Microstructural Stability and Creep Behavior of a Re/Ru Single-Crystal Nickel-Based Alloy

Abstract

:1. Introduction

2. Experimental Procedures

3. Analysis of Test Results

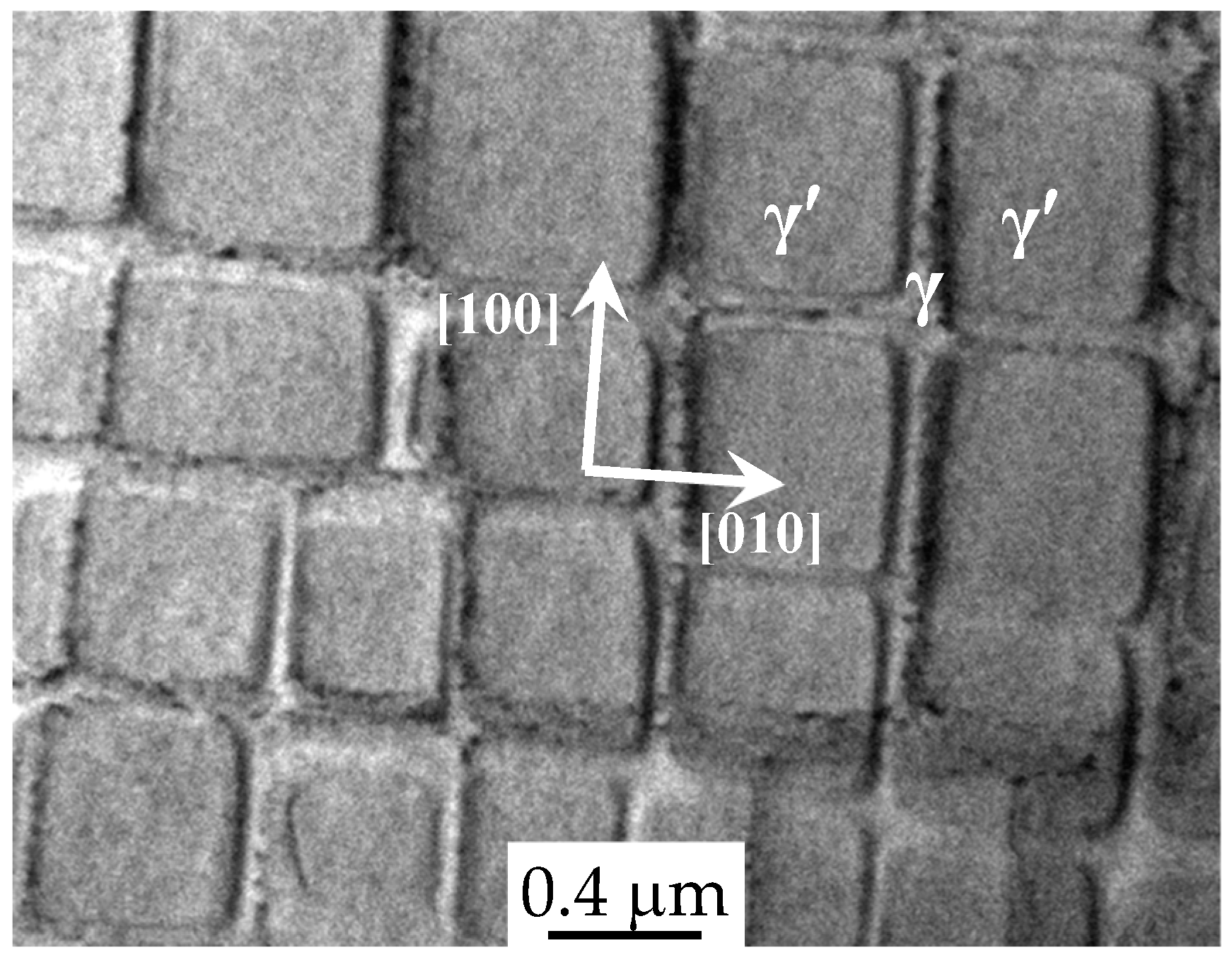

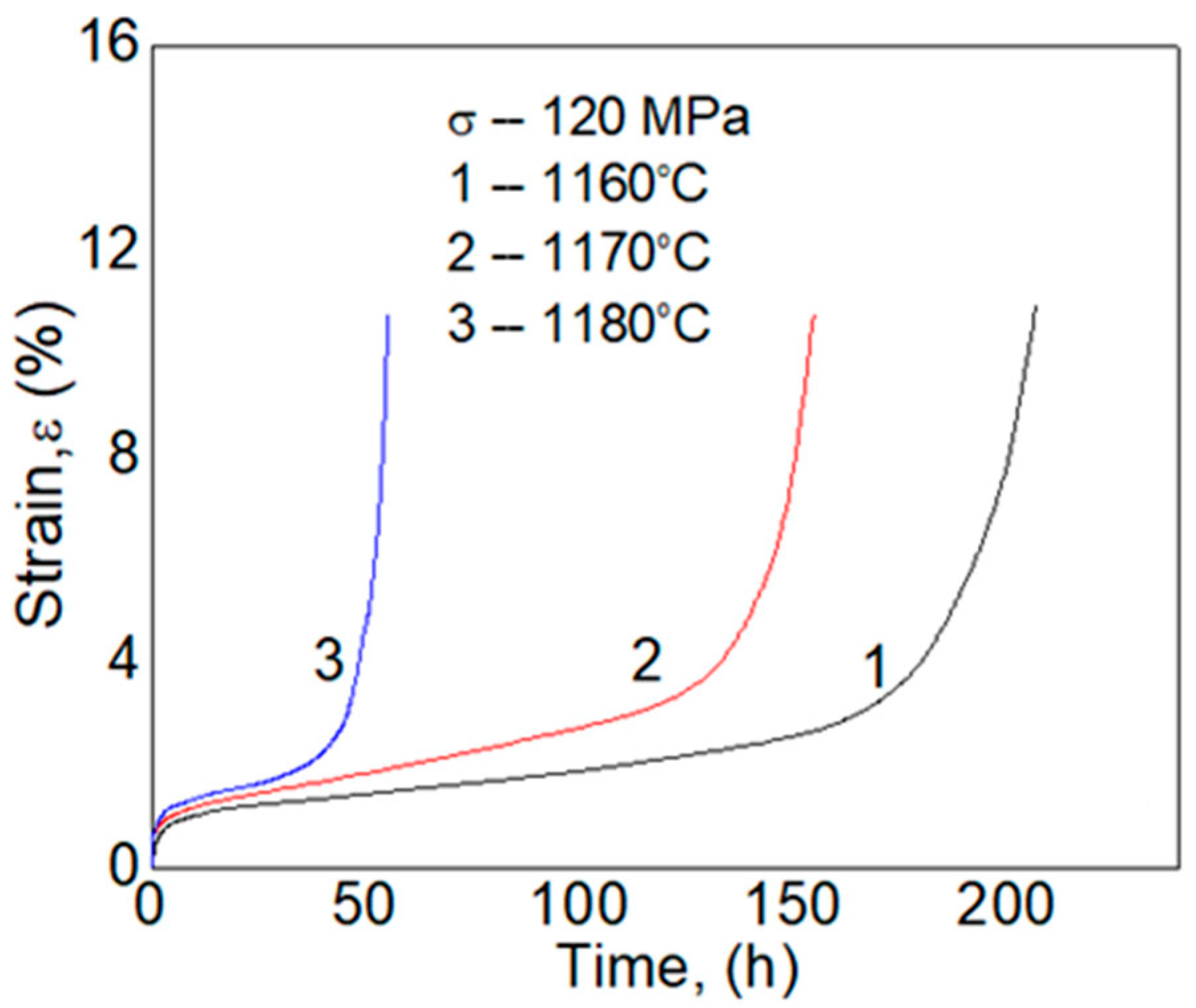

3.1. Microscopic Morphology and Creep Properties

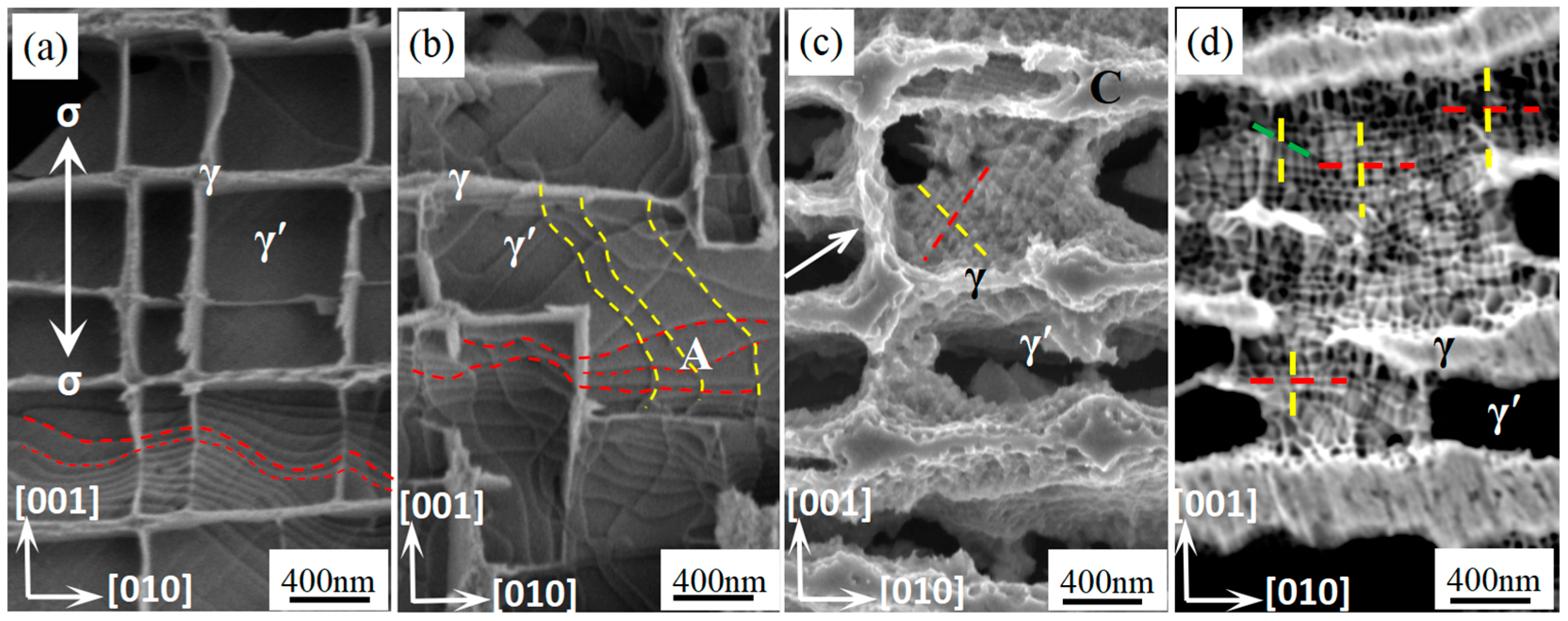

3.2. Microstructure Evolution

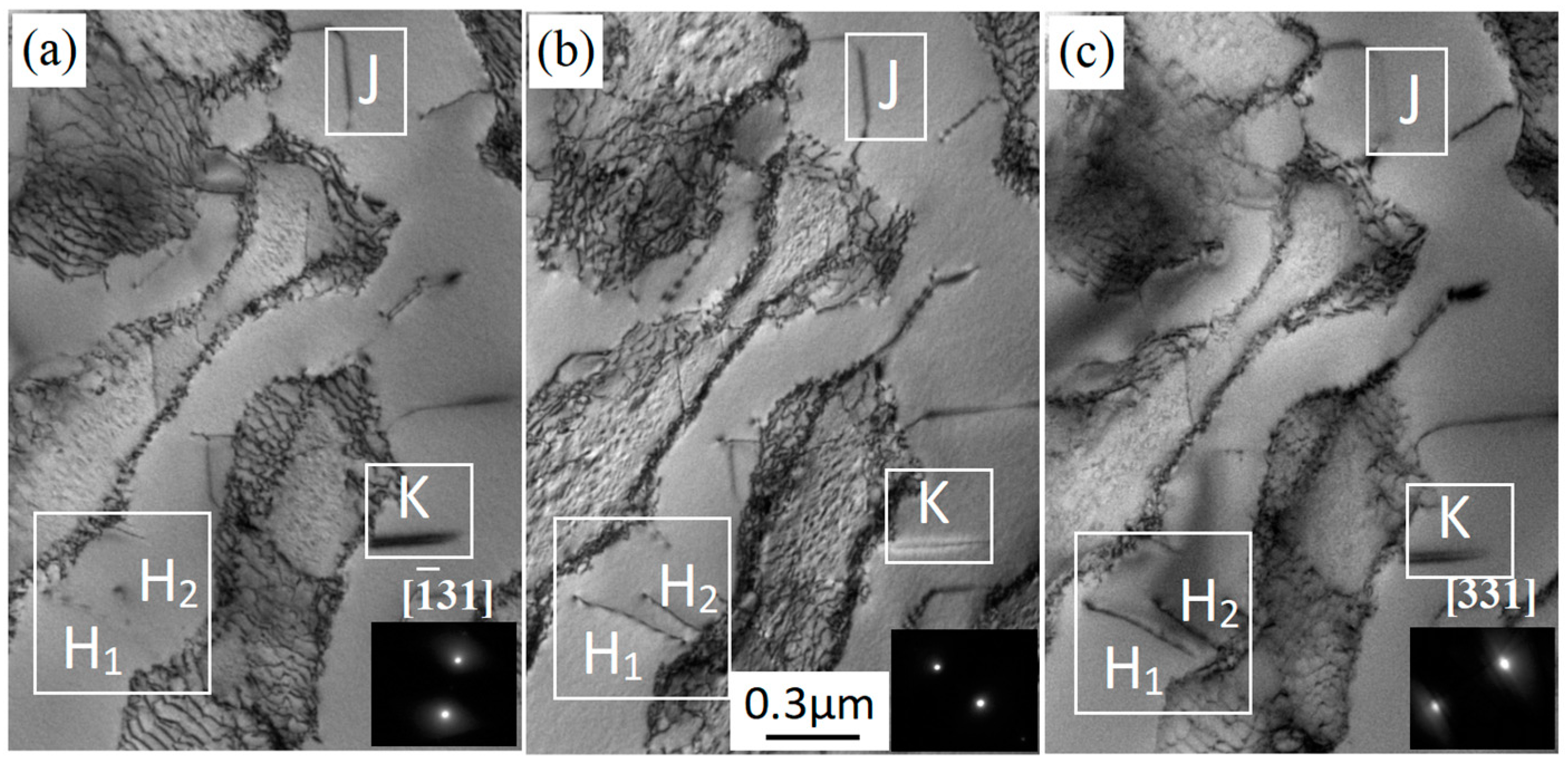

3.3. Dislocation Configuration at Different g-Vectors

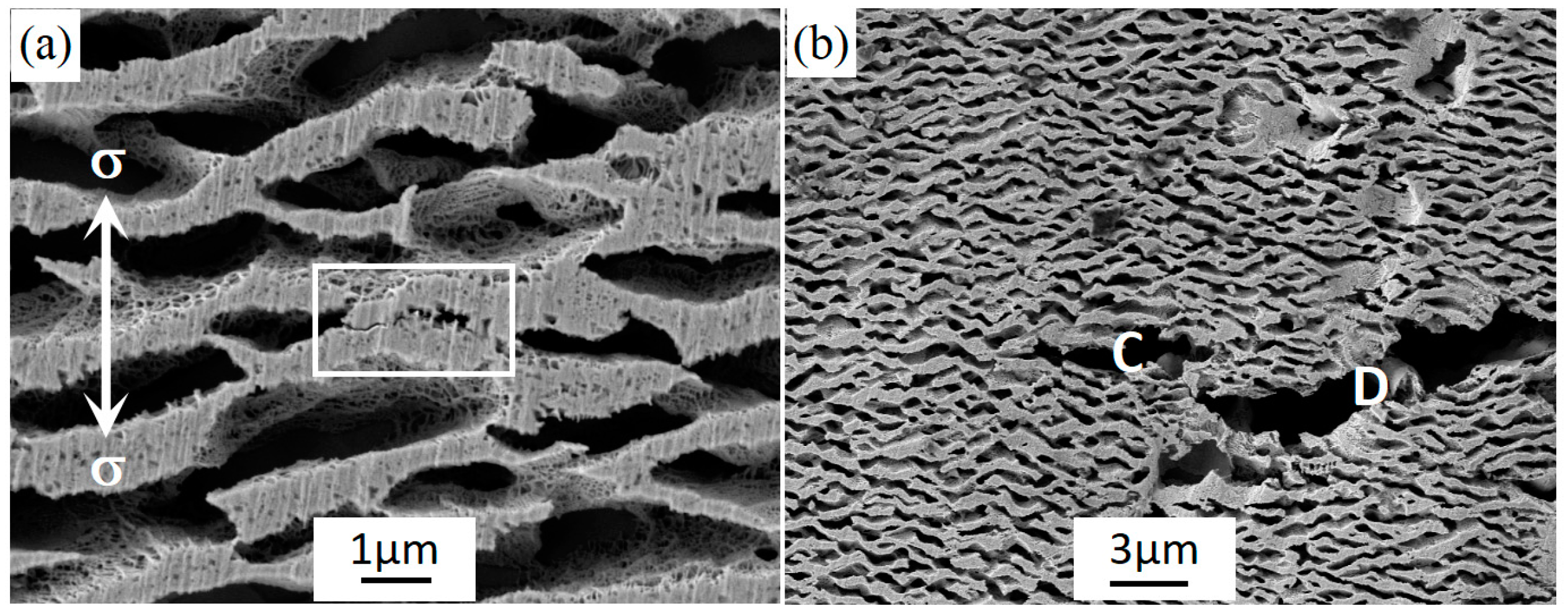

3.4. Creep Damage of Alloy

4. Discussion

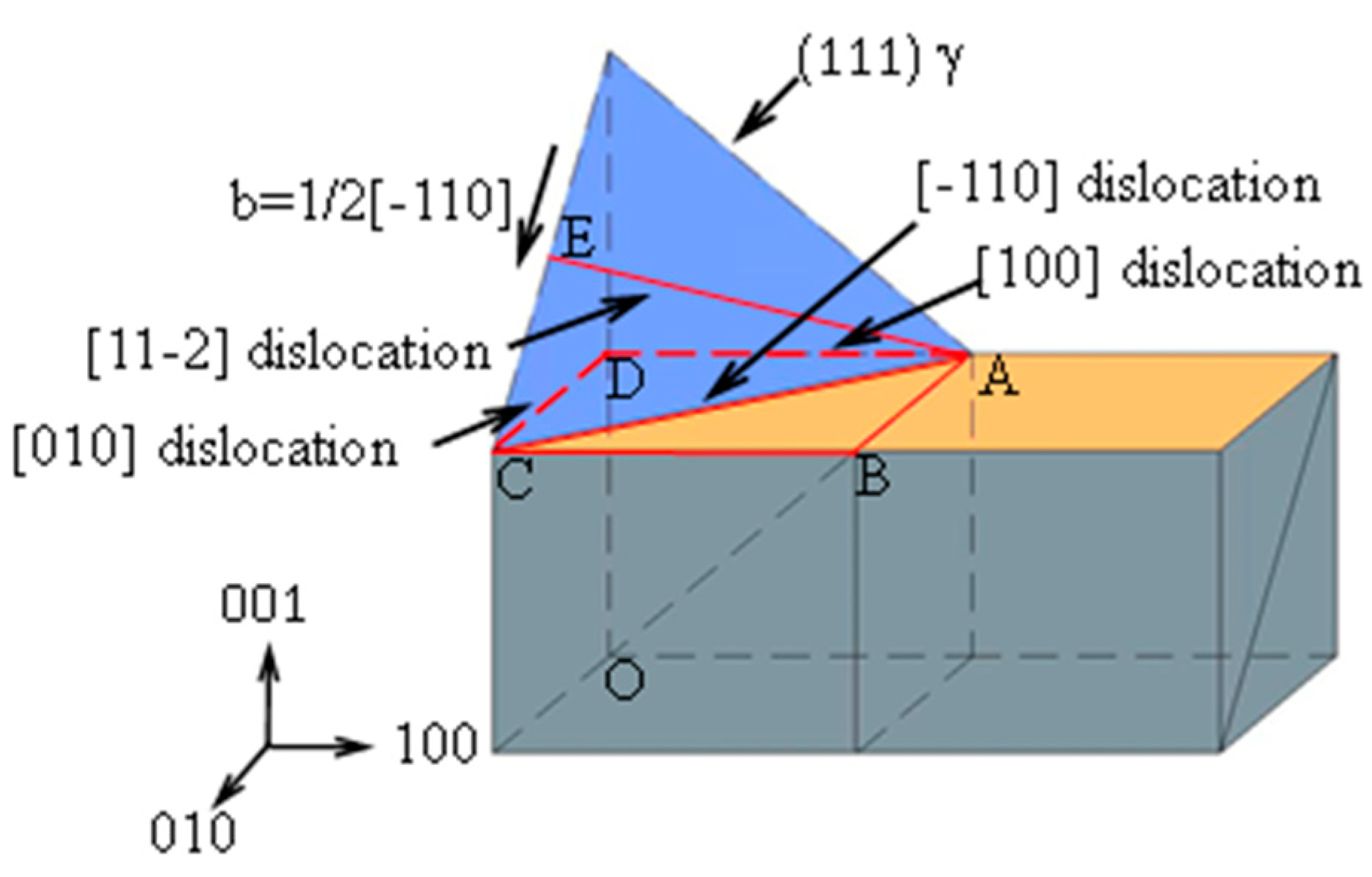

4.1. Dislocation Network Transformation Processes

