Progress in Contact, Doping and Mobility Engineering of MoS2: An Atomically Thin 2D Semiconductor

Abstract

:Contents

| 1. Introduction…………………………………………………………………………………………. [3] |

| 2. Projected Performance of 2D MoS2……………………………………………………………… [5] |

| 3. Major Challenges in Contact, Doping and Mobility Engineering of 2D MoS2………...… [7] |

| 3.1. The Schottky Barrier and the van der Waals (vdW) Gap………………………………………...[7] |

| 3.2. Contact Length Scaling, Doping and Extrinsic Carrier Scattering……………………………..[10] |

| 3.3. Tackling the Major Challenges…………………………………………………………………... [11] |

| 4. Contact Work Function Engineering…………………………………………………….….…....[11] |

| 4.1. N-Type Work Function Engineering……………………………………………………………. [12] |

| 4.2. P-Type Work Function Engineering…………………………………………………………….. [14] |

| 5. Effect of Stoichiometry, Contact Morphology and Deposition Conditions……………….. [14] |

| 6. Electric Double Layer (EDL) Gating……………………………………….…………………….. [16] |

| 7. Surface Charge Transfer Doping.…….………………………………………………………….. [18] |

| 7.1. Charge Transfer Electron Doping……………………………………………………………….. [19] |

| 7.2. Charge Transfer Hole Doping…………………………………………………………………… [21] |

| 8. Use of Interfacial Contact ‘Tunnel’ Barriers……………………………………………………. [23] |

| 9. Graphene 2D Contacts to MoS2………………………………………………………………….. [26] |

| 10. Effects of MoS2 Layer Thickness……………………………………………………………….. [30] |

| 11. Effects of Contact Architecture (Top versus Edge)…………………………………………... [34] |

| 12. Hybridization and Phase Engineering……………………………………………………........ [37] |

| 13. Engineering Structural Defects, Interface Traps and Surface States………………..…...... [40] |

| 14. Role of Dielectrics in Doping and Mobility Engineering……………………….………….. [44] |

| 14.1. Dielectrics as Dopants………………………………………………………………………….. [45] |

| 14.2. Mobility Engineering with Dielectrics: Role of High-κ………………………………………...[47] |

| 14.3. Limitations of High-κ Dielectrics and Advantages of Nitride Dielectric Environments……... [50] |

| 15. Substitutional Doping of 2D MoS2…………………………………………………………….. [55] |

| 15.1. Hole Doping by Cation Substitution…………………………………………………………… [57] |

| 15.2. Electron Doping by Cation Substitution……………………………………………………….. [58] |

| 15.3. Electron and Hole Doping by Anion Substitution……………………………………………... [59] |

| 15.4. Towards Controlled and Area-Selective Substitutional Doping………………….…………..... [62] |

