Rheological Behavior of Amino-Functionalized Multi-Walled Carbon Nanotube/Polyacrylonitrile Concentrated Solutions and Crystal Structure of Composite Fibers

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. In Situ Polymerization of Amino-CNT/PAN Concentrated Solutions

2.3. Wet-Spinning of Amino-CNT/PAN Composite Fibers

2.4. Characterization

2.4.1. Rheology

2.4.2. Scanning Electron Micriscope

2.4.3. X-ray Diffraction

2.4.4. Fourier Transform Infrared Spectroscopy

2.4.5. Raman Spectroscopy

2.4.6. Differential Scanning Calorimetry

2.4.7. Mechanical Properties

3. Results and Discussion

3.1. Rheological Behavior

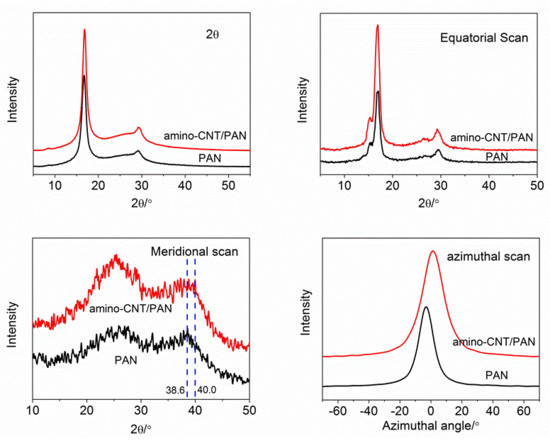

3.2. XRD Analysis

3.3. FTIR Analysis

3.4. Raman Spectroscopy

3.5. Morphology of Amino-CNT/PAN Composite Fiber

3.6. DSC Curves

3.7. Mechanical Properties of Amino-CNT/PAN Composite Fibers

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Levshov, D.; Than, T.X.; Arenal, R.; Popov, V.N.; Parret, R.; Paillet, M.; Jourdain, V.; Zahab, A.A.; Michel, T.; Yuzyuk, Y.I.; et al. Experimental evidence of a mechanical coupling between layers in an individual double-walled carbon nanotube. Nano Lett. 2011, 11, 4800–4804. [Google Scholar] [CrossRef] [PubMed]

- Song, B.J.; Ahn, J.W.; Cho, K.K.; Roh, J.S.; Lee, D.Y.; Yang, Y.S.; Lee, J.B.; Hwang, D.Y.; Kim, H.S. Electrical and mechanical properties as a processing condition in polyvinylchloride multi walled carbon nanotube composites. J. Nanosci. Nanotechnol. 2013, 13, 7723–7727. [Google Scholar] [CrossRef] [PubMed]

- Souier, T.; Santos, S.; AI Ghaferi, A.; Stefancich, M.; Chiesa, M. Enhanced electrical properties of vertically aligned carbon nanotube-epoxy nanocomposites with high packing density. Nanoscale Res. Lett. 2012, 7, 630–637. [Google Scholar] [CrossRef] [PubMed]

- Kueseng, P.; Sae-oui, P.; Rattanasom, N. Mechanical and electrical properties of natural rubber and nitrile rubber blends filled with multi-wall carbon nanotube: Effect of preparation methods. Polym. Test. 2013, 32, 731–738. [Google Scholar] [CrossRef]

- Malik, S.; Krasheninnikov, A.V.; Marchesan, S. Advances in nanocarbon composite materials. Beilstein J. Nanotechnol. 2018, 9, 20–21. [Google Scholar] [CrossRef] [PubMed]

- Gulotty, R.; Castellino, M.; Jagdale, P.; Tagliaferro, A.; Balandin, A.A. Effects of functionalization on thermal properties of single-wall and multi-wall carbon nanotube-polymer nanocomposites. ACS Nano 2013, 7, 5114–5121. [Google Scholar] [CrossRef] [PubMed]

- Szatkowski, P.; Pielichowska, K.; Blazewicz, S. Mechanical and thermal properties of carbon nanotube reinforced self-healing polyurethanes. J. Mater. Sci. 2017, 52, 12221–12234. [Google Scholar] [CrossRef]

