Hybrid Effect of Twisted Steel and Polyethylene Fibers on the Tensile Performance of Ultra-High-Performance Cementitious Composites

Abstract

:1. Introduction

2. Experimental Program

2.1. Mix Proportions of UHPCCs

2.2. Mixing Process and Specimen Fabrication

2.3. Experimental Setups for Compressive and Tensile Tests

3. Test Results and Analysis

3.1. Compressive Strength

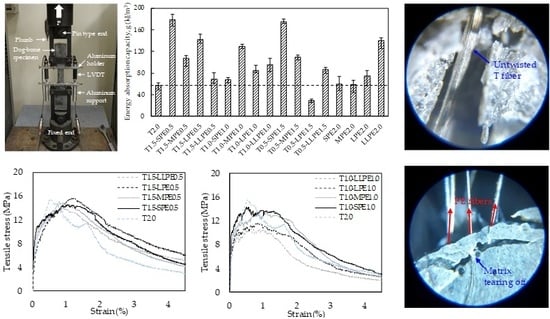

3.2. Hybrid Effect of T and PE Fibers on the Tensile Properties

3.2.1. Tensile Stress–Strain Behavior: Post-Cracking Stiffness and Post-Peak Ductility

3.2.2. Tensile Strength and Strain Capacity

3.2.3. Energy Absorption Capacity per Unit Volume

3.2.4. Cracking Patterns and Behaviors

4. Conclusions

- (1)

- The compressive strength of UHPCCs increased proportionally to the volume fraction of T fibers. This effect was inversely proportional to the volume fraction of PE fibers, regardless of their aspect ratio.

- (2)

- T fibers were more effective in increasing the tensile strength of UHPCCs than PE fibers, while PE fibers were more effective in improving the strain capacity and energy absorption capacity of UHPCCs.

- (3)

- Using both T and SPE or MPE fibers led to a great synergetic effect that enhanced the tensile strength, strain capacity, and energy absorption capacity of UHPCCs relative to that with only T fibers. However, the specimens with T and LPE or LLPE fibers showed relatively minor improvements in the tensile performance.

- (4)

- For UHPCCs with hybridized T and PE fibers, the tensile performance was deteriorated by increasing the aspect ratio of PE fibers. This effect became more obvious with the higher volume content of PE fibers.

- (5)

- There was no clear relationship between the tensile strain capacity and the number of microcracks. However, the number of microcracks was closely related to the pullout mechanisms of the fibers. The T fibers generated greater number of microcracks than the PE fibers.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, D.-J.; Naaman, A.E.; El-Tawil, S. High performance fiber reinforced cement composites with innovative slip Hardending twisted steel fibers. Int. J. Concr. Struct. Mater. 2009, 3, 119–126. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.; Park, G.J.; Park, J.J.; Kim, S.W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- ACI Committee 239. Ultra-High Performance Concrete; ACI Fall Convention: Toronto, ON, Canada, 2012. [Google Scholar]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Hassan, A.M.T.; Jones, S.W.; Mahmud, G.H. Experimental test methods to determine the uniaxial tensile and compressive behaviour of Ultra High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2012, 37, 874–882. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Lee, J.Y.; Yoon, Y.S. Effect of fiber geometric property on rate dependent flexural behavior of ultra-high-performance cementitious composite. Cem. Concr. Compos. 2018, 86, 57–71. [Google Scholar] [CrossRef]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHP-FRC with low fiber contents. Mater. Struct. Constr. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Naaman, A.E. New Fiber Technology. Cem. Ceram. Polym. Compos. 1998, 1, 57–62. [Google Scholar]

- Banthia, N.; Trottier, J.F. Concrete reinforced with deformed steel fibers. 2. Toughness characterization. ACI Mater. J. 1995, 92, 146–154. [Google Scholar]

- Yao, W.; Li, J.; Wu, K. Mechanical properties of hybrid fiber-reinforced concrete at low fiber volume fraction. Cem. Concr. Res. 2003, 33, 27–30. [Google Scholar] [CrossRef]

- Park, J.J.; Kang, S.T.; Koh, K.T. Influence of the ingredients on the compressive strength of UHPC as a fundamental study to optimize the mixing proportion. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 105–112. [Google Scholar]

- Ma, J.; Orgass, M.; Dehn, F.; Schmidt, D.; Tue, N.V. Comparative Investigations on Ultra-High Performance Concrete with or without Coarse Aggregates. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 205–212. [Google Scholar]

- Orgass, M.; Klug, Y. Fibre Reinforced Ultra-High Strength Concretes. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 637–647. [Google Scholar]

- Collepardi, S.; Coppola, L.; Troli, R.; Collepardi, M. Mechanical properties of modified reactive powder concrete. ACI Spec. Publ. 1997, 173, 1–22. [Google Scholar]

- Graybeal, B.; Davis, M. Cylinder or Cube Strength Testing of 80 to 200 MPa Ultra-High-Performance Fiber-Reinforced-Concrete. ACI Mater. J. 2008, 105, 603–609. [Google Scholar]

- ASTM C1437. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–2.

- ASTM C 39-96, Standard test method for compressive strength of cylindrical concrete specimens. Am. Soc. Test. Mater. 1998, 4, 17–21.