4.2. Analysis of Re/Ru for Improving Creep Resistance

5. Conclusions

- Stacking Faults in the γ′ Phase: The presence of stacking faults in the γ′ phase during the steady-state creep stage is a key factor contributing to the alloy’s excellent mechanical properties, even under ultra-high temperature conditions.

- Re and Ru Content: The higher content of Re and Ru in the alloy enhances the driving force for dislocation motion, which promotes the formation of a dense dislocation network before the γ′ phase fully forms a raft-like structure. This dense dislocation network is a crucial factor in the alloy’s excellent mechanical properties during ultra-high-temperature creep.

- Dislocation Network Formation: The process of dislocation network formation involves the dislocations at the γ/γ′ two-phase interface transforming into <110> 60° mixed dislocations that slip along the (100) plane. These 60° mixed dislocations, which sweep and slip on different {111} planes, meet at the (100)/two-phase interface, leading to the formation of a <110> dislocation network. As creep progresses, the 60° mixed dislocations can be transformed into edge dislocations along the <100> direction, transitioning the dislocation network to a <100>-type. The intermediate state of this transformation is a <110>-<100> mixed dislocation network.

- Dislocation Shearing and K-W Lock Formation: In the late creep stage, a large number of dislocations shear into the γ′ phase. Some of these dislocations can cross slip to the {100} plane, forming a K-W lock. The high concentration of Ru in the γ′ phase enhances the alloying effect, preventing dislocations from cross slipping back to the {111} plane. This mechanism is a significant contributor to the alloy’s outstanding mechanical properties under ultra-high-temperature conditions.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, Y.T.; D’Souza, N.; Roebuck, B.; Karamched, P.; Panwisawas, C.; Collins, D.M. Ultra-high