Study on the Main Influencing Factors in the Removal Process of Non-Stick Fluoropolymer Coatings Using Nd:YAG Laser

Abstract

:1. Introduction

1.1. The Fluoropolymers

1.2. Precedents and Objectives

2. Materials and Methods

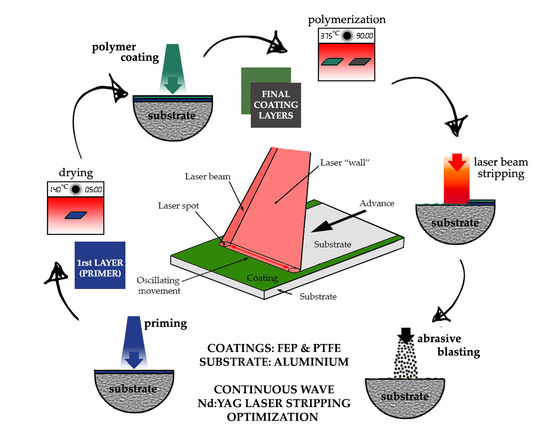

2.1. Processing Procedure

2.2. Influence Factors in the (CW) Nd:YAG Laser Coating Removal Process

3. Results

3.1. Physical and Optical Properties of the Coatings

3.2. Stripping of Non-Stick Coatings by (CW) Nd:YAG Laser

3.3. State of the Aluminum Substrate

4. Discussion

4.1. Continuous Wave 1kW Nd:YAG Laser Efficiency

4.2. Substrate

5. Conclusions

- Stripping process by (CW) Nd:YAG laser is much more efficient for PTFE than for FEP coatings, after evaluating the process fluence (J/cm2) and the stripping rate (cm2/min).

- The greater efficiency of laser stripping technique is related to the lower reflectance of the fluoropolymer and the lower thickness value of the coating.

- The microhardness of the fluoropolymer coating does not show any relationship with the efficiency of the laser stripping.

- The Nd:YAG laser stripping of PTFE coatings seems to produce a smaller increase in Ra and Rz roughness on substrates than those produced in the case of FEP.

- The mechanical properties, tensile strength, and Vickers hardness of the aluminum alloy EN AW 5251 H34 suffer little significant variations (1%–2%) after successive cycles of (CW) Nd:YAG laser coating removal, both for PTFE and FEP.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ebnesajjad, S. Fluoroplastics. Melt Processible Fluoropolymers—The Definitive User’s Guide and Data Book, 2nd ed.; William Andrew, Inc.: Amsterdam, The Netherlands, 2015; ISBN 9781455731978. [Google Scholar]

- Cardoso, V.F.; Correia, D.M.; Ribeiro, C.; Fernandes, M.M.; Lanceros-m, S. Fluorinated Polymers as Smart Materials for Advanced Biomedical Applications. Polymers 2018, 10, 161. [Google Scholar] [CrossRef]

- McKeen, L. Fluorinated Coatings and Finishes Handbook, 1st ed.; William Andrew, Inc.: Wilmington, DC, USA, 2006; ISBN 9780815515227. [Google Scholar]

- Drobny, J.G. Technology of Fluoropolymers, 2nd ed.; CRC Press-Taylor & Francis Group: Boca Raton, FL, USA, 2008; ISBN 978-1420063172. [Google Scholar]

- Ashokkumar, S.; Adler-Nissen, J. Evaluating non-stick properties of different surface materials for contact frying. J. Food Eng. 2011, 105, 537–544. [Google Scholar] [CrossRef]

- Teng, H. Overview of the Development of the Fluoropolymer Industry. Appl. Sci. 2012, 2, 496–512. [Google Scholar] [CrossRef] [Green Version]

- Thomas, P. The use of fluoropolymers for non-stick cooking utensils. JOCCA Surf. Coat. Int. 1998, 81, 604–609. [Google Scholar] [CrossRef]

- Loeb, G.I.; Schrader, M.E. Modern Approaches to Wettability. Theory and Applications, 1st ed.; Springer: New York, NY, USA, 1992; ISBN 978-0-306-43985-8. [Google Scholar]