| 16. Conclusions and Future Outlook………………………………………………………………... [64] |

1. Introduction

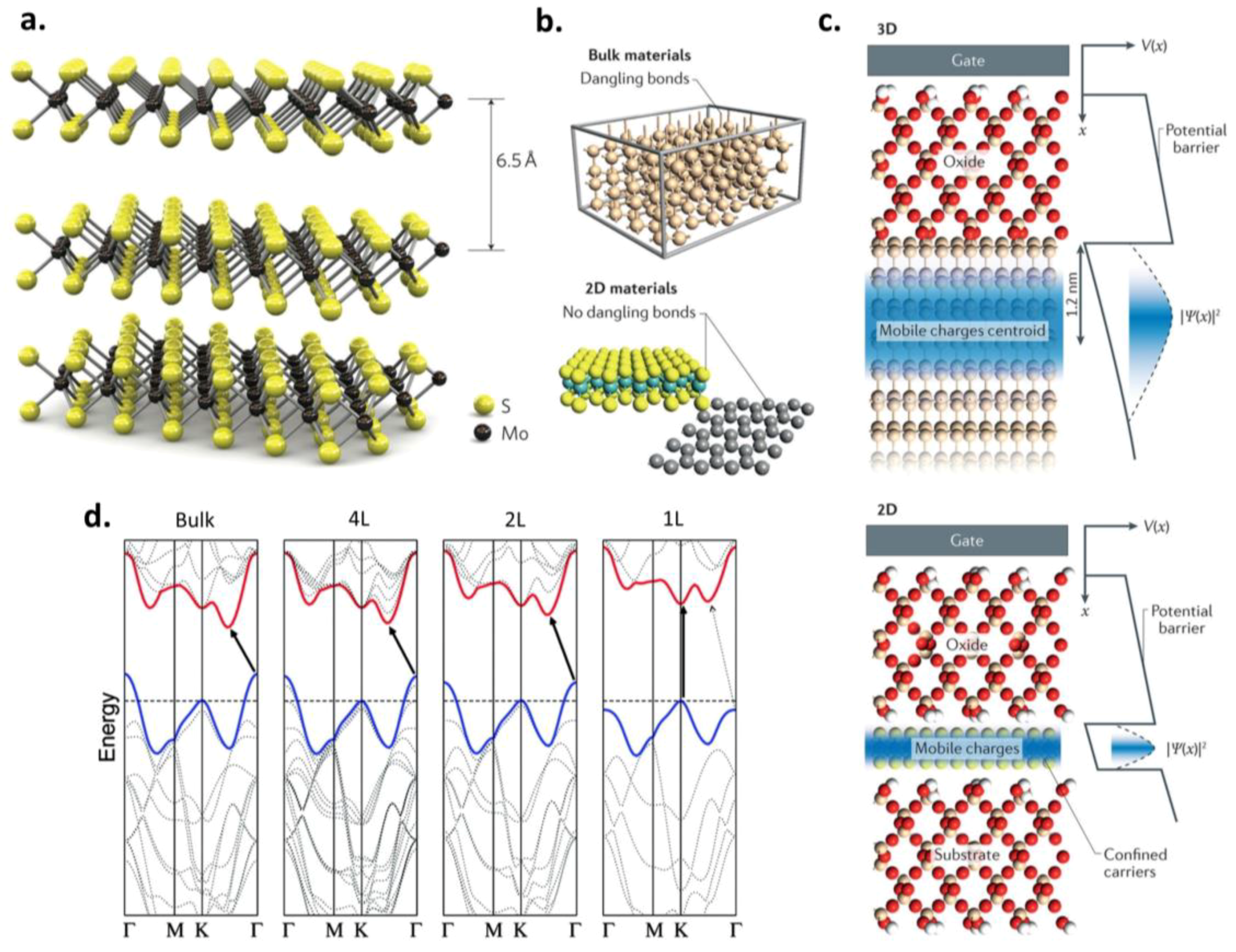

2. Projected Performance of 2D MoS2

3. Major Challenges in Contact, Doping and Mobility Engineering of 2D MoS2

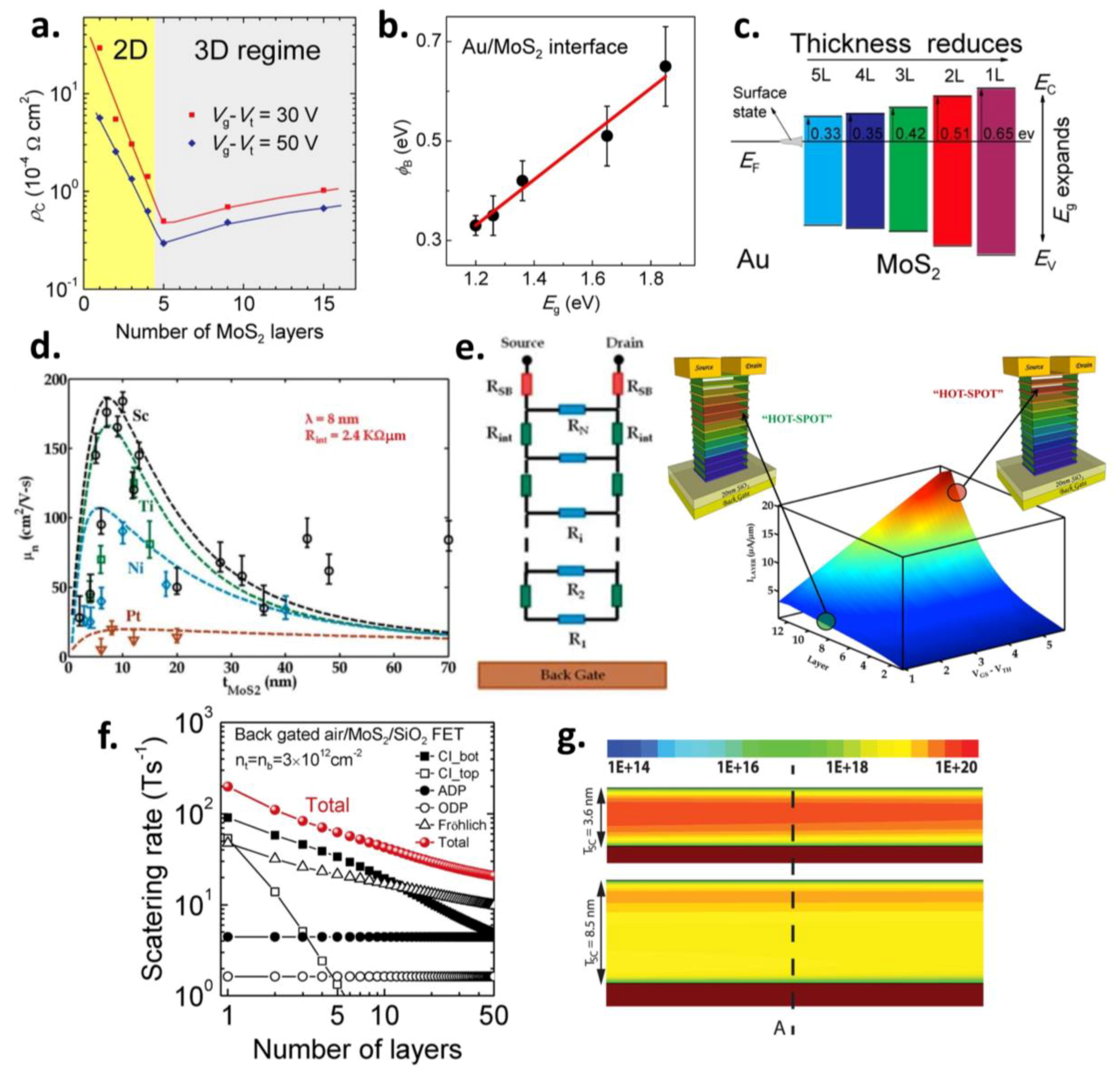

3.1. The Schottky Barrier and the van der Waals (vdW) Gap

3.2. Contact Length Scaling, Doping and Extrinsic Carrier Scattering

3.3. Tackling the Major Challenges

4. Contact Work Function Engineering

4.1. N-Type Work Function Engineering

4.2. P-Type Work Function Engineering

5. Effect of Stoichiometry, Contact Morphology and Deposition Conditions

6. Electric Double Layer (EDL) Gating

7. Surface Charge Transfer Doping

7.1. Charge Transfer Electron Doping

7.2. Charge Transfer Hole Doping

8. Use of Interfacial Contact “Tunnel” Barriers

9. Graphene 2D Contacts to MoS2

10. Effects of MoS2 Layer Thickness

11. Effects of Contact Architecture (Top versus Edge)

12. Hybridization and Phase Engineering

13. Engineering Structural Defects, Interface Traps and Surface States

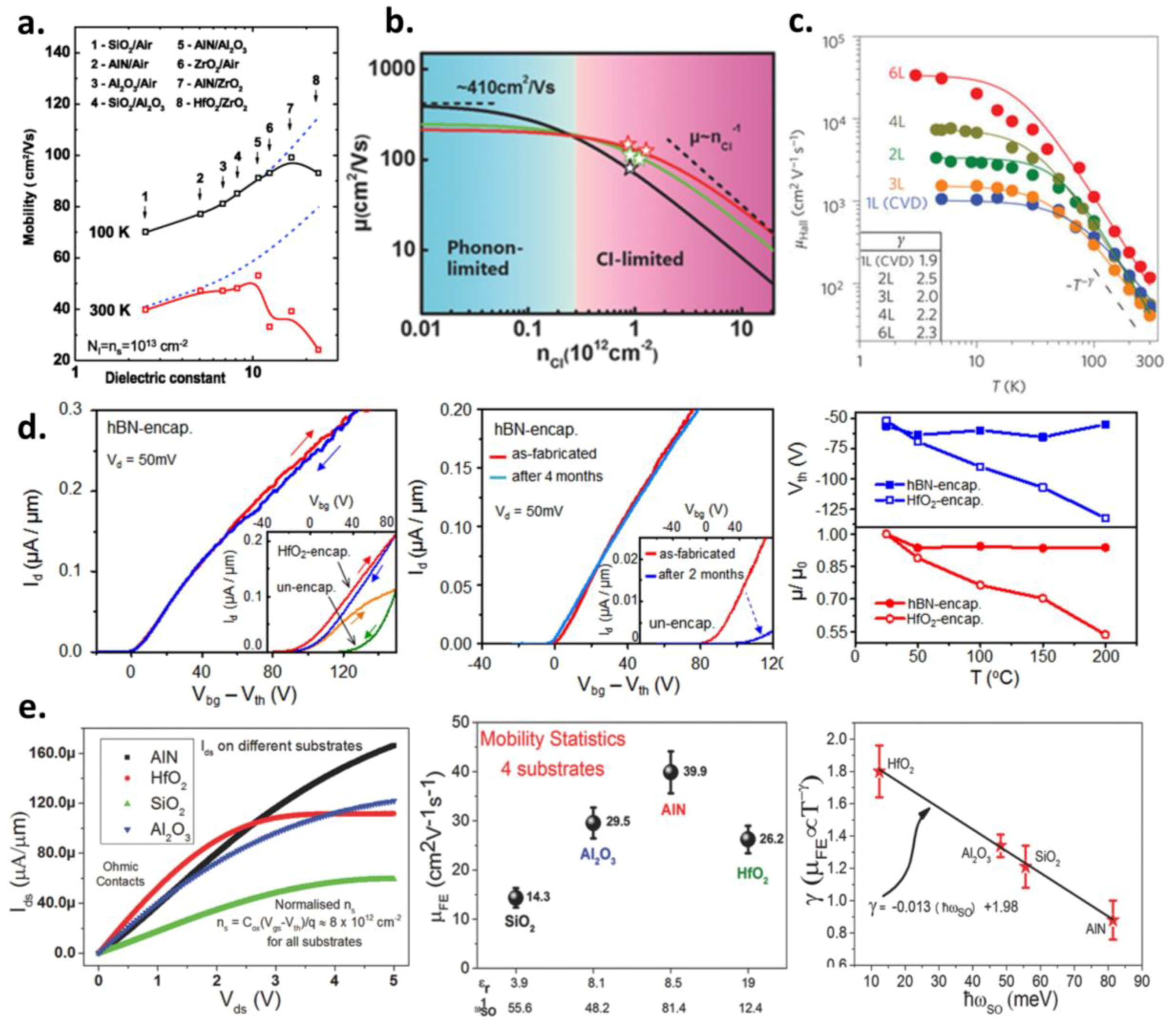

14. Role of Dielectrics in Doping and Mobility Engineering

14.1. Dielectrics as Dopants

14.2. Mobility Engineering with Dielectrics: Role of High-κ

14.3. Limitations of High-κ Dielectrics and Advantages of Nitride Dielectric Environments

15. Substitutional Doping of 2D MoS2

15.1. Hole Doping by Cation Substitution

15.2. Electron Doping by Cation Substitution

15.3. Electron and Hole Doping by Anion Substitution

15.4. Towards Controlled and Area-Selective Substitutional Doping

16. Conclusions and Future Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moore, G.E. No exponential is forever: But “Forever” can be delayed! [semiconductor industry]. In Proceedings of the 2003 IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 13 February 2003; Volume 1, pp. 20–23. [Google Scholar] [CrossRef]

- Schaller, R.R. Moore’s law: Past, present and future. IEEE Spectr. 1997, 34, 52–59. [Google Scholar] [CrossRef]

- Moore, G.E. Cramming more components onto integrated circuits, Reprinted from Electronics, volume 38, number 8, April 19, 1965, pp. 114 ff. IEEE Solid-State Circuits Soc. Newsl. 2006, 11, 33–35. [Google Scholar] [CrossRef]

- Mistry, K. A 45 nm logic technology with high-κ/metal gate transistors, strained silicon, 9 Cu interconnect layers. 193 nm dry patteming, and 100%Pb-free packaging. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), Washington, DC, USA, 10–12 December 2007; pp. 247–250. [Google Scholar] [CrossRef]

- Davari, B.; Dennard, R.H.; Shahidi, G.G. CMOS scaling for high performance and low power-the next ten years. Proc. IEEE 1995, 83, 595–606. [Google Scholar] [CrossRef]

- Cartwright, J. Intel enters the third dimension. Nat. News 2011. [Google Scholar] [CrossRef]

- Auth, C.; Allen, C.; Blattner, A.; Bergstrom, D.; Brazier, M.; Bost, M.; Buehler, M.; Chikarmane, V.; Ghani, T.; Glassman, T.; et al. A 22 nm high performance and low-power CMOS technology featuring fully-depleted tri-gate transistors, self-aligned contacts and high density MIM capacitors. In Proceedings of the 2012 Symposium on VLSI Technology (VLSIT), Honolulu, HI, USA, 12–14 June 2012; pp. 131–132. [Google Scholar] [CrossRef]

- Thompson, S.E.; Parthasarathy, S. Moore’s law: The future of Si microelectronics. Mater. Today 2006, 9, 20–25. [Google Scholar] [CrossRef]

- Alamo, J.A. del Nanometre-scale electronics with III–V compound semiconductors. Nature 2011, 479, 317. [Google Scholar] [CrossRef] [PubMed]

- Waldrop, M.M. The chips are down for Moore’s law. Nat. News 2016, 530, 144. [Google Scholar] [CrossRef] [PubMed]

- Thompson, S. Mos scaling: Transistor challenges for the 21st century. Intel Technol. J. 1998, Q3, 1–19. [Google Scholar]

- Haron, N.Z.; Hamdioui, S. Why is CMOS scaling coming to an END? In Proceedings of the 2008 3rd International Design and Test Workshop, Monastir, Tunisia, 20–22 December 2008; pp. 98–103. [Google Scholar] [CrossRef]

- Frank, D.J. Power-constrained CMOS scaling limits. IBM J. Res. Dev. 2002, 46, 235–244. [Google Scholar] [CrossRef]

- Yong-Bin, K. Challenges for Nanoscale MOSFETs and Emerging Nanoelectronics. Trans. Electr. Electron. Mater. 2010, 11, 93–105. [Google Scholar] [CrossRef] [Green Version]

- Horowitz, M.; Alon, E.; Patil, D.; Naffziger, S.; Kumar, R.; Bernstein, K. Scaling, power, and the future of CMOS. In Proceedings of the IEEE International Electron Devices Meeting, Washington, DC, USA, 5 December 2005; pp. 7–15. [Google Scholar] [CrossRef]

- Kuhn, K.J. Considerations for Ultimate CMOS Scaling. IEEE Trans. Electron Devices 2012, 59, 1813–1828. [Google Scholar] [CrossRef]

- Skotnicki, T.; Hutchby, J.A.; King, T.-J.; Wong, H.S.P.; Boeuf, F. The end of CMOS scaling: Toward the introduction of new materials and structural changes to improve MOSFET performance. IEEE Circuits Devices Mag. 2005, 21, 16–26. [Google Scholar] [CrossRef]

- Cavin, R.K.; Lugli, P.; Zhirnov, V.V. Science and Engineering Beyond Moore’s Law. Proc. IEEE 2012, 100, 1720–1749. [Google Scholar] [CrossRef]

- Kuhn, K.J.; Avci, U.; Cappellani, A.; Giles, M.D.; Haverty, M.; Kim, S.; Kotlyar, R.; Manipatruni, S.; Nikonov, D.; Pawashe, C.; et al. The ultimate CMOS device and beyond. In Proceedings of the 2012 International Electron Devices Meeting, San Francisco, CA, USA, 10–13 December 2012; pp. 8.1.1–8.1.4. [Google Scholar] [CrossRef]

- Geim, A.K. Graphene: Status and Prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Fal′ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192. [Google Scholar] [CrossRef] [PubMed]

- Schwierz, F. Graphene transistors. Nat. Nanotechnol. 2010, 5, 487. [Google Scholar] [CrossRef] [PubMed]

- Schwierz, F. Graphene Transistors: Status, Prospects, and Problems. Proc. IEEE 2013, 101, 1567–1584. [Google Scholar] [CrossRef]

- Mas-Ballesté, R.; Gómez-Navarro, C.; Gómez-Herrero, J.; Zamora, F. 2D materials: To graphene and beyond. Nanoscale 2011, 3, 20–30. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Liang, T.; Shi, M.; Chen, H. Graphene-Like Two-Dimensional Materials. Chem. Rev. 2013, 113, 3766–3798. [Google Scholar] [CrossRef] [PubMed]

- Gibney, E. The super materials that could trump graphene. Nat. News 2015, 522, 274. [Google Scholar] [CrossRef] [PubMed]

- Chhowalla, M.; Shin, H.S.; Eda, G.; Li, L.-J.; Loh, K.P.; Zhang, H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013, 5, 263. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Das, S.; Robinson, J.A.; Dubey, M.; Terrones, H.; Terrones, M. Beyond Graphene: Progress in Novel Two-Dimensional Materials and van der Waals Solids. Annu. Rev. Mater. Res. 2015, 45. [Google Scholar] [CrossRef]

- Gong, C.; Zhang, H.; Wang, W.; Colombo, L.; Wallace, R.M.; Cho, K. Band alignment of two-dimensional transition metal dichalcogenides: Application in tunnel field effect transistors. Appl. Phys. Lett. 2013, 103, 053513. [Google Scholar] [CrossRef]

- McDonnell, S.J.; Wallace, R.M. Atomically-thin layered films for device applications based upon 2D TMDC materials. Thin Solid Films 2016, 616, 482–501. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.; Cao, W.; Xie, X.; Sarkar, D.; Liu, W.; Banerjee, K. Graphene and beyond-graphene 2D crystals for next-generation green electronics. In Micro-and Nanotechnology Sensors, Systems, and Applications VI; International Society for Optics and Photonics: Baltimore, MD, USA, 2014; Volume 9083, p. 908305. [Google Scholar] [CrossRef]

- Chhowalla, M.; Jena, D.; Zhang, H. Two-dimensional semiconductors for transistors. Nat. Rev. Mater. 2016, 1, 16052. [Google Scholar] [CrossRef]

- Fiori, G.; Bonaccorso, F.; Iannaccone, G.; Palacios, T.; Neumaier, D.; Seabaugh, A.; Banerjee, S.K.; Colombo, L. Electronics based on two-dimensional materials. Nat. Nanotechnol. 2014, 9, 768. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Lauhon, L.J.; Marks, T.J.; Hersam, M.C. Emerging Device Applications for Semiconducting Two-Dimensional Transition Metal Dichalcogenides. ACS Nano 2014, 8, 1102–1120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhimanapati, G.R.; Lin, Z.; Meunier, V.; Jung, Y.; Cha, J.; Das, S.; Xiao, D.; Son, Y.; Strano, M.S.; Cooper, V.R.; et al. Recent Advances in Two-Dimensional Materials beyond Graphene. ACS Nano 2015, 9, 11509–11539. [Google Scholar] [CrossRef] [PubMed]

- Schwierz, F.; Pezoldt, J.; Granzner, R. Two-dimensional materials and their prospects in transistor electronics. Nanoscale 2015, 7, 8261–8283. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef] [PubMed]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.-Y.; Galli, G.; Wang, F. Emerging Photoluminescence in Monolayer MoS2. Nano Lett. 2010, 10, 1271–1275. [Google Scholar] [CrossRef] [PubMed]

- Ellis, J.K.; Lucero, M.J.; Scuseria, G.E. The indirect to direct band gap transition in multilayered MoS2 as predicted by screened hybrid density functional theory. Appl. Phys. Lett. 2011, 99, 261908. [Google Scholar] [CrossRef]

- Cheiwchanchamnangij, T.; Lambrecht, W.R.L. Quasiparticle band structure calculation of monolayer, bilayer, and bulk MoS2. Phys. Rev. B 2012, 85, 205302. [Google Scholar] [CrossRef]

- Kuc, A.; Zibouche, N.; Heine, T. Influence of quantum confinement on the electronic structure of the transition metal sulfide TS2. Phys. Rev. B 2011, 83, 245213. [Google Scholar] [CrossRef]

- Schwierz, F. Nanoelectronics: Flat transistors get off the ground. Nat. Nanotechnol. 2011, 6, 135. [Google Scholar] [CrossRef] [PubMed]

- Lembke, D.; Bertolazzi, S.; Kis, A. Single-Layer MoS2 Electronics. Acc. Chem. Res. 2015, 48, 100–110. [Google Scholar] [CrossRef] [PubMed]

- Ganatra, R.; Zhang, Q. Few-Layer MoS2: A Promising Layered Semiconductor. ACS Nano 2014, 8, 4074–4099. [Google Scholar] [CrossRef] [PubMed]

- Venkata Subbaiah, Y.P.; Saji, K.J.; Tiwari, A. Atomically Thin MoS2: A Versatile Nongraphene 2D Material. Adv. Funct. Mater. 2016, 26, 2046–2069. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Z.; Jiang, C.; Yin, L.; Cheng, R.; Zhan, X.; Xu, K.; Wang, F.; Zhang, Y.; He, J. Progress on Electronic and Optoelectronic Devices of 2D Layered Semiconducting Materials. Small 2017, 13, 1604298. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Cao, X.; Wu, X.-J.; He, Q.; Yang, J.; Zhang, X.; Chen, J.; Zhao, W.; Han, S.; Nam, G.-H.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Kang, J.; Liu, W.; Khatami, Y.; Sarkar, D.; Banerjee, K. 2D electronics: Graphene and beyond. In Proceedings of the 2013 Proceedings of the European Solid-State Device Research Conference (ESSDERC), Bucharest, Romania, 16–20 September 2013; pp. 37–44. [Google Scholar] [CrossRef]

- Liu, Y.; Weiss, N.O.; Duan, X.; Cheng, H.-C.; Huang, Y.; Duan, X. Van der Waals heterostructures and devices. Nat. Rev. Mater. 2016, 1, 16042. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Neto, A.H.C. Two-dimensional crystals-based heterostructures: Materials with tailored properties. Phys. Scr. 2012, 2012, 014006. [Google Scholar] [CrossRef]

