Improvement of Rice Husk/HDPE Bio-Composites Interfacial Properties by Silane Coupling Agent and Compatibilizer Complementary Modification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composite Materials

2.3. Bending Properties

2.4. ATR-FTIR Analysis

2.5. Thermal Properties

2.6. Dynamic Viscoelasticity

2.7. Scanning Electron Microscopy (SEM) Analysis

2.8. Surface Contact Angle Measurement

3. Results and Discussions

3.1. Effect of Interface Modification on Bending Strength

3.2. Effect of Interface Modification on Chemical Structure

3.3. Effect of Interface Modification on Thermal Stability

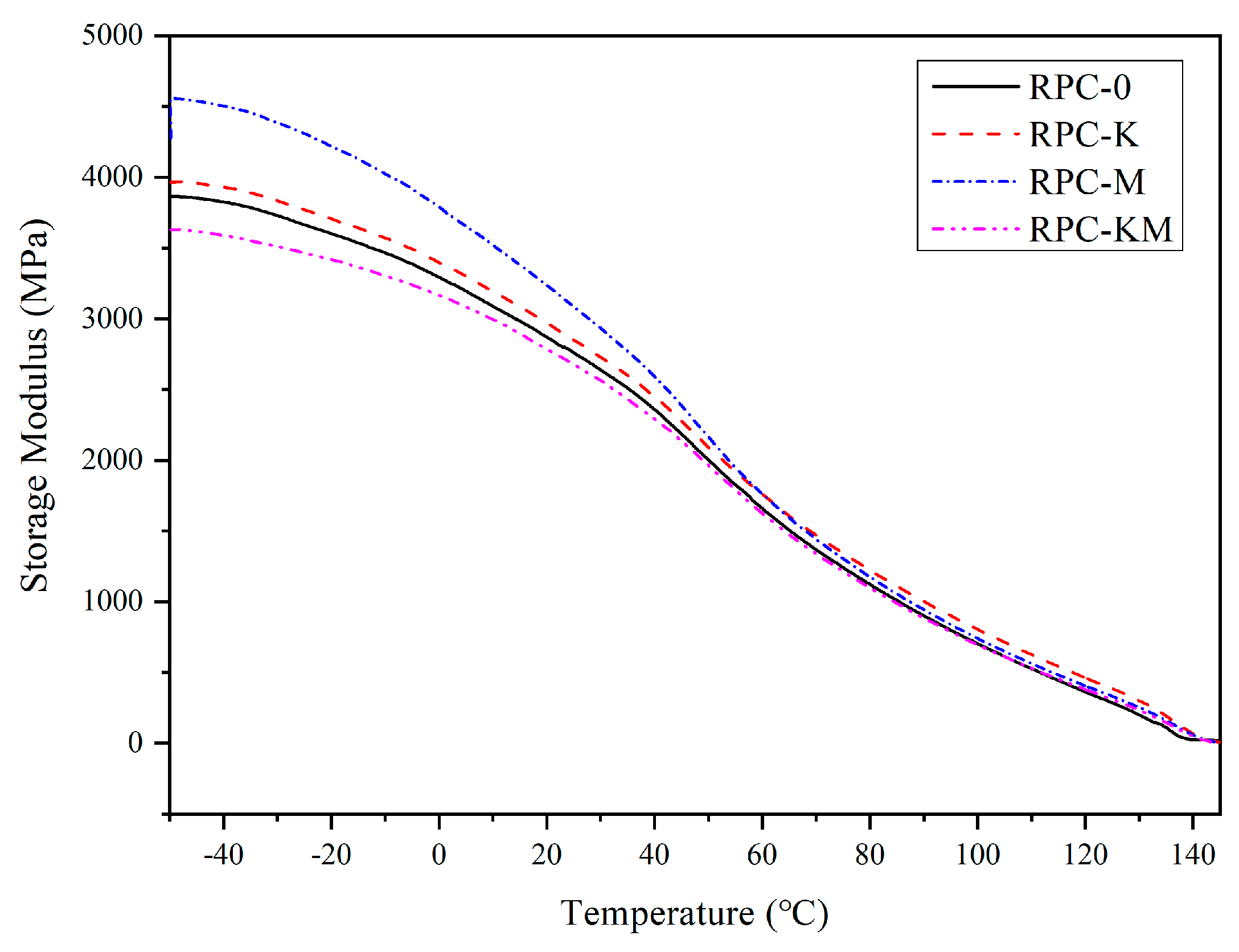

3.4. Effect of Interface Modification on Dynamic Thermomechanical Properties

3.5. Effect of Interface Modification on Microstructure

3.6. Effect of Interfacial Modification on Hydrophobic Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar, A.; Sengupta, B.; Dasgupta, D.; Mandal, T.; Datta, S. Recovery of value-added products from rice husk ash to explore an economic way for recycle and reuse of agricultural waste. Rev. Environ. Sci. Bio/Technol. 2015, 15, 47–65. [Google Scholar] [CrossRef]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crops Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Imagawa, A.; Seto, R.; Nagaosa, Y. Adsorption of chlorinated hydrocarbons from air and aqueous solutions by carbonized rice husk. Carbon 2000, 38, 628–630. [Google Scholar] [CrossRef]

- Adam, F.; Chua, J.-H. The adsorption of palmytic acid on rice husk ash chemically modified with Al(III) ion using the sol–gel technique. J. Colloid Interface Sci. 2004, 280, 55–61. [Google Scholar] [CrossRef]

- Akhtar, M.; Bhanger, M.I.; Iqbal, S.; Hasany, S.M. Sorption potential of rice husk for the removal of 2,4-dichlorophenol from aqueous solutions: Kinetic and thermodynamic investigations. J. Hazard. Mater. 2006, 128, 44–52. [Google Scholar] [CrossRef]

- Mohammadi, A.; Cowie, A.L.; Mai, T.L.A.; Brandao, M.; de la Rosa, R.A.; Kristiansen, P.; Joseph, S. Climate-change and health effects of using rice husk for biochar-compost: Comparing three pyrolysis systems. J. Clean. Prod. 2017, 162, 260–272. [Google Scholar] [CrossRef]