- Japan Society of Civil Engineers (JSCE). Recommendations for Design and Construction of Ultra High Performance Fiber Reinforced Concrete Structures (Draft); Japan Society of Civil Engineers: Tokyo, Japan, 2004. [Google Scholar]

- Rizzuti, L.; Bencardino, F. Effects of fibre volume fraction on the compressive and flexural experimental behaviour of SFRC. Contemp. Eng. Sci. 2014, 7, 379–390. [Google Scholar] [CrossRef]

- Kim, M.J.; Yoo, D.Y.; Kim, S.; Shin, M.; Banthia, N. Effects of fiber geometry and cryogenic condition on mechanical properties of ultra-high-performance fiber-reinforced concrete. Cem. Concr. Res. 2018, 107, 30–40. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Shin, H.O.; Yang, J.M.; Yoon, Y.S. Material and bond properties of ultra high performance fiber reinforced concrete with micro steel fibers. Compos. Part B Eng. 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Atiş, C.D.; Karahan, O. Properties of steel fiber reinforced fly ash concrete. Constr. Build. Mater. 2009, 23, 392–399. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Naaman, A.E. Toughness, ductility, surface energy and deflection-hardening FRC composites. In Proceedings of the JCI International Workshop on Ductile Fiber Reinforced Cementitious Composites—Application and Evaluation, Takayama, Japan, 21–22 October 2002; pp. 33–57. [Google Scholar]

- Martinie, L.; Roussel, N. Simple tools for fiber orientation prediction in industrial practice. Cem. Concr. Res. 2011, 41, 993–1000. [Google Scholar] [CrossRef]

| W/B † | Unit Weight (kg/m3) | |||||

|---|---|---|---|---|---|---|

| Water | Cement | Silica Fume | Silica Sand | Silica Flour | Superplasticizer * | |

| 0.2 | 160.3 | 788.5 | 197.1 | 867.4 | 236.6 | 52.6 |

| Composition % (mass) | Cement * | Silica Fume |

|---|---|---|

| CaO | 61.33 | 0.38 |

| Al2O3 | 6.40 | 0.25 |

| SiO2 | 21.01 | 96.00 |

| Fe2O3 | 3.12 | 0.12 |

| MgO | 3.02 | 0.10 |

| SO3 | 2.30 | - |

| Specific surface area (cm2/g) | 3413 | 200,000 |

| Density (g/cm3) | 3.15 | 2.10 |

| Specimen | T2.0 | T1.5-SPE0.5 | T1.5-MPE0.5 | T1.5-LPE0.5 | T1.5-LLPE0.5 | T1.0-SPE1.0 | T1.0-MPE1.0 | T1.0-LPE1.0 | T1.0-LLPE1.0 | T0.5-SPE1.5 | T0.5-MPE1.5 | T0.5-LPE1.5 | T0.5-LLPE1.5 | SPE2.0 | MPE2.0 | LPE2.0 | LLPE2.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Superplasticizer content (g) | 470 | 526 | 526 | 526 | 526 | 490 | 526 | 555 | 555 | 670 | 526 | 526 | 526 | 740 | 740 | 740 | 740 |

| Flow (mm) | 170 | 195 | 180 | 180 | 160 | 205 | 175 | 160 | 135 | 120 | 145 | 135 | 130 | 160 | 140 | 145 | 140 |

| Name | df (mm) | Lf (mm) | Aspect Ratio (Lf/df) | Density (g/cm3) | ft (MPa) | Ef (GPa) |

|---|---|---|---|---|---|---|

| T | 0.30 | 30 | 100.0 | 7.9 | 2428 | 200 |

| SPE | 0.03 | 12 | 400.0 | 0.97 | 3030 | 88 |

| MPE | 0.03 | 18 | 600 | 0.97 | 3030 | 88 |

| LPE | 0.03 | 27 | 900 | 0.97 | 3030 | 88 |

| LLPE | 0.03 | 36 | 1200 | 0.97 | 3030 | 88 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.-J.; Kim, S.; Yoo, D.-Y. Hybrid Effect of Twisted Steel and Polyethylene Fibers on the Tensile Performance of Ultra-High-Performance Cementitious Composites. Polymers 2018, 10, 879. https://doi.org/10.3390/polym10080879

Kim M-J, Kim S, Yoo D-Y. Hybrid Effect of Twisted Steel and Polyethylene Fibers on the Tensile Performance of Ultra-High-Performance Cementitious Composites. Polymers. 2018; 10(8):879. https://doi.org/10.3390/polym10080879

Chicago/Turabian StyleKim, Min-Jae, Soonho Kim, and Doo-Yeol Yoo. 2018. "Hybrid Effect of Twisted Steel and Polyethylene Fibers on the Tensile Performance of Ultra-High-Performance Cementitious Composites" Polymers 10, no. 8: 879. https://doi.org/10.3390/polym10080879

APA StyleKim, M.-J., Kim, S., & Yoo, D.-Y. (2018). Hybrid Effect of Twisted Steel and Polyethylene Fibers on the Tensile Performance of Ultra-High-Performance Cementitious Composites. Polymers, 10(8), 879. https://doi.org/10.3390/polym10080879