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419. [Google Scholar] [CrossRef] [PubMed]

- Lotsch, B.V. Vertical 2D Heterostructures. Annu. Rev. Mater. Res. 2015, 45, 85–109. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Q.; Chen, Y.; Wang, Z.; Wee, A.T.S. Van der Waals stacked 2D layered materials for optoelectronics. 2D Mater. 2016, 3, 022001. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.H.C. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef] [PubMed]

- Hamann, D.M.; Hadland, E.C.; Johnson, D.C. Heterostructures containing dichalcogenides-new materials with predictable nanoarchitectures and novel emergent properties. Semicond. Sci. Technol. 2017, 32, 093004. [Google Scholar] [CrossRef]

- Jariwala, D.; Marks, T.J.; Hersam, M.C. Mixed-dimensional van der Waals heterostructures. Nat. Mater. 2017, 16, 170. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Neal, A.T.; Ye, P.D. Channel Length Scaling of MoS2 MOSFETs. ACS Nano 2012, 6, 8563–8569. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Guo, J.; Wu, Y.; Zhu, E.; Weiss, N.O.; He, Q.; Wu, H.; Cheng, H.-C.; Xu, Y.; Shakir, I.; et al. Pushing the Performance Limit of Sub-100 nm Molybdenum Disulfide Transistors. Nano Lett. 2016, 16, 6337–6342. [Google Scholar] [CrossRef] [PubMed]

- Nourbakhsh, A.; Zubair, A.; Sajjad, R.N.; Tavakkoli, A.K.G.; Chen, W.; Fang, S.; Ling, X.; Kong, J.; Dresselhaus, M.S.; Kaxiras, E.; et al. MoS2 Field-Effect Transistor with Sub-10 nm Channel Length. Nano Lett. 2016, 16, 7798–7806. [Google Scholar] [CrossRef] [PubMed]

- Desai, S.B.; Madhvapathy, S.R.; Sachid, A.B.; Llinas, J.P.; Wang, Q.; Ahn, G.H.; Pitner, G.; Kim, M.J.; Bokor, J.; Hu, C.; et al. MoS2 transistors with 1-nanometer gate lengths. Science 2016, 354, 99–102. [Google Scholar] [CrossRef] [PubMed]

- Radisavljevic, B.; Whitwick, M.B.; Kis, A. Integrated Circuits and Logic Operations Based on Single-Layer MoS2. ACS Nano 2011, 5, 9934–9938. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yu, L.; Lee, Y.-H.; Shi, Y.; Hsu, A.; Chin, M.L.; Li, L.-J.; Dubey, M.; Kong, J.; Palacios, T. Integrated Circuits Based on Bilayer MoS2 Transistors. Nano Lett. 2012, 12, 4674–4680. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Lee, Y.-H.; Ling, X.; Santos, E.J.G.; Shin, Y.C.; Lin, Y.; Dubey, M.; Kaxiras, E.; Kong, J.; Wang, H.; et al. Graphene/MoS2 Hybrid Technology for Large-Scale Two-Dimensional Electronics. Nano Lett. 2014, 14, 3055–3063. [Google Scholar] [CrossRef] [PubMed]

- Sachid, A.B.; Tosun, M.; Desai, S.B.; Hsu, C.-Y.; Lien, D.-H.; Madhvapathy, S.R.; Chen, Y.-Z.; Hettick, M.; Kang, J.S.; Zeng, Y.; et al. Monolithic 3D CMOS Using Layered Semiconductors. Adv. Mater. 2016, 28, 2547–2554. [Google Scholar] [CrossRef] [PubMed]

- Bertolazzi, S.; Krasnozhon, D.; Kis, A. Nonvolatile Memory Cells Based on MoS2/Graphene Heterostructures. ACS Nano 2013, 7, 3246–3252. [Google Scholar] [CrossRef] [PubMed]

- Kshirsagar, C.U.; Xu, W.; Su, Y.; Robbins, M.C.; Kim, C.H.; Koester, S.J. Dynamic Memory Cells Using MoS2 Field-Effect Transistors Demonstrating Femtoampere Leakage Currents. ACS Nano 2016, 10, 8457–8464. [Google Scholar] [CrossRef] [PubMed]

- Zhang, E.; Wang, W.; Zhang, C.; Jin, Y.; Zhu, G.; Sun, Q.; Zhang, D.W.; Zhou, P.; Xiu, F. Tunable Charge-Trap Memory Based on Few-Layer MoS2. ACS Nano 2015, 9, 612–619. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Kim, S.; Kim, Y.; Cho, J.H. One-Transistor–One-Transistor (1T1T) Optoelectronic Nonvolatile MoS2 Memory Cell with Nondestructive Read-Out. ACS Appl. Mater. Interfaces 2017, 9, 26357–26362. [Google Scholar] [CrossRef] [PubMed]

- Radisavljevic, B.; Whitwick, M.B.; Kis, A. Small-signal amplifier based on single-layer MoS2. Appl. Phys. Lett. 2012, 101, 043103. [Google Scholar] [CrossRef]

- Sanne, A.; Ghosh, R.; Rai, A.; Yogeesh, M.N.; Shin, S.H.; Sharma, A.; Jarvis, K.; Mathew, L.; Rao, R.; Akinwande, D.; et al. Radio Frequency Transistors and Circuits Based on CVD MoS2. Nano Lett. 2015, 15, 5039–5045. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.-Y.; Yogeesh, M.N.; Ghosh, R.; Rai, A.; Sanne, A.; Yang, S.; Lu, N.; Banerjee, S.K.; Akinwande, D. Large-Area Monolayer MoS2 for Flexible Low-Power RF Nanoelectronics in the GHz Regime. Adv. Mater. 2016, 28, 1818–1823. [Google Scholar] [CrossRef] [PubMed]

- Sanne, A.; Park, S.; Ghosh, R.; Yogeesh, M.N.; Liu, C.; Mathew, L.; Rao, R.; Akinwande, D.; Banerjee, S.K. Embedded gate CVD MoS2 microwave FETs. Npj 2D Mater. Appl. 2017, 1, 26. [Google Scholar] [CrossRef]

- Choi, M.S.; Qu, D.; Lee, D.; Liu, X.; Watanabe, K.; Taniguchi, T.; Yoo, W.J. Lateral MoS2 p–n Junction Formed by Chemical Doping for Use in High-Performance Optoelectronics. ACS Nano 2014, 8, 9332–9340. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Luo, Z.; Conrad, N.J.; Liu, H.; Gong, Y.; Najmaei, S.; Ajayan, P.M.; Lou, J.; Xu, X.; Ye, P.D. Black Phosphorus–Monolayer MoS2 van der Waals Heterojunction p–n Diode. ACS Nano 2014, 8, 8292–8299. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Wu, C.-C.; Prabhumirashi, P.L.; Geier, M.L.; Marks, T.J.; Lauhon, L.J.; Hersam, M.C. Gate-tunable carbon nanotube–MoS2 heterojunction p-n diode. Proc. Natl. Acad. Sci. USA 2013, 110, 18076–18080. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.W.; Lee, C.H.; Paul, P.K.; Ma, L.; McCulloch, W.D.; Krishnamoorthy, S.; Wu, Y.; Arehart, A.R.; Rajan, S. Layer-transferred MoS2/GaN PN diodes. Appl. Phys. Lett. 2015, 107, 103505. [Google Scholar] [CrossRef]

- Lopez-Sanchez, O.; Lembke, D.; Kayci, M.; Radenovic, A.; Kis, A. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 2013, 8, 497–501. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.H.; Lee, Y.; Jang, S.K.; Kang, J.; Jeon, J.; Lee, C.; Lee, J.Y.; Kim, H.; Hwang, E.; Lee, S.; et al. Dye-Sensitized MoS2 Photodetector with Enhanced Spectral Photoresponse. ACS Nano 2014, 8, 8285–8291. [Google Scholar] [CrossRef] [PubMed]

- De Fazio, D.; Goykhman, I.; Yoon, D.; Bruna, M.; Eiden, A.; Milana, S.; Sassi, U.; Barbone, M.; Dumcenco, D.; Marinov, K.; et al. High Responsivity, Large-Area Graphene/MoS2 Flexible Photodetectors. ACS Nano 2016, 10, 8252–8262. [Google Scholar] [CrossRef] [PubMed]

- Kufer, D.; Konstantatos, G. Highly Sensitive, Encapsulated MoS2 Photodetector with Gate Controllable Gain and Speed. Nano Lett. 2015, 15, 7307–7313. [Google Scholar] [CrossRef] [PubMed]

- Sundaram, R.S.; Engel, M.; Lombardo, A.; Krupke, R.; Ferrari, A.C.; Avouris, P.; Steiner, M. Electroluminescence in Single Layer MoS2. Nano Lett. 2013, 13, 1416–1421. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Sanchez, O.; Alarcon Llado, E.; Koman, V.; Fontcuberta i Morral, A.; Radenovic, A.; Kis, A. Light Generation and Harvesting in a van der Waals Heterostructure. ACS Nano 2014, 8, 3042–3048. [Google Scholar] [CrossRef] [PubMed]

- Withers, F.; Pozo-Zamudio, O.D.; Mishchenko, A.; Rooney, A.P.; Gholinia, A.; Watanabe, K.; Taniguchi, T.; Haigh, S.J.; Geim, A.K.; Tartakovskii, A.I.; et al. Light-emitting diodes by band-structure engineering in van der Waals heterostructures. Nat. Mater. 2015, 14, 301. [Google Scholar] [CrossRef] [PubMed]

- Cheng, R.; Li, D.; Zhou, H.; Wang, C.; Yin, A.; Jiang, S.; Liu, Y.; Chen, Y.; Huang, Y.; Duan, X. Electroluminescence and Photocurrent Generation from Atomically Sharp WSe2/MoS2 Heterojunction p–n Diodes. Nano Lett. 2014, 14, 5590–5597. [Google Scholar] [CrossRef] [PubMed]

- Salehzadeh, O.; Djavid, M.; Tran, N.H.; Shih, I.; Mi, Z. Optically Pumped Two-Dimensional MoS2 Lasers Operating at Room-Temperature. Nano Lett. 2015, 15, 5302–5306. [Google Scholar] [CrossRef] [PubMed]

- Woodward, R.I.; Howe, R.C.T.; Hu, G.; Torrisi, F.; Zhang, M.; Hasan, T.; Kelleher, E.J.R. Few-layer MoS2 saturable absorbers for short-pulse laser technology: Current status and future perspectives. Photonics Res. 2015, 3, A30–A42. [Google Scholar] [CrossRef]

- Fontana, M.; Deppe, T.; Boyd, A.K.; Rinzan, M.; Liu, A.Y.; Paranjape, M.; Barbara, P. Electron-hole transport and photovoltaic effect in gated MoS2 Schottky junctions. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.-L.; Su, S.-H.; Chang, J.-K.; Tsai, D.-S.; Chen, C.-H.; Wu, C.-I.; Li, L.-J.; Chen, L.-J.; He, J.-H. Monolayer MoS2 Heterojunction Solar Cells. ACS Nano 2014, 8, 8317–8322. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.Z.; Gao, W.; Liu, Y.J.; Han, Z.D.; Xue, Q.Z.; Guo, W.Y.; Zhu, J.; Li, Y.R. High-performance n-MoS2/i-SiO2/p-Si heterojunction solar cells. Nanoscale 2015, 7, 8304–8308. [Google Scholar] [CrossRef] [PubMed]

- Ur Rehman, A.; Khan, M.F.; Shehzad, M.A.; Hussain, S.; Bhopal, M.F.; Lee, S.H.; Eom, J.; Seo, Y.; Jung, J.; Lee, S.H. n-MoS2/p-Si Solar Cells with Al2O3 Passivation for Enhanced Photogeneration. ACS Appl. Mater. Interfaces 2016, 8, 29383–29390. [Google Scholar] [CrossRef] [PubMed]

- Perkins, F.K.; Friedman, A.L.; Cobas, E.; Campbell, P.M.; Jernigan, G.G.; Jonker, B.T. Chemical Vapor Sensing with Monolayer MoS2. Nano Lett. 2013, 13, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Cho, B.; Hahm, M.G.; Choi, M.; Yoon, J.; Kim, A.R.; Lee, Y.-J.; Park, S.-G.; Kwon, J.-D.; Kim, C.S.; Song, M.; et al. Charge-transfer-based Gas Sensing Using Atomic-layer MoS2. Sci. Rep. 2015, 5, 8052. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, Y.; Wong, J.I.; Palacios, T.; Kong, J.; Yang, H.Y. Functionalized MoS2 Nanosheet-Based Field-Effect Biosensor for Label-Free Sensitive Detection of Cancer Marker Proteins in Solution. Small 2014, 10, 1101–1105. [Google Scholar] [CrossRef] [PubMed]

- Park, M.; Park, Y.J.; Chen, X.; Park, Y.-K.; Kim, M.-S.; Ahn, J.-H. MoS2-Based Tactile Sensor for Electronic Skin Applications. Adv. Mater. 2016, 28, 2556–2562. [Google Scholar] [CrossRef] [PubMed]

