Reynolds Stress Model for Viscoelastic Drag-Reducing Flow Induced by Polymer Solution

Abstract

:1. Introduction

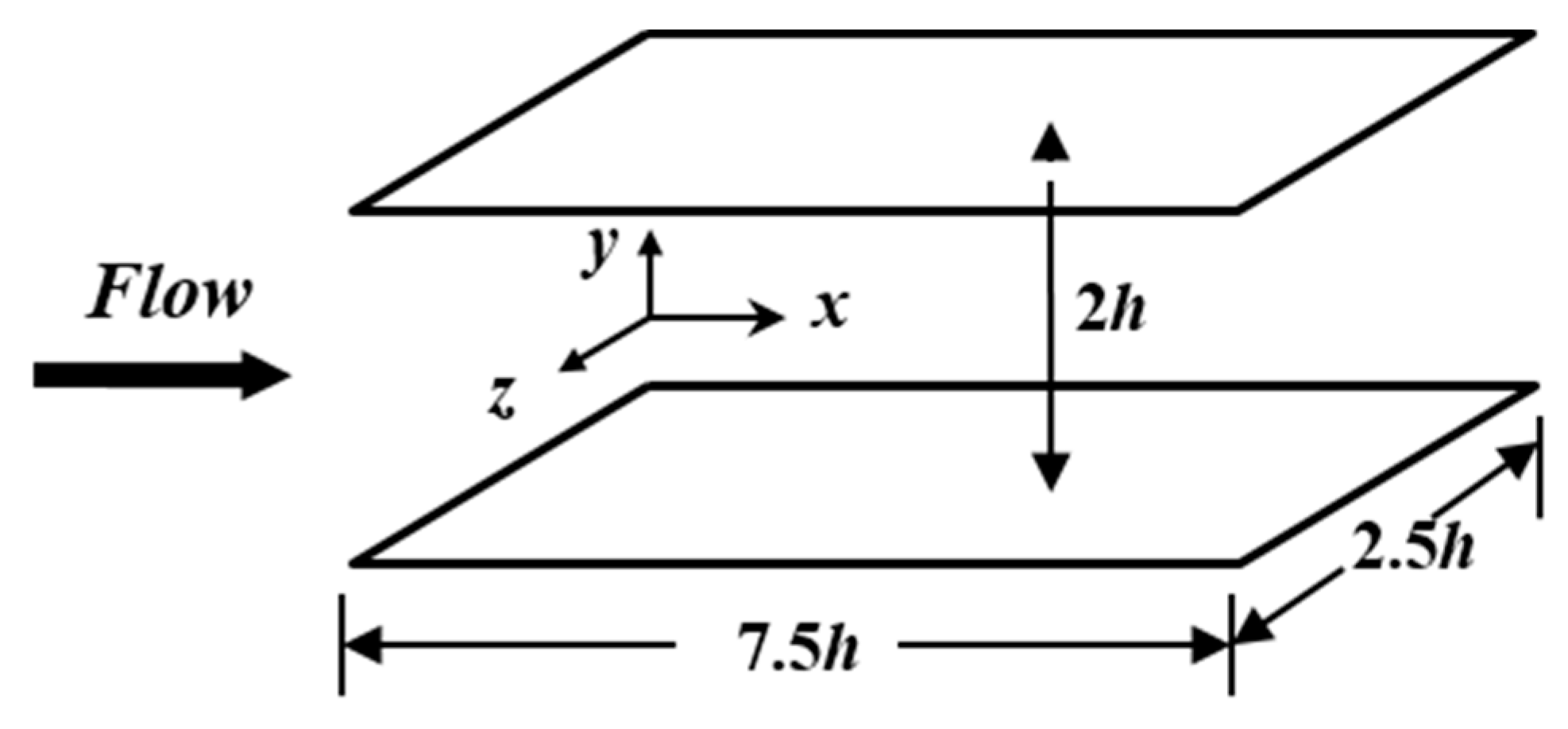

2. Governing Equations

2.1. Instantaneous Equations

2.2. Time-Average Equations

3. Modeling of High-Order Moments of Fluctuations

3.1. High-Order Moments Directly Related to Viscoelasticity

