Role of Aliphatic Chain Characteristics on the Anti-Cracking Properties of Polymer-Modified Asphalt at Low Temperatures

Abstract

:1. Introduction

2. Experimental Materials and Design

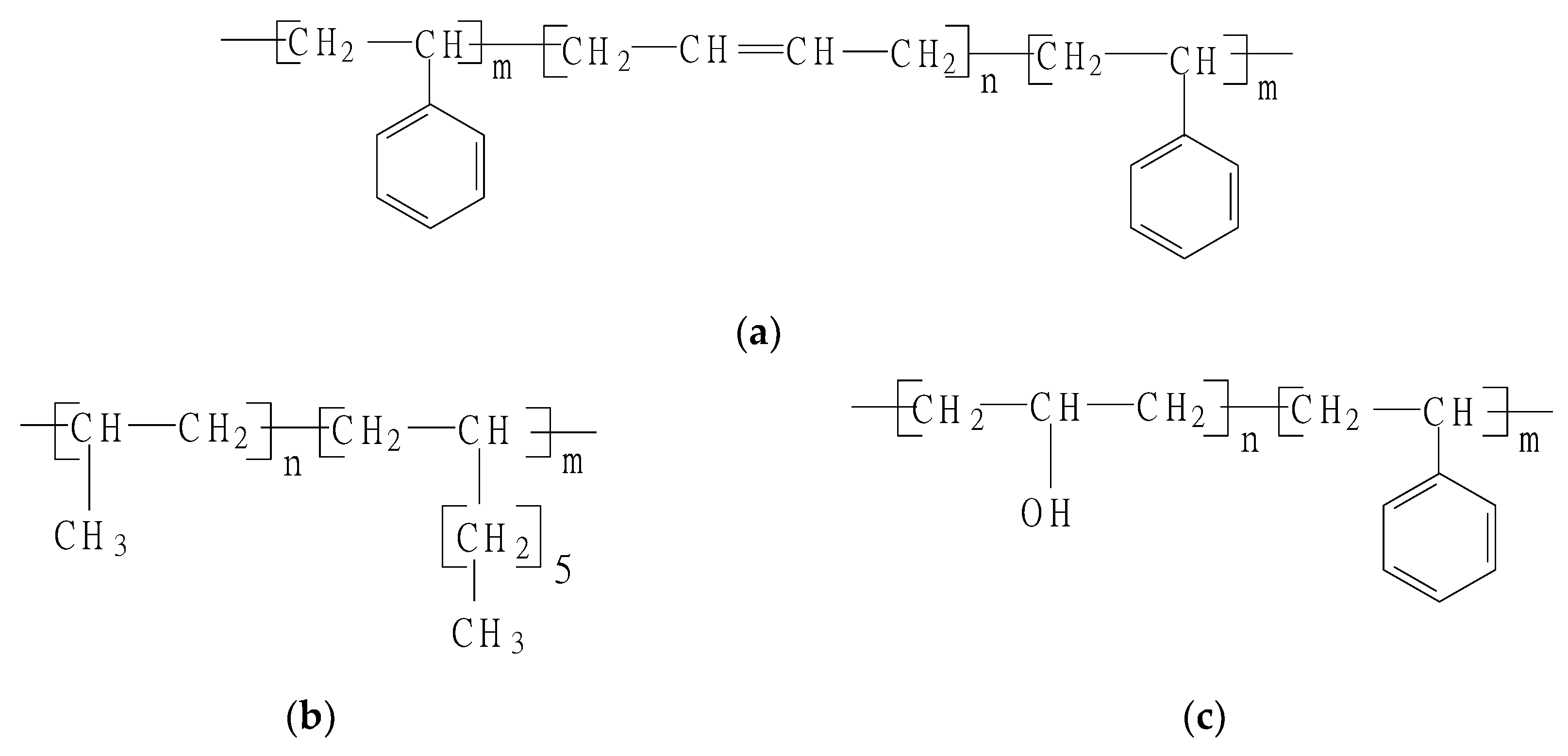

2.1. Experimental Materials

2.2. Preparation of Polymer-Modified Asphalt Samples

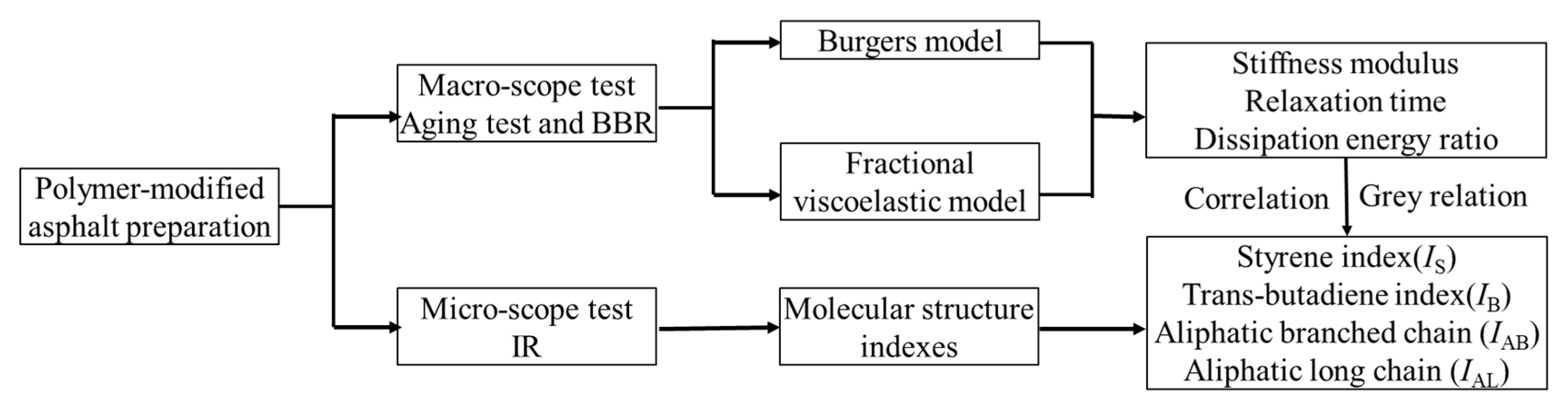

2.3. Experimental Design

3. Results and Discussions

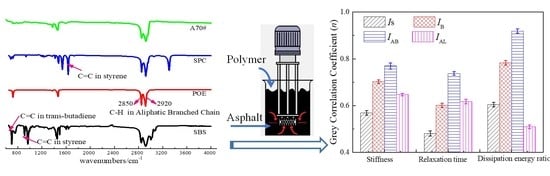

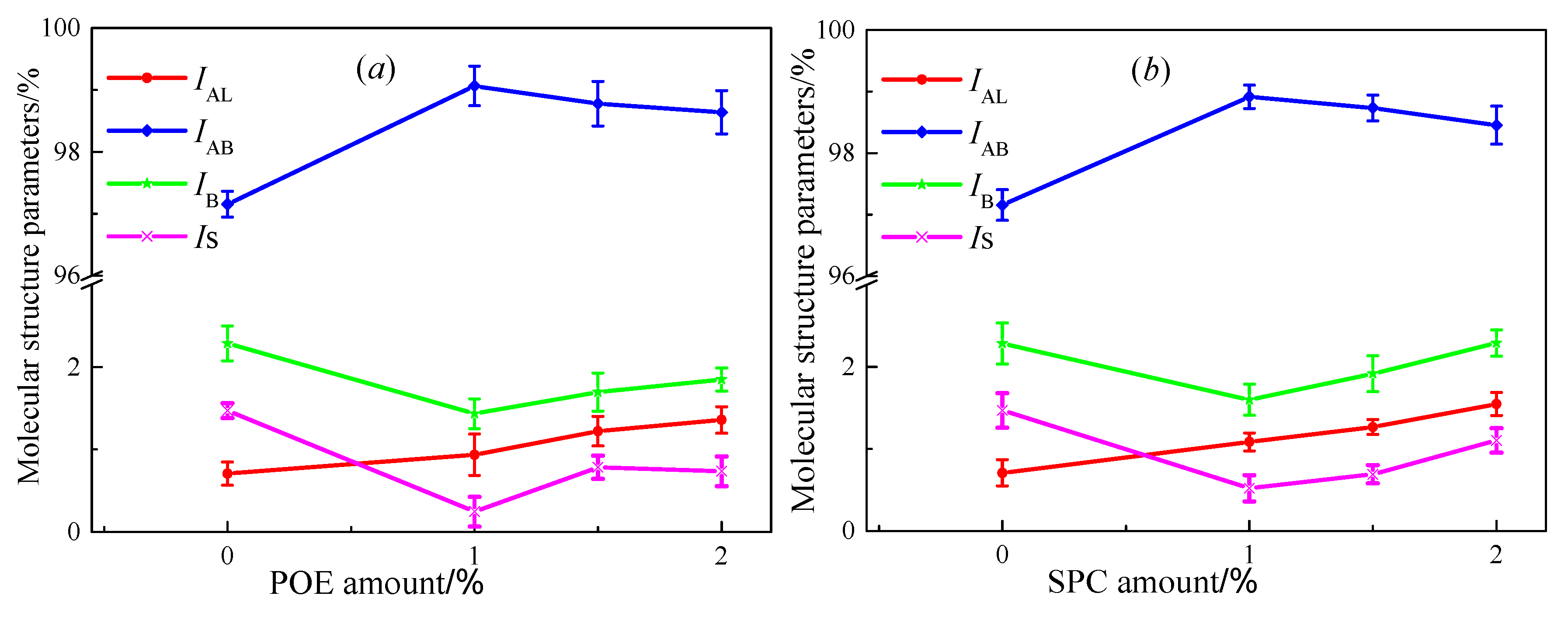

3.1. Molecular Structure Characteristics of Polymer Modifiers

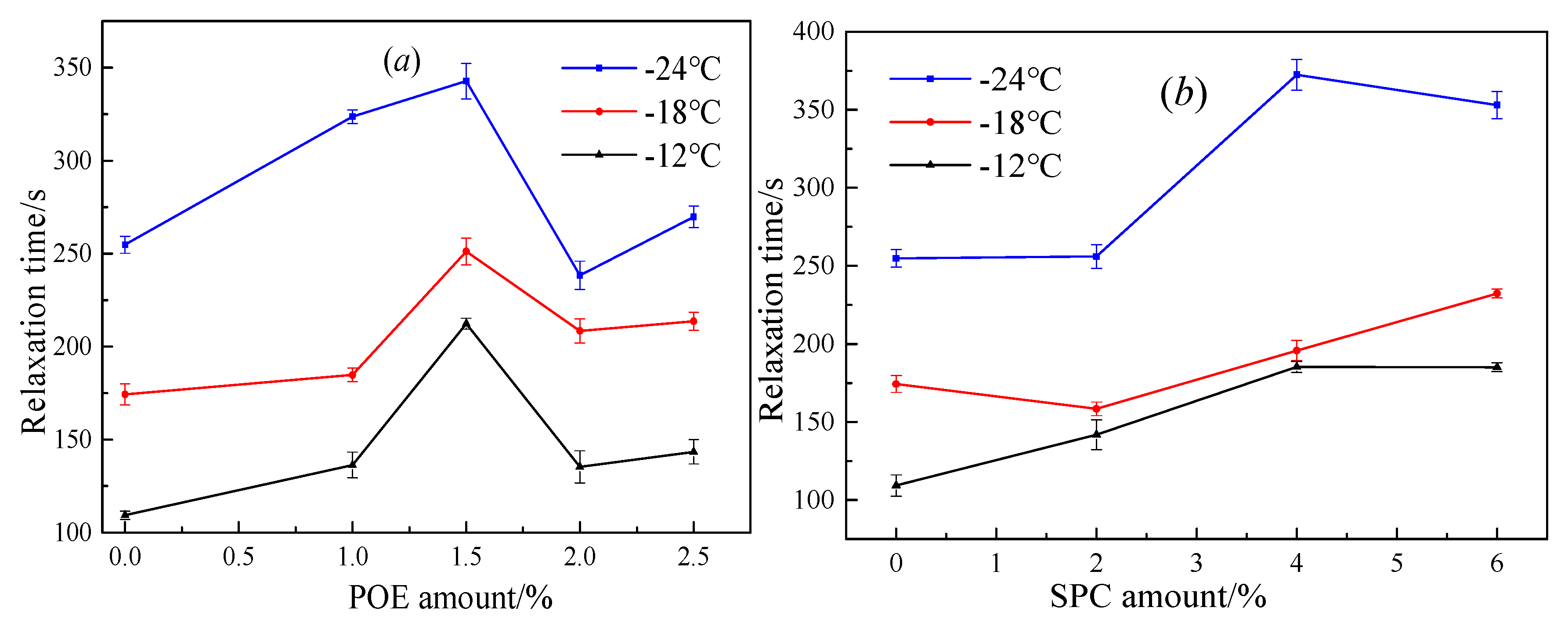

3.2. Relaxation Time at Low Temperature Based on the Burgers Model

3.3. Dissipation Energy Ratio Based on Fractional Viscoelastic Model

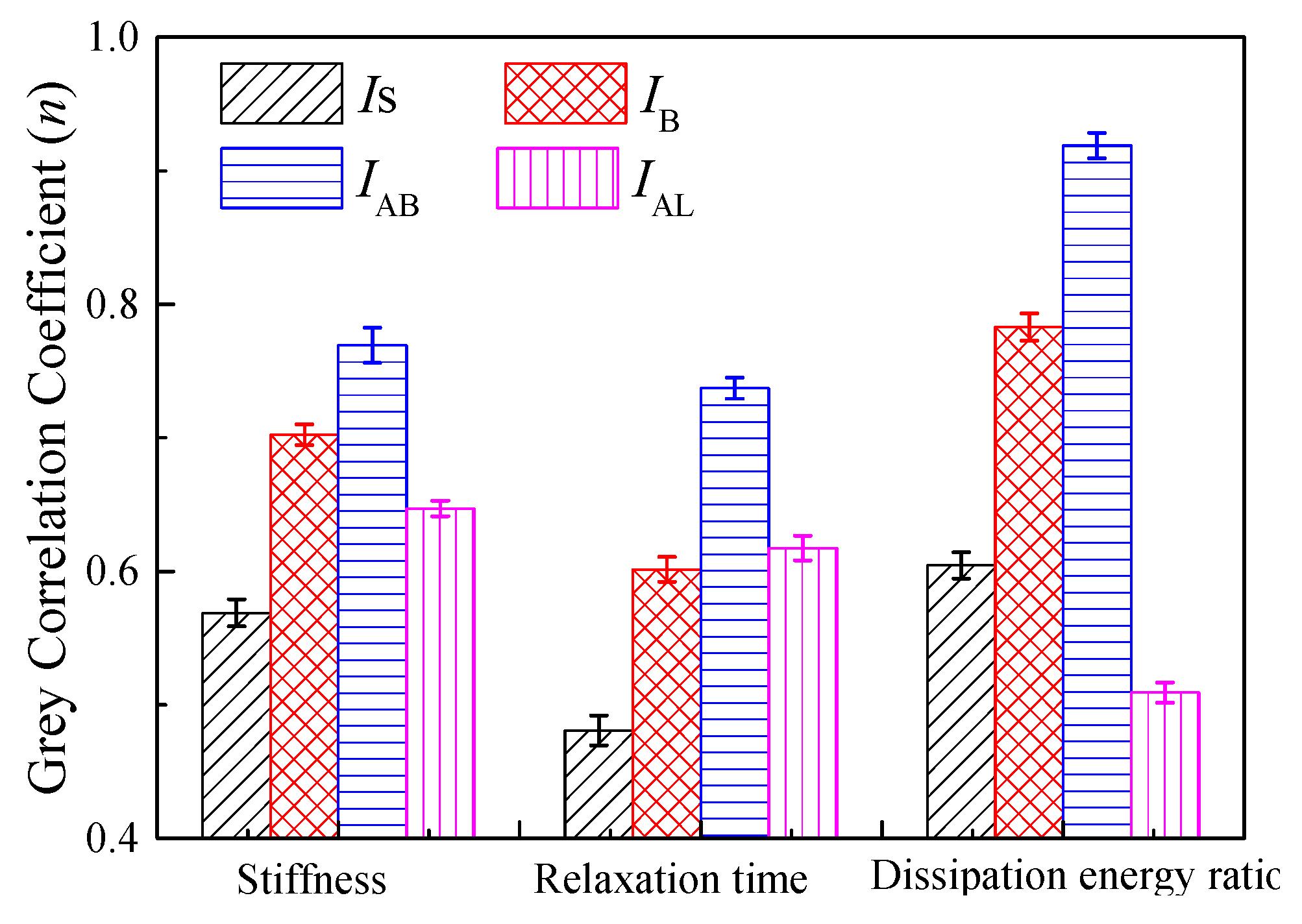