- Roy, T.; Tosun, M.; Cao, X.; Fang, H.; Lien, D.-H.; Zhao, P.; Chen, Y.-Z.; Chueh, Y.-L.; Guo, J.; Javey, A. Dual-Gated MoS2/WSe2 van der Waals Tunnel Diodes and Transistors. ACS Nano 2015, 9, 2071–2079. [Google Scholar] [CrossRef] [PubMed]

- Krishnamoorthy, S.; Lee, E.W.; Lee, C.H.; Zhang, Y.; McCulloch, W.D.; Johnson, J.M.; Hwang, J.; Wu, Y.; Rajan, S. High current density 2D/3D MoS2/GaN Esaki tunnel diodes. Appl. Phys. Lett. 2016, 109, 183505. [Google Scholar] [CrossRef]

- Movva, H.C.P.; Kang, S.; Rai, A.; Kim, K.; Fallahazad, B.; Taniguchi, T.; Watanabe, K.; Tutuc, E.; Banerjee, S.K. Room temperature gate-tunable negative differential resistance in MoS2/hBN/WSe2 heterostructures. In Proceedings of the 2016 74th Device Research Conference (DRC), Newark, DE, USA, 19–22 June 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Balaji, Y.; Smets, Q.; de la Rosa, C.J.L.; Lu, A.K.A.; Chiappe, D.; Agarwal, T.; Lin, D.; Huyghebaert, C.; Radu, I.; Mocuta, D.; et al. Tunneling transistors based on MoS2/MoTe2 Van der Waals heterostructures. In Proceedings of the 2017 47th European Solid-State Device Research Conference (ESSDERC), Leuven, Belgium, 11–14 September 2017; pp. 106–109. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, Y.; Xiao, J.; Liu, M.; Xiong, S.; Wong, Z.J.; Ye, Z.; Ye, Y.; Yin, X.; Zhang, X. Observation of piezoelectricity in free-standing monolayer MoS2. Nat. Nanotechnol. 2015, 10, 151. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Wang, L.; Li, Y.; Zhang, F.; Lin, L.; Niu, S.; Chenet, D.; Zhang, X.; Hao, Y.; Heinz, T.F.; et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 2014, 514, 470. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.F.; Wong, S.L.; Chi, D.Z. CVD Growth of MoS2-based Two-dimensional Materials. Chem. Vap. Depos. 2015, 21, 241–259. [Google Scholar] [CrossRef]

- Walsh, L.A.; Hinkle, C.L. Van der Waals epitaxy: 2D materials and topological insulators. Appl. Mater. Today 2017, 9, 504–515. [Google Scholar] [CrossRef]

- Wong, S.L.; Liu, H.; Chi, D. Recent progress in chemical vapor deposition growth of two-dimensional transition metal dichalcogenides. Prog. Cryst. Growth Charact. Mater. 2016, 62, 9–28. [Google Scholar] [CrossRef]

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 17033. [Google Scholar] [CrossRef]

- Landauer, R. Spatial Variation of Currents and Fields Due to Localized Scatterers in Metallic Conduction. IBM J. Res. Dev. 1957, 1, 223–231. [Google Scholar] [CrossRef]

- Sharvin, Y.V. A Possible Method for Studying Fermi Surfaces. Sov. J. Exp. Theor. Phys. 1965, 21, 655. [Google Scholar]

- Allain, A.; Kang, J.; Banerjee, K.; Kis, A. Electrical contacts to two-dimensional semiconductors. Nat. Mater. 2015, 14, 1195–1205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jena, D.; Banerjee, K.; Xing, G.H. 2D crystal semiconductors: Intimate contacts. Nat. Mater. 2014, 13, 1076. [Google Scholar] [CrossRef] [PubMed]

- ITRS 2.0 Home Page. Available online: http://www.itrs2.net/ (accessed on 18 January 2018).

- Kaasbjerg, K.; Thygesen, K.S.; Jacobsen, K.W. Phonon-limited mobility in n-type single-layer MoS2 from first principles. Phys. Rev. B 2012, 85, 115317. [Google Scholar] [CrossRef]

- Li, X.; Mullen, J.T.; Jin, Z.; Borysenko, K.M.; Buongiorno Nardelli, M.; Kim, K.W. Intrinsic electrical transport properties of monolayer silicene and MoS2 from first principles. Phys. Rev. B 2013, 87, 115418. [Google Scholar] [CrossRef]

- Jin, Z.; Li, X.; Mullen, J.T.; Kim, K.W. Intrinsic transport properties of electrons and holes in monolayer transition-metal dichalcogenides. Phys. Rev. B 2014, 90, 045422. [Google Scholar] [CrossRef]

- Gunst, T.; Markussen, T.; Stokbro, K.; Brandbyge, M. First-principles method for electron-phonon coupling and electron mobility: Applications to two-dimensional materials. Phys. Rev. B 2016, 93, 035414. [Google Scholar] [CrossRef]

- Cai, Y.; Zhang, G.; Zhang, Y.-W. Polarity-Reversed Robust Carrier Mobility in Monolayer MoS2 Nanoribbons. J. Am. Chem. Soc. 2014, 136, 6269–6275. [Google Scholar] [CrossRef] [PubMed]

- Akinwande, D.; Petrone, N.; Hone, J. Two-dimensional flexible nanoelectronics. Nat. Commun. 2014, 5, 5678. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, H.-Y.; Yang, S.; Lee, J.; Tao, L.; Hwang, W.-S.; Jena, D.; Lu, N.; Akinwande, D. High-Performance, Highly Bendable MoS2 Transistors with High-κ Dielectrics for Flexible Low-Power Systems. ACS Nano 2013, 7, 5446–5452. [Google Scholar] [CrossRef] [PubMed]

- Pu, J.; Yomogida, Y.; Liu, K.-K.; Li, L.-J.; Iwasa, Y.; Takenobu, T. Highly Flexible MoS2 Thin-Film Transistors with Ion Gel Dielectrics. Nano Lett. 2012, 12, 4013–4017. [Google Scholar] [CrossRef] [PubMed]

- Schwierz, F. (Invited) Performance of Graphene and Beyond Graphene 2D Semiconductor Devices. ECS Trans. 2015, 69, 231–240. [Google Scholar] [CrossRef]

- Yoon, Y.; Ganapathi, K.; Salahuddin, S. How Good Can Monolayer MoS2 Transistors Be? Nano Lett. 2011, 11, 3768–3773. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Lu, Y.; Guo, J. On Monolayer MoS2 Field-Effect Transistors at the Scaling Limit. IEEE Trans. Electron Devices 2013, 60, 4133–4139. [Google Scholar] [CrossRef]

- Granzner, R.; Geng, Z.; Kinberger, W.; Schwierz, F. MOSFET scaling: Impact of two-dimensional channel materials. In Proceedings of the 2016 13th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT), Hangzhou, China, 25–28 October 2016; pp. 466–469. [Google Scholar] [CrossRef]

- Uchida, K.; Watanabe, H.; Kinoshita, A.; Koga, J.; Numata, T.; Takagi, S. Experimental study on carrier transport mechanism in ultrathin-body SOI nand p-MOSFETs with SOI thickness less than 5 nm. In Proceedings of the International Electron Devices Meeting, San Francisco, CA, USA, 8–11 December 2002; pp. 47–50. [Google Scholar] [CrossRef]

- Jena, D. Tunneling Transistors Based on Graphene and 2-D Crystals. Proc. IEEE 2013, 101, 1585–1602. [Google Scholar] [CrossRef]

- Lee, J.; Chang, H.Y.; Ha, T.J.; Li, H.; Ruoff, R.S.; Dodabalapur, A.; Akinwande, D. High-performance flexible nanoelectronics: 2D atomic channel materials for low-power digital and high-frequency analog devices. In Proceedings of the 2013 IEEE International Electron Devices Meeting, Washington, DC, USA, 9–11 December 2013; pp. 19.2.1–19.2.4. [Google Scholar] [CrossRef]

- Park, S.; Zhu, W.; Chang, H.Y.; Yogeesh, M.N.; Ghosh, R.; Banerjee, S.K.; Akinwande, D. High-frequency prospects of 2D nanomaterials for flexible nanoelectronics from baseband to sub-THz devices. In Proceedings of the 2015 IEEE International Electron Devices Meeting (IEDM), Washington, DC, USA, 7–9 December 2015; pp. 32.1.1–32.1.4. [Google Scholar] [CrossRef]

- Zhu, W.; Park, S.; Yogeesh, M.N.; Akinwande, D. Advancements in 2D flexible nanoelectronics: From material perspectives to RF applications. Flex. Print. Electron. 2017, 2, 043001. [Google Scholar] [CrossRef]

- Cao, W.; Kang, J.; Sarkar, D.; Liu, W.; Banerjee, K. Performance evaluation and design considerations of 2D semiconductor based FETs for sub-10 nm VLSI. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 30.5.1–30.5.4. [Google Scholar] [CrossRef]

- Smithe, K.K.H.; English, C.D.; Suryavanshi, S.V.; Pop, E. Intrinsic electrical transport and performance projections of synthetic monolayer MoS2 devices. 2D Mater. 2017, 4, 011009. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, C.; Du, S.; Yang, J.; Yu, B.; Luo, J.; Yin, W.; Li, E.; Dong, S.; Ye, P.; et al. Contacts between Two- and Three-Dimensional Materials: Ohmic, Schottky, and p–n Heterojunctions. ACS Nano 2016, 10, 4895–4919. [Google Scholar] [CrossRef] [PubMed]

- Giannazzo, F.; Fisichella, G.; Piazza, A.; Di Franco, S.; Greco, G.; Agnello, S.; Roccaforte, F. Impact of contact resistance on the electrical properties of MoS2 transistors at practical operating temperatures. Beilstein J. Nanotechnol. 2017, 8, 254–263. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Sarkar, D.; Kang, J.; Cao, W.; Banerjee, K. Impact of Contact on the Operation and Performance of Back-Gated Monolayer MoS2 Field-Effect-Transistors. ACS Nano 2015, 9, 7904–7912. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Chen, H.-Y.; Penumatcha, A.V.; Appenzeller, J. High Performance Multilayer MoS2 Transistors with Scandium Contacts. Nano Lett. 2012, 13, 100–105. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, N.; Nipane, A.; Basheer, F.; Dubey, S.; Grover, S.; Deshmukh, M.M.; Lodha, S. Schottky barrier heights for Au and Pd contacts to MoS2. Appl. Phys. Lett. 2014, 105, 113505. [Google Scholar] [CrossRef]

- Maurel, C.; Ajustron, F.; Péchou, R.; Seine, G.; Coratger, R. Electrical behavior of the Au/MoS2 interface studied by light emission induced by scanning tunneling microscopy. Surf. Sci. 2006, 600, 442–447. [Google Scholar] [CrossRef]

- Dankert, A.; Langouche, L.; Kamalakar, M.V.; Dash, S.P. High-Performance Molybdenum Disulfide Field-Effect Transistors with Spin Tunnel Contacts. ACS Nano 2014, 8, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Gong, C.; Addou, R.; McDonnell, S.; Azcatl, A.; Qin, X.; Wang, W.; Wang, W.; Hinkle, C.L.; Wallace, R.M. Schottky Barrier Height of Pd/MoS2 Contact by Large Area Photoemission Spectroscopy. ACS Appl. Mater. Interfaces 2017, 9, 38977–38983. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Stradins, P.; Wei, S.-H. Van der Waals metal-semiconductor junction: Weak Fermi level pinning enables effective tuning of Schottky barrier. Sci. Adv. 2016, 2, e1600069. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McDonnell, S.; Addou, R.; Buie, C.; Wallace, R.M.; Hinkle, C.L. Defect-Dominated Doping and Contact Resistance in MoS2. ACS Nano 2014, 8, 2880–2888. [Google Scholar] [CrossRef] [PubMed]

- Addou, R.; Colombo, L.; Wallace, R.M. Surface Defects on Natural MoS2. ACS Appl. Mater. Interfaces 2015, 7, 11921–11929. [Google Scholar] [CrossRef] [PubMed]

- Addou, R.; McDonnell, S.; Barrera, D.; Guo, Z.; Azcatl, A.; Wang, J.; Zhu, H.; Hinkle, C.L.; Quevedo-Lopez, M.; Alshareef, H.N.; et al. Impurities and Electronic Property Variations of Natural MoS2 Crystal Surfaces. ACS Nano 2015, 9, 9124–9133. [Google Scholar] [CrossRef] [PubMed]

- Bampoulis, P.; van Bremen, R.; Yao, Q.; Poelsema, B.; Zandvliet, H.J.W.; Sotthewes, K. Defect Dominated Charge Transport and Fermi Level Pinning in MoS2/Metal Contacts. ACS Appl. Mater. Interfaces 2017, 9, 19278–19286. [Google Scholar] [CrossRef] [PubMed]

- KC, S.; Longo, R.C.; Addou, R.; Wallace, R.M.; Cho, K. Impact of intrinsic atomic defects on the electronic structure of MoS2 monolayers. Nanotechnology 2014, 25, 375703. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Wu, Z.; Xu, S.; Chen, X.; Wang, L.; Wang, Y.; Xiong, W.; Han, T.; Ye, W.; Lin, J.; et al. Probing Defect-Induced Midgap States in MoS2 Through Graphene–MoS2 Heterostructures. Adv. Mater. Interfaces 2015, 2, 1500064. [Google Scholar] [CrossRef]

