Phase and Residual Stress Evaluation of Dual-Phase Al70Cr30N and Al80Cr20N PVD Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Deposition

2.2. Coating Analysis

2.3. X-ray Diffraction

2.3.1. Phase Characterizations

2.3.2. Residual Stress Analysis

3. Results and Discussions

3.1. Mechanical Coating Properties

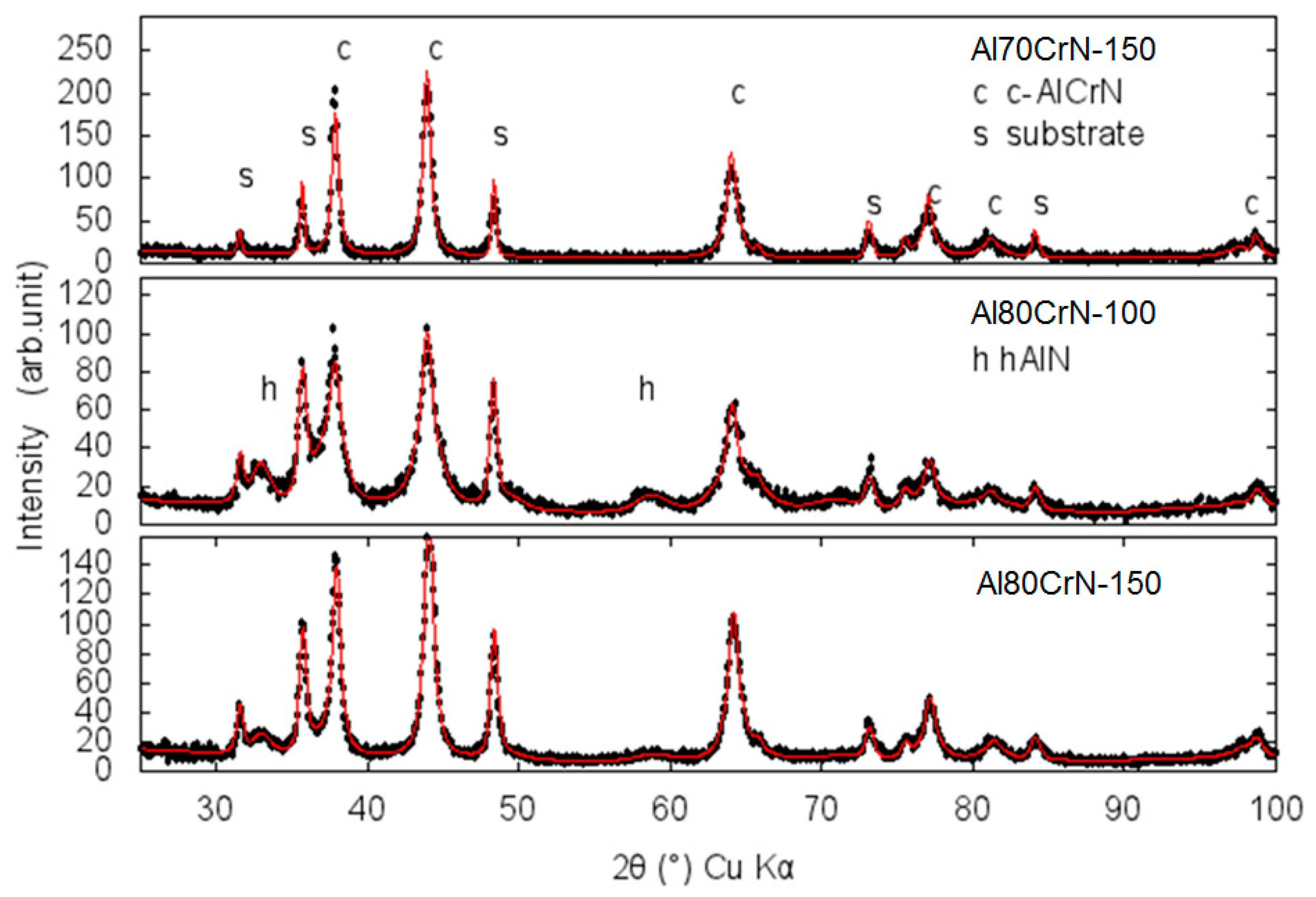

3.2. Phase Analysis

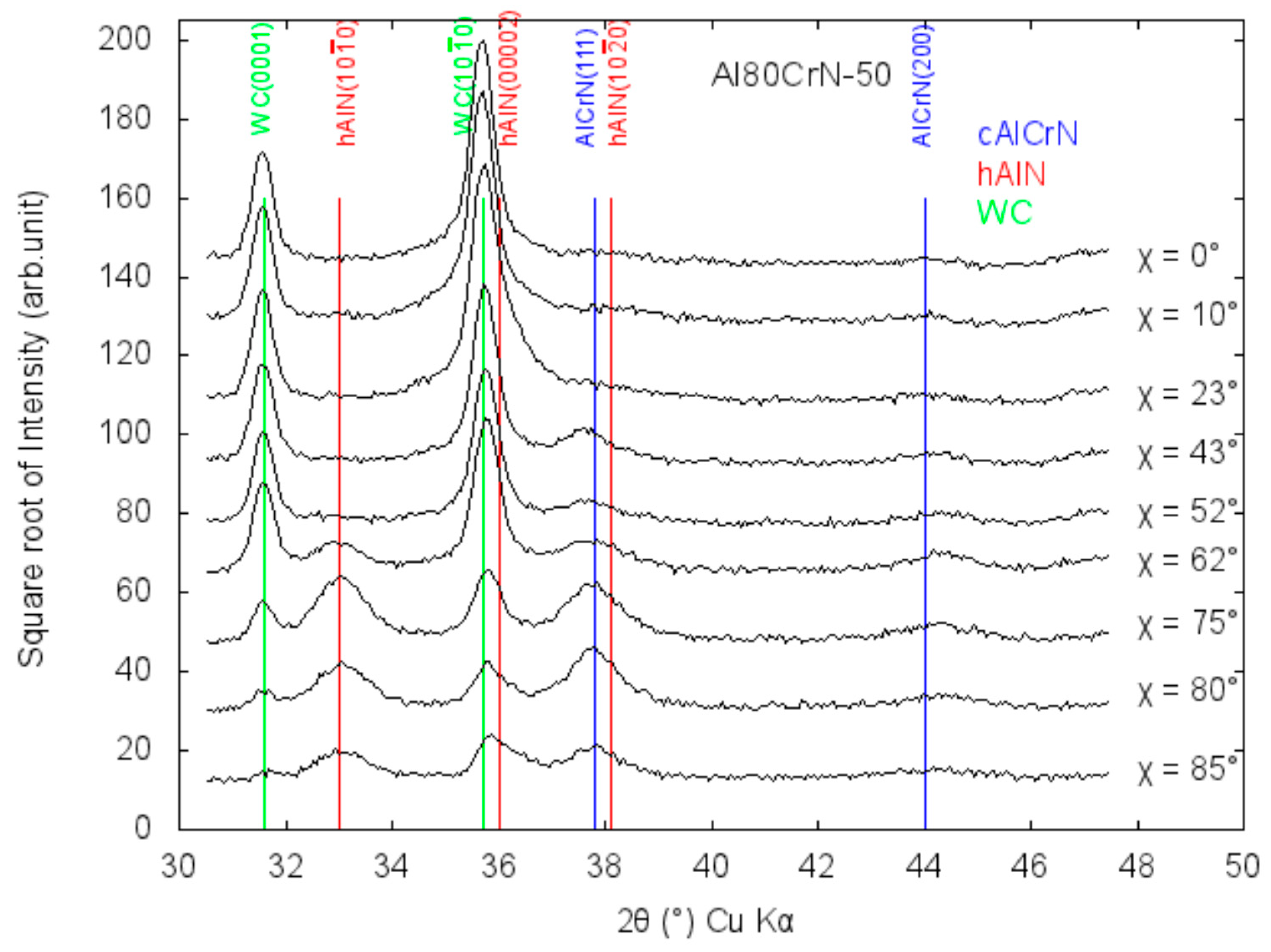

3.3. Residual Stress Analysis

3.4. Hexagonal AlN Phase

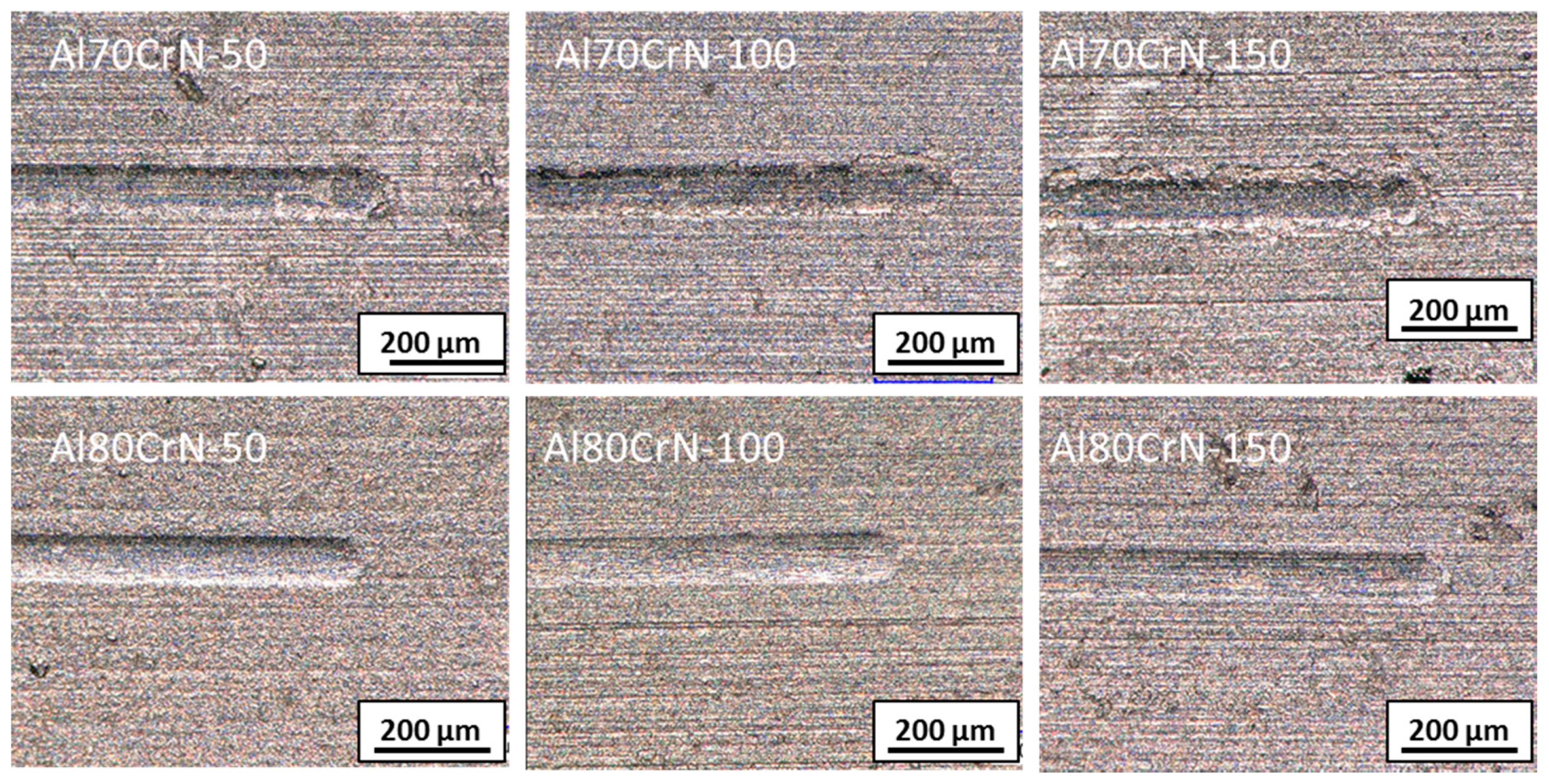

3.5. Wear Testing

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Endrino, J.L.; Fox–Rabinovich, G.S.; Gey, C. Hard AlTiN, AlCrN PVD coatings for machining of austenitic stainless steel. Surf. Coat. Technol. 2006, 200(24), 6840–6845. [Google Scholar] [CrossRef]