- Huang, H.J.; Yuan, X.Z.; Zeng, G.M.; Liu, Y.; Li, H.; Yin, J.; Wang, X.L. Thermochemical liquefaction of rice husk for bio-oil production with sub- and supercritical ethanol as solvent. J. Anal. Appl. Pyrolysis 2013, 102, 60–67. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, X.Z.; Huang, H.J.; Wang, X.L.; Wang, H.; Zeng, G.M. Thermochemical liquefaction of rice husk for bio-oil production in mixed solvent (ethanol–water). Fuel Process. Technol. 2013, 112, 93–99. [Google Scholar] [CrossRef]

- Ndazi, B.S.; Karlsson, S.; Tesha, J.V.; Nyahumwa, C.W. Chemical and physical modifications of rice husks for use as composite panels. Compos. Part A Appl. Sci. Manuf. 2007, 38, 925–935. [Google Scholar] [CrossRef]

- Park, B.D.; Wi, S.G.; Lee, K.H.; Singh, A.P.; Yoon, T.H.; Kim, Y.S. Characterization of anatomical features and silica distribution in rice husk using microscopic and micro-analytical techniques. Biomass Bioenergy 2003, 23, 319–327. [Google Scholar] [CrossRef]

- Bekhta, P.; Korkut, S.; Hiziroglu, S. Effect of Pretreatment of Raw Material on Properties of Particleboard Panels Made from Wheat Straw. Bioresources 2013, 8, 4766–4774. [Google Scholar] [CrossRef]

- Mamun, A.A.; Bledzki, A.K. Enzyme Modification of Grain By-products and Their Biocomposites: Characterization, Mechanical and Thermal Properties. Macromol. Mater. Eng. 2014, 299, 248–256. [Google Scholar] [CrossRef]

- Le Moigne, N.; Longerey, M.; Taulemesse, J.M.; Bénézet, J.C.; Bergeret, A. Study of the interface in natural fibres reinforced poly(lactic acid) biocomposites modified by optimized organosilane treatments. Ind. Crops Prod. 2014, 52, 481–494. [Google Scholar] [CrossRef]

- Qian, S.; Wang, H.; Zarei, E.; Sheng, K. Effect of hydrothermal pretreatment on the properties of moso bamboo particles reinforced polyvinyl chloride composites. Compos. Part B Eng. 2015, 82, 23–29. [Google Scholar] [CrossRef]

- Carvalho, A.G.; Zanuncio, A.J.V.; Vital, B.R.; Carneiro, A.D.C.O.; da Silva, C.M.S.; Tonoli, G.H.D. Hydrothermal treatment of strand particles of pine for the improvement of OSB panels. Eur. J. Wood Wood Prod. 2018, 76, 155–162. [Google Scholar] [CrossRef]

