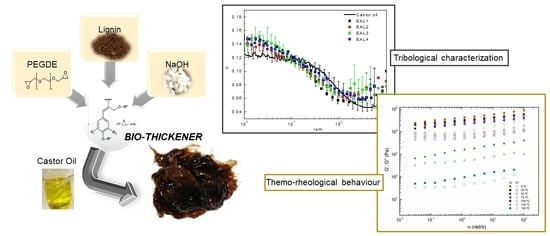

Modification of Alkali Lignin with Poly(Ethylene Glycol) Diglycidyl Ether to Be Used as a Thickener in Bio-Lubricant Formulations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Epoxide-Functionalized Alkali Lignin (EAL)

2.3. Preparation of Oleogels

2.4. Epoxy Index Determination

2.5. NaOH Residual Analysis

2.6. Fourier Transform Infrared (FTIR) Spectroscopy

2.7. Thermal Analysis (TG/DTA)

2.8. Rheological Characterization

2.9. Penetration Tests

2.10. Tribological Measurements

3. Results and Discussion

3.1. Lignin Epoxidation with PEGDE

3.2. Rheological Characterization of Oleogels

3.3. Lubrication Performance of Oleogels

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luther, R. Lubricants in the environment. In Lubricants and Lubrication; Mang, T., Dresel, W., Eds.; Wiley-VCH: Weinheim, Germany, 2007; pp. 119–182. [Google Scholar]

- Flynn, F.B. Screening for the potential of lubricant additives to biodegrade. NLGI Spokesm. 2000, 63, 8–13. [Google Scholar]

- Panchal, T.M.; Patel, A.; Chauhan, D.D.; Thomas, M.; Patel, J.V. A methodological review on bio-lubricants from vegetable oil based resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Erhan, S.; Asadauskas, S.; Dunn, R.; Knothe, G. Vegetable Oils for Environmentally Friendly Applications. In Proceedings of the 48th Oilseed Conference, Competing in World Markets in the New Millennium, New Orleans, LA, USA, 28 Febrary 1999. [Google Scholar]

- Goodrum, J.W.; Geller, D.P. Influence of fatty acid methyl esters from hydroxylated vegetable oils on diesel fuel lubricity. Bioresour. Technol. 2005, 96, 851–855. [Google Scholar] [CrossRef] [PubMed]

- Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A. Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol. Int. 2014, 69, 110–117. [Google Scholar] [CrossRef]

- Delgado, M.A.; Quinchia, L.A.; Spikes, H.A.; Gallegos, C. Suitability of ethyl cellulose as multifunctional additive for blends of vegetable oil-based lubricants. J. Clean. Prod. 2017, 151, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Development of new green lubricating grease formulations based on cellulosic derivatives and castor oil. Green Chem. 2009, 11, 686–693. [Google Scholar] [CrossRef]

- Núñez, N.; Martín-Alfonso, J.E.; Valencia, C.; Sánchez, M.C.; Franco, J.M. Rheology of new green lubricating grease formulations containing cellulose pulp and its methylated derivative as thickener agents. Ind. Crops Prod. 2012, 37, 500–507. [Google Scholar] [CrossRef]

- Sánchez, R.; Fiedler, M.; Kuhn, E.; Franco, J.M. Tribological characterization of green lubricating greases formulated with castor oil and different biogenic thickener agents: A comparative experimental study. Ind. Lubr. Tribol. 2011, 63, 446–452. [Google Scholar] [CrossRef]

- Gallego, R.; Arteaga, J.F.; Valencia, C.; Díaz, M.J.; Franco, J.M. Gel-Like Dispersions of HMDI-Cross-Linked Lignocellulosic Materials in Castor Oil: Toward Completely Renewable Lubricating Grease Formulations. ACS Sustain. Chem. Eng. 2015, 3, 2130–2141. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Valencia, C.; Franco, J.M. Rheology of lignin-based chemical oleogels prepared using diisocyanate crosslinkers: Effect of the diisocyanate and curing kinetics. Eur. Polym. J. 2017, 89, 311–323. [Google Scholar] [CrossRef]

- El Mansouri, N.-E.; Yuan, Q.; Huang, F. Synthesis and characterization of kraft lignin- based epoxy resins. BioResources 2011, 6, 2647–2662. [Google Scholar]

- Singh, A.; Yadav, K.; Kumar Sen, A. Sal (Shorea Robusta) Leaves Lignin Epoxidation and Its Use in Epoxy Based Coatings. Am. J. Polym. Sci. 2012, 2, 14–18. [Google Scholar] [CrossRef]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Recent advances in green hydrogels from lignin: A review. Int. J. Biol. Macromol. 2015, 72, 834–847. [Google Scholar] [CrossRef] [PubMed]