3.2. High-Order Moments Indirectly Related to Viscoelasticity

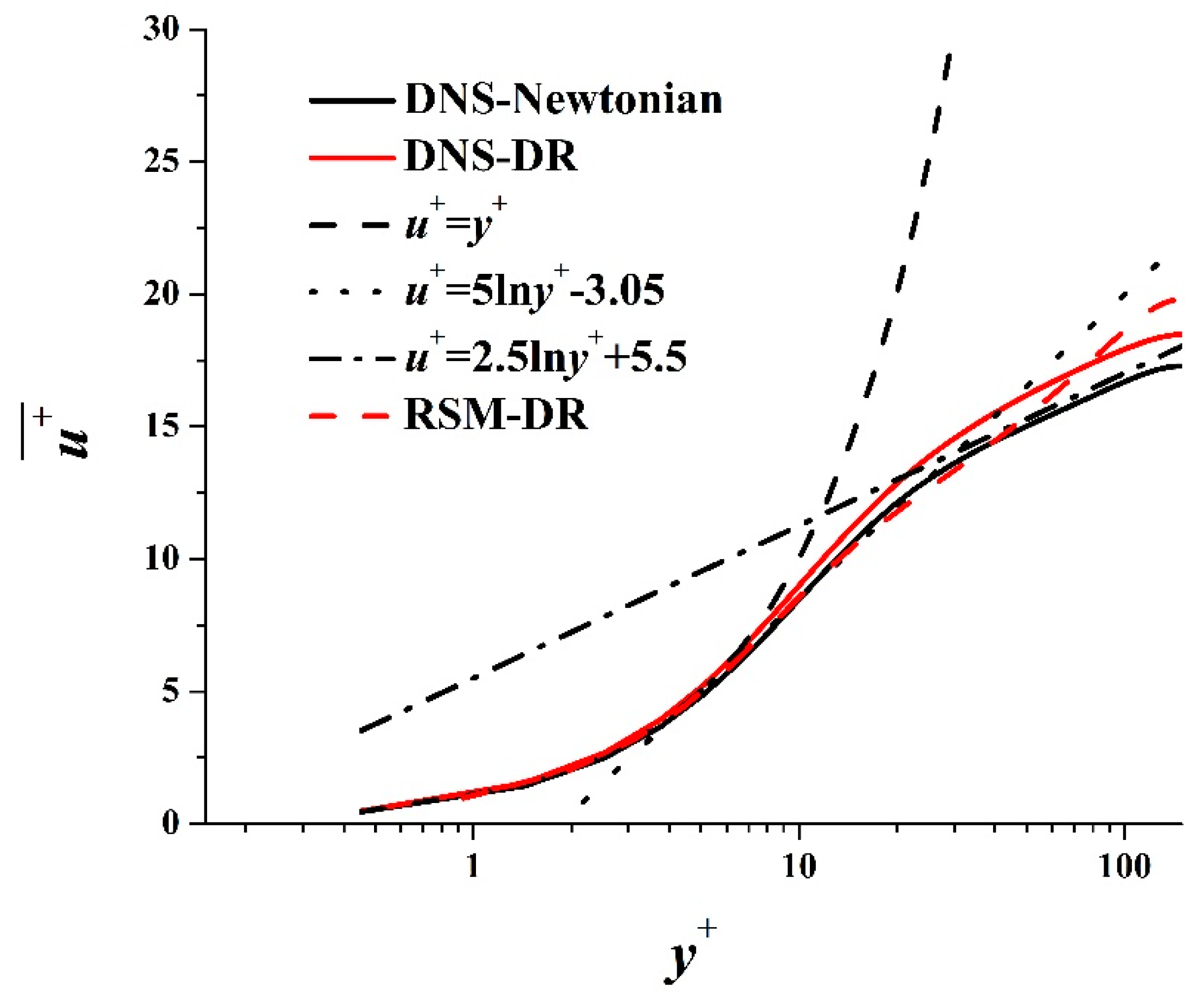

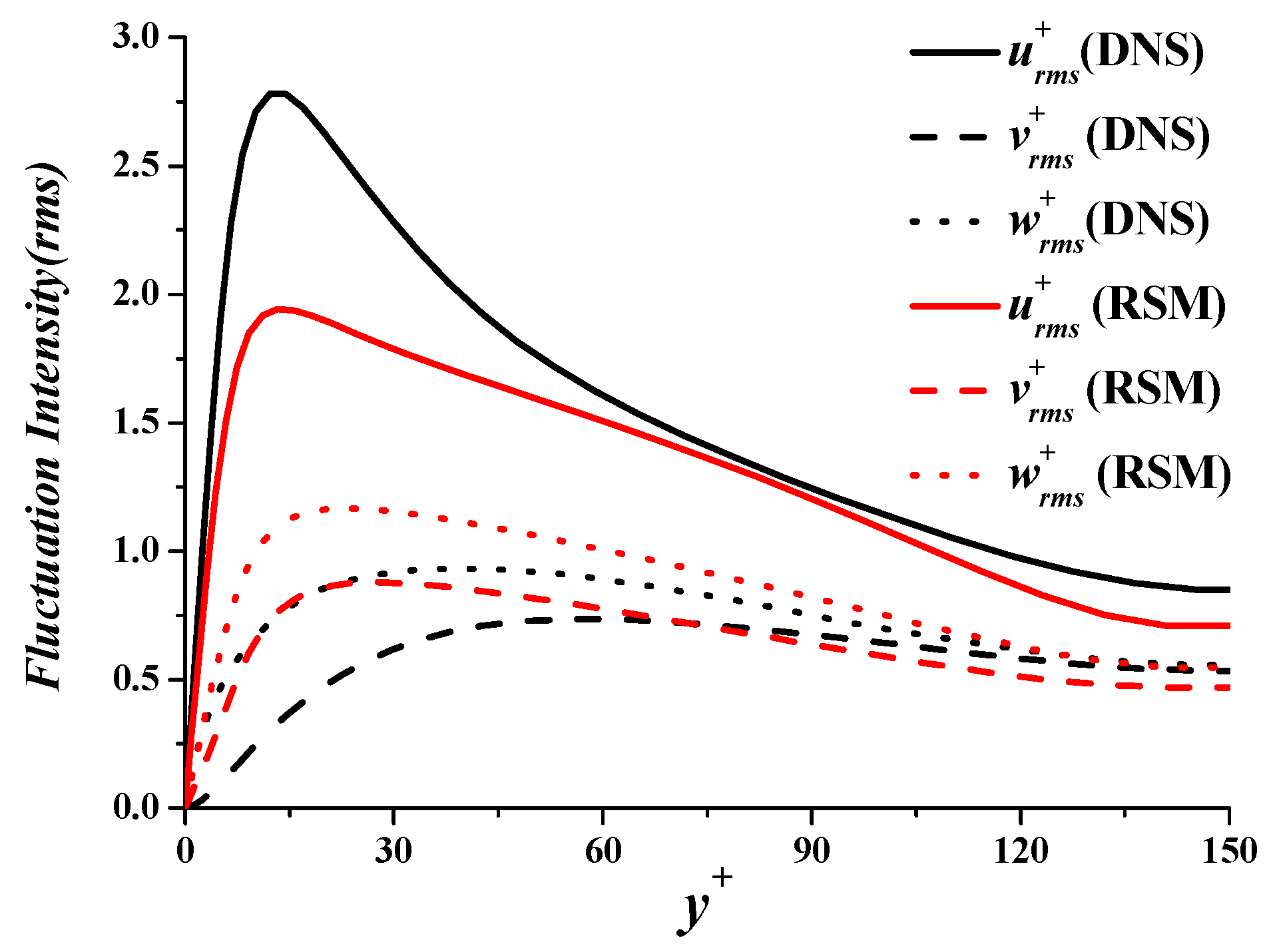

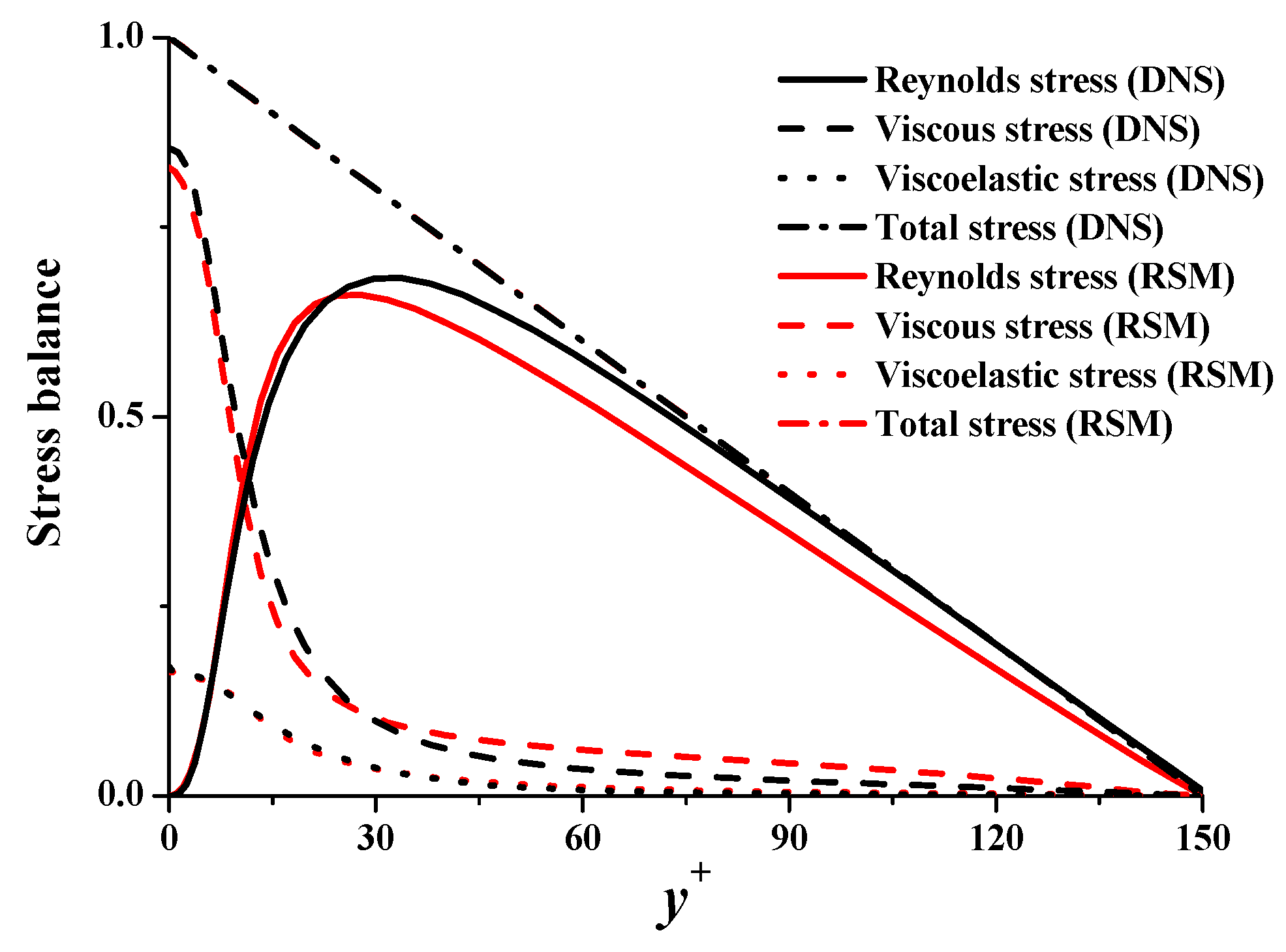

4. Results and Discussion

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Toms, B.A. Some observations on the flow of linear polymer solutions through straight tubes at large Reynolds numbers. Proc. Int. Congr. Rheol. 1948, 135, 1948. [Google Scholar]

- Burger, E.D.; Munk, W.R.; Wahl, H.A. Flow increase in the Trans Alaska Pipeline through use of a polymeric drag reducing additive. J. Petrol. Technol. 1982, 34, 377–386. [Google Scholar] [CrossRef]

- Motier, J.F.; Chou, L.C.; Kommareddi, N.S. Commercial drag reduction: Past, present, and future. In Proceedings of the ASME Fluids Engineering Division Summer Meeting; ASME: San Diego, CA, USA, 1996; pp. 229–234. [Google Scholar]

- Nijs, L. New generation drag reducer. Pipeline Technology 1995, 2, 143–149. [Google Scholar]