temperature deformation in a single crystal superalloy: Mesoscale process simulation and micromechanisms. Acta Mater. 2021, 203, 116468. [Google Scholar] [CrossRef]

- Yan, H.; Tian, S.; Zhao, G.; Tian, N.; Zhang, S. Creep and damage of a Re/Ru-containing single crystal nickel-based alloy at high temperature. Mater. Sci. Eng. A 2021, 808, 140870. [Google Scholar] [CrossRef]

- Yeh, A.C.; Tin, S. Effects of Ru and Re additions on the high temperature flow stresses of Ni-base single crystal superalloys. Scr. Mater. 2005, 52, 519–524. [Google Scholar] [CrossRef]

- Liu, S.H.; Liu, C.P.; Liu, W.Q.; Zhang, X.N.; Yan, P.; Wang, C.Y. Investigation of the elemental partitioning behaviour and site preference in ternary model nickel-based superalloys by atom probe tomography and first-principles calculations. Philos. Mag. Struct. Prop. Condens. Matter 2016, 96, 2204–2218. [Google Scholar] [CrossRef]

- Liang, X.; Wu, J.; Zhao, Y. Creep Fracture Mechanism of a Single Crystal Nickel Base Alloy Under High Temperature and Low Stress. Met. Mater. Int. 2022, 28, 841–847. [Google Scholar] [CrossRef]

- Latief, F.H.; Kakehi, K. Effects of Re content and crystallographic orientation on creep behavior of aluminized Ni-base single crystal superalloys. Mater. Des. 2013, 49, 485–492. [Google Scholar] [CrossRef]

