Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing

Abstract

:1. Introduction

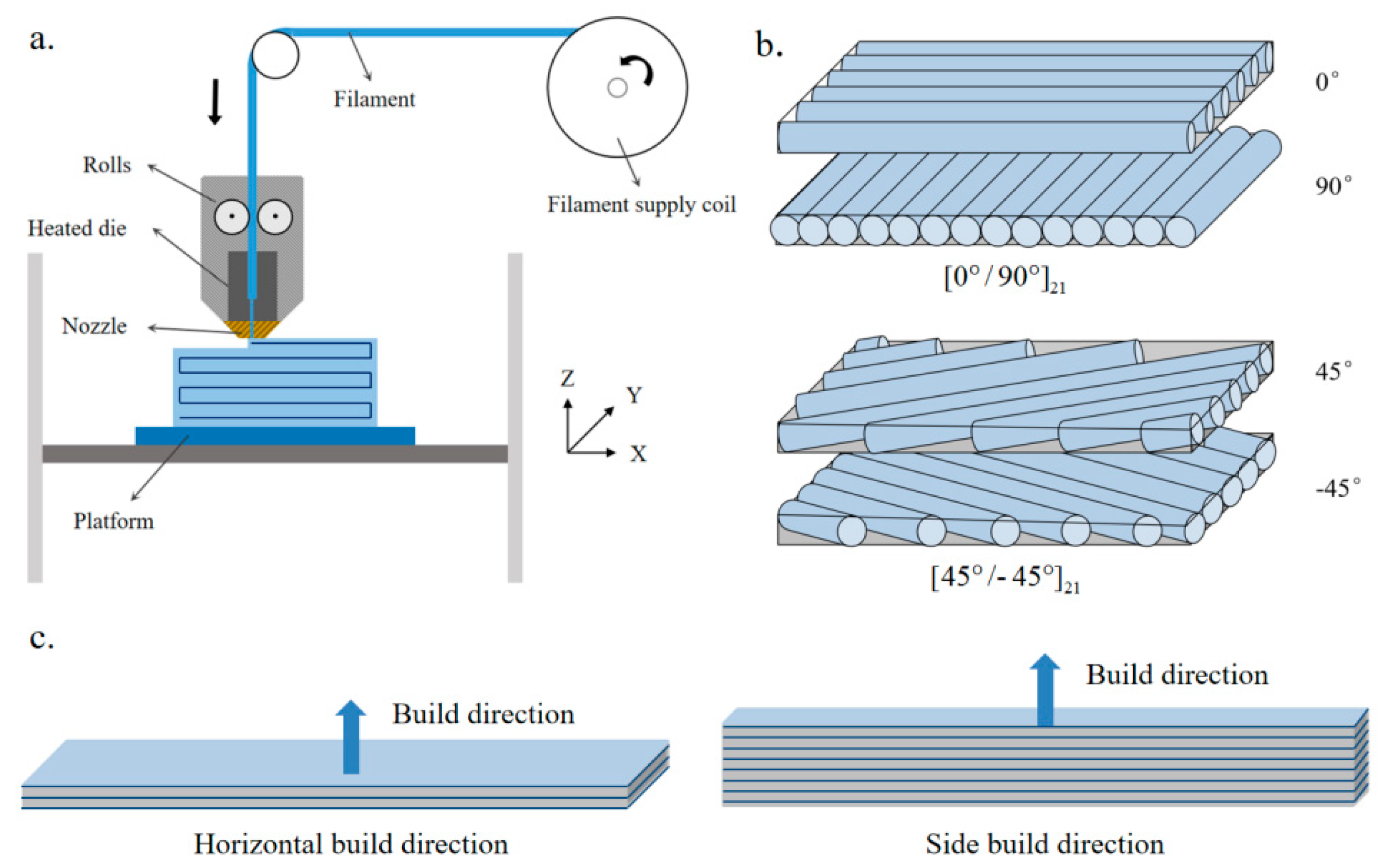

2. Experimental Methodology

2.1. Materials and Processing

2.2. Characterization

3. Results and Discussion

3.1. Thermal and Morphological Behaviors of the Filament Tows

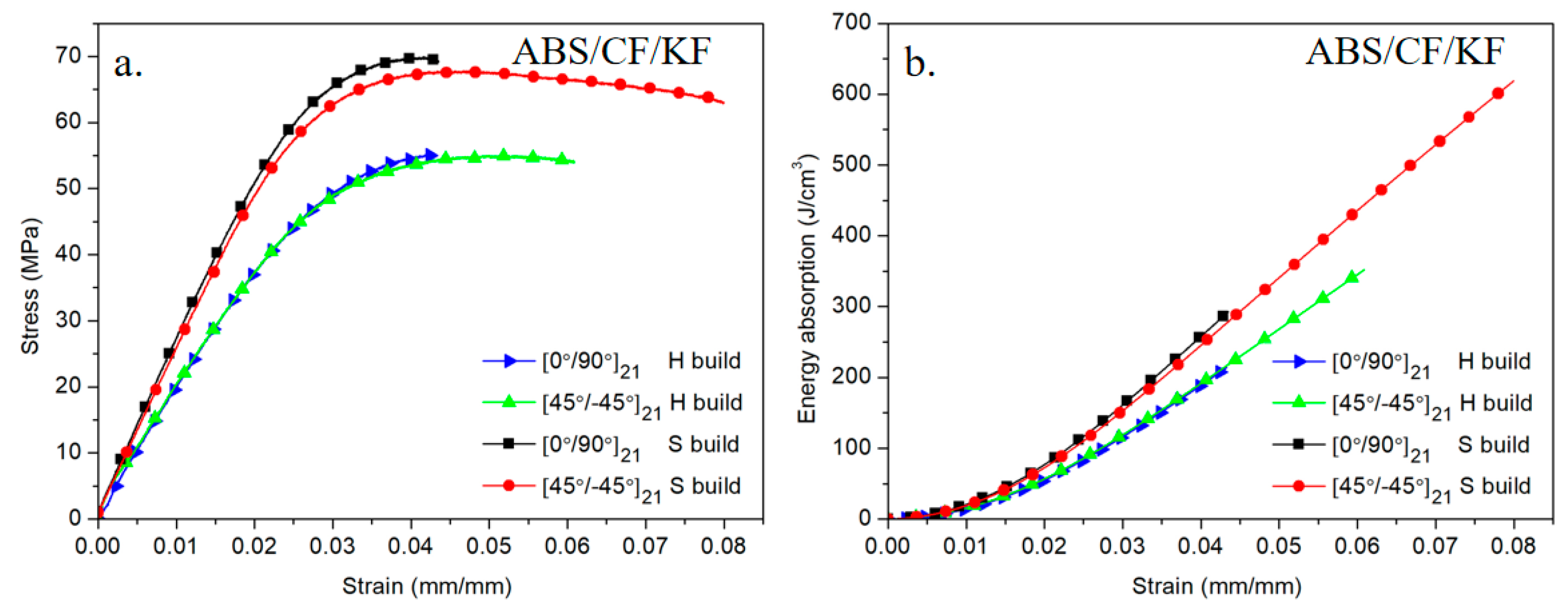

3.2. Flexural Behavior of the Printed Materials

3.2.1. Effect of Raster Orientations