3.4. Relationship between Molecular Structure and Viscoelastic Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mouillet, V.; Farcas, F.; Chailleux, E. Physico-Chemical Techniques for Analysing the Ageing of Polymer Modified Bitumen. In Polymer Modified Bitumen; Woodhead Publishing Limited: Méditerranée, France, 2011; pp. 366–395. [Google Scholar]

- Hill, B.; Oldham, D.; Behnia, B.; Fini, E.H.; Buttlar, W.G.; Reis, H. Evaluation of low temperature viscoelastic properties and fracture behavior of bio-asphalt mixtures. Int. J. Pavement Eng. 2018, 19, 362–369. [Google Scholar] [CrossRef]

- Nciri, N.; Kim, N.; Cho, N. New insights into the effects of styrene-butadiene-styrene polymer modifier on the structure, properties, and performance of asphalt binder: The case of AP-5 asphalt and solvent deasphalting pitch. Mater. Chem. Phys. 2017, 193, 477–495. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrenebutadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Y.; Gong, J.; Li, C.; Xi, Z.; Cai, J.; Xie, H. Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater. Struct. 2018, 51, 86. [Google Scholar] [CrossRef]

- Masson, J.F.; Bundalo-Perc, S.A.; Delgado, A. Glass transitions and mixed phases in block SBS. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 276–279. [Google Scholar] [CrossRef]

- Consolati, G.; Panzarasa, G.; Quasso, F. Morphology of free volume holes in an amorphous polyether-polyester polyurethane of biomedical interest. Polym. Test. 2018, 68, 208–212. [Google Scholar] [CrossRef]

- Sharma, J.; Tewari, K.; Arya, R.K. Diffusion in polymeric systems–A review on free volume theory. Prog. Organ. Coat. 2017, 111, 83–92. [Google Scholar] [CrossRef]

