar] [CrossRef]

- Dang, Z.C.; Peng, Y.H.; Yang, R.J.; Yan, L.; Gan, X.D.; Ge, D.Y. Experimental study on the effect of reaming on the fatigue life of split-sleeve cold-expanded Ti-6Al-4V alloy components. Int. J. Fatigue 2024, 188, 108521. [Google Scholar] [CrossRef]

- Faghih, S.; Shaha, S.K.; Behravesh, S.B.; Jahed, H. Split sleeve cold expansion of AZ31B sheet: Microstructure, texture and residual stress. Mater. Des. 2020, 186, 108213. [Google Scholar] [CrossRef]

- Su, R.; Li, J.Y.; Liu, W.G.; Xu, C.Z.; Gao, L.J.; Liang, X.Z.; Wu, D.Y.; Huang, X.; Dong, H.C.; Ma, H.K. Investigation on fatigue failure of split-sleeve cold expansion holes of 7075-T651 aluminum alloy. Mater. Today Commun. 2023, 35, 106290. [Google Scholar] [CrossRef]

| Elements | Si | Zn | Mg | Cu | Fe | Mn | Cr | Zr | Al |

|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 0.03 | 6.02 | 2.31 | 2.04 | 0.11 | 0.003 | 0.009 | 0.1 | Rest |

| Density ) | Young’s Modulus E (Gpa) | Poisson’s Radio | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation A (%) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|---|---|---|

| 2830 | 70.3 | 0.33 | 564.7 | 479.4 | 13.3 | 30 |

| Initial Diameter (mm) | Mandrel Diameter (mm) | Split-Sleeve Thickness (mm) | Expansion Ratio (%) |

|---|---|---|---|

| 4.3 | 4.17 | 0.152 | 4.04 |

| 5.3 | 5.21 | 0.152 | 4.03 |

| 7.18 | 7.06 | 0.203 | 3.98 |

| 11.1 | 11.04 | 0.253 | 4.01 |

| Specimen | Quantity (PCS) | Initial Diameter (mm) | Expansion Ratio (%) | Final Diameter (mm) | Load Spectra | |

|---|---|---|---|---|---|---|

| Stress Amplitude (MPa) | Stress Ratio R | |||||

| A1-01 | 4 | 4.3 | 4.04 | 4.6 | 108 | 0.1 |

| A1-02 | 4 | 4.3 | 4.04 | 4.7 | 108 | 0.1 |

| A1-03 | 4 | 4.3 | 4.04 | 5.0 | 108 | 0.1 |

| A1-04 | 4 | 4.3 | 4.04 | 5.2 | 108 | 0.1 |

| A1-05 | 4 | 4.3 | 4.04 | 5.4 | 108 | 0.1 |

| A2-01 | 4 | 5.3 | 4.03 | 5.4 | 108 | 0.1 |

| A2-02 | 4 | 5.3 | 4.03 | 5.9 | 108 | 0.1 |

| A2-03 | 4 | 5.3 | 4.03 | 6.1 | 108 | 0.1 |

| A2-04 | 4 | 5.3 | 4.03 | 6.3 | 108 | 0.1 |

| A2-05 | 4 | 5.3 | 4.03 | 6.5 | 108 | 0.1 |

| A3-01 | 4 | 7.18 | 3.98 | 7.6 | 108 | 0.1 |

| A3-02 | 4 | 7.18 | 3.98 | 7.8 | 108 | 0.1 |

| A3-03 | 4 | 7.18 | 3.98 | 8.0 | 108 | 0.1 |

| A3-04 | 4 | 7.18 | 3.98 | 8.2 | 108 | 0.1 |

| A3-05 | 4 | 7.18 | 3.98 | 8.4 | 108 | 0.1 |

| A4-01 | 4 | 11.1 | 4.01 | 11.7 | 108 | 0.1 |

| A4-02 | 4 | 11.1 | 4.01 | 12.0 | 108 | 0.1 |

| A4-03 | 4 | 11.1 | 4.01 | 12.3 | 108 | 0.1 |

| A4-04 | 4 | 11.1 | 4.01 | 12.6 | 108 | 0.1 |

| A4-05 | 4 | 11.1 | 4.01 | 12.9 | 108 | 0.1 |

| A1-00 | 4 | 4.3 | 0% | 4.3 | 108 | 0.1 |

| A2-00 | 4 | 5.3 | 0% | 5.3 | 108 | 0.1 |

| A3-00 | 4 | 7.18 | 0% | 7.18 | 108 | 0.1 |

| A4-00 | 4 | 11.1 | 0% | 11.1 | 108 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, M.; Xue, Q.; Zhuang, Z.; Hu, Q.; Qi, H. Experimental Study of Reaming Sizes on Fatigue Life of Cold-Expanded 7050-T7451 Aluminum Alloy. Crystals 2024, 14, 803. https://doi.org/10.3390/cryst14090803

Guan M, Xue Q, Zhuang Z, Hu Q, Qi H. Experimental Study of Reaming Sizes on Fatigue Life of Cold-Expanded 7050-T7451 Aluminum Alloy. Crystals. 2024; 14(9):803. https://doi.org/10.3390/cryst14090803

Chicago/Turabian StyleGuan, Muyu, Qichao Xue, Zixin Zhuang, Quansheng Hu, and Hui Qi. 2024. "Experimental Study of Reaming Sizes on Fatigue Life of Cold-Expanded 7050-T7451 Aluminum Alloy" Crystals 14, no. 9: 803. https://doi.org/10.3390/cryst14090803

APA StyleGuan, M., Xue, Q., Zhuang, Z., Hu, Q., & Qi, H. (2024). Experimental Study of Reaming Sizes on Fatigue Life of Cold-Expanded 7050-T7451 Aluminum Alloy. Crystals, 14(9), 803. https://doi.org/10.3390/cryst14090803