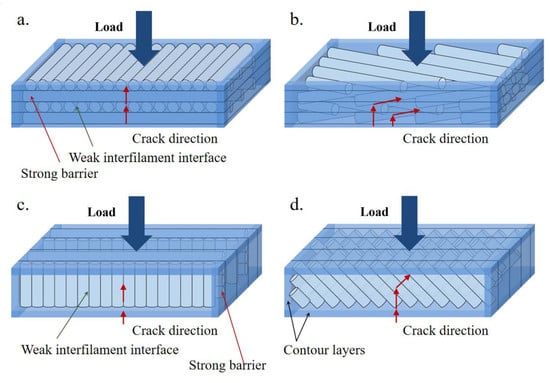

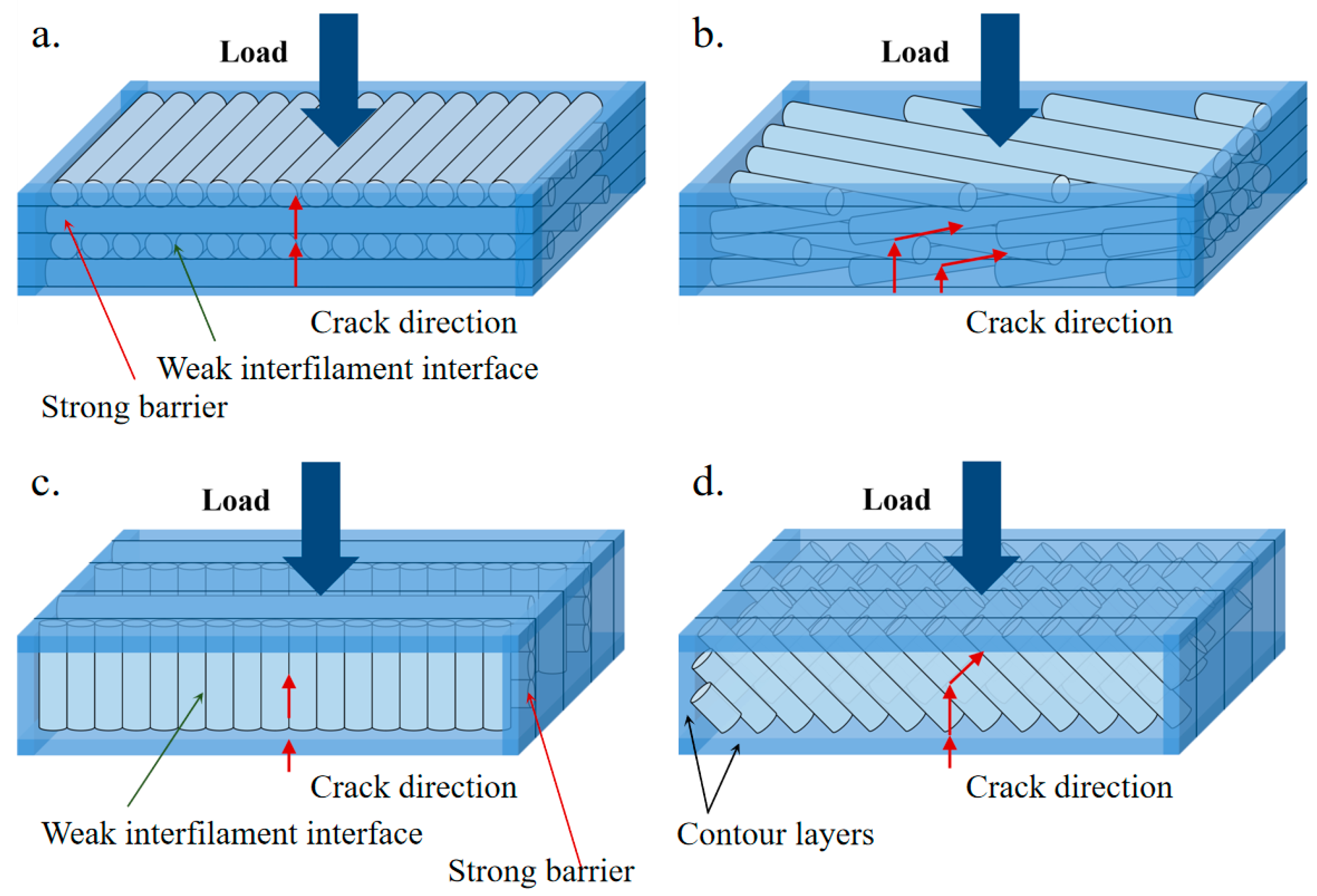

3.2.2. Effect of Building Directions

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Nizam, A.; Gopal, R.; Naing, N.; Hakim, A.; Samsudin, A. Dimensional accuracy of the skull models produced by rapid prototyping technology using stereolithography apparatus. Arch. Orofac. Sci. 2006, 1, 60–66. [Google Scholar]

- Singh, R. Process capability study of polyjet printing for plastic components. J. Mech. Sci. Technol. 2011, 25, 1011–1015. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Zhong, W.; Li, F.; Zhang, Z.; Song, L.; Li, Z. Short fiber reinforced composites for fused deposition modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Kumar, S.; Pityana, S. Laser-based additive manufacturing of metals. Adv. Mater. Res. Trans. Tech. Publ. 2011, 227, 92–95. [Google Scholar] [CrossRef]