- Arndt, M.; Kacsich, T. Performance of new AlTiN coatings in dry and high speed cutting. Surf. Coat. Technol. 2003, 163–164, 674–680. [Google Scholar] [CrossRef]

- Liew, W.Y.H. Low-speed milling of stainless steel with TiAlN single-layer and TiAlN/AlCrN nano–multilayer coated carbide tools under different lubrication conditions. Wear 2010, 269, 617–631. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Sol. Films 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Makino, Y. Prediction of phase change in pseudobinary transition metal aluminum nitrides by band parameters method. Surf. Coat. Technol. 2005, 193, 185–191. [Google Scholar] [CrossRef]

- Makino, Y.; Nogi, K. Synthesis of pseudobinary Cr–Al–N films with B1 structure by rf–assisted magnetron sputtering method. Surf. Coat. Technol. 1998, 98, 1008–1012. [Google Scholar] [CrossRef]

- Reiter, A.E.; Derflinger, V.H.; Hanselmann, B.; Bachmann, T. Investigation of the properties of Al1−xCrxN coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2005, 200, 2114–2122. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Willmann, H.; Reiter, A.E. Structure and phase evolution of Cr–Al–N coatings during annealing. Surf. Coat. Technol. 2008, 202, 4935–4938. [Google Scholar] [CrossRef]

- Lomello, F.; Sanchette, F.; Schuster, F.; Tabarant, M.; Billard, A. Influence of bias voltage on properties of AlCrN coatings prepared by cathodic arc deposition. Surf. Coat. Technol. 2013, 225, 77–81. [Google Scholar] [CrossRef]

- Sabitzer, C.; Paulitsch, J.; Kolozsvári, S.; Rachbauer, R.; Mayrhofer, P.H. Influence of bias potential and layer arrangement on structure and mechanical properties of arc evaporated Al–Cr–N coatings. Vacuum 2014, 106, 49–52. [Google Scholar] [CrossRef]

- Sabitzer, C.; Paulitsch, J.; Kolozsvári, S.; Rachbauer, R.; Mayrhofer, P.H. Impact of bias potential and layer arrangement on thermal stability of arc evaporated Al–Cr–N coatings. Thin Sol. Films 2016, 610, 26–34. [Google Scholar] [CrossRef]

- Kohlscheen, J.; Bareiss, C. Effect of hexagonal phase content on wear behaviour of AlTiN arc PVD coatings. Coat. 2018, 8, 72. [Google Scholar] [CrossRef]

- Ullner, C. Hardness testing; Herrmann, K., Ed.; ASTM International: Materials Park, OH, USA, 2011; Chapter 6; p. 187. [Google Scholar]

- Birkholz, M.; Genzel, C. Thin film analysis by X–ray scattering; Birkholz, M., Ed.; Wiley VCH: Weinheim, Germany, 2006; Chapter 6; p. 273. [Google Scholar]

- Matej, Z.; Kuzel, R.; Nichtova, L. XRD total pattern fitting applied to study of microstructure of TiO2 films. Powder Diffr. 2010, 25, 125–131. [Google Scholar] [CrossRef]

- Zhou, L.; Holec, D.; Mayrhofer, P.H. First principles study of elastic properties of cubic Cr1–xAlxN alloys. J. Appl. Phys. 2013, 113, 043511. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Varghese, V.; Akhil, K.; Ramesh, M.R.; Chakradhar, D. Investigation on the performance of AlCrN and AlTiN coated cemented carbide inserts during end milling of maraging steel under dry, wet and cryogenic environments. J. Manuf. Proc. 2019, 43, 136–144. [Google Scholar] [CrossRef]

- Romero, J.; Gomez, M.A.; Esteve, J.; Montala, F.; Carreras, L.; Grifol, M.; Lousa, A. CrAlN coatings deposited by cathodic arc evaporation at different substrate bias. Thin Solid Films 2006, 515, 113–117. [Google Scholar] [CrossRef]