- Marchesan, S.; Melchionna, M.; Prato, M. Wire up to carbon nanostructures! How to play a winning game. ACS Nano 2015, 9, 9441–9450. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Melchionna, M.; Prato, M. Functionalizing carbon nanotubes: An indispensible step towards applications carbon nanostructures and devices. ECS J. Solid State Sci. Technol. 2013, 2, 3040–3045. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, Y.; Wang, Q.; Wang, T. Shape memory properties of multi-walled carbon nanotube/polyurethane composites prepared by in situ polymerization. J. Mater. Sci. 2013, 48, 2207–2214. [Google Scholar] [CrossRef]

- Zhang, K.; Lim, J.Y.; Choi, H.J.; Lee, J.H.; Choi, W.J. Ultrasonically prepared polystyrene/multi-walled carbon nanotube nanocomposites. J. Mater. Sci. 2013, 48, 3088–3096. [Google Scholar] [CrossRef]

- Saeed, K.; Park, S.Y.; Haider, S.; Baek, J.B. In situ polymerization of multi-walled carbon nanotube/nylon-6 nanocomposites and their electrospun nanofibers. Nanoscale Res. Lett. 2009, 4, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Xu, L.; Yang, F.; Geng, L. The synthesis of polyacrylonitrile/carbon nanotube microspheres by aqueous deposition polymerization under ultrasonication. Carbon 2010, 48, 688–695. [Google Scholar] [CrossRef]

- Casey, J.P.; Bachilo, S.M.; Moran, C.H.; Weisman, R.B. Chirality-resolved length analysis of single-walled carbon nanotube samples through shear-aligned photoluminescence anisotropy. ACS Nano 2008, 2, 1738–1746. [Google Scholar] [CrossRef] [PubMed]

- Barman, S.N.; LeMieux, M.C.; Baek, J.; Rivera, R.; Bao, Z. Effects of dispersion conditions of single-walled carbon nanotubes on the electrical characteristics of thin film network transistors. ACS Appl. Mater. Interfaces 2010, 2, 2672–2678. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Lu, Y.; Zhao, W.; Qin, X. A comparison of the effect of hot stretching on microstructures and properties of polyacrylonitrile and rayon-based carbon fibers. J. Mater. Sci. 2014, 49, 5017–5029. [Google Scholar] [CrossRef]

- Wang, W.; Murthy, N.S.; Chae, H.G.; Kumar, S. Structural changes during deformation in carbon nanotube-reinforced polyacrylonitrile fibers. Polymer 2008, 49, 2133–2145. [Google Scholar] [CrossRef]

- Chae, H.G.; Sreekumar, T.V.; Uchida, T.; Kumar, S. A comparison of reinforcement efficiency of various types of carbon nanotubes in polyacrylonitrile fiber. Polymer 2005, 46, 10925–10935. [Google Scholar] [CrossRef]

- Sreekumar, T.V.; Chandra, L.; Srivastava, A.; Kumar, S. Oxidative stabilization of polyacrylonitrile in the presence of functionalized carbon nanotubes. Carbon 2007, 45, 1114–1116. [Google Scholar] [CrossRef]

- Newcomb, B.A.; Chae, H.G.; Gulgunje, P.V.; Gupta, K.; Liu, Y.; Tsentalovich, D.E.; Pasquali, M.; Kuamr, S. Stress transfer in polyacrylonitrile/carbon nanotube composite fibers. Polymer 2014, 55, 2734–2743. [Google Scholar] [CrossRef]

- Li, X.; Ji, X.; Qin, A.; He, C. The plasticized spinning and cyclization behaviors of functionalized carbon nanotube/polyacrylonitrile fibers. RSC Adv. 2015, 5, 52226–52234. [Google Scholar] [CrossRef]

- Quan, L.; Zhang, H.; Xu, L. Orientation and thermal properties of carbon nanotube/polyacrylonitrile nascent composite fibers. J. Polym. Res. 2015, 22, 1–6. [Google Scholar] [CrossRef]

- Ray, S.S.; Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar]

- Akhlaghi, O.; Akbulut, O.; Menceloglu, Y.Z. Shear and extensional rheological characterization of poly(acrylonitrile)/halloysite nanocomposite solutions. Eur. Polym. J. 2015, 73, 17–25. [Google Scholar] [CrossRef]