- Gomes, A.; Matsuo, T.; Goda, K.; Ohgi, J. Development and effect of alkalitreatment on tensile properties of curaua fiber green composites. Compos. Part A: Appl. Sci. Manuf. 2007, 38, 1811–1820. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre rein-forced polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Lucka-Gabor, M.; Gutowski, V.S. The effects ofacetylation on properties of flax fibre and its polypropylene composites. ExpressPolym. Lett. 2008, 2, 413–422. [Google Scholar] [CrossRef]

- Lung, C.Y.K.; Matinlinna, J.P. Aspects of silane coupling agents and surface conditioning in dentistry: An overview. Dent. Mater. 2012, 28, 467–477. [Google Scholar] [CrossRef]

- Park, B.-D.; Wi, S.G.; Lee, K.H.; Singh, A.P.; Yoon, T.-H.; Kim, Y.S. X-ray photoelec-tron spectroscopy of rice husk surface modified with maleated polypropyleneand silane. Biomass Bioenergy 2004, 27, 353–363. [Google Scholar] [CrossRef]

- Li, Y.; Wang, B.; Yang, Y.; Liu, Y.; Guo, H. Preparation and Characterization of Dyed Corn Straw by Acid Red GR and Active Brilliant X-3B Dyes. Materials (Basel, Switzerland) 2019, 12, 3483. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Via, B.K.; Pan, Y.; Cheng, Q.; Guo, H.; Auad, M.L.; Taylor, S. Preparation and Characterization of Epoxy Resin Cross-Linked with High Wood Pyrolysis Bio-Oil Substitution by Acetone Pretreatment. Polymers 2017, 9, 106. [Google Scholar] [CrossRef] [PubMed]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P. Effect of thermal-treatment of wood fibres on properties of flat-pressed wood plastic composites. Polym. Degrad. Stab. 2011, 96, 818–822. [Google Scholar] [CrossRef]

- Xiong, L.; Sekiya, E.H.; Wada, S.; Saito, K. Facile Catalytic Combustion of Rice Husk and Burning Temperature Dependence of the Ashes. ACS Appl. Mater. Interfaces 2009, 1, 2509–2518. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.P.T.; Benezet, J.C.; Bergeret, A. Rice and Einkorn wheat husks reinforced poly(lactic acid) (PLA) biocomposites: Effects of alkaline and silane surface treatments of husks. Industrial Crops and Products 2014, 58, 111–124. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mishra, R.; Saha, P.; Kushwaha, P. Adsorption thermodynamics, kinetics and isosteric heat of adsorption of malachite green onto chemically modified rice husk. Desalination 2011, 265, 159–168. [Google Scholar] [CrossRef]

- Ozmen, N.; Cetin, N.S.; Mengeloglu, F. Effect of wood acytelation with vinyl acetate and acetic anhydride on the properties of wood plastic composites. Bioresources 2013, 8, 753–767. [Google Scholar]

- Mohanty, S.; Nayak, S.K. Short Bamboo Fiber-reinforced HDPE Composites: Influence of Fiber Content and Modification on Strength of the Composite. J. Reinf. Plast. Compos. 2010, 29, 2199–2210. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, B.H.; Choi, S.W.; Kim, S.; Kim, H.J. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Enescu, D.; Hamciuc, V.; Ardeleanu, R.; Cristea, M.; Ioanid, A.; Harabagiu, V.; Simionescu, B.C. Polydimethylsiloxane modified chitosan. Part III: Preparation and characterization of hybrid membranes. Carbohydr. Polym. 2009, 76, 268–278. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Bonnia, N.N.; Ahmad, S. Basic properties of grain by-products and their viability in polypropylene composites. Ind. Crops Prod. 2012, 37, 427–434. [Google Scholar] [CrossRef]

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Zurina, M.; Ismail, H.; Bakar, A.A. Rice husk powder–filled polystyrene/styrene butadiene rubber blends. J. Appl. Polym. Sci. 2004, 92, 3320–3332. [Google Scholar] [CrossRef]

- Seki, Y. Innovative multifunctional siloxane treatment of jute fiber surface and its effect on the mechanical properties of jute/thermoset composites. Mater. Sci. Eng. A 2009, 508, 247–252. [Google Scholar] [CrossRef]

- Threepopnatkul, P.; Kaerkitcha, N.; Athipongarporn, N. Effect of surface treatment on performance of pineapple leaf fiber–polycarbonate composites. Compos. Part B Eng. 2009, 40, 628–632. [Google Scholar] [CrossRef]