- Lu, C.-P.; Li, G.; Mao, J.; Wang, L.-M.; Andrei, E.Y. Bandgap, Mid-Gap States, and Gating Effects in MoS2. Nano Lett. 2014, 14, 4628–4633. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Liu, W.; Sarkar, D.; Jena, D.; Banerjee, K. Computational Study of Metal Contacts to Monolayer Transition-Metal Dichalcogenide Semiconductors. Phys. Rev. X 2014, 4, 031005. [Google Scholar] [CrossRef]

- Gong, C.; Colombo, L.; Wallace, R.M.; Cho, K. The Unusual Mechanism of Partial Fermi Level Pinning at Metal–MoS2 Interfaces. Nano Lett. 2014, 14, 1714–1720. [Google Scholar] [CrossRef] [PubMed]

- Farmanbar, M.; Brocks, G. First-principles study of van der Waals interactions and lattice mismatch at MoS2/metal interfaces. Phys. Rev. B 2016, 93, 085304. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, D.; Robertson, J. 3D Behavior of Schottky Barriers of 2D Transition-Metal Dichalcogenides. ACS Appl. Mater. Interfaces 2015, 7, 25709–25715. [Google Scholar] [CrossRef] [PubMed]

- Monch, W. On the physics of metal-semiconductor interfaces. Rep. Prog. Phys. 1990, 53, 221. [Google Scholar] [CrossRef]

- Louie, S.G.; Chelikowsky, J.R.; Cohen, M.L. Ionicity and the theory of Schottky barriers. Phys. Rev. B 1977, 15, 2154–2162. [Google Scholar] [CrossRef]

- Tersoff, J. Schottky Barrier Heights and the Continuum of Gap States. Phys. Rev. Lett. 1984, 52, 465–468. [Google Scholar] [CrossRef]

- Kim, C.; Moon, I.; Lee, D.; Choi, M.S.; Ahmed, F.; Nam, S.; Cho, Y.; Shin, H.-J.; Park, S.; Yoo, W.J. Fermi Level Pinning at Electrical Metal Contacts of Monolayer Molybdenum Dichalcogenides. ACS Nano 2017, 11, 1588–1596. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, N.; Grover, S.; Deshmukh, M.M.; Lodha, S. Metal Contacts to MoS2. In 2D Inorganic Materials beyond Graphene; World Scientific (Europe): London, UK, 2016; pp. 317–347. ISBN 978-1-78634-269-0. [Google Scholar]

- Liu, H.; Si, M.; Deng, Y.; Neal, A.T.; Du, Y.; Najmaei, S.; Ajayan, P.M.; Lou, J.; Ye, P.D. Switching Mechanism in Single-Layer Molybdenum Disulfide Transistors: An Insight into Current Flow across Schottky Barriers. ACS Nano 2014, 8, 1031–1038. [Google Scholar] [CrossRef] [PubMed]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices; John Wiley & Sons: Hoboken, NJ, USA, 2006; Online ISBN: 9780470068328. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, F.; Sup Choi, M.; Liu, X.; Jong Yoo, W. Carrier transport at the metal–MoS2 interface. Nanoscale 2015, 7, 9222–9228. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-L.; Tsukagoshi, K.; Orgiu, E.; Samorì, P. Charge transport and mobility engineering in two-dimensional transition metal chalcogenide semiconductors. Chem. Soc. Rev. 2016, 45, 118–151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, J.; Sarkar, D.; Liu, W.; Jena, D.; Banerjee, K. A computational study of metal-contacts to beyond-graphene 2D semiconductor materials. In Proceedings of the 2012 International Electron Devices Meeting, San Francisco, CA, USA, 10–12 December 2012; pp. 17.4.1–17.4.4. [Google Scholar] [CrossRef]

- Deng, J.; Kim, K.; Chuang, C.T.; Wong, H.S.P. The Impact of Device Footprint Scaling on High-Performance CMOS Logic Technology. IEEE Trans. Electron Devices 2007, 54, 1148–1155. [Google Scholar] [CrossRef]

- Wei, L.; Deng, J.; Chang, L.W.; Kim, K.; Chuang, C.T.; Wong, H.S.P. Selective Device Structure Scaling and Parasitics Engineering: A Way to Extend the Technology Roadmap. IEEE Trans. Electron Devices 2009, 56, 312–320. [Google Scholar] [CrossRef]

- English, C.D.; Shine, G.; Dorgan, V.E.; Saraswat, K.C.; Pop, E. Improved Contacts to MoS2 Transistors by Ultra-High Vacuum Metal Deposition. Nano Lett. 2016, 16, 3824–3830. [Google Scholar] [CrossRef] [PubMed]

- Taur, Y.; Ning, T.H. Fundamentals of Modern VLSI Devices; Cambridge University Press: Cambridge, UK, 2013; ISBN 978-1-107-39399-8. [Google Scholar]

- Yuan, H.; Cheng, G.; Yu, S.; Walker, A.R.H.; Richter, C.A.; Pan, M.; Li, Q. Field effects of current crowding in metal-MoS2 contacts. Appl. Phys. Lett. 2016, 108, 103505. [Google Scholar] [CrossRef]

- Guo, Y.; Han, Y.; Li, J.; Xiang, A.; Wei, X.; Gao, S.; Chen, Q. Study on the Resistance Distribution at the Contact between Molybdenum Disulfide and Metals. ACS Nano 2014, 8, 7771–7779. [Google Scholar] [CrossRef] [PubMed]

- Berger, H.H. Models for contacts to planar devices. Solid-State Electron. 1972, 15, 145–158. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, K.; Pan, F.; Zhou, C.; Zhou, F.; Chai, Y. Doping, Contact and Interface Engineering of Two-Dimensional Layered Transition Metal Dichalcogenides Transistors. Adv. Funct. Mater. 2017, 27, 1603484. [Google Scholar] [CrossRef]

- Porte, L.; de Villeneuve, C.H.; Phaner, M. Scanning tunneling microscopy observation of local damages induced on graphite surface by ion implantation. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1991, 9, 1064–1067. [Google Scholar] [CrossRef]

- Yu, Z.; Ong, Z.-Y.; Li, S.; Xu, J.-B.; Zhang, G.; Zhang, Y.-W.; Shi, Y.; Wang, X. Analyzing the Carrier Mobility in Transition-Metal Dichalcogenide MoS2 Field-Effect Transistors. Adv. Funct. Mater. 2017, 27, 1604093. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Kis, A. Mobility engineering and a metal–insulator transition in monolayer MoS2. Nat. Mater. 2013, 12, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Baugher, B.W.H.; Churchill, H.O.H.; Yang, Y.; Jarillo-Herrero, P. Intrinsic Electronic Transport Properties of High-Quality Monolayer and Bilayer MoS2. Nano Lett. 2013, 13, 4212–4216. [Google Scholar] [CrossRef] [PubMed]

- Jena, D.; Li, M.; Ma, N.; Hwang, W.S.; Esseni, D.; Seabaugh, A.; Xing, H.G. Electron transport in 2D crystal semiconductors and their device applications. In Proceedings of the 2014 Silicon Nanoelectronics Workshop (SNW), Honolulu, HI, USA, 8–9 June 2014; pp. 1–2. [Google Scholar] [CrossRef]

- He, G.; Ghosh, K.; Singisetti, U.; Ramamoorthy, H.; Somphonsane, R.; Bohra, G.; Matsunaga, M.; Higuchi, A.; Aoki, N.; Najmaei, S.; et al. Conduction Mechanisms in CVD-Grown Monolayer MoS2 Transistors: From Variable-Range Hopping to Velocity Saturation. Nano Lett. 2015, 15, 5052–5058. [Google Scholar] [CrossRef] [PubMed]

- Khair, K.; Ahmed, S. Dissipative transport in monolayer MoS2: Role of remote coulomb scattering. In Proceedings of the 2015 International Workshop on Computational Electronics (IWCE), West Lafayette, IN, USA, 2 September 2015; pp. 1–2. [Google Scholar] [CrossRef]

- Mori, T.; Ninomiya, N.; Kubo, T.; Uchida, N.; Watanabe, E.; Tsuya, D.; Moriyama, S.; Tanaka, M.; Ando, A. Characterization of Effective Mobility and Its Degradation Mechanism in MoS2 MOSFETs. IEEE Trans. Nanotechnol. 2016, 15, 651–656. [Google Scholar] [CrossRef]

- Ahmed, S.; Yi, J. Two-Dimensional Transition Metal Dichalcogenides and Their Charge Carrier Mobilities in Field-Effect Transistors. Nano-Micro Lett. 2017, 9, 50. [Google Scholar] [CrossRef] [Green Version]

- Mirabelli, G.; Gity, F.; Monaghan, S.; Hurley, P.K.; Duffy, R. Impact of impurities, interface traps and contacts on MoS2 MOSFETs: Modelling and experiments. In Proceedings of the 2017 47th European Solid-State Device Research Conference (ESSDERC), Leuven, Belgium, 11–14 September 2017; pp. 288–291. [Google Scholar] [CrossRef]

- Tung, R.T. The physics and chemistry of the Schottky barrier height. Appl. Phys. Rev. 2014, 1, 011304. [Google Scholar] [CrossRef] [Green Version]

- Nishimura, T.; Kita, K.; Toriumi, A. Evidence for strong Fermi-level pinning due to metal-induced gap states at metal/germanium interface. Appl. Phys. Lett. 2007, 91, 123123. [Google Scholar] [CrossRef]

- Hasegawa, H. Fermi Level Pinning and Schottky Barrier Height Control at Metal-Semiconductor Interfaces of InP and Related Materials. Jpn. J. Appl. Phys. 1999, 38, 1098. [Google Scholar] [CrossRef]

- Liu, W.; Kang, J.; Cao, W.; Sarkar, D.; Khatami, Y.; Jena, D.; Banerjee, K. High-performance few-layer-MoS2 field-effect-transistor with record low contact-resistance. In Proceedings of the 2013 IEEE International Electron Devices Meeting, Washington, DC, USA, 9–11 December 2013; pp. 19.4.1–19.4.4. [Google Scholar] [CrossRef]

- Hong, Y.K.; Yoo, G.; Kwon, J.; Hong, S.; Song, W.G.; Liu, N.; Omkaram, I.; Yoo, B.; Ju, S.; Kim, S.; et al. High performance and transparent multilayer MoS2 transistors: Tuning Schottky barrier characteristics. AIP Adv. 2016, 6, 055026. [Google Scholar] [CrossRef]

- Dai, Z.; Wang, Z.; He, X.; Zhang, X.-X.; Alshareef, H.N. Large-Area Chemical Vapor Deposited MoS2 with Transparent Conducting Oxide Contacts toward Fully Transparent 2D Electronics. Adv. Funct. Mater. 2017, 27, 1703119. [Google Scholar] [CrossRef]

- Liu, Y.; Xiao, H.; Goddard, W.A. Schottky-Barrier-Free Contacts with Two-Dimensional Semiconductors by Surface-Engineered MXenes. J. Am. Chem. Soc. 2016, 138, 15853–15856. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chuang, S.; Battaglia, C.; Azcatl, A.; McDonnell, S.; Kang, J.S.; Yin, X.; Tosun, M.; Kapadia, R.; Fang, H.; Wallace, R.M.; et al. MoS2 P-type Transistors and Diodes Enabled by High Work Function MoOx Contacts. Nano Lett. 2014, 14, 1337–1342. [Google Scholar] [CrossRef] [PubMed]

- McDonnell, S.; Azcatl, A.; Addou, R.; Gong, C.; Battaglia, C.; Chuang, S.; Cho, K.; Javey, A.; Wallace, R.M. Hole Contacts on Transition Metal Dichalcogenides: Interface Chemistry and Band Alignments. ACS Nano 2014, 8, 6265–6272. [Google Scholar] [CrossRef] [PubMed]

- Musso, T.; Kumar, P.V.; Foster, A.S.; Grossman, J.C. Graphene Oxide as a Promising Hole Injection Layer for MoS2-Based Electronic Devices. ACS Nano 2014, 8, 11432–11439. [Google Scholar] [CrossRef] [PubMed]

- Chuang, H.-J.; Chamlagain, B.; Koehler, M.; Perera, M.M.; Yan, J.; Mandrus, D.; Tománek, D.; Zhou, Z. Low-Resistance 2D/2D Ohmic Contacts: A Universal Approach to High-Performance WSe2, MoS2, and MoSe2 Transistors. Nano Lett. 2016, 16, 1896–1902. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Kim, A.R.; Yang, J.H.; Chang, K.E.; Kwon, J.-D.; Choi, S.Y.; Park, J.; Lee, K.E.; Kim, D.-H.; Choi, S.M.; et al. Alloyed 2D Metal–Semiconductor Heterojunctions: Origin of Interface States Reduction and Schottky Barrier Lowering. Nano Lett. 2016, 16, 5928–5933. [Google Scholar] [CrossRef] [PubMed]

- Giannazzo, F.; Fisichella, G.; Piazza, A.; Agnello, S.; Roccaforte, F. Nanoscale inhomogeneity of the Schottky barrier and resistivity in MoS2 multilayers. Phys. Rev. B 2015, 92, 081307. [Google Scholar] [CrossRef]