- Martins, J.N.; Kersch, M.; Altstädt, V.; Oliveira, R.V.B. Poly(vinylidene fluoride)/polyaniline/carbon nanotubes nanocomposites: Influence of preparation method and oscillatory shear on morphology and electrical conductivity. Polym. Test. 2013, 32, 1511–1521. [Google Scholar] [CrossRef]

- Gupta, A.; Choudhary, V. Rheologic and mechanical properties of multiwalled carbon nanotubes-reinforced poly(trimethylene terephthalalte) composites. J. Mater. Sci. 2013, 48, 3347–3356. [Google Scholar] [CrossRef]

- Zonder, L.; Ophir, A.; Kenig, S.; McCarthy, S. The effect of carbon nanotubes on the rheology and electrical resistivity of polyamide 12/high density polyethylene blends. Polymer 2011, 52, 5085–5091. [Google Scholar] [CrossRef]

- Chae, D.W.; Hong, S.M. Rheology, crystallization behavior under shear, and resultant morphology of PVDF/multiwalled carbon nanotube composites. Macromol. Res. 2011, 19, 326–331. [Google Scholar] [CrossRef]

- Lalko, M.P.; Rakesh, L.; Hirschi, S. Rheology of polycarbonate reinforced with functionalized and unfunctionalized single-walled carbon nanotubes. J. Therm. Anal. Calorim. 2009, 95, 203–206. [Google Scholar] [CrossRef]

- Amr, I.T.; Al-Amer, A.; Thomas, S.; Al-Harthi, M.; Girei, S.A.; Sougrat, R.; Atieh, M.A. Effect of acid treated carbon nanotubes on mechanical, rheological and thermal properties of polystyrene nanocomposites. Compos. Part B Eng. 2011, 42, 1554–1561. [Google Scholar] [CrossRef]

- Yan, X.L.; Gong, Z.L.; Gong, J.; Gao, S.; Zhang, Z.; Wang, B. Investigation of the rheological and conductive properties of multi-walled carbon nanotube/polycarbonate composites by positron annihilation techniques. Carbon 2012, 50, 2899–2907. [Google Scholar] [CrossRef]

- Kim, K.S.; Park, S.J. Influence of amine-grafted multi-walled carbon nanotubes on physical and rheological properties of PMMA-based nanocomposites. J. Solid State Chem. 2011, 184, 3021–3027. [Google Scholar] [CrossRef]

- Zhang, H.; Quan, L.; Xu, L. Effects of amino-functionalized carbon nanotubes on the crystal structure and thermal properties of polyacrylonitrile homopolymer microspheres. Polymers 2017, 9, 332. [Google Scholar] [CrossRef]

- Quan, L.; Zhang, H.; Xu, L. The non-isothermal cyclization kinetics of amino-functionalized carbon nanotubes/polyacrylonitrile composites by in situ polymerization. J. Therm. Anal. Calorim. 2015, 119, 1081–1089. [Google Scholar] [CrossRef]

- Bashir, Z. Thermoreversible gelation and plasticization of polyacrylonitrile. Polymer 1992, 33, 4304–4313. [Google Scholar] [CrossRef]

- Chafidz, A.; Ali, M.A.; Elleithy, R. Morphological, thermal rheological, and mechanical properties of polypropylene-nanoclay composites prepared from masterbatch in a twin screw extruder. J. Mater. Sci. 2011, 46, 6075–6086. [Google Scholar] [CrossRef]

- Akhlaghi, O.; Menceloglu, Y.Z.; Akbulut, O. Rheological behavior of poly(acrylonitrile) concentrated solutions: Effect of Sb2O3 nanoparticles on shear and extensional flow. Colloid Polym. Sci. 2016, 294, 1463–1473. [Google Scholar] [CrossRef]

- Xu, D.H.; Wang, Z.G. Influence of carbon nanotube aspect ratio on normal stress differences in isotactic polypropylene nanocomposite melts. Macromolecules 2008, 41, 815–825. [Google Scholar] [CrossRef]

- Zhang, K.; Choi, H.J. Fabrication and viscoelastic characteristics of amino-functionalized multi-walled carbon nanotube/poly(methyl methacrylate) nanocomposites. Compos. Struct. 2015, 125, 170–175. [Google Scholar] [CrossRef]