- Gordobil, O.; Egüés, I.; Labidi, J. Modification of Eucalyptus and Spruce organosolv lignins with fatty acids to use as filler in PLA. React. Funct. Polym. 2016, 104, 45–52. [Google Scholar] [CrossRef]

- Pan, H.; Sun, G.; Zhao, T. Synthesis and characterization of aminated lignin. Int. J. Biol. Macromol. 2013, 59, 221–226. [Google Scholar] [CrossRef] [PubMed]

- Carvajal, J.C.; Gómez, Á.; Cardona, C.A. Comparison of lignin extraction processes: Economic and environmental assessment. Bioresour. Technol. 2016, 214, 468–476. [Google Scholar] [CrossRef] [PubMed]

- Gîlcă, I.-A.; Popa, V.I. Study on Biocidal Properties of Some Nanoparticles Based on Epoxy Lignin. Cellul. Chem. Technol. Cellul. Chem. Technol 2013, 47, 3–4. [Google Scholar]

- Cortés-Triviño, E.; Valencia, C.; Franco, J.M. Influence of epoxidation conditions on the rheological properties of gel-like dispersions of epoxidized kraft lignin in castor oil. Holzforschung 2017, 71, 777–784. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Viscosity modification of different vegetable oils with EVA copolymer for lubricant applications. Ind. Crops Prod. 2010, 32, 607–612. [Google Scholar] [CrossRef]

- Balan, C.; Franco, J.M. Influence of the geometry on the transient and steady flow of lubricating greases. Tribol. Trans. 2001, 44, 53–58. [Google Scholar] [CrossRef]

- Heyer, P.; Läuger, J. Correlation between friction and fl ow of lubricating greases in a new tribometer device. Lubr. Sci. 2009, 21, 253–268. [Google Scholar] [CrossRef]

- Malutan, T.; Nicu, R.; Popa, V.I. Contribution to the study of hydroxymetylation reaction of alkali lignin. BioResources 2008, 3, 13–20. [Google Scholar] [CrossRef]

- Ferdosian, F.; Yuan, Z.; Anderson, M.; Xu, C.C. Chemically modified lignin through epoxidation and its thermal properties. J-FOR 2012, 2, 11–15. [Google Scholar]

- Lai, C.; Tang, S.; Yang, B.; Gao, Z.; Li, X.; Yong, Q. Enhanced enzymatic saccharification of corn stover by in situ modification of lignin with poly(ethylene glycol) ether during low temperature alkali pretreatment. Bioresour. Technol. 2017, 244, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Delmas, G.-H.; Benjelloun-Mlayah, B.; Bigot, Y.L.; Delmas, M. BioligninTM based epoxy resins. J. Appl. Polym. Sci. 2013, 127, 1863–1872. [Google Scholar] [CrossRef]

- Pandey, K.K. A study of chemical structure of soft and harwood and wood polymers by FTIR spectrscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Plácido, J.; Capareda, S. Analysis of alkali ultrasonication pretreatment in bioethanol production from cotton gin trash using FT-IR spectroscopy and principal component analysis. Bioresour. Bioprocess. 2014, 1, 23. [Google Scholar] [CrossRef] [Green Version]

- González-González, M.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on Epoxy Resins—Identification, Monitoring the Curing Process, Phase Separation and Water Uptake. In Infrared Spectroscopy—Materials Science, Engineering and Technology; Theophile, T., Ed.; InTech: Vienna, Austria, 2012; Volume 2, pp. 261–284. ISBN 978-953-51-0537-4. [Google Scholar]

- Passauer, L. Highly swellable lignin hydrogels: Novel materials with interesting properties. ACS Symp. Ser. 2012, 1107, 211–228. [Google Scholar] [CrossRef]

- Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and characterization of lignin from different biomass resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Jakab, E.; Faix, O.; Till, F.; Székely, T. The effect of cations on the thermal decomposition of lignins. J. Anal. Appl. Pyrolysis 1993, 25, 185–194. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Zhang, S.; Gao, Q.; Li, J.; Zhang, W. Fast curing bio-based phenolic resins via lignin demethylated under mild reaction condition. Polymers 2017, 9, 428. [Google Scholar] [CrossRef]

- Kleen, M.; Gellerstedt, G. Influence of inorganic species on the formation of polysaccharide and lignin degradation products in the analytical pyrolysis of pulps. J. Anal. Appl. Pyrolysis 1995, 35, 15–41. [Google Scholar] [CrossRef]

- Delgado, M.A.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Influence of Soap Concentration and Oil Viscosity on the Rheology and Microstructure of Lubricating Greases. Ind. Eng. Chem. Res. 2006, 45, 1902–1910. [Google Scholar] [CrossRef]

- NLGI. Lubricating Greases Guide, 5th ed.; National Lubricating Grease Institute: Kansas City, MO, USA, 2006. [Google Scholar]