- Hu, F.; Chen, L.; Wu, X. Effect of interfacial modification on flexural strength of glass fiber reinforced polypropylene. J. Funct. Polym. 1994, 7, 306–309. [Google Scholar]

- Qin, L.; Qiu, J.; Liu, M.; Ding, S.; Shao, L.; Lv, S.; Zhang, G.; Zhao, Y.; Fu, X. Mechanical and thermal properties of poly (lactic acid)composites with rice straw fiber modified by poly (butylacrylate). Chem. Eng. J. 2011, 166, 772–778. [Google Scholar] [CrossRef]

- Worasuwannarak, N.; Sonobe, T.; Tanthapanichakoon, W. Pyrolysis behaviors of rice straw, rice husk, and corncob by TG-MS technique. J. Anal. Appl. Pyrolysis 2007, 78, 265–271. [Google Scholar] [CrossRef]

- Biswas, B.; Pandey, N.; Bisht, Y.; Singh, R.; Kumar, J.; Bhaskar, T. Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk. Bioresour. Technol. 2017, 237, 57–63. [Google Scholar] [CrossRef]

- Wang, S.; Guo, X.; Wang, K.; Luo, Z. Influence of the interaction of components on the pyrolysis behavior of biomass. J. Anal. Appl. Pyrolysis 2011, 91, 183–189. [Google Scholar] [CrossRef]

- Obataya, E.; Furuta, Y.; Gril, J. Dynamic viscoelastic properties of wood acetylated with acetic anhydride solution of glucose pentaacetate. J. Wood Sci. 2003, 49, 152–157. [Google Scholar] [CrossRef]

- You, Z.P.; Li, D.G. The dynamical viscoelasticity and tensile property of new highly filled charcoal powder/ultra-high molecular weight polyethylene composites. Mater. Lett. 2013, 112, 197–199. [Google Scholar] [CrossRef]

- Espert, A.; Camacho, W.; Karlson, S. Thermal and thermomechanical properties of biocomposites made from modified recycled cellulose and recycled polypropylene. J. Appl. Polym. Sci. 2003, 89, 2353–2360. [Google Scholar] [CrossRef]

| Composition | Cellulose | Hemicellulose | Lignin | Silica | Lipid | Moisture | Ash |

|---|---|---|---|---|---|---|---|

| Content (%) | 30–35 | 15–25 | 20–26 | 20 | 0.7–1.3 | 5 | 15–25 |

| Sample | RH (parts) | HDPE (parts) | KH-550 (parts) | MAPE (parts) | CaCO3 (parts) |

|---|---|---|---|---|---|

| RPC-0 | 40 | 60 | - | - | 10 |

| RPC-K | 40 | 60 | 5 | - | 10 |

| RPC-M | 40 | 60 | - | 5 | 10 |

| RPC-KM | 40 | 60 | 5 | 5 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Pang, Y.; Yang, Y.; Zhao, J.; Xia, R.; Li, Y.; Liu, Y.; Guo, H. Improvement of Rice Husk/HDPE Bio-Composites Interfacial Properties by Silane Coupling Agent and Compatibilizer Complementary Modification. Polymers 2019, 11, 1928. https://doi.org/10.3390/polym11121928

Sun J, Pang Y, Yang Y, Zhao J, Xia R, Li Y, Liu Y, Guo H. Improvement of Rice Husk/HDPE Bio-Composites Interfacial Properties by Silane Coupling Agent and Compatibilizer Complementary Modification. Polymers. 2019; 11(12):1928. https://doi.org/10.3390/polym11121928

Chicago/Turabian StyleSun, Jingmeng, Yao Pang, Yingni Yang, Junqi Zhao, Rongqi Xia, Yanchen Li, Yi Liu, and Hongwu Guo. 2019. "Improvement of Rice Husk/HDPE Bio-Composites Interfacial Properties by Silane Coupling Agent and Compatibilizer Complementary Modification" Polymers 11, no. 12: 1928. https://doi.org/10.3390/polym11121928

APA StyleSun, J., Pang, Y., Yang, Y., Zhao, J., Xia, R., Li, Y., Liu, Y., & Guo, H. (2019). Improvement of Rice Husk/HDPE Bio-Composites Interfacial Properties by Silane Coupling Agent and Compatibilizer Complementary Modification. Polymers, 11(12), 1928. https://doi.org/10.3390/polym11121928