A Facile Approach for Fabricating Microstructured Surface Based on Etched Template by Inkjet Printing Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Water-Soluble Polymer Ink

2.3. Preparation of Inkjet Printing Substrate

2.4. Inkjet Printing Water-Soluble Polymer Ink

2.5. Fabrication of Inkjet Printed Template

2.6. Characterization

3. Results and Discussions

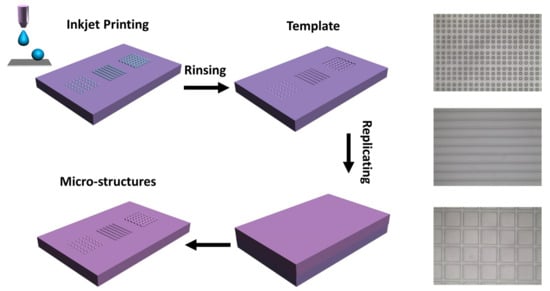

3.1. Fabricating Microstructured Surfaces Based on Etched Template by Inkjet Printing Technology

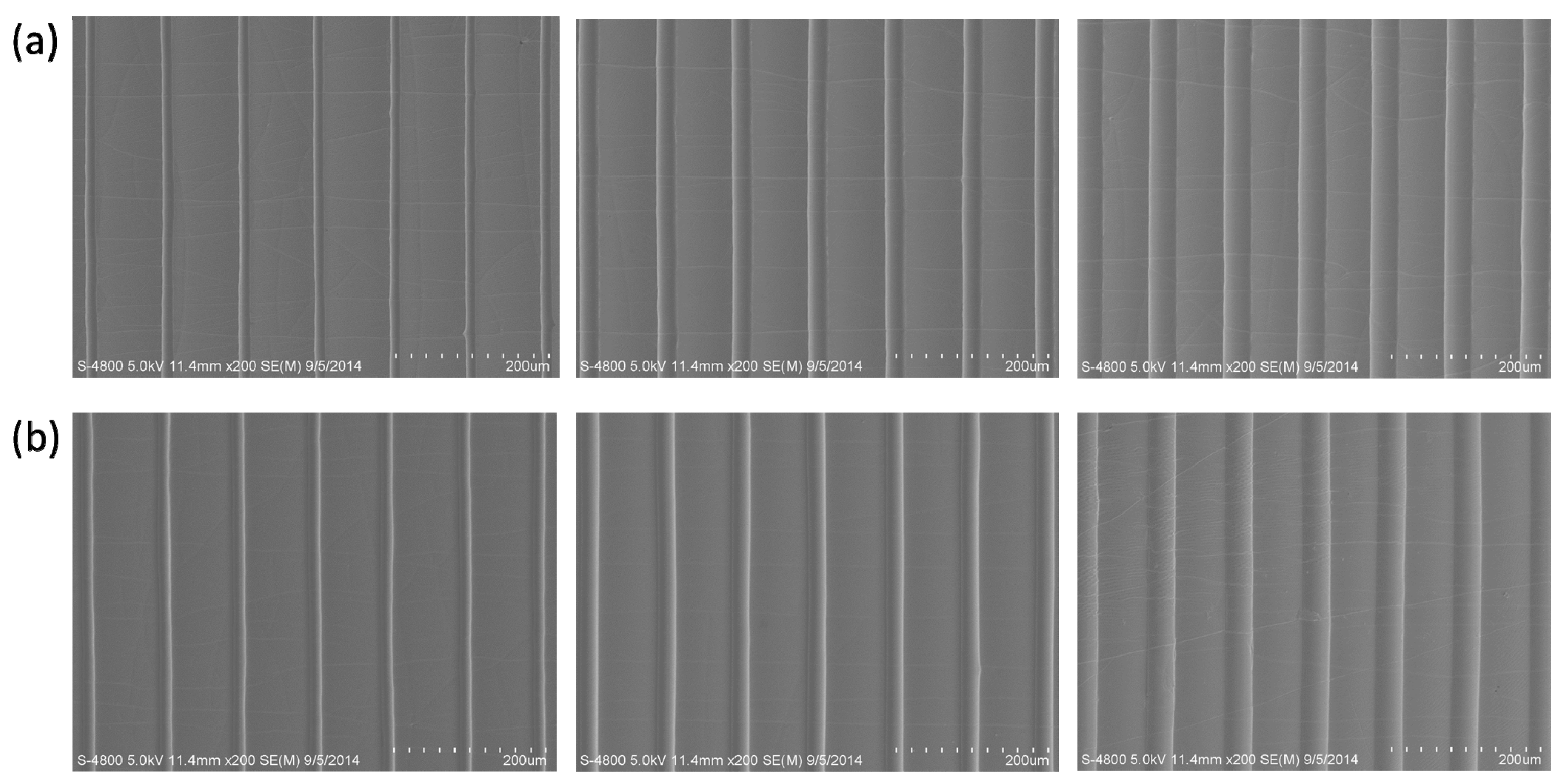

3.2. Controllable Fabrication of Microstructured Surfaces Based on Etched Template by Inkjet Printing Technology

3.3. Anisotropic Wetting Behavior on Fabricated Microstructured Surfaces

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yao, X.; Song, Y.L.; Jiang, L. Applications of bio-inspired special wettable surfaces. Adv. Mater. 2011, 23, 719–734. [Google Scholar] [CrossRef] [PubMed]

- Pikul, J.H.; Li, S.; Bai, H.; Hanlon, R.T.; Cohen, I.; Shepherd, R.F. Stretchable surfaces with programmable 3D texture morphing for synthetic camouflaging skins. Science 2017, 358, 210–214. [Google Scholar] [CrossRef] [PubMed]

- Hensel, R.; Finn, A.; Helbig, R.; Braun, H.G.; Neinhuis, C.; Fischer, W.J.; Werner, C. Biologically inspired omniphobic surfaces by reverse imprint lithography. Adv. Mater. 2014, 26, 2029–2033. [Google Scholar] [CrossRef] [PubMed]