- Weigel, S.; Stephan, D. Differentiation of bitumen according to the refinery and ageing state based on FTIR spectroscopy and multivariate analysis methods. Mater. Struct. 2018, 51, 130. [Google Scholar] [CrossRef]

- Marasteanu, M.O.; Cannone Falchetto, A. Review of experimental characterisation and modelling of asphalt binders at low temperature. Int. J. Pavement Eng. 2018, 19, 279–291. [Google Scholar] [CrossRef]

- Aflaki, S.; Hajikarimi, P. Implementing viscoelastic rheological methods to evaluate low temperature performance of modified asphalt binders. Constr. Build. Mater. 2012, 36, 110–118. [Google Scholar] [CrossRef]

- Liu, S.; Cao, W.; Shang, S.; Qi, H.; Fang, J. Analysis and application of relationships between low-temperature rheological performance parameters of asphalt binders. Constr. Build. Mater. 2010, 24, 471–478. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- Asgharzadeh, S.M.; Tabatabaee, N.; Naderi, K.; Partl, M.N. Evaluation of rheological master curve models for bituminous binders. Mater. Struct. 2015, 48, 393–406. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H. Micromechanical-analogical modelling of asphalt binder and asphalt mixture creep stiffness properties at low temperature. Road. Mater. Pavement Des. 2015, 16 (Suppl. 1), 111–137. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Z.; Tan, Y.Q.; Liu, Z.Y. Anti-ageing properties of styrene-butadiene-styrene copolymer-modified asphalt combined with multi-walled carbon nanotubes. Road Mater. Pavement Des. 2017, 18, 533–549. [Google Scholar] [CrossRef]