- Yuan, H.; Cheng, G.; You, L.; Li, H.; Zhu, H.; Li, W.; Kopanski, J.J.; Obeng, Y.S.; Hight Walker, A.R.; Gundlach, D.J.; et al. Influence of Metal–MoS2 Interface on MoS2 Transistor Performance: Comparison of Ag and Ti Contacts. ACS Appl. Mater. Interfaces 2015, 7, 1180–1187. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.-Y.; Amani, M.; Ahn, G.H.; Song, Y.; Javey, A.; Chung, S.; Lee, T. Electrical Properties of Synthesized Large-Area MoS2 Field-Effect Transistors Fabricated with Inkjet-Printed Contacts. ACS Nano 2016, 10, 2819–2826. [Google Scholar] [CrossRef] [PubMed]

- English, C.D.; Shine, G.; Dorgan, V.E.; Saraswat, K.C.; Pop, E. Improving contact resistance in MoS2 field effect transistors. In Proceedings of the 72nd Device Research Conference, Santa Barbara, CA, USA, 2014, 22–25 June 2014; pp. 193–194. [Google Scholar] [CrossRef]

- McDonnell, S.; Smyth, C.; Hinkle, C.L.; Wallace, R.M. MoS2–Titanium Contact Interface Reactions. ACS Appl. Mater. Interfaces 2016, 8, 8289–8294. [Google Scholar] [CrossRef] [PubMed]

- Smyth, C.M.; Addou, R.; McDonnell, S.; Hinkle, C.L.; Wallace, R.M. Contact Metal–MoS2 Interfacial Reactions and Potential Implications on MoS2-Based Device Performance. J. Phys. Chem. C 2016, 120, 14719–14729. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, J.; Matsuhashi, Y.; Iwasa, Y. Ambipolar MoS2 Thin Flake Transistors. Nano Lett. 2012, 12, 1136–1140. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.-W.; Liu, L.; Lan, Q.; Tan, X.; Dhindsa, K.S.; Zeng, P.; Naik, V.M.; Cheng, M.M.-C.; Zhou, Z. Mobility enhancement and highly efficient gating of monolayer MoS2 transistors with polymer electrolyte. J. Phys. Appl. Phys. 2012, 45, 345102. [Google Scholar] [CrossRef]

- Perera, M.M.; Lin, M.-W.; Chuang, H.-J.; Chamlagain, B.P.; Wang, C.; Tan, X.; Cheng, M.M.-C.; Tománek, D.; Zhou, Z. Improved Carrier Mobility in Few-Layer MoS2 Field-Effect Transistors with Ionic-Liquid Gating. ACS Nano 2013, 7, 4449–4458. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Stepanov, P.; Gray, M.; Lau, C.N.; Itkis, M.E.; Haddon, R.C. Ionic Liquid Gating of Suspended MoS2 Field Effect Transistor Devices. Nano Lett. 2015, 15, 5284–5288. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.J.; Ye, J.T.; Yomogida, Y.; Takenobu, T.; Iwasa, Y. Formation of a Stable p–n Junction in a Liquid-Gated MoS2 Ambipolar Transistor. Nano Lett. 2013, 13, 3023–3028. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Kuroda, M.A.; Ahyi, A.C.; Isaacs-Smith, T.; Mirkhani, V.; Park, M.; Dhar, S. Chitosan solid electrolyte as electric double layer in multilayer MoS2 transistor for low-voltage operation. Phys. Status Solidi A 2015, 212, 2219–2225. [Google Scholar] [CrossRef]

- Fathipour, S.; Li, H.M.; Remškar, M.; Yeh, L.; Tsai, W.; Lin, Y.; Fullerton-Shirey, S.; Seabaugh, A. Record high current density and low contact resistance in MoS2 FETs by ion doping. In Proceedings of the 2016 International Symposium on VLSI Technology, Systems and Application (VLSI-TSA), Hsinchu, Taiwan, 25–27 April 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Liang, J.; Xu, K.; Fullerton, S. MoS2 Field-Effect Transistors Gated with a Two-Dimensional Electrolyte. In Meeting Abstracts 2017; The Electrochemical Society: New Orleans, LA, USA, 2017; p. 1362. [Google Scholar]

- Stavitski, N.; van Dal, M.J.H.; Lauwers, A.; Vrancken, C.; Kovalgin, A.Y.; Wolters, R.A.M. Systematic TLM Measurements of NiSi and PtSi Specific Contact Resistance to n- and p-Type Si in a Broad Doping Range. IEEE Electron Device Lett. 2008, 29, 378–381. [Google Scholar] [CrossRef] [Green Version]

- Murakoshi, A.; Iwase, M.; Niiyama, H.; Koike, M.; Suguro, K. Ultralow Contact Resistivity for a Metal/p-Type Silicon Interface by High-Concentration Germanium and Boron Doping Combined with Low-Temperature Annealing. Jpn. J. Appl. Phys. 2013, 52, 075802. [Google Scholar] [CrossRef]

- Yu, H.; Schaekers, M.; Demuynck, S.; Barla, K.; Mocuta, A.; Horiguchi, N.; Collaert, N.; Thean, A.V.Y.; Meyer, K.D. MIS or MS? Source/drain contact scheme evaluation for 7nm Si CMOS technology and beyond. In Proceedings of the 2016 16th International Workshop on Junction Technology (IWJT), Shanghai, China, 9–10 May 2016; pp. 19–24. [Google Scholar] [CrossRef]

- Du, Y.; Liu, H.; Neal, A.T.; Si, M.; Ye, P.D. Molecular Doping of Multilayer Field-Effect Transistors: Reduction in Sheet and Contact Resistances. IEEE Electron Device Lett. 2013, 34, 1328–1330. [Google Scholar] [CrossRef]

- Fang, H.; Tosun, M.; Seol, G.; Chang, T.C.; Takei, K.; Guo, J.; Javey, A. Degenerate n-Doping of Few-Layer Transition Metal Dichalcogenides by Potassium. Nano Lett. 2013, 13, 1991–1995. [Google Scholar] [CrossRef] [PubMed]

- Kiriya, D.; Tosun, M.; Zhao, P.; Kang, J.S.; Javey, A. Air-Stable Surface Charge Transfer Doping of MoS2 by Benzyl Viologen. J. Am. Chem. Soc. 2014, 136, 7853–7856. [Google Scholar] [CrossRef] [PubMed]

- Rai, A.; Valsaraj, A.; Movva, H.C.P.; Roy, A.; Ghosh, R.; Sonde, S.; Kang, S.; Chang, J.; Trivedi, T.; Dey, R.; et al. Air Stable Doping and Intrinsic Mobility Enhancement in Monolayer Molybdenum Disulfide by Amorphous Titanium Suboxide Encapsulation. Nano Lett. 2015, 15, 4329–4336. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rai, A.; Valsaraj, A.; Movva, H.C.P.; Roy, A.; Tutuc, E.; Register, L.F.; Banerjee, S.K. Interfacial-oxygen-vacancy mediated doping of MoS2 by high-κ dielectrics. In Proceedings of the 2015 73rd Annual Device Research Conference (DRC), Columbus, OH, USA, 21–24 June 2015; pp. 189–190. [Google Scholar] [CrossRef]

- Valsaraj, A.; Chang, J.; Rai, A.; Register, L.F.; Banerjee, S.K. Theoretical and experimental investigation of vacancy-based doping of monolayer MoS2 on oxide. 2D Mater. 2015, 2, 045009. [Google Scholar] [CrossRef]

- Alharbi, A.; Shahrjerdi, D. Contact engineering of monolayer CVD MoS2 transistors. In Proceedings of the 2017 75th Annual Device Research Conference (DRC), South Bend, IN, USA, 25–28 June 2017; pp. 1–2. [Google Scholar] [CrossRef]

- McClellan, C.J.; Yalon, E.; Smithe, K.K.H.; Suryavanshi, S.V.; Pop, E. Effective n-type doping of monolayer MoS2 by AlOx. In Proceedings of the 2017 75th Annual Device Research Conference (DRC), South Bend, IN, USA, 25–28 June 2017; pp. 1–2. [Google Scholar] [CrossRef]

- De la Rosa, C.J.L.; Nourbakhsh, A.; Heyne, M.; Asselberghs, I.; Huyghebaert, C.; Radu, I.; Heyns, M.; Gendt, S.D. Highly efficient and stable MoS2 FETs with reversible n-doping using a dehydrated poly(vinyl-alcohol) coating. Nanoscale 2016, 9, 258–265. [Google Scholar] [CrossRef] [PubMed]

- Lim, D.; Kannan, E.S.; Lee, I.; Rathi, S.; Li, L.; Lee, Y.; Khan, M.A.; Kang, M.; Park, J.; Kim, G.-H. High performance MoS2-based field-effect transistor enabled by hydrazine doping. Nanotechnology 2016, 27, 225201. [Google Scholar] [CrossRef] [PubMed]

- Andleeb, S.; Singh, A.K.; Eom, J. Chemical doping of MoS2 multilayer by p-toluene sulfonic acid. Sci. Technol. Adv. Mater. 2015, 16, 035009. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Niu, X.; Qian, H.; Guan, L.; Zhao, M.; Ding, X.; Zhang, S.; Wang, Y.; Sha, J. Surface charge transfer doping of monolayer molybdenum disulfide by black phosphorus quantum dots. Nanotechnology 2016, 27, 505204. [Google Scholar] [CrossRef] [PubMed]

- Lockhart de la Rosa, C.J.; Phillipson, R.; Teyssandier, J.; Adisoejoso, J.; Balaji, Y.; Huyghebaert, C.; Radu, I.; Heyns, M.; De Feyter, S.; De Gendt, S. Molecular doping of MoS2 transistors by self-assembled oleylamine networks. Appl. Phys. Lett. 2016, 109, 253112. [Google Scholar] [CrossRef]

- Liu, X.; Qu, D.; Ryu, J.; Ahmed, F.; Yang, Z.; Lee, D.; Yoo, W.J. P-Type Polar Transition of Chemically Doped Multilayer MoS2 Transistor. Adv. Mater. 2016, 28, 2345–2351. [Google Scholar] [CrossRef] [PubMed]

- Tarasov, A.; Zhang, S.; Tsai, M.-Y.; Campbell, P.M.; Graham, S.; Barlow, S.; Marder, S.R.; Vogel, E.M. Controlled Doping of Large-Area Trilayer MoS2 with Molecular Reductants and Oxidants. Adv. Mater. 2015, 27, 1175–1181. [Google Scholar] [CrossRef] [PubMed]

- Sim, D.M.; Kim, M.; Yim, S.; Choi, M.-J.; Choi, J.; Yoo, S.; Jung, Y.S. Controlled Doping of Vacancy-Containing Few-Layer MoS2 via Highly Stable Thiol-Based Molecular Chemisorption. ACS Nano 2015, 9, 12115–12123. [Google Scholar] [CrossRef] [PubMed]

- Min, S.-W.; Yoon, M.; Yang, S.J.; Ko, K.R.; Im, S. Charge Transfer-Induced P-type Channel in MoS2 Flake Field Effect Transistor. ACS Appl. Mater. Interfaces 2018. [Google Scholar] [CrossRef] [PubMed]

- Connelly, D.; Faulkner, C.; Clifton, P.A.; Grupp, D.E. Fermi-level depinning for low-barrier Schottky source/drain transistors. Appl. Phys. Lett. 2006, 88, 012105. [Google Scholar] [CrossRef]

- Kobayashi, M.; Kinoshita, A.; Saraswat, K.; Wong, H.-S.P.; Nishi, Y. Fermi level depinning in metal/Ge Schottky junction for metal source/drain Ge metal-oxide-semiconductor field-effect-transistor application. J. Appl. Phys. 2009, 105, 023702. [Google Scholar] [CrossRef]

- Paramahans Manik, P.; Kesh Mishra, R.; Pavan Kishore, V.; Ray, P.; Nainani, A.; Huang, Y.-C.; Abraham, M.C.; Ganguly, U.; Lodha, S. Fermi-level unpinning and low resistivity in contacts to n-type Ge with a thin ZnO interfacial layer. Appl. Phys. Lett. 2012, 101, 182105. [Google Scholar] [CrossRef]

- Agrawal, A.; Shukla, N.; Ahmed, K.; Datta, S. A unified model for insulator selection to form ultra-low resistivity metal-insulator-semiconductor contacts to n-Si, n-Ge, and n-InGaAs. Appl. Phys. Lett. 2012, 101, 042108. [Google Scholar] [CrossRef]

- Gupta, S.; Paramahans Manik, P.; Kesh Mishra, R.; Nainani, A.; Abraham, M.C.; Lodha, S. Contact resistivity reduction through interfacial layer doping in metal-interfacial layer-semiconductor contacts. J. Appl. Phys. 2013, 113, 234505. [Google Scholar] [CrossRef]

- Lee, D.; Raghunathan, S.; Wilson, R.J.; Nikonov, D.E.; Saraswat, K.; Wang, S.X. The influence of Fermi level pinning/depinning on the Schottky barrier height and contact resistance in Ge/CoFeB and Ge/MgO/CoFeB structures. Appl. Phys. Lett. 2010, 96, 052514. [Google Scholar] [CrossRef]

- Roy, A.M.; Lin, J.Y.J.; Saraswat, K.C. Specific Contact Resistivity of Tunnel Barrier Contacts Used for Fermi Level Depinning. IEEE Electron Device Lett. 2010, 31, 1077–1079. [Google Scholar] [CrossRef]

- Chen, J.-R.; Odenthal, P.M.; Swartz, A.G.; Floyd, G.C.; Wen, H.; Luo, K.Y.; Kawakami, R.K. Control of Schottky Barriers in Single Layer MoS2 Transistors with Ferromagnetic Contacts. Nano Lett. 2013, 13, 3106–3110. [Google Scholar] [CrossRef] [PubMed]