- Dujmovich, T.; Gallegos, A. Drag reducers improve throughput cut costs. Offshore 2005, 65, 1–4. [Google Scholar]

- Motier, J.F.; Carreir, A.M. Recent studies on polymer drag reduction in commercial pipelines. In Drag Reduction in Fluid Flows: Techniques for Friction Control; Sellin, R., Moses, R., Eds.; Ellis Horwood: West Sussex, UK, 1989; pp. 197–204. [Google Scholar]

- Sureshkumar, R.; Beris, A.N.; Handler, R.A. Direct numerical simulation of the turbulent channel flow of a polymer solution. Phys. Fluids 1997, 9, 743–755. [Google Scholar] [CrossRef]

- Dimitropoulos, C.D.; Sureshkumar, R.; Beris, A.N. Direct numerical simulation of viscoelastic turbulent channel flow exhibiting drag reduction: Effect of the variation of rheological parameters. J. Non-Newtonian Fluid Mech. 1998, 78, 433–468. [Google Scholar] [CrossRef]

- Min, T.; Yoo, J.Y.; Choi, H.; Joseph, D.D. Drag reduction by polymer additives in a turbulent channel flow. J. Fluid Mech. 2003, 486, 213–238. [Google Scholar] [CrossRef] [Green Version]

- Ptasinski, P.K.; Boersma, B.J.; Nieuwstadt, F.T.M.; Hulsen, M.A.; Van Den Brule, B.H.A.A.; Hunt, J.C.R. Turbulent channel flow near maximum drag reduction: Simulations, experiments and mechanisms. J. Fluid Mech. 2003, 490, 251–291. [Google Scholar] [CrossRef]

- White, C.M.; Mungal, M.G. Mechanics and prediction of turbulent drag reduction with polymer additives. Ann. Rev. Fluid Mech. 2008, 40, 235–256. [Google Scholar] [CrossRef]

- Dubief, Y.; White, C.; Terrapon, V.; Shaqfeh, E.; Moin, P.; Lele, S. On the coherent drag-reducing and turbulence-enhancing behaviour of polymers in wall flows. J. Fluid Mech. 2004, 514, 271–280. [Google Scholar] [CrossRef]

- Graham, M.D. Drag reduction and the dynamics of turbulence in simple and complex fluids. Phys. Fluids 2014, 26, 625–656. [Google Scholar] [CrossRef]

- Thais, L.; Mompean, G.; Gatski, T.B. Spectral analysis of turbulent viscoelastic and Newtonian channel flows. J. Non-Newtonian. Fluid Mech. 2013, 200, 165–176. [Google Scholar] [CrossRef]

- Pereira, A.S.; Mompean, G.; Thais, L.; Thompson, R.L. Statistics and tensor analysis of polymer coil-stretch mechanism in turbulent drag reducing channel flow. J. Fluid Mech. 2017, 824, 135–173. [Google Scholar] [CrossRef]

- Pereira, A.S.; Mompean, G.; Thais, L.; Soares, E.J.; Thompson, R.L. Active and hibernating turbulence in drag-reducing plane Couette flows. Phys. Rev. Fluids 2017, 2, 084605. [Google Scholar] [CrossRef]

- Edwards, M.F.; Smith, R. The use of eddy viscosity expressions for predecting velocity profiles in Newtonian, non-Newtonian and drag-reducing turbulent pipe flow. J. Non-Newtonian. Fluid Mech. 1980, 7, 153–169. [Google Scholar] [CrossRef]

- Azouz, I.; Shirazi, S.A. Numerical simulation of drag reducing turbulent flow in annular conduits. ASME J. Fluids Eng. 1997, 119, 838–846. [Google Scholar] [CrossRef]

- Durst, F.; Rastogi, A.K. Calculations of turbulent boundary layer flows with drag reducing polymer additives. Phys. Fluids 1977, 20, 1975–1985. [Google Scholar] [CrossRef]

- Hassid, S.; Poreh, M. A turbulent energy model for flows with drag reduction. ASME J. Fluids Eng. 1975, 97, 234–241. [Google Scholar] [CrossRef]

- Hassid, S.; Poreh, M. A Turbulent energy dissipation model for flows with drag reduction. Trans. ASME J. Fluids Eng. 1978, 100, 107–112. [Google Scholar] [CrossRef]