- Leo Wu, Z.; Govinda Raju, G.R. Electrical conduction in polyimide-FEP fluoropolymer films. Conf. Electr. Insul. Dielectr. Phenom. Annu. Rep. 2002, 2, 578–581. [Google Scholar] [CrossRef]

- Wood, K.A. Optimizing the exterior durability of new fluoropolymer coatings. Prog. Org. Coat. 2001, 43, 207–213. [Google Scholar] [CrossRef]

- Gardiner, J. Fluoropolymers: Origin, Production, and Industrial and Commercial Applications. Aust. J. Chem. 2015, 68, 13–22. [Google Scholar] [CrossRef]

- Leivo, E.; Wilenius, T.; Kinos, T.; Vuoristo, P.; Mäntylä, T. Properties of thermally sprayed fluoropolymer PVDF, ECTFE, PFA and FEP coatings. Prog. Org. Coat. 2004, 49, 69–73. [Google Scholar] [CrossRef]

- Ebnesajjad, S.; Khaladkar, P.R. Fluoropolymers Applications; William Andrew, Inc.: Burlington, MA, USA, 2005; ISBN 0-8155-1502-2. [Google Scholar]

- Ross, B.; Bares, J.; Fromme, C. A Semi-Autonomous Robot for Stripping Paint from Large Vessels. Int. J. Rob. Res. 2003, 22, 617–626. [Google Scholar] [CrossRef]

- Nudelman, A.K.; Abbott, K. Plastic media blasting. Met. Finish. 1999, 97, 476–480. [Google Scholar] [CrossRef]

- Babets, K.; Geskin, E.S. Application of fuzzy logic for modeling of waterjet depainting. Mach. Sci. Technol. 2000, 4, 81–100. [Google Scholar] [CrossRef]

- Yanishevsky, M.; Merati, A.; Bombardier, Y. Effect of Atmospheric Plasma Paint Removal on the Fatigue Performance of 2024-T3 Aluminium Alloy Sheet. J. Miner. Mater. Charact. Eng. 2018, 06, 15–24. [Google Scholar] [CrossRef]

- Bauer, J.P.; Ruddy, E.N. Options for complying with the aerospace MACT standard for depainting. Met. Finish. 1996, 94, 28–39. [Google Scholar] [CrossRef]

- Hensley, C. A Systems Approach To Depaint Chemistry by Chris Hensley; AeroChem Inc.: Oklahoma City, OK, USA, 2009. [Google Scholar]

- Kirts, E.; Stone, P.L. Paint Removal Using Cryogenic Processes; DTIC Selected: Port Hueneme, CA, USA, 1992. [Google Scholar]

- Grapperhaus, M.J.; Schaefer, R.B. Lead paint removal with high-intensity light pulses. Environ. Sci. Technol. 2006, 40, 7925–7929. [Google Scholar] [CrossRef] [PubMed]

- Simon, C.M.; Kaminsky, W. Chemical recycling of polytetrafluoroethylene by pyrolysis. Polym. Degrad. Stab. 1998, 62, 1–7. [Google Scholar] [CrossRef]

- Pezzetti, F.; Riva, A. A Process for Removing Fluorocarbon Resin-Based Coatings; European Patent Office: Milan, Italy, 1995. [Google Scholar]

- Tsunemi, A.; Hagiwara, K.; Saito, N.; Nagasaka, K.; Miyamoto, Y.; Suto, O.; Tashiro, H. Complete removal of paint from metal surface by ablation with a TEA CO 2 laser. Appl. Phys. A Mater. Sci. Process. 1996, 63, 435–439. [Google Scholar] [CrossRef]

- Schmidt, M.J.J.; Li, L.; Spencer, J.T. Removal of chlorinated rubber coatings from concrete surfaces using an RF excited CO2 laser. J. Mater. Process. Technol. 2001, 114, 139–144. [Google Scholar] [CrossRef]

- Chen, G.X.; Kwee, T.J.; Tan, K.P.; Choo, Y.S.; Hong, M.H. Laser cleaning of steel for paint removal. Appl. Phys. A Mater. Sci. Process. 2010, 101, 249–253. [Google Scholar] [CrossRef]