- Martín Alfonso, J.E.; Yañez, R.; Valencia, C.; Franco, J.M.; Díaz, M.J. Optimization of the methylation conditions of kraft cellulose pulp for its use as a thickener agent in biodegradable lubricating greases. Ind. Eng. Chem. Res. 2009, 48, 6765–6771. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.E.; Franco, J.M. Influence of polymer reprocessing cycles on the microstructure and rheological behavior of polypropylene/mineral oil oleogels. Polym. Test. 2015, 45, 12–19. [Google Scholar] [CrossRef]

- Delgado, M.A.; Valencia, C.; Sánchez, M.C.; Franco, J.M.; Gallegos, C. Thermorheological behaviour of a lithium lubricating grease. Tribol. Lett. 2006, 23, 47–54. [Google Scholar] [CrossRef]

- Sánchez, R.; Valencia, C.; Franco, J.M. Rheological and Tribological Characterization of a New Acylated Chitosan–Based Biodegradable Lubricating Grease: A Comparative Study with Traditional Lithium and Calcium Greases. Tribol. Trans. 2014, 57, 445–454. [Google Scholar] [CrossRef]

- De Laurentis, N.; Cann, P.; Lugt, P.M.; Kadiric, A. The Influence of Base Oil Properties on the Friction Behaviour of Lithium Greases in Rolling/Sliding Concentrated Contacts. Tribol. Lett. 2017, 65, 128. [Google Scholar] [CrossRef]

| Sample | AL (g) | PEGDE (g) | Epoxy index (mol/kg) | NaOH (mol/kg) |

|---|---|---|---|---|

| EAL1 | 10 | 2.5 | 0.79 | 5.9 |

| EAL2 | 10 | 5 | 0.52 | 5.4 |

| EAL3 | 10 | 10 | 0.37 | 4.7 |

| EAL4 | 10 | 20 | 0.28 | 2.8 |

| EAL5 | 10 | 50 | 0.15 | 1.4 |

| Sample | Tonset (°C) | Tmax (°C) | Tfinal (°C) | ∆W (%) | Residue (%) |

|---|---|---|---|---|---|

| AL | 130/234/335 | 150/277/380 | 221/299/423 | 5/8/40 | 47 |

| EAL1 | 110/241/377 | 129/277/459 | 143/304/482 | 28/7/3 | 62 |

| EAL2 | 109/261/375/442 | 123/277/390/464 | 144/301/417/489 | 31/6/2/4 | 57 |

| EAL3 | 104/256/324/431 | 116/285/335/455 | 135/297/362/483 | 20/13/11/6 | 50 |

| EAL4 | 115/254/322/431 | 120/274/339/451 | 142/290/361/475 | 17/13/15/7 | 48 |

| EAL5 | 81/249/337/434 | 106/305/350/465 | 112/314/363/487 | 7/25/30/4 | 34 |

| EAL Sample | EAL concentration (wt %) | Penetration (mm/10) | NLGI consistency number |

|---|---|---|---|

| EAL1 | 10 | 171 | 4 |

| EAL1 | 2.5 | 350 | 0 |

| EAL1 | 5 | 246 | 3 |

| EAL2 | 5 | 316 | 1 |

| EAL3 | 5 | 344 | 1 |

| EAL4 | 5 | 328 | 1 |

| EAL sample | Ea (kJ/mol) | |

|---|---|---|

| 5–100 °C | 100–150 °C | |

| EAL1 | 1.2 | 148 |

| EAL2 | 0.1 | 116 |

| EAL3 | 5.8 | 98 |

| EAL4 | 7 | 96 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cortés-Triviño, E.; Valencia, C.; Delgado, M.A.; Franco, J.M. Modification of Alkali Lignin with Poly(Ethylene Glycol) Diglycidyl Ether to Be Used as a Thickener in Bio-Lubricant Formulations. Polymers 2018, 10, 670. https://doi.org/10.3390/polym10060670

Cortés-Triviño E, Valencia C, Delgado MA, Franco JM. Modification of Alkali Lignin with Poly(Ethylene Glycol) Diglycidyl Ether to Be Used as a Thickener in Bio-Lubricant Formulations. Polymers. 2018; 10(6):670. https://doi.org/10.3390/polym10060670

Chicago/Turabian StyleCortés-Triviño, Esperanza, Concepción Valencia, Miguel A. Delgado, and José M. Franco. 2018. "Modification of Alkali Lignin with Poly(Ethylene Glycol) Diglycidyl Ether to Be Used as a Thickener in Bio-Lubricant Formulations" Polymers 10, no. 6: 670. https://doi.org/10.3390/polym10060670

APA StyleCortés-Triviño, E., Valencia, C., Delgado, M. A., & Franco, J. M. (2018). Modification of Alkali Lignin with Poly(Ethylene Glycol) Diglycidyl Ether to Be Used as a Thickener in Bio-Lubricant Formulations. Polymers, 10(6), 670. https://doi.org/10.3390/polym10060670