- Poreh, M.; Hassid, S. Mean velocity and turbulent energy closures for flows with drag reduction. Phys. Fluids 1977, 20, S193–S196. [Google Scholar] [CrossRef]

- Cruz, D.O.A.; Pinho, F.T. Turbulent pipe flow predictions with a low Reynolds number k–ε model for drag reducing fluids. J. Non-Newtonian. Fluid Mech. 2003, 114, 109–148. [Google Scholar] [CrossRef]

- Pinho, F.T. A GNF framework for turbulent flow models of drag reducing fluids and proposal for a k–ε type closure. J. Non-Newtonian. Fluid Mech. 2003, 114, 149–184. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, B.; Wu, X.; Wang, P. POD and wavelet analyses on the flow structures of a polymer drag-reducing flow based on DNS data. Int. J. Heat Mass Transf. 2012, 55, 4849–4861. [Google Scholar] [CrossRef]

- Daly, B.J.; Harlow, F.H. Transport Equations in turbulence. Phys. Fluids 1970, 13, 2634–2649. [Google Scholar] [CrossRef]

- Shima, N. Low-Reynolds-number second-moment closure without wall-reflection redistribution terms. Int. J. Heat Fluid Flow 1998, 19, 549–555. [Google Scholar] [CrossRef]

- Dean, R.B. Reynolds number dependence of skin friction and other bulk flow variables in two-dimensional rectangular duct flow. J. Fluids Eng. 1978, 100, 215–223. [Google Scholar] [CrossRef]

- Virk, P.S.; Mickley, H.S.; Smith, K.A. The ultimate asymptote and mean flow structure in Toms’ phenomenon. J. Appl. Mech. 1970, 37, 488–493. [Google Scholar] [CrossRef]

- Yu, B.; Kawaguchi, Y. Effect of Weissenberg number on the flow structure DNS study of drag-reducing flow with surfactant additives. Int. J. Heat Fluid Flow 2003, 24, 491–499. [Google Scholar] [CrossRef]

- Housiadas, K.D.; Beris, A.N. On the skin friction coefficient in viscoelastic wall-bounded flows. Int. J. Heat Fluid Flow 2013, 42, 49–67. [Google Scholar] [CrossRef]