- Mitchell, C.A.; Bahr, J.L.; Arepalli, S.; Tour, J.M.; Krishnamoori, R. Dispersion of functionalized carbon nanotubes in polystyrene. Macromolecular 2002, 35, 8825–8830. [Google Scholar] [CrossRef]

- Ke, K.; Wang, Y.; Yang, W.; Xie, B.H.; Yang, M.B. Crystallization and reinforcement of poly(vinylidene fluoride) nanocomposites: Role of high molecular weight resin and carbon nanotubes. Polym. Test. 2012, 31, 117–126. [Google Scholar] [CrossRef]

- Kim, K.S.; Byun, J.H.; Lee, G.H.; Park, S.J. Influence of GMA grafted MWNTs on physical and rheological properties of PMMA-based nanocomposites by in situ polymerization. Macromol. Res. 2011, 19, 14–20. [Google Scholar] [CrossRef]

- Bose, S.; Bhattacharyya, A.R.; Kulkarni, A.R.; Pötschke, P. Electrical, rheological and morphological studies in co-continuous blends of polyamide 6 and acrylonitrile–butadiene–styrene with multiwall carbon nanotubes prepared by melt blending. Compos. Sci. Technol. 2009, 69, 365–372. [Google Scholar] [CrossRef]

- Xu, Z.; Niu, Y.; Yang, L.; Xie, W.; Li, H.; Gan, Z.; Wang, Z. Morphology, rheology and crystallization behavior of polylactide composites prepared through addition of five-armed star polylactide grafted multiwalled carbon nanotubes. Polymer 2010, 51, 730–737. [Google Scholar] [CrossRef]

- Ke, K.; Wen, R.; Wang, Y.; Yang, W.; Xie, B.H.; Yang, M.B. Crystallization behavior of poly(vinylidence fluoride)/multi-walled carbon nanotubes nanocomposites. J. Mater. Sci. 2011, 46, 1542–1550. [Google Scholar] [CrossRef]

- Sawai, D.; Yamane, A.; Kameda, T.; Kanamoto, T. Uniaxial drawing of isotactic poly(acrylonitrile): Development of oriented structure and tensile properties. Macromolecules 1999, 32, 5622–5630. [Google Scholar] [CrossRef]

- Mikolajczyk, T.; Rabiej, S.; Szparaga, G.; Bogun, M.; Fraczek-Szczypta, A.; Blazewicz, S. Strength properties of polyacrylonitrile (PAN) fibres modified with carbon nanotubes with respect to their porous and supramolecular structure. Fibres Text. East Eur. 2009, 77, 13–20. [Google Scholar]

- Sharifnejad, F.; Bahrami, S.H.; Noorpanah, P. Kinetics studies on copolymerization of acrylonitrile vinyl acids by solvent-water suspension polymerization. J. Appl. Polym. Sci. 2005, 97, 1284–1291. [Google Scholar] [CrossRef]

- Santhana Krishnan, G.; Thomas, P.; Murali, N. Synthesis, characterization, and thermo-mechanical properties of poly(acrylonitrile-co-2,3-dimethyl-1,3-butadiene-co-itaconic acid) as carbon fibre polymer precursors. RSC Adv. 2016, 6, 6182–6190. [Google Scholar] [CrossRef]

- Simitzis, J.C.; Georgiou, P.C. Functional group changes of polyacrylonitrile fibres during their oxidative, carbonization and electrochemical treatment. J. Mater. Sci. 2015, 50, 4547–4564. [Google Scholar] [CrossRef]

- Karacan, I.; Erdogan, G. The influence of thermal stabilization stage on the molecular structure of polyacrylonitrile fibers prior to the carbonization stage. Fiber Polym. 2012, 13, 295–302. [Google Scholar] [CrossRef]

- Eom, Y.; Park, Y.; Jung, Y.M.; Kim, B.C. Effects of conformational change of polyacrylonitrile on the aging behavior of the solutions in N,N-dimethyl formamide. Polymer 2017, 108, 193–205. [Google Scholar] [CrossRef]

- Cai, J.; Chawla, S.; Naraghi, M. Microstructural evolution and mechanics of hot-drawn CNT-reinforced polymeric nanofibers. Carbon 2016, 109, 813–822. [Google Scholar] [CrossRef]