- Trung, T.Q.; Dang, V.Q.; Lee, H.B.; Kim, D.I.; Moon, S.; Lee, N.E.; Lee, H. An omnidirectionally stretchable photodetector based on organic−inorganic heterojunctions. ACS Appl. Mater. Interfaces 2017, 9, 35958–35967. [Google Scholar] [CrossRef] [PubMed]

- Maeng, J.; Kim, Y.J.; Meng, C.Z.; Irazoqui, P.P. Three-dimensional microcavity array electrodes for high-capacitance all-solid-state flexible microsupercapacitors. ACS Appl. Mater. Interfaces 2016, 8, 13458–13465. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Lee, J.; Kim, G.; Kim, Y.; Kang, S.; Cho, S.; Kim, S.G.; Kim, J.K.; Lee, W.; Kim, D.E.; et al. Rough-surface-enabled capacitive pressure sensors with 3D touch capability. Small 2017, 13, 1700368. [Google Scholar] [CrossRef] [PubMed]

- Daniel, S.; Chaudhury, M.K.; Chen, J.C. Fast drop movements resulting from the phase change on a gradient surface. Science 2001, 291, 633–636. [Google Scholar] [CrossRef] [PubMed]

- Menard, E.; Meitl, M.A.; Sun, Y.G.; Park, J.U.; Shir, D.J.L.; Nam, Y.S.; Jeon, S.; Rogers, J.A. Micro- and nanopatterning techniques for organic electronic and optoelectronic systems. Chem. Rev. 2007, 107, 1117–1160. [Google Scholar] [CrossRef] [PubMed]