- Park, W.; Kim, Y.; Lee, S.K.; Jung, U.; Yang, J.H.; Cho, C.; Kim, Y.J.; Lim, S.K.; Hwang, I.S.; Lee, H.B.R.; et al. Contact resistance reduction using Fermi level de-pinning layer for MoS2 FETs. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 5.1.1–5.1.4. [Google Scholar] [CrossRef]

- Kaushik, N.; Nipane, A.; Karande, S.; Lodha, S. Contact resistance reduction in MoS2 FETs using ultra-thin TiO2 interfacial layers. In Proceedings of the 2015 73rd Annual Device Research Conference (DRC), Columbus, OH, USA, 21–24 June 2015; pp. 211–212. [Google Scholar] [CrossRef]

- Kaushik, N.; Karmakar, D.; Nipane, A.; Karande, S.; Lodha, S. Interfacial n-Doping Using an Ultrathin TiO2 Layer for Contact Resistance Reduction in MoS2. ACS Appl. Mater. Interfaces 2016, 8, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Tang, A.; Aloni, S.; Philip Wong, H.-S. Statistical Study on the Schottky Barrier Reduction of Tunneling Contacts to CVD Synthesized MoS2. Nano Lett. 2016, 16, 276–281. [Google Scholar] [CrossRef] [PubMed]

- Farmanbar, M.; Brocks, G. Controlling the Schottky barrier at MoS2/metal contacts by inserting a BN monolayer. Phys. Rev. B 2015, 91, 161304. [Google Scholar] [CrossRef]

- Su, J.; Feng, L.; Zeng, W.; Liu, Z. Designing high performance metal–mMoS2 interfaces by two-dimensional insertions with suitable thickness. Phys. Chem. Chem. Phys. 2016, 18, 31092–31100. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yao, Q.; Huang, C.-W.; Zou, X.; Liao, L.; Chen, S.; Fan, Z.; Zhang, K.; Wu, W.; Xiao, X.; et al. High Mobility MoS2 Transistor with Low Schottky Barrier Contact by Using Atomic Thick h-BN as a Tunneling Layer. Adv. Mater. 2016, 28, 8302–8308. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Shih, E.-M.; Jauregui, L.A.; Chae, S.H.; Kim, Y.D.; Li, B.; Seo, D.; Pistunova, K.; Yin, J.; Park, J.-H.; et al. Low-Temperature Ohmic Contact to Monolayer MoS2 by van der Waals Bonded Co/h-BN Electrodes. Nano Lett. 2017, 17, 4781–4786. [Google Scholar] [CrossRef] [PubMed]

- Chai, J.W.; Yang, M.; Callsen, M.; Zhou, J.; Yang, T.; Zhang, Z.; Pan, J.S.; Chi, D.Z.; Feng, Y.P.; Wang, S.J. Tuning Contact Barrier Height between Metals and MoS2 Monolayer through Interface Engineering. Adv. Mater. Interfaces 2017, 4, 1700035. [Google Scholar] [CrossRef]

- Farmanbar, M.; Brocks, G. Ohmic Contacts to 2D Semiconductors through van der Waals Bonding. Adv. Electron. Mater. 2016, 2, 1500405. [Google Scholar] [CrossRef] [Green Version]

- Musso, T.; Kumar, P.V.; Grossman, J.C.; Foster, A.S. Engineering Efficient p-Type TMD/Metal Contacts Using Fluorographene as a Buffer Layer. Adv. Electron. Mater. 2017, 3, 1600318. [Google Scholar] [CrossRef]

- Su, J.; Feng, L.; Zheng, X.; Hu, C.; Lu, H.; Liu, Z. Promising Approach for High-Performance MoS2 Nanodevice: Doping the BN Buffer Layer to Eliminate the Schottky Barriers. ACS Appl. Mater. Interfaces 2017, 9, 40940–40948. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.; Lahiri, I.; Seelaboyina, R.; Kang, Y.S. Synthesis of Graphene and Its Applications: A Review. Crit. Rev. Solid State Mater. Sci. 2010, 35, 52–71. [Google Scholar] [CrossRef]

- Castro Neto, A.H.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef] [Green Version]

- Partoens, B.; Peeters, F.M. From graphene to graphite: Electronic structure around the K point. Phys. Rev. B 2006, 74, 075404. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef] [Green Version]

- Lemme, M.C.; Echtermeyer, T.J.; Baus, M.; Kurz, H. A Graphene Field-Effect Device. IEEE Electron Device Lett. 2007, 28, 282–284. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.-J.; Zhao, Y.; Ryu, S.; Brus, L.E.; Kim, K.S.; Kim, P. Tuning the Graphene Work Function by Electric Field Effect. Nano Lett. 2009, 9, 3430–3434. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, Y.; Yang, L.; Zhang, J.; Liu, H.; Majumdar, K.; Kirsch, P.D.; Ye, P.D. Physical understanding of graphene/metal hetero-contacts to enhance MoS2 field-effect transistors performance. In Proceedings of the 72nd Device Research Conference, Santa Barbara, CA, USA, 22–25 June 2014; pp. 147–148. [Google Scholar] [CrossRef]

- Du, Y.; Yang, L.; Zhang, J.; Liu, H.; Majumdar, K.; Kirsch, P.D.; Ye, P.D. MoS2 Field-Effect Transistors with Graphene/Metal Heterocontacts. IEEE Electron Device Lett. 2014, 35, 599–601. [Google Scholar] [CrossRef]

- Leong, W.S.; Luo, X.; Li, Y.; Khoo, K.H.; Quek, S.Y.; Thong, J.T.L. Low Resistance Metal Contacts to MoS2 Devices with Nickel-Etched-Graphene Electrodes. ACS Nano 2015, 9, 869–877. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wu, H.; Cheng, H.-C.; Yang, S.; Zhu, E.; He, Q.; Ding, M.; Li, D.; Guo, J.; Weiss, N.O.; et al. Toward Barrier Free Contact to Molybdenum Disulfide Using Graphene Electrodes. Nano Lett. 2015, 15, 3030–3034. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Hwang, C.; Eom, J. Low-Voltage and High-Performance Multilayer MoS2 Field-Effect Transistors with Graphene Electrodes. ACS Appl. Mater. Interfaces 2016, 8, 34699–34705. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Lee, G.-H.; Kim, Y.D.; Arefe, G.; Huang, P.Y.; Lee, C.-H.; Chenet, D.A.; Zhang, X.; Wang, L.; Ye, F.; et al. Multi-terminal transport measurements of MoS2 using a van der Waals heterostructure device platform. Nat. Nanotechnol. 2015, 10, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.-H.; Cui, X.; Kim, Y.D.; Arefe, G.; Zhang, X.; Lee, C.-H.; Ye, F.; Watanabe, K.; Taniguchi, T.; Kim, P.; et al. Highly Stable, Dual-Gated MoS2 Transistors Encapsulated by Hexagonal Boron Nitride with Gate-Controllable Contact, Resistance, and Threshold Voltage. ACS Nano 2015, 9, 7019–7026. [Google Scholar] [CrossRef] [PubMed]

- Guimarães, M.H.D.; Gao, H.; Han, Y.; Kang, K.; Xie, S.; Kim, C.-J.; Muller, D.A.; Ralph, D.C.; Park, J. Atomically Thin Ohmic Edge Contacts Between Two-Dimensional Materials. ACS Nano 2016, 10, 6392–6399. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, S.-L.; Komatsu, K.; Nakaharai, S.; Lin, Y.-F.; Yamamoto, M.; Duan, X.; Tsukagoshi, K. Thickness Scaling Effect on Interfacial Barrier and Electrical Contact to Two-Dimensional MoS2 Layers. ACS Nano 2014, 8, 12836–12842. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.; Lee, J.-Y.; Yu, Y.-J.; Lee, C.-H.; Cui, X.; Hone, J.; Lee, G.-H. Thickness-dependent Schottky barrier height of MoS2 field-effect transistors. Nanoscale 2017, 9, 6151–6157. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Appenzeller, J. Screening and interlayer coupling in multilayer MoS2. Phys. Status Solidi RRL Rapid Res. Lett. 2013, 7, 268–273. [Google Scholar] [CrossRef]

- Das, S.; Appenzeller, J. Where Does the Current Flow in Two-Dimensional Layered Systems? Nano Lett. 2013, 13, 3396–3402. [Google Scholar] [CrossRef] [PubMed]

- Na, J.; Shin, M.; Joo, M.-K.; Huh, J.; Jeong Kim, Y.; Jong Choi, H.; Hyung Shim, J.; Kim, G.-T. Separation of interlayer resistance in multilayer MoS2 field-effect transistors. Appl. Phys. Lett. 2014, 104, 233502. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Ganapathi, K.L.; Nath, D.N.; Bhat, N. Intrinsic Limit for Contact Resistance in Exfoliated Multilayered MoS2 FET. IEEE Electron Device Lett. 2016, 37, 119–122. [Google Scholar] [CrossRef]

- Schmidt, H.; Giustiniano, F.; Eda, G. Electronic transport properties of transition metal dichalcogenide field-effect devices: Surface and interface effects. Chem. Soc. Rev. 2015, 44, 7715–7736. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-L.; Wakabayashi, K.; Xu, Y.; Nakaharai, S.; Komatsu, K.; Li, W.-W.; Lin, Y.-F.; Aparecido-Ferreira, A.; Tsukagoshi, K. Thickness-Dependent Interfacial Coulomb Scattering in Atomically Thin Field-Effect Transistors. Nano Lett. 2013, 13, 3546–3552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, M.-W.; Kravchenko, I.I.; Fowlkes, J.; Li, X.; Puretzky, A.A.; Rouleau, C.M.; Geohegan, D.B.; Xiao, K. Thickness-dependent charge transport in few-layer MoS2 field-effect transistors. Nanotechnology 2016, 27, 165203. [Google Scholar] [CrossRef] [PubMed]

- Lockhart de la Rosa, C.J.; Arutchelvan, G.; Leonhardt, A.; Huyghebaert, C.; Radu, I.; Heyns, M.; De Gendt, S. Relation between film thickness and surface doping of MoS2 based field effect transistors. APL Mater. 2018, 6, 058301. [Google Scholar] [CrossRef]

- Yun, W.S.; Han, S.W.; Hong, S.C.; Kim, I.G.; Lee, J.D. Thickness and strain effects on electronic structures of transition metal dichalcogenides: 2H-MX2 semiconductors (M = Mo, W; X = S, Se, Te). Phys. Rev. B 2012, 85, 033305. [Google Scholar] [CrossRef]

- Wang, L.; Meric, I.; Huang, P.Y.; Gao, Q.; Gao, Y.; Tran, H.; Taniguchi, T.; Watanabe, K.; Campos, L.M.; Muller, D.A.; et al. One-Dimensional Electrical Contact to a Two-Dimensional Material. Science 2013, 342, 614–617. [Google Scholar] [CrossRef] [PubMed]

- Min Song, S.; Yong Kim, T.; Jae Sul, O.; Cheol Shin, W.; Jin Cho, B. Improvement of graphene–metal contact resistance by introducing edge contacts at graphene under metal. Appl. Phys. Lett. 2014, 104, 183506. [Google Scholar] [CrossRef]

- Park, H.-Y.; Jung, W.-S.; Kang, D.-H.; Jeon, J.; Yoo, G.; Park, Y.; Lee, J.; Jang, Y.H.; Lee, J.; Park, S.; et al. Extremely Low Contact Resistance on Graphene through n-Type Doping and Edge Contact Design. Adv. Mater. 2016, 28, 864–870. [Google Scholar] [CrossRef] [PubMed]

- Khatami, Y.; Li, H.; Xu, C.; Banerjee, K. Metal-to-Multilayer-Graphene Contact—Part I: Contact Resistance Modeling. IEEE Trans. Electron Devices 2012, 59, 2444–2452. [Google Scholar] [CrossRef]

- Khatami, Y.; Li, H.; Xu, C.; Banerjee, K. Metal-to-Multilayer-Graphene Contact—Part II: Analysis of Contact Resistance. IEEE Trans. Electron Devices 2012, 59, 2453–2460. [Google Scholar] [CrossRef]

- Yoo, G.; Lee, S.; Yoo, B.; Han, C.; Kim, S.; Oh, M.S. Electrical Contact Analysis of Multilayer MoS2 Transistor with Molybdenum Source/Drain Electrodes. IEEE Electron Device Lett. 2015, 36, 1215–1218. [Google Scholar] [CrossRef]

- Chai, Y.; Ionescu, R.; Su, S.; Lake, R.; Ozkan, M.; Ozkan, C.S. Making one-dimensional electrical contacts to molybdenum disulfide-based heterostructures through plasma etching. Phys. Status Solidi A 2016, 213, 1358–1364. [Google Scholar] [CrossRef]

- Zheng, J.; Yan, X.; Lu, Z.; Qiu, H.; Xu, G.; Zhou, X.; Wang, P.; Pan, X.; Liu, K.; Jiao, L. High-Mobility Multilayered MoS2 Flakes with Low Contact Resistance Grown by Chemical Vapor Deposition. Adv. Mater. 2017, 29, 1604540. [Google Scholar] [CrossRef] [PubMed]