- Wang, G.L.; Liu, J.L.; Liu, J.D.; Wang, X.G.; Zhou, Y.Z.; Sun, X.D.; Zhang, H.F.; Jin, T. Temperature dependence of tensile behavior and deformation microstructure of a Re-containing Ni-base single crystal superalloy. Mater. Des. 2017, 130, 131–139. [Google Scholar] [CrossRef]

- Wang, X.G.; Liu, J.L.; Jin, T.; Sun, X.F.; Hu, Z.Q.; Do, J.H.; Choi, B.G.; Kim, I.S.; Jo, C.Y. Dislocation motion during high-temperature low-stress creep in Ru-free and Ru-containing single-crystal superalloys. Mater. Des. 2015, 67, 543–551. [Google Scholar] [CrossRef]

- Heckl, A.; Neumeier, S.; Göken, M.; Singer, R.F. The effect of Re and Ru on γ/γ′ microstructure, γ-solid solution strengthening and creep strength in nickel-base superalloys. Mater. Sci. Eng. A 2011, 528, 3435–3444. [Google Scholar] [CrossRef]

- Vorontsov, V.A.; Kovarik, L.; Mills, M.J. High-resolution electron microscopy of dislocation ribbons in a CMSX-4 superalloy single crystal. Acta Mater. 2012, 60, 4866–4878. [Google Scholar] [CrossRef]

- Zhang, J.X.; Harada, H. Dislocation Configurations in Single-Crystal Superalloys during High-Temperature Low-Stress Creep. Adv. Mater. Res. 2011, 306, 433–437. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Koizumi, Y.; Kobayashi, T.; Harada, H.; Masaki, S. Interfacial dislocation networks strengthening a fourth-generation single-crystal TMS-138 superalloy. Metall. Mater. Trans. A 2002, 33, 3741–3746. [Google Scholar] [CrossRef]

- Zhang, J.X.; Harada, H.; Koizumi, Y.; Kobayashi, T. Dislocation motion in the early stages of high-temperature low-stress creep in a single-crystal superalloy with a small lattice misfit. J. Mater. Sci. 2009, 45, 523–532. [Google Scholar] [CrossRef]

- Long, H.; Wei, H.; Liu, Y.; Mao, S.; Zhang, J.; Xiang, S.; Chen, Y.; Gui, W.; Li, Q.; Zhang, Z.; et al. Effect of lattice misfit on the evolution of the dislocation structure in Ni-based single crystal superalloys during thermal exposure. Acta Mater. 2016, 120, 95–107. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Xiang, S.; Chen, Y.; Wei, H.; Zhou, Y.; Liu, J.; Liu, Y. A modification on Brooke formula in calculating the misfit of Ni-based superalloys. Mater. Des. 2017, 126, 12–17. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Harada, H.; Koizumi, Y. The Effect of Lattice Misfit on the Dislocation Motion in Superalloys During High-Temperature Low-Stress Creep. Acta Mater. 2005, 53, 4623–4633. [Google Scholar] [CrossRef]

- Carroll, L.J.; Feng, Q.; Pollock, T.M. Interfacial Dislocation Networks and Creep in Directional Coarsened Ru-Containing Nickel-Base Single-Crystal Superalloys. Metall. Mater. Trans. A 2008, 39, 1290–1307. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Harada, H.; Koizumi, Y.; Kobayashi, T. Creep Deformation Mechanisms in Some Modern Single-Cryatal Superalloys. Superalloys 2004, 2004, 189–195. [Google Scholar] [CrossRef]

- Huang, M.; Zhu, J. An overview of rhenium effect in single-crystal superalloys. Rare Met. 2016, 35, 127–139. [Google Scholar] [CrossRef]

- Tian, S.; Su, Y.; Qian, B.; Yu, X.; Liang, F.; Li, A. Creep Behavior of Single Crystal Nickel-Baesd Superalloy Containing 4.2% Re. Mater. Des. 2012, 37, 236–242. [Google Scholar] [CrossRef]

- Zhang, J.X. Strengthening by γ interfacial dislocation networks in TMS-162 toward a fifth-generation single-crystal superalloy. Metall. Mater. Trans. 2004, 35A, 1911–1913. [Google Scholar] [CrossRef]

- Bachurin, D.V.; Weygand, D.; Gumbsch, P. Dislocation-grain boundary interaction in <111> textured thin metal fflms. Acta Mater. 2010, 58, 5232–5241. [Google Scholar]