- Feygin, M.; Hsieh, B. Laminated object manufacturing (LOM): A simpler process. In Proceedings of the 1991 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 1991. [Google Scholar]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive layer manufacturing of poly (ether ether ketone) via FDM. Compos. Part B Eng. 2018, 145, 162–172. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, W.; Li, Y.; Yang, W.; Wang, G. Flexural properties and fracture behavior of CF/PEEK in orthogonal building orientation by FDM: Microstructure and mechanism. Polymers 2019, 11, 656. [Google Scholar] [CrossRef]

- Christiyan, K.J.; Chandrasekhar, U.; Venkateswarlu, K. A study on the influence of process parameters on the Mechanical Properties of 3D printed ABS composite. In Proceedings of the IOP Conference Series. Materials Science and Engineering, Kozani, Greece, 23–25 September 2016; IOP Publishing: Bristol, UK, 2016; p. 012109. [Google Scholar]

- Chacón, J.; Caminero, M.; García-Plaza, E.; Núñez, P. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D printed long fibre reinforced composites. Compos. Struct. 2018, 185, 537–548. [Google Scholar] [CrossRef]

- Wang, K.; Addiego, F.; Bahlouli, N.; Ahzi, S.; Rémond, Y.; Toniazzo, V. Impact response of recycled polypropylene-based composites under a wide range of temperature: Effect of filler content and recycling. Compos. Sci. Technol. 2014, 95, 89–99. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Fan, J.; Chen, A. Studying a flexible polyurethane elastomer with improved impact-resistant performance. Polymers 2019, 11, 467. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, Y.; Hou, L.; Wang, D.; Tian, G.; Li, Z. Multistage impact energy distribution for whole vehicles in high-speed train collisions: Modeling and solution methodology. IEEE Trans. Ind. Inform. 2019. [Google Scholar] [CrossRef]

- Cui, H.; Thomson, D.; Pellegrino, A.; Wiegand, J.; Petrinic, N. Effect of strain rate and fibre rotation on the in-plane shear response of±45° laminates in tension and compression tests. Compos. Sci. Technol. 2016, 135, 106–115. [Google Scholar] [CrossRef]

- Fernandez-Vicente, M.; Calle, W.; Ferrandiz, S.; Conejero, A. Effect of infill parameters on tensile mechanical behavior in desktop 3D printing. 3D Print. Addit. Manuf. 2016, 3, 183–192. [Google Scholar] [CrossRef]

- Ziemian, C.; Sharma, M.; Ziemian, S. Anisotropic mechanical properties of ABS parts fabricated by fused deposition modelling. In Mechanical Engineering; InTechOpen: London, UK, 2012. [Google Scholar]

- Jian, R.-K.; Chen, L.; Chen, S.-Y.; Long, J.-W.; Wang, Y.-Z. A novel flame-retardant acrylonitrile-butadiene-styrene system based on aluminum isobutylphosphinate and red phosphorus: Flame retardance, thermal degradation and pyrolysis behavior. Polym. Degrad. Stab. 2014, 109, 184–193. [Google Scholar] [CrossRef]

- Serbezeanu, D.; Popa, A.M.; Stelzig, T.; Sava, I.; Rossi, R.M.; Fortunato, G. Preparation and characterization of thermally stable polyimide membranes by electrospinning for protective clothing applications. Text. Res. J. 2015, 85, 1763–1775. [Google Scholar] [CrossRef]

- Nie, W.; LIu, J.; LIu, W.; Wang, J.; Tang, T. Decomposition of waste carbon fiber reinforced epoxy resin composites in molten potassium hydroxide. Polym. Degrad. Stab. 2015, 111, 247–256. [Google Scholar] [CrossRef]

- Berber, S.; Kwon, Y.-K.; Tománek, D. Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 2000, 84, 4613. [Google Scholar] [CrossRef]