- Movva, H.C.P.; Rai, A.; Kang, S.; Kim, K.; Fallahazad, B.; Taniguchi, T.; Watanabe, K.; Tutuc, E.; Banerjee, S.K. High-Mobility Holes in Dual-Gated WSe2 Field-Effect Transistors. ACS Nano 2015, 9, 10402–10410. [Google Scholar] [CrossRef] [PubMed]

- Popov, I.; Seifert, G.; Tománek, D. Designing Electrical Contacts to MoS2 Monolayers: A Computational Study. Phys. Rev. Lett. 2012, 108, 156802. [Google Scholar] [CrossRef] [PubMed]

- Stokbro, K.; Engelund, M.; Blom, A. Atomic-scale model for the contact resistance of the nickel-graphene interface. Phys. Rev. B 2012, 85, 165442. [Google Scholar] [CrossRef]

- Kang, J.; Liu, W.; Banerjee, K. High-performance MoS2 transistors with low-resistance molybdenum contacts. Appl. Phys. Lett. 2014, 104, 093106. [Google Scholar] [CrossRef]

- Song, X.; Zan, W.; Xu, H.; Ding, S.; Zhou, P.; Bao, W.; Zhang, D.W. A novel synthesis method for large-area MoS2 film with improved electrical contact. 2D Mater. 2017, 4, 025051. [Google Scholar] [CrossRef]

- Abraham, M.; Mohney, S.E. Annealed Ag contacts to MoS2 field-effect transistors. J. Appl. Phys. 2017, 122, 115306. [Google Scholar] [CrossRef]

- Kappera, R.; Voiry, D.; Yalcin, S.E.; Branch, B.; Gupta, G.; Mohite, A.D.; Chhowalla, M. Phase-engineered low-resistance contacts for ultrathin MoS2 transistors. Nat. Mater. 2014, 13, 1128–1134. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-C.; Dumcenco, D.O.; Huang, Y.-S.; Suenaga, K. Atomic mechanism of the semiconducting-to-metallic phase transition in single-layered MoS2. Nat. Nanotechnol. 2014, 9, 391–396. [Google Scholar] [CrossRef] [PubMed]

- Kappera, R.; Voiry, D.; Yalcin, S.E.; Jen, W.; Acerce, M.; Torrel, S.; Branch, B.; Lei, S.; Chen, W.; Najmaei, S.; et al. Metallic 1T phase source/drain electrodes for field effect transistors from chemical vapor deposited MoS2. APL Mater. 2014, 2, 092516. [Google Scholar] [CrossRef]

- Ma, N.; Jena, D. Charge Scattering and Mobility in Atomically Thin Semiconductors. Phys. Rev. X 2014, 4, 011043. [Google Scholar] [CrossRef]

- Ghatak, S.; Pal, A.N.; Ghosh, A. Nature of Electronic States in Atomically Thin MoS2 Field-Effect Transistors. ACS Nano 2011, 5, 7707–7712. [Google Scholar] [CrossRef] [PubMed]

- Komsa, H.-P.; Kurasch, S.; Lehtinen, O.; Kaiser, U.; Krasheninnikov, A.V. From point to extended defects in two-dimensional MoS2: Evolution of atomic structure under electron irradiation. Phys. Rev. B 2013, 88, 035301. [Google Scholar] [CrossRef]

- Qiu, H.; Xu, T.; Wang, Z.; Ren, W.; Nan, H.; Ni, Z.; Chen, Q.; Yuan, S.; Miao, F.; Song, F.; et al. Hopping transport through defect-induced localized states in molybdenum disulphide. Nat. Commun. 2013, 4, 2642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghatak, S.; Mukherjee, S.; Jain, M.; Sarma, D.D.; Ghosh, A. Microscopic Origin of Charged Impurity Scattering and Flicker Noise in MoS2 field-effect Transistors. arXiv, 2014; arXiv:1403.3333. [Google Scholar]

- Liu, D.; Guo, Y.; Fang, L.; Robertson, J. Sulfur vacancies in monolayer MoS2 and its electrical contacts. Appl. Phys. Lett. 2013, 103, 183113. [Google Scholar] [CrossRef]

- Yu, Z.; Pan, Y.; Shen, Y.; Wang, Z.; Ong, Z.-Y.; Xu, T.; Xin, R.; Pan, L.; Wang, B.; Sun, L.; et al. Towards intrinsic charge transport in monolayer molybdenum disulfide by defect and interface engineering. Nat. Commun. 2014, 5, 5290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amani, M.; Lien, D.-H.; Kiriya, D.; Xiao, J.; Azcatl, A.; Noh, J.; Madhvapathy, S.R.; Addou, R.; Kc, S.; Dubey, M.; et al. Near-unity photoluminescence quantum yield in MoS2. Science 2015, 350, 1065–1068. [Google Scholar] [CrossRef] [PubMed]

- Najmaei, S.; Zou, X.; Er, D.; Li, J.; Jin, Z.; Gao, W.; Zhang, Q.; Park, S.; Ge, L.; Lei, S.; et al. Tailoring the Physical Properties of Molybdenum Disulfide Monolayers by Control of Interfacial Chemistry. Nano Lett. 2014, 14, 1354–1361. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giannazzo, F.; Fisichella, G.; Piazza, A.; Franco, S.D.; Greco, G.; Agnello, S.; Roccaforte, F. Effect of temperature–bias annealing on the hysteresis and subthreshold behavior of multilayer MoS2 transistors. Phys. Status Solidi RRL Rapid Res. Lett. 2016, 11, 797–801. [Google Scholar] [CrossRef]

- Bolshakov, P.; Zhao, P.; Azcatl, A.; Hurley, P.K.; Wallace, R.M.; Young, C.D. Electrical characterization of top-gated molybdenum disulfide field-effect-transistors with high-κ dielectrics. Microelectron. Eng. 2017, 178, 190–193. [Google Scholar] [CrossRef]

- Bolshakov, P.; Zhao, P.; Azcatl, A.; Hurley, P.K.; Wallace, R.M.; Young, C.D. Improvement in top-gate MoS2 transistor performance due to high quality backside Al2O3 layer. Appl. Phys. Lett. 2017, 111, 032110. [Google Scholar] [CrossRef]

- Young, C.D.; Zhao, P.; Bolshakov-Barrett, P.; Azcatl, A.; Hurley, P.K.; Gomeniuk, Y.Y.; Schmidt, M.; Hinkle, C.L.; Wallace, R.M. Evaluation of Few-Layer MoS2 Transistors with a Top Gate and HfO2 Dielectric. ECS Trans. 2016, 75, 153–162. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Ganapathi, K.L.; Nath, D.N.; Bhat, N. Surface State Engineering of Metal/MoS2 Contacts Using Sulfur Treatment for Reduced Contact Resistance and Variability. IEEE Trans. Electron Devices 2016, 63, 2556–2562. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Ganapathi, K.L.; Mohan, S.; Bhat, N. (Invited) Interface Engineering of High-κ Dielectrics and Metal Contacts for High Performance Top-Gated MoS2 FETs. ECS Trans. 2017, 80, 101–107. [Google Scholar] [CrossRef]

- Nan, H.; Wu, Z.; Jiang, J.; Zafar, A.; You, Y.; Ni, Z. Improving the electrical performance of MoS2 by mild oxygen plasma treatment. J. Phys. Appl. Phys. 2017, 50, 154001. [Google Scholar] [CrossRef]

- Guo, J.; Yang, B.; Zheng, Z.; Jiang, J. Observation of abnormal mobility enhancement in multilayer MoS2 transistor by synergy of ultraviolet illumination and ozone plasma treatment. Phys. E Low-Dimens. Syst. Nanostructures 2017, 87, 150–154. [Google Scholar] [CrossRef]

- Leonhardt, A.; Chiappe, D.; Asselberghs, I.; Huyghebaert, C.; Radu, I.; Gendt, S.D. Improving MOCVD MoS2 Electrical Performance: Impact of Minimized Water and Air Exposure Conditions. IEEE Electron Device Lett. 2017, 38, 1606–1609. [Google Scholar] [CrossRef]

- Cheng, Z.; Cardenas, J.A.; McGuire, F.; Franklin, A.D. Using Ar Ion beam exposure to improve contact resistance in MoS2 FETs. In Proceedings of the 2016 74th Annual Device Research Conference (DRC), Newark, DE, USA, 19–22 June 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Ho, Y.T.; Chu, Y.C.; Jong, C.A.; Chen, H.Y.; Lin, M.W.; Zhang, M.; Chien, P.Y.; Tu, Y.Y.; Woo, J.; Chang, E.Y. Contact resistance reduction on layered MoS2 by Ar plasma pre-treatment. In Proceedings of the 2016 IEEE Silicon Nanoelectronics Workshop (SNW), Honolulu, HI, USA, 12–13 June 2016; pp. 52–53. [Google Scholar] [CrossRef]

- Liu, H. Recent Progress in Atomic Layer Deposition of Multifunctional Oxides and Two-Dimensional Transition Metal Dichalcogenides. J. Mol. Eng. Mater. 2016, 4, 1640010. [Google Scholar] [CrossRef]

- Brent, J.R.; Savjani, N.; O’Brien, P. Synthetic approaches to two-dimensional transition metal dichalcogenide nanosheets. Prog. Mater. Sci. 2017, 89, 411–478. [Google Scholar] [CrossRef]

- Zhou, W.; Zou, X.; Najmaei, S.; Liu, Z.; Shi, Y.; Kong, J.; Lou, J.; Ajayan, P.M.; Yakobson, B.I.; Idrobo, J.-C. Intrinsic Structural Defects in Monolayer Molybdenum Disulfide. Nano Lett. 2013, 13, 2615–2622. [Google Scholar] [CrossRef] [PubMed]

- Najmaei, S.; Yuan, J.; Zhang, J.; Ajayan, P.; Lou, J. Synthesis and Defect Investigation of Two-Dimensional Molybdenum Disulfide Atomic Layers. Acc. Chem. Res. 2015, 48, 31–40. [Google Scholar] [CrossRef] [PubMed]

- Roy, A.; Ghosh, R.; Rai, A.; Sanne, A.; Kim, K.; Movva, H.C.P.; Dey, R.; Pramanik, T.; Chowdhury, S.; Tutuc, E.; et al. Intra-domain periodic defects in monolayer MoS2. Appl. Phys. Lett. 2017, 110, 201905. [Google Scholar] [CrossRef]

- Young, C.D.; Bolshakov, P.; Zhao, P.; Smyth, C.; Khosravi, A.; Hurley, P.K.; Hinkle, C.L.; Wallace, R.M. (Invited) Investigation of Critical Interfaces in Few-Layer MoS2 Field Effect Transistors with High-κ Dielectrics. ECS Trans. 2017, 80, 219–225. [Google Scholar] [CrossRef]

- Ye, M.; Zhang, D.; Yap, Y.K. Recent Advances in Electronic and Optoelectronic Devices Based on Two-Dimensional Transition Metal Dichalcogenides. Electronics 2017, 6, 43. [Google Scholar] [CrossRef]

- Price, K.M.; Franklin, A.D. Integration of 3.4 nm HfO2 into the gate stack of MoS2 and WSe2 top-gate field-effect transistors. In Proceedings of the 2017 75th Annual Device Research Conference (DRC), South Bend, IN, USA, 25–28 June 2017; pp. 1–2. [Google Scholar] [CrossRef]

- Casademont, H.; Fillaud, L.; Lefèvre, X.; Jousselme, B.; Derycke, V. Electrografted Fluorinated Organic Ultrathin Film as Efficient Gate Dielectric in MoS2 Transistors. J. Phys. Chem. C 2016, 120, 9506–9510. [Google Scholar] [CrossRef]

- Zhao, P.; Azcatl, A.; Bolshakov, P.; Moon, J.; Hinkle, C.L.; Hurley, P.K.; Wallace, R.M.; Young, C.D. Effects of annealing on top-gated MoS2 transistors with HfO2 dielectric. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2017, 35, 01A118. [Google Scholar] [CrossRef]

- Yang, W.; Sun, Q.-Q.; Geng, Y.; Chen, L.; Zhou, P.; Ding, S.-J.; Zhang, D.W. The Integration of Sub-10 nm Gate Oxide on MoS2 with Ultra Low Leakage and Enhanced Mobility. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, S.; Zou, X.; Ho, J.; Liao, L.; Xiao, X.; Jiang, C.; Hu, W.; Wang, J.; Li, J. Integration of High-κ Oxide on MoS2 by Using Ozone Pretreatment for High-Performance MoS2 Top-Gated Transistor with Thickness-Dependent Carrier Scattering Investigation. Small 2015, 11, 5932–5938. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Wang, J.; Chiu, C.-H.; Wu, Y.; Xiao, X.; Jiang, C.; Wu, W.-W.; Mai, L.; Chen, T.; Li, J.; et al. Interface Engineering for High-Performance Top-Gated MoS2 Field-Effect Transistors. Adv. Mater. 2014, 26, 6255–6261. [Google Scholar] [CrossRef] [PubMed]

- Qian, Q.; Zhang, Z.; Hua, M.; Tang, G.; Lei, J.; Lan, F.; Xu, Y.; Yan, R.; Chen, K.J. Enhanced dielectric deposition on single-layer MoS2 with low damage using remote N2 plasma treatment. Nanotechnology 2017, 28, 175202. [Google Scholar] [CrossRef] [PubMed]