- Malvadkar, N.A.; Hancock, M.J.; Sekeroglu, K.; Dressick, W.J.; Demirel, M.C. An engineered anisotropic nanofilm with unidirectional wetting properties. Nat. Mater. 2010, 9, 1023–1028. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Ling, X.Y.; van Bennekom, J.; Duan, X.; Ludden, M.J.W.; Reinhoudt, D.N.; Wessling, M.; Lammertink, R.G.H.; Huskens, J. Microcontact printing of dendrimers, proteins, and nanoparticles by porous stamps. J. Am. Chem. Soc. 2009, 131, 797–803. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Yao, J.M.; Lu, G.; Chen, X.; Zhang, K.; Yang, B. Microcontact printing of colloidal crystals. J. Am. Chem. Soc. 2004, 126, 10510–10511. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.B.; Bae, C.W.; Duy, L.T.; Sohn, I.Y.; Kim, D.I.; Song, Y.J.; Kim, Y.J.; Lee, N.E. Mogul-patterned elastomeric substrate for stretchable electronics. Adv. Mater. 2016, 27, 3069–3077. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.H.; Xu, J.L.; Gao, X.; Sun, Y.L.; Lv, J.J.; Shen, S.; Chen, L.S.; Wang, S.D. Freestanding transparent metallic network based ultrathin, foldable and designable supercapacitors. Energy Environ. Sci. 2017, 10, 2534–2543. [Google Scholar] [CrossRef]

- Geissler, M.; Xia, Y.N. Patterning: Principles and some new developments. Adv. Mater. 2004, 16, 1249–1269. [Google Scholar] [CrossRef]

- De Gans, B.J.; Duineveld, P.C.; Schubert, U.S. Inkjet printing of polymers: State of the art and future developments. Adv. Mater. 2004, 16, 203–213. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing-process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.Z.; Guo, Y.Z.; Cui, B.; Chu, F.Q.; Li, H.Z.; Li, Y.; He, M.; Ding, D.; Liu, R.P.; Li, L.H.; et al. Inkjet printing bendable circuits based on an oil-water interface reaction. Appl. Surf. Sci. 2018, 445, 391–397. [Google Scholar] [CrossRef]

- Sun, J.Z.; Bao, B.; He, M.; Zhou, H.H.; Song, Y.L. Recent advances in controlling the depositing morphologies of inkjet droplets. ACS Appl. Mater. Interfaces 2015, 7, 28086–28099. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.Y.; Huang, N.G.; Xu, F.; Tong, J.D.; Chen, Z.W.; Gui, X.C.; Fu, Y.L.; Lao, C.S. 3D printing technologies for flexible tactile sensors toward wearable electronics and electronic skin. Polymers 2018, 10, 6. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Zhang, X.Y.; Xin, Z.Q.; Deng, M.M.; Wen, Y.Q.; Song, Y.L. Controlled inkjetting of a conductive pattern of silver nanoparticles based on the coffee-ring effect. Adv. Mater. 2016, 28, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.Z.; Cui, B.; Chu, F.Q.; Yun, C.H.; He, M.; Li, L.H.; Song, Y.L. Printable nanomaterials for the fabrication of high-performance supercapacitors. Nanomaterials 2018, 8, 528. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.P.; Chiu, H.L.; Wang, P.H.; Liao, Y.C. Inkjet printed conductive tracks for printed electronics. ECS J. Solid State Sci. Technol. 2015, 4, 3026–3033. [Google Scholar] [CrossRef]

- Kang, B.; Lee, W.H.; Cho, K. Recent advances in organic transistor printing processes. ACS Appl. Mater. Interfaces 2013, 5, 2302–2315. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.H.; Yoo, J.T.; Chang, K.L.; Lee, S.Y. All-inkjet-printed, solid-state flexible supercapacitors on paper. Energy Environ. Sci. 2016, 9, 2812–2821. [Google Scholar] [CrossRef]

- Huang, Q.J.; Al-Milaji, K.N.; Zhao, H. Inkjet printing of silver nanowires for stretchable heaters. ACS Appl. Nano Mater. 2018, 1, 4528–4536. [Google Scholar] [CrossRef]