| Rem | Cf | DR% | ||

|---|---|---|---|---|

| Direct numerical simulation (DNS) | 15.87 | 4762 | 0.0079 | 9.7% |

| Reynolds stress model (RSM) | 15.96 | 4789 | 0.0078 | 10.6% |

| Rem | Cf | DR% | ||

|---|---|---|---|---|

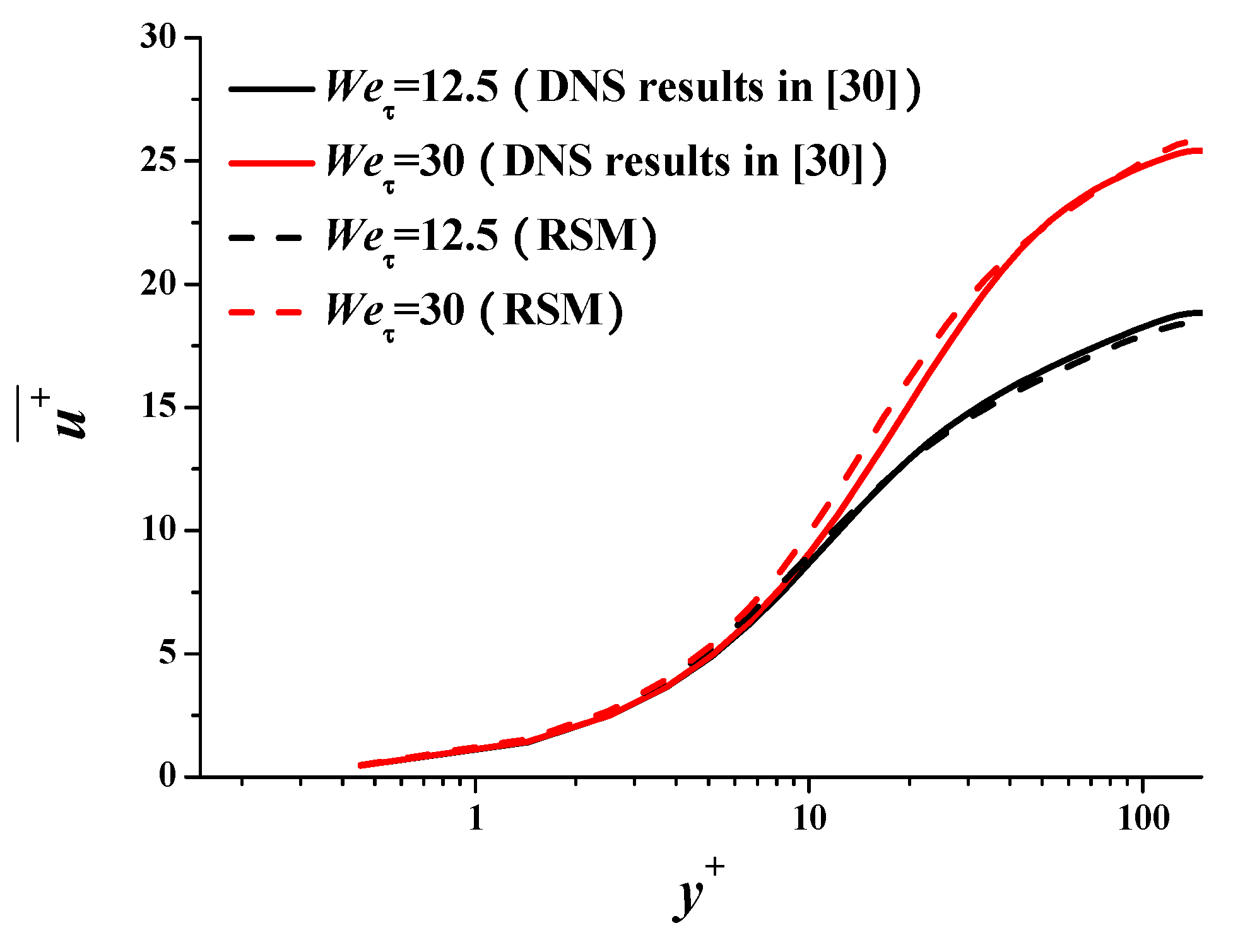

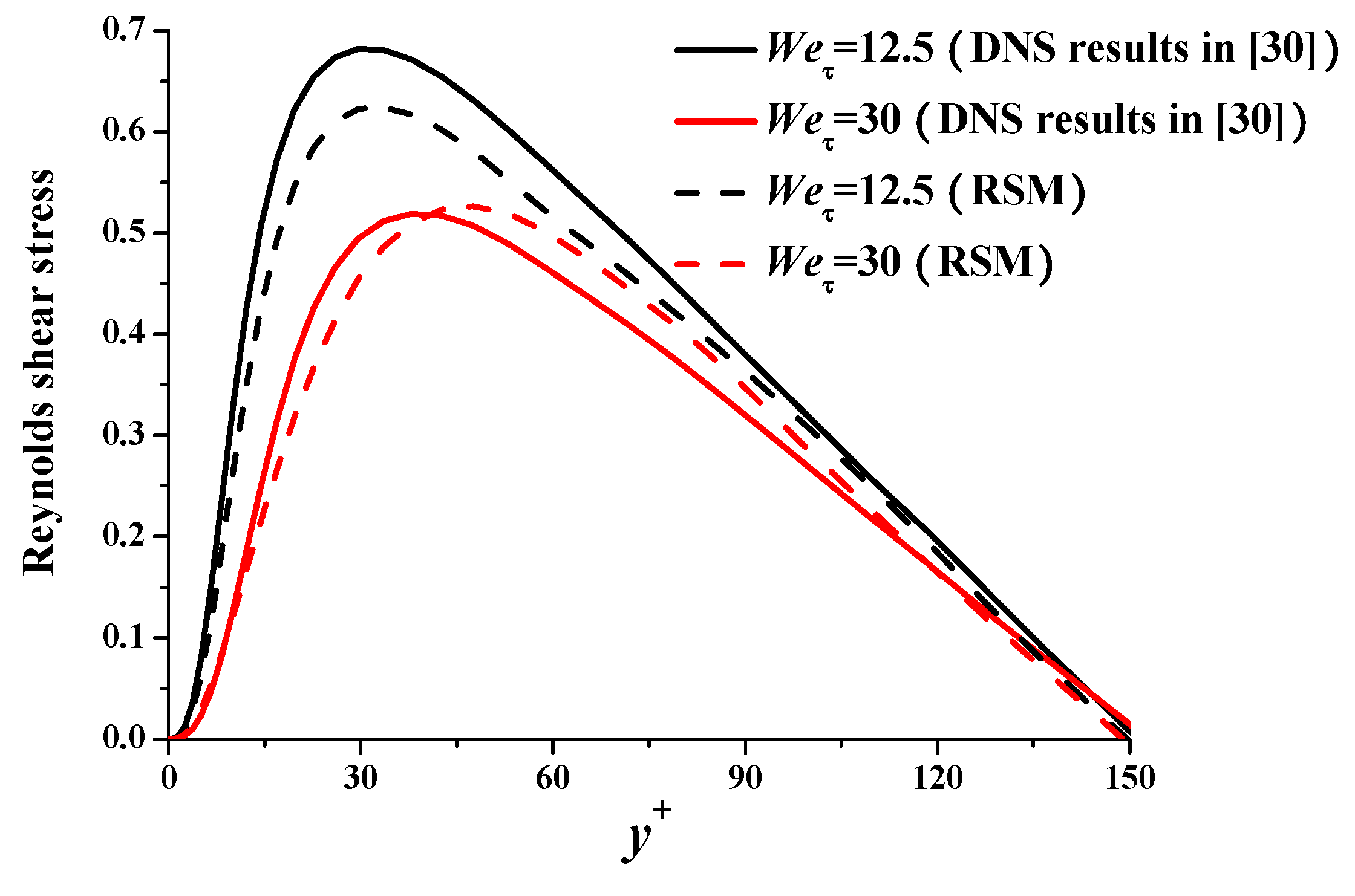

| DNS (Weτ = 12.5) [30] | 16.13 | 4838 | 0.00769 | 12.1% |

| RSM (Weτ = 12.5) | 16.10 | 4829 | 0.00772 | 11.9% |

| DNS (Weτ = 30) [30] | 20.6 | 6180 | 0.00471 | 42.8% |

| RSM (Weτ = 30) | 21.2 | 6373 | 0.00443 | 45.8% |

| DNS | RSM | Acceleration Ratio |

|---|---|---|

| 604,800s | 5s | 120,960 |

| Case | DNS | RSM | Deviation |

|---|---|---|---|

| Reτ = 125, Weτ = 50, β = 0.9 | 29.8% | 29.2% | 2.0% |

| Reτ = 180, Weτ = 50, β = 0.9 | 29.9% | 28.6% | 4.3% |

| Reτ = 395, Weτ = 50, β = 0.9 | 29.6% | 25.7% | 13.2% |

| Case | DR% |

|---|---|

| Reτ = 395, Weτ = 25, β = 0.9 | 24.7% |

| Reτ = 395, Weτ = 50, β = 0.9 | 25.7% |

| Reτ = 395, Weτ = 100, β = 0.9 | 28.0% |

| Reτ = 395, Weτ = 150, β = 0.9 | 33.8% |

| Reτ = 395, Weτ = 200, β = 0.9 | 41.1% |

| Reτ = 395, Weτ = 250, β = 0.9 | 44.4% |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y. Reynolds Stress Model for Viscoelastic Drag-Reducing Flow Induced by Polymer Solution. Polymers 2019, 11, 1659. https://doi.org/10.3390/polym11101659

Wang Y. Reynolds Stress Model for Viscoelastic Drag-Reducing Flow Induced by Polymer Solution. Polymers. 2019; 11(10):1659. https://doi.org/10.3390/polym11101659

Chicago/Turabian StyleWang, Yi. 2019. "Reynolds Stress Model for Viscoelastic Drag-Reducing Flow Induced by Polymer Solution" Polymers 11, no. 10: 1659. https://doi.org/10.3390/polym11101659

APA StyleWang, Y. (2019). Reynolds Stress Model for Viscoelastic Drag-Reducing Flow Induced by Polymer Solution. Polymers, 11(10), 1659. https://doi.org/10.3390/polym11101659