- Jäger, N.; Klima, S.; Hruby, H.; Julin, J.; Burghammer, M.; Kecke, J.F.; Mitterer, C.; Daniel, R. Evolution of structure and residual stress of a fcc/hex–AlCrN multi–layered system upon thermal loading revealed by cross–sectional X–ray nano diffraction. Acta Mat. 2019, 162, 55–66. [Google Scholar] [CrossRef]

- Khan, S.; Shahid, M.; Mahmood, A.; Shah, A.; Ahmed, I.; Mehmood, M. Texture of the nano–crystalline AlN thin films and the growth conditions in DC magnetron sputtering. Progr. Nat. Sci. 2015, 25, 282–290. [Google Scholar] [CrossRef]

- Molleja, J.G.; Gomez, B.J.; Ferron, J.; Gautron, E.; Burgi, J.; Bassam, A.; Djouadi, M.A.; Feugeas, J.; Jouan, P.Y. AlN thin films deposited by DC reactive magnetron sputtering: Effect of oxygen on film growth. Eur. Phys. J. Appl. Phys. 2013, 64, 20302. [Google Scholar] [CrossRef]

| x in AlxCr100–xN | Bias Voltage, V | Thickness, µm | Designation |

|---|---|---|---|

| 70 | 50 | 1.5 | Al70CrN–050 |

| 70 | 100 | 1.3 | Al70CrN–100 |

| 70 | 150 | 1.3 | Al70CrN–150 |

| 80 | 50 | 1.8 | Al80CrN–050 |

| 80 | 100 | 1.9 | Al80CrN–100 |

| 80 | 150 | 1.3 | Al80CrN–150 |

| Designation | HIT (GPa) | EIT (Gpa) | HIT/EIT |

|---|---|---|---|

| Al70CrN–050 | 30 | 448 | 0.064 |

| Al70CrN–100 | 33 | 444 | 0.074 |

| Al70CrN–150 | 33 | 428 | 0.077 |

| Al80CrN–050 | 20 | 296 | 0.068 |

| Al80CrN–100 | 28 | 357 | 0.078 |

| Al80CrN–150 | 32 | 460 | 0.070 |

| Designation | Cubic 111 | Cubic 200 | wp Fit, Cubic | wp Fit, Hexag. |

|---|---|---|---|---|

| Al70CrN–050 | −2.6 ± 0.1 | −2.4 ± 0.9 | −3.0 ± 0.2 | |

| Al70CrN–100 | −5.6 ± 0.2 | −4.5 ± 0.2 | −6.5 ± 0.2 | |

| Al70CrN–150 | −5.2 ± 0.2 | −5.2 ± 0.1 | −5.4 ± 0.1 | |

| Al80CrN–050 | −1.7 ± 0.2 | −1.8 ± 0.3 | −0.7 ± 0.5 | |

| Al80CrN–100 | −3.5 ± 0.1 | −3.6 ± 0.3 | −4.3 ± 0.2 | |

| Al80CrN–150 | −4.1 ± 0.2 | −4.5 ± 0.2 | −4.5 ± 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kohlscheen, J.; Shibata, T. Phase and Residual Stress Evaluation of Dual-Phase Al70Cr30N and Al80Cr20N PVD Films. Crystals 2019, 9, 362. https://doi.org/10.3390/cryst9070362

Kohlscheen J, Shibata T. Phase and Residual Stress Evaluation of Dual-Phase Al70Cr30N and Al80Cr20N PVD Films. Crystals. 2019; 9(7):362. https://doi.org/10.3390/cryst9070362

Chicago/Turabian StyleKohlscheen, Joern, and Tomohiro Shibata. 2019. "Phase and Residual Stress Evaluation of Dual-Phase Al70Cr30N and Al80Cr20N PVD Films" Crystals 9, no. 7: 362. https://doi.org/10.3390/cryst9070362

APA StyleKohlscheen, J., & Shibata, T. (2019). Phase and Residual Stress Evaluation of Dual-Phase Al70Cr30N and Al80Cr20N PVD Films. Crystals, 9(7), 362. https://doi.org/10.3390/cryst9070362