- Sakuma, K.; Hasegawa, S.; Takahashi, H.; Ota, M.; Hayasaki, Y. Holographic laser sweeper for in-process debris removal. Appl. Phys. B Lasers Opt. 2015, 119, 533–538. [Google Scholar] [CrossRef]

- Pantelakis, S.G.; Kermanidis, T.B.; Haidemenopoulos, G.N. Mechanical behavior of 2024 Al alloy specimen subjected to paint stripping by laser radiation and plasma etching. Theor. Appl. Fract. Mech. 1996, 25, 139–146. [Google Scholar] [CrossRef]

- Head, J.D.; Niedzielski, J.P. Laser Paint Stripping; DTIC Selected: South Lion, MI, USA, 1991. [Google Scholar]

- Kumar, M.; Bhargava, P.; Biswas, A.K.; Sahu, S.; Mandloi, V.; Ittoop, M.O.; Khattak, B.Q.; Tiwari, M.K.; Kukreja, L.M. Epoxy-paint stripping using TEA CO2 laser: Determination of threshold fluence and the process parameters. Opt. Laser Technol. 2013, 46, 29–36. [Google Scholar] [CrossRef]

- Klingenberg, M.L.; Naguy, D.A.; Naguy, T.A.; Straw, R.J.; Joseph, C.; Mongelli, G.A.; Nelson, G.C.; Denny, S.L.; Arthur, J.J. Transitioning laser technology to support air force depot transformation needs. Surf. Coat. Technol. 2007, 202, 45–57. [Google Scholar] [CrossRef]

- Madhukar, Y.K.; Mullick, S.; Shukla, D.K.; Kumar, S.; Nath, A.K. Effect of laser operating mode in paint removal with a fiber laser. Appl. Surf. Sci. 2013, 264, 892–901. [Google Scholar] [CrossRef]

- Barletta, M.; Gisario, A.; Tagliaferri, V. Advance in paint stripping from aluminium substrates. J. Mater. Process. Technol. 2006, 173, 232–239. [Google Scholar] [CrossRef]

- Coutouly, J.F.; Deprez, P.; Breaban, F.; Longuemard, J.P. Optimisation of a paint coating ablation process by CO2 TEA laser: Thermal field modelling and real-time monitoring of the process. J. Mater. Process. Technol. 2009, 209, 5730–5735. [Google Scholar] [CrossRef]

- Brygo, F.; Dutouquet, C.; Le Guern, F.; Oltra, R.; Semerok, A.; Weulersse, J.M. Laser fluence, repetition rate and pulse duration effects on paint ablation. Appl. Surf. Sci. 2006, 252, 2131–2138. [Google Scholar] [CrossRef]

- Straw, R.; Arthur, J.; Bowman, R. Robotic Laser Coating Removal System, ESTCP Project WP-0526; EEUU: Arlington, Virginia, 2008. [Google Scholar]

- Siano, S.; Agresti, J.; Cacciari, I.; Ciofini, D.; Mascalchi, M.; Osticioli, I.; Mencaglia, A.A. Laser cleaning in conservation of stone, metal, and painted artifacts: State of the art and new insights on the use of the Nd:YAG lasers. Appl. Phys. A Mater. Sci. Process. 2012, 106, 419–446. [Google Scholar] [CrossRef]

- German Institute for Standardisation. DIN EN 573-3:2009-08, Aluminium and Aluminium Alloys—Chemical Composition and form of Wrought Products—Part 3: Chemical Composition and form of Products; German Institute for Standardisation: Berlin-Tiegarten, Germany, 2009; Volume 1, p. 32. [Google Scholar]

- Lü, S.L.; Wu, S.S.; Zhu, Z.M.; An, P.; Mao, Y.W. Effect of semi-solid processing on microstructure and mechanical properties of 5052 aluminum alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 758–762. [Google Scholar] [CrossRef]

- AENOR. Una Norma Española-European Standarization. UNE 38347:2004. Aluminio y Aleaciones de Aluminio Para Forja. Serie 5000; AENOR: Madrid, Spain, 2004. [Google Scholar]

- Whitford Company Industrial Bakeware. Runcorn, Cheshire, UK. Available online: https://www.whitfordww.com/markets-we-serve/industrial-bakeware/ (accessed on 18 November 2018).