- Ma, H.Y.; Tong, L.F.; Xu, Z.B.; Fang, Z.P. Functionalizing carbon nanotubes by grafting on intumscent flame retardant: Nanocomposite synthesis, morphology, rheology, and flammability. Adv. Funct. Mater. 2008, 18, 414–421. [Google Scholar] [CrossRef]

- Edwards, H.G.M.; Hoskins, A.R.; Johnson, A.F.; Lewis, I.R. Raman spectroscopic studies of the polyacrylonitrile-zinc complexes in aqueous solutions of zinc chloride and bromide. Polym. Int. 1993, 30, 25–32. [Google Scholar] [CrossRef]

- Bajaj, P.; Sreekumar, T.V.; Sen, K. Thermal behavior of acrylonitrile copolymers having methacrylic and itaconic acid comonomers. Polymer 2001, 42, 1707–1718. [Google Scholar] [CrossRef]

- Zhou, T.; Wang, X.; Wang, T. Cure reaction of multi-walled carbon nanotubes/diglycidyl ether of bisphenol A/2-ethyl-4-methylimidazole (MWCNTs/DGEBA/EMI-2,4) nanocomposites: Effect of carboxylic functionalization of MWCNTS. Polym. Int. 2009, 58, 445–452. [Google Scholar] [CrossRef]

- Zhou, H.; Tang, X.; Dong, Y.; Chen, L.; Zhang, L.; Wang, W.; Xiong, X. Multiwalled carbon nanotube/polyacrylonitrile composite fibers prepared by in situ polymerization. J. Appl. Polym. Sci. 2011, 120, 1385–1389. [Google Scholar] [CrossRef]

| Samples | Degree of Crystallization (%) | Crystal Size (Å) | Orientation of Crystal Region |

|---|---|---|---|

| PAN | 50.5 | 83.4 | 0.943 |

| Amino-CNT/PAN | 46.5 | 77.7 | 0.914 |

| Samples | Ti (°C) | Tm (°C) | Tf (°C) | ΔH (J/g) | ΔT (°C) | ΔH/ΔT (J/(g·°C)) |

|---|---|---|---|---|---|---|

| PAN | 266.5 | 279.4 | 285.7 | 489.8 | 19.2 | 25.51 |

| Amino-CNT/PAN | 258.3 | 276.4 | 285.8 | 473.7 | 27.5 | 17.23 |

| Samples | Density (g/cm3) | Tensile Strength (GPa) | Tensile Modulus (GPa) | Breaking Elongation (%) |

|---|---|---|---|---|

| PAN | 1.185 ± 0.002 | 0.74 ± 0.06 | 16.03 ± 1.01 | 10.73 ± 0.86 |

| Amino-CNT/PAN | 1.164 ± 0.002 | 0.83 ± 0.05 | 28.37 ± 1.70 | 8.79 ± 0.53 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Quan, L.; Shi, F.; Li, C.; Liu, H.; Xu, L. Rheological Behavior of Amino-Functionalized Multi-Walled Carbon Nanotube/Polyacrylonitrile Concentrated Solutions and Crystal Structure of Composite Fibers. Polymers 2018, 10, 186. https://doi.org/10.3390/polym10020186

Zhang H, Quan L, Shi F, Li C, Liu H, Xu L. Rheological Behavior of Amino-Functionalized Multi-Walled Carbon Nanotube/Polyacrylonitrile Concentrated Solutions and Crystal Structure of Composite Fibers. Polymers. 2018; 10(2):186. https://doi.org/10.3390/polym10020186

Chicago/Turabian StyleZhang, Hailong, Ling Quan, Fengjun Shi, Changqing Li, Huanqiang Liu, and Lianghua Xu. 2018. "Rheological Behavior of Amino-Functionalized Multi-Walled Carbon Nanotube/Polyacrylonitrile Concentrated Solutions and Crystal Structure of Composite Fibers" Polymers 10, no. 2: 186. https://doi.org/10.3390/polym10020186

APA StyleZhang, H., Quan, L., Shi, F., Li, C., Liu, H., & Xu, L. (2018). Rheological Behavior of Amino-Functionalized Multi-Walled Carbon Nanotube/Polyacrylonitrile Concentrated Solutions and Crystal Structure of Composite Fibers. Polymers, 10(2), 186. https://doi.org/10.3390/polym10020186