- Ma, S.; Carroll, L.; Pollock, T.M. Development of γ phase stacking faults during high temperature creep of Ru-containing single crystal superalloys. Acta Mater. 2007, 55, 5802–5812. [Google Scholar] [CrossRef]

- Tian, S.; Zhang, B.; Yu, H.; Tian, N.; Li, Q. Microstructure evolution and creep behaviors of a directionally solidified nickel-base alloy under long-life service condition. Mater. Sci. Eng. A 2016, 673, 391–399. [Google Scholar] [CrossRef]

- Tian, N.; Zhao, G.; Meng, T.; Tian, S.; Liu, L.; Yan, H.; Wang, G.; Jin, F. Ultra-high-temperature creep behavior of a single-crystal nickel-based superalloy containing 6%Re/5%Ru. Mater. Charact. 2021, 180, 111394. [Google Scholar]

- Caron, F.D. On the creep behavior at 1033K of new generation single-crystal superalloys. Mater. Sci. Eng. A 2004, 385, 245–257. [Google Scholar]

- Fleischmann, E.; Miller, M.K.; Affeldt, E.; Glatzel, U. Quantitative experimental determination of the solid solution hardening potential of rhenium, tungsten and molybdenum in single-crystal nickel-based superalloys. Acta Mater. 2015, 87, 350–356. [Google Scholar] [CrossRef]

- Wu, W.P.; Chen, B.; Shen, H.F.; Ding, Z.J. Molecular dynamics simulation of rhenium effects on creep behavior of Ni-based single crystal superalloys. Prog. Nat. Sci. Mater. Int. 2022, 32, 259–266. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Huang, M. Atomistic modeling of the interaction between matrix dislocation and interfacial misfit dislocation networks in Ni-based single crystal superalloy. Comput. Mater. Sci. 2013, 70, 178–186. [Google Scholar] [CrossRef]

- Hosford, W.F. Mechanical Behavior of Materials; Cambridge University: Cambridge, UK, 2005. [Google Scholar]

- Shu, D.; Tian, S.; Tian, N.; Liu, L.; Liang, S.; Zhang, B. Influence of Re/Ru on concentration distribution in the γ/γ′ phase of nickel-based single crystal superalloys. Mater. Des. 2017, 132, 197–207. [Google Scholar] [CrossRef]

- Asadi, E.; Zaeem, M.A.; Moitra, A.; Tschopp, M.A. Effect of vacancy defects on generalized stacking fault energy of fcc metals. J. Phys. Condens. Matter 2014, 26, 115404. [Google Scholar] [CrossRef] [PubMed]

- Mackay, R.A.; Gabb, T.P.; Nathal, M.V. Microstructure-sensitive creep models for nickelbase superalloy single crystals. Mater. Sci. Eng. A 2013, 582, 397–408. [Google Scholar] [CrossRef]

- Blavette, D.; Cadel, E.; Pareige, C.; Deconihout, B.; Caron, P. Caron. Phase Transformation and Segregation to Lattice Defects in Ni-Base Superalloys. Microsc. Microanal. 2007, 13, 464–483. [Google Scholar] [CrossRef] [PubMed]

| Element | Al | Ta | Cr | Co | Mo | W | Re | Ru | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Chemical composition | 5.5 | -- | 2.97 | 7.1 | -- | 6.0 | 6 | 5 | 60.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, N. Microstructural Stability and Creep Behavior of a Re/Ru Single-Crystal Nickel-Based Alloy. Crystals 2025, 15, 370. https://doi.org/10.3390/cryst15040370

Tian N. Microstructural Stability and Creep Behavior of a Re/Ru Single-Crystal Nickel-Based Alloy. Crystals. 2025; 15(4):370. https://doi.org/10.3390/cryst15040370

Chicago/Turabian StyleTian, Ning. 2025. "Microstructural Stability and Creep Behavior of a Re/Ru Single-Crystal Nickel-Based Alloy" Crystals 15, no. 4: 370. https://doi.org/10.3390/cryst15040370

APA StyleTian, N. (2025). Microstructural Stability and Creep Behavior of a Re/Ru Single-Crystal Nickel-Based Alloy. Crystals, 15(4), 370. https://doi.org/10.3390/cryst15040370