- International Organization for Standardization. International Standard ISO 2808:2007 Paint and Varnishes—Determination of Film Thikness; International Organization for Standardization: Geneva, Switzerland, 2007; pp. 1–38. [Google Scholar]

- International Organization for Standardization. ISO 14577-1:2015, Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method; International Organization for Standardization: Geneva, Switzerland, 2015; pp. 1–46. [Google Scholar]

- Ruiz-Cabello, F.J.M.; Rodríguez-Valverde, M.A.; Cabrerizo-Vílchez, M. A new method for evaluating the most stable contact angle using tilting plate experiments. Soft Matter 2011, 7, 10457–10461. [Google Scholar] [CrossRef]

- Ruiz-Cabello, F.J.M.; Rodríguez-Criado, J.C.; Cabrerizo-Vílchez, M.; Rodríguez-Valverde, M.A.; Guerrero-Vacas, G. Towards super-nonstick aluminized steel surfaces. Prog. Org. Coat. 2017, 109, 135–143. [Google Scholar] [CrossRef]

- AENOR. Una Norma Española-European Standarization. UNE-EN ISO 6892-1:2009 Materiales Metálicos. Ensayo de Tracción. Parte 1: Método de Ensayo a Temperatura Ambiente; AENOR: Madrid, Spain, 2010. [Google Scholar]

- Matienzo, L.J.; Zimmerman, J.A.; Egitto, F.D. Surface modification of fluoropolymers with vacuum ultraviolet irradiation Surface modification of fluoropolymers with vacuum ultraviolet irradiation. J. Vac. Sci. Technol. A 2014, 12, 2662–2671. [Google Scholar] [CrossRef]

- Bogdanowicz, K.A.; Pirone, D.; Prats-reig, J.; Id, V.A.; Reina, A.; Giamberini, M. In Situ Raman Spectroscopy as a Tool for Structural Insight into Cation Non-Ionomeric Polymer Interactions during Ion Transport. Polymers 2018, 10, 416. [Google Scholar] [CrossRef]

- Schmidt, M.J.J.; Li, L.; Spencer, J.T. Ablation of a chlorinated rubber polymer and TiO2 ceramic mixture with a Nd:YAG laser. Appl. Surf. Sci. 2000, 154–155, 53–59. [Google Scholar] [CrossRef]

- Schmidt, M.J.J.; Li, L.; Spencer, J.T. An investigation into the feasibility and characteristics of using a 2.5 kW high power diode laser for paint stripping. J. Mater. Process. Technol. 2003, 138, 109–115. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Agnew, S.R.; Brooks, J.R.; Tyler, T.J.; Fitz-Gerald, J.M. Effects of laser ablation coating removal (LACR) on a steel substrate: Part 2: Residual stress and fatigue. Surf. Coat. Technol. 2015, 281, 206–214. [Google Scholar] [CrossRef]

- Guerrero-Vacas, G. Análisis Comparativo de los Procesos de Eliminación de Recubrimientos Antiadherentes Fluoro-Poliméricos en Superficies Metálicas Entre Tecnologías Láser y Pirolíticas. Ph.D. Thesis, Universidad de Málaga, Málaga, Spain, 2013. [Google Scholar]

- Pantelakis, S.G.; Haidemenopoulos, G.N. Effect of novel paint removal processes on the fatigue behavior of aluminum alloy 2024. Surf. Coat. Technol. 1998, 106, 198–204. [Google Scholar] [CrossRef]

- Nemeth, J.P.; Klingenberg, M.L.; Valencia, J.J.; Price, G.A.; Adams, J.R.; Blair, T.P. Naval Application of Laser Ablation Paint Removal Technology; Navy Metalworking Center–Office of Naval Research: Johnstown, PA, USA, 2010. [Google Scholar]