- Li, D.-S.; Yao, Q.-Q.; Jiang, N.; Jiang, L. Bend properties and failure mechanism of a carbon/carbon composite with a 3D needle-punched preform at room and high temperatures. New Carbon Mater. 2016, 31, 437–444. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, Y.; Wang, K.; Gao, G.; Ahzi, S. Synergistic reinforcement of polyamide-based composites by combination of short and continuous carbon fibers via fused filament fabrication. Compos. Struct. 2019, 207, 232–239. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Mechanical properties of continuous kevlar fiber reinforced composites fabricated by fused deposition modeling process. Procedia Manuf. 2018, 26, 774–781. [Google Scholar] [CrossRef]

- Pourdeyhimi, B.; Robinson, H.; Schwartz, P.; Wagner, H. Fracture toughness of Kevlar 29/poly (methyl methacrylate) composite materials for surgical implantations. Ann. Biomed. Eng. 1986, 14, 277–294. [Google Scholar] [CrossRef]

- Rabbi, M.; Chalivendra, V.; Li, D. A novel approach to increase dynamic fracture toughness of additively manufactured polymer. Exp. Mech. 2019, 59, 1–13. [Google Scholar] [CrossRef]

- Zaldivar, R.; Witkin, D.; McLouth, T.; Patel, D.; Schmitt, K.; Nokes, J. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM® 9085 material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- McLouth, T.D.; Severino, J.V.; Adams, P.M.; Patel, D.N.; Zaldivar, R.J. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit. Manuf. 2017, 18, 103–109. [Google Scholar] [CrossRef]

- Melenka, G.W.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation of dimensional accuracy and material properties of the MakerBot 3D desktop printer. Rapid Prototyp. J. 2015, 21, 618–627. [Google Scholar] [CrossRef]

| Fiber | Mean Length (μm) | Mono Fiber Diameter (μm) | Fiber Population (Unit/g of Filament) |

|---|---|---|---|

| CF | 251.00 | 7.00 ± 2.00 | 4.37 × 106 |

| KF | 215.00 | 10.00 ± 2.00 | 5.00 × 106 |

| Material | Raster Orientation | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|

| ABS | 0°/90° | 48.45 ± 1.55 | 1563.00 ± 44.10 |

| ±45° | 48.38 ± 1.80 | 1419.52 ± 30.38 | |

| ABS/CF | 0°/90° | 53.73 ± 1.35 | 2351.00 ± 31.51 |

| ±45° | 56.44 ± 1.60 | 2253.48 ± 35.04 | |

| ABS/KF | 0°/90° | 45.50 ± 0.66 | 1618.67 ± 39.22 |

| ±45° | 43.40 ± 1.35 | 1730.78 ± 47.31 | |

| ABS/CF/KF | 0°/90° | 56.46 ± 0.55 | 2167.17 ± 36.69 |

| ±45° | 55.51 ± 2.19 | 2110.08 ± 29.79 |

| Raster Orientation | Building Direction | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|

| 0°/90° | Horizontal | 56.46 ± 0.55 | 2167.17 ± 36.69 |

| Side | 69.87 ± 0.24 | 2683.33 ± 36.17 | |

| ±45° | Horizontal | 55.51 ± 2.19 | 2110.08 ± 29.79 |

| Side | 67.92 ± 0.09 | 2513.33 ± 43.12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Li, S.; Rao, Y.; Wu, Y.; Peng, Y.; Yao, S.; Zhang, H.; Ahzi, S. Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing. Polymers 2019, 11, 1878. https://doi.org/10.3390/polym11111878

Wang K, Li S, Rao Y, Wu Y, Peng Y, Yao S, Zhang H, Ahzi S. Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing. Polymers. 2019; 11(11):1878. https://doi.org/10.3390/polym11111878

Chicago/Turabian StyleWang, Kui, Shixian Li, Yanni Rao, Yiyun Wu, Yong Peng, Song Yao, Honghao Zhang, and Said Ahzi. 2019. "Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing" Polymers 11, no. 11: 1878. https://doi.org/10.3390/polym11111878

APA StyleWang, K., Li, S., Rao, Y., Wu, Y., Peng, Y., Yao, S., Zhang, H., & Ahzi, S. (2019). Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing. Polymers, 11(11), 1878. https://doi.org/10.3390/polym11111878