- Slabov, V.; Vinogradov, A.V.; Yakovlev, A.V. Inkjet printing of specular holograms based on a coffee-ring effect concave structure. J. Mater. Chem. C. 2018, 6, 5269–5277. [Google Scholar] [CrossRef]

- Al-Milaji, K.N.; Secondo, R.R.; Ng, T.N.; Kinsey, N.; Zhao, H. Interfacial self-assembly of colloidal nanoparticles in dual-droplet inkjet printing. Adv. Mater. Interfaces 2018, 5, 1701561. [Google Scholar] [CrossRef]

- Szilasi, S.Z.; Cserháti, C. Selective etching of PDMS: Etching technique for application as a positive tone resist. Appl. Surf. Sci. 2018, 457, 662–669. [Google Scholar] [CrossRef]

- Liu, Y.W.; Wang, S.Y.; Wang, Y.H. Patterned fibers embedded microfluidic chips based on PLA and PDMS for Ag nanoparticle safety testing. Polymers 2016, 8, 402. [Google Scholar] [CrossRef]

- Wang, H.L.; Cheng, C.; Zhang, L.; Liu, H.T.; Zhao, Y.; Guo, Y.L.; Hu, W.P.; Yu, G.; Liu, Y.Q. Inkjet printing short-channel polymer transistors with high-performance and ultrahigh photoresponsivity. Adv. Mater. 2014, 26, 4683–4689. [Google Scholar] [CrossRef] [PubMed]

- Melzer, M.; Karnaushenko, D.; Lin, G.G.; Baunack, S.; Makarov, D.; Schmidt, O.G. Direct transfer of magnetic sensor devices to elastomeric supports for stretchable electronics. Adv. Mater. 2015, 27, 1333–1338. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, R.; Singh, V.; Jurney, P.; Shi, L.; Sreenivasan, S.V.; Roy, K. Scalable imprinting of shape-specific polymeric nano carriers using a release layer of switchable water solubility. ACS Nano 2012, 6, 2524–2531. [Google Scholar] [CrossRef] [PubMed]

- Bao, B.; Jiang, J.K.; Li, F.Y.; Zhang, P.C.; Chen, S.R.; Yang, Q.; Wang, S.T.; Su, B.; Jiang, L.; Song, Y.L. Fabrication of patterned concave microstructures by inkjet imprinting. Adv. Funct. Mater. 2015, 25, 3286–3294. [Google Scholar] [CrossRef]

- Bao, B.; Sun, J.Z.; Gao, M.; Zhang, X.Y.; Jiang, L.; Song, Y.L. Patterning liquids on inkjet-imprinted surfaces with highly adhesive superhydrophobicity. Nanoscale 2016, 8, 9556–9562. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Yun, C.; Cui, B.; Li, P.; Liu, G.; Wang, X.; Chu, F. A Facile Approach for Fabricating Microstructured Surface Based on Etched Template by Inkjet Printing Technology. Polymers 2018, 10, 1209. https://doi.org/10.3390/polym10111209

Sun J, Yun C, Cui B, Li P, Liu G, Wang X, Chu F. A Facile Approach for Fabricating Microstructured Surface Based on Etched Template by Inkjet Printing Technology. Polymers. 2018; 10(11):1209. https://doi.org/10.3390/polym10111209

Chicago/Turabian StyleSun, Jiazhen, Chenghu Yun, Bo Cui, Pingping Li, Guangping Liu, Xin Wang, and Fuqiang Chu. 2018. "A Facile Approach for Fabricating Microstructured Surface Based on Etched Template by Inkjet Printing Technology" Polymers 10, no. 11: 1209. https://doi.org/10.3390/polym10111209

APA StyleSun, J., Yun, C., Cui, B., Li, P., Liu, G., Wang, X., & Chu, F. (2018). A Facile Approach for Fabricating Microstructured Surface Based on Etched Template by Inkjet Printing Technology. Polymers, 10(11), 1209. https://doi.org/10.3390/polym10111209