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Analyzed | 0.15 | 0.37 | 0.07 | 0.52 | 1.89 | 0.02 | 0.37 | 0.01 | 96.59 |

| UNE 38347:2004 | 0–0.40 | 0–0.50 | 0–0.15 | 0.1–0.5 | 1.7–2.4 | 0–0.15 | 0–0.15 | 0–0.15 | rest |

| Coating | Roughness | Cycle 1 | Cycle 2 | Cycle 3 |

|---|---|---|---|---|

| FEP | Ra (μm) | 0.22 | 0.26 | 0.27 |

| Rz (μm) | 1.21 | 1.49 | 1.48 | |

| PTFE | Ra (μm) | 0.73 | 1.01 | 2.40 |

| Rz (μm) | 5.01 | 5.61 | 12.33 |

| Coating Thickness (µm ± σ) | Microhardness (MPa/µm) | Angle (°) Static/Advance/Retreat | Reflectance (%) at 1064 nm | |

|---|---|---|---|---|

| FEP | 61.3 ± 0.88 | 30/8 | 104/109/97 | 28–29 |

| 22/20 | ||||

| PTFE | 19.09 ± 4.09 | 70/0.3 | 112/114/103 | 5–6 |

| 60/2 |

| Test Number | Power (W) | Scanning Frequency (Hz) | Advance Speed (mm/s) | Passes | Stripping Rate (cm2/min) | Process Fluence (J/cm2) | |

|---|---|---|---|---|---|---|---|

| PTFE | T1 | 500 | 800 | 8.33 | 1 | 600 | 50 |

| T2 | 500 | 400 | 8.33 | 1 | 600 | 50 | |

| T3 | 500 | 500 | 8.33 | 1 | 600 | 50 | |

| T4 | 500 | 600 | 8.33 | 1 | 600 | 50 | |

| T5 | 500 | 600 | 10 | 1 | 720 | 41.6 | |

| FEP | T6 | 800 | 200 | 2.5 | 2 | 90 | 266.6 |

| T7 | 900 | 200 | 2.5 | 2 | 90 | 300 | |

| T8 | 800 | 200 | 4.16 | 2 | 150 | 160 | |

| T9 | 600 | 200 | 5.83 | 2 | 210 | 85.7 | |

| T10 | 600 | 200 | 9.16 | 2 | 330 | 54.5 |

| Coating | Property (Substrate) | State of Supply (Transversal/Longitudinal) | Cycle 1 | Cycle 2 | Cycle 3 |

|---|---|---|---|---|---|

| FEP | Ra (μm) | 0.41/0.13 | 3.15 | 3.71 | 3.58 |

| Rz (μm) | 2.62/0.78 | 23.05 | 23.76 | 24.12 | |

| Thickness (mm) | 1.212 | 1.228 | 1.225 | 1.215 | |

| PTFE | Ra (μm) | 0.41/0.13 | 1.87 | 2.27 | 3.11 |

| Rz (μm) | 2.62/0.78 | 12.57 | 21.54 | 24.89 | |

| Thickness (mm) | 1.212 | 1.225 | 1.221 | 1.209 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Alabanda, Ó.; Romero, P.E.; Soriano, C.; Sevilla, L.; Guerrero-Vaca, G. Study on the Main Influencing Factors in the Removal Process of Non-Stick Fluoropolymer Coatings Using Nd:YAG Laser. Polymers 2019, 11, 123. https://doi.org/10.3390/polym11010123

Rodríguez-Alabanda Ó, Romero PE, Soriano C, Sevilla L, Guerrero-Vaca G. Study on the Main Influencing Factors in the Removal Process of Non-Stick Fluoropolymer Coatings Using Nd:YAG Laser. Polymers. 2019; 11(1):123. https://doi.org/10.3390/polym11010123

Chicago/Turabian StyleRodríguez-Alabanda, Óscar, Pablo E. Romero, Carlos Soriano, Lorenzo Sevilla, and Guillermo Guerrero-Vaca. 2019. "Study on the Main Influencing Factors in the Removal Process of Non-Stick Fluoropolymer Coatings Using Nd:YAG Laser" Polymers 11, no. 1: 123. https://doi.org/10.3390/polym11010123

APA StyleRodríguez-Alabanda, Ó., Romero, P. E., Soriano, C., Sevilla, L., & Guerrero-Vaca, G. (2019). Study on the Main Influencing Factors in the Removal Process of Non-Stick Fluoropolymer Coatings Using Nd:YAG Laser. Polymers, 11(1), 123. https://doi.org/10.3390/polym11010123