- Zhai, F.; Feng, Y.; Zhou, K.; Wang, L.; Zheng, Z.; Feng, W. Graphene-based chiral liquid crystal materials for optical applications. J. Mater. Chem. C 2019, 7, 2146–2171. [Google Scholar] [CrossRef]

- Wang, P.; Zhai, F.; Dong, Z.J.; Wang, L.Z.; Liao, J.P.; Li, G.R. Micromorphology of Asphalt Modified by Polymer and Carbon Nanotubes through Molecular Dynamics Simulation and Experiments: Role of Strengthened Interfacial Interactions. Energy Fuels 2018, 32, 1179–1187. [Google Scholar] [CrossRef]

- Singh, S.K.; Kumar, Y.; Ravindranath, S.S. Thermal degradation of SBS in bitumen during storage: Influence of temperature, SBS concentration, polymer type and base bitumen. Polym. Degrad. Stab. 2018, 147, 64–75. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Karimi, M.M.; Nejad, F.M.; Jahangiri, B. Viscoelastic-based approach to evaluate low temperature performance of asphalt binders. Constr. Build. Mater. 2016, 128, 384–398. [Google Scholar] [CrossRef]

- Fini, E.H.; Khodaii, A.; Hajikarimi, A.P. Fractional Viscoelastic Study of Low-Temperature Characteristics of Biomodified Asphalt Binders. J. Mater. Civ. Eng. 2016, 9, 4016078. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourkhaki, A.; Daryaee, D. Evaluation of fatigue behavior of asphalt binders containing reclaimed asphalt binder using simplified viscoelastic continuum damage approach. Constr. Build. Mater. 2019, 202, 374–386. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Dalmazzo, D.; Tsantilis, L. Investigating cohesive healing of asphalt binders by means of a dissipated energy approach. Int. J. Pavement Res. Technol. 2017, 10, 403–409. [Google Scholar] [CrossRef]

- Xu, H.; Chen, F.; Yao, X.; Tan, Y. Micro-scale moisture distribution and hydrologically active pores in partially saturated asphalt mixtures by X-ray computed tomography. Constr. Build. Mater. 2018, 160, 653–667. [Google Scholar] [CrossRef]

| Wavenumbers/cm−1 | Functional Group | Chemical Type | Functional Group Amount/% | |||

|---|---|---|---|---|---|---|

| A70# | SBS | POE | SPC | |||

| 699 | Stretching vibration of C=C in benzene | Polystyrene | 0 | 8 | 0 | 0 |

| 720 | Methylene(–CH3) chain synergy vibration (n ≥ 4) | Aliphatic long chain (saturate) | 4 | 0 | 10 | 1 |

| 760 | Aromatic branched chain bending vibration | Aromatic | 4 | 7 | 0 | 0 |

| 910 | Benzene stretching vibration | Aromatic | 0 | 3 | 0 | 0 |

| 966 | Butadiene stretching vibration | Butadiene | 0 | 8 | 0 | 0 |

| 1377 | Methyl (–CH3) umbrella vibration | Aliphatic branched chain (saturate) | 13 | 0 | 1 | 1 |

| 1450–1475 | Methylene (–CH3) shear type vibration | Aliphatic branched chain (saturate) | 16 | 9 | 10 | 4 |

| 1493 | Asymmetric benzene ring breathing vibration | Benzene ring and carboxyl | 0 | 2 | 0 | 0 |

| 1540 | Carbon-carbon double bond (C=C) stretching vibration | Aromatic | 0 | 0 | 0 | 9 |

| 1640 | Carbon-carbon double bond (C=C) stretching vibration | Aromatic | 0 | 0 | 0 | 10 |

| 2850 | Methyl (–CH) symmetry vibration | Aliphatic branched chain (saturate) | 20 | 24 | 29 | 29 |

| 2920 | Methyl (–CH) symmetry vibration | Aliphatic branched chain (saturate) | 42 | 29 | 49 | 29 |

| 3006 | Hydrocarbon stretching vibration in olefins | Olefins | 0 | 10 | 0 | 0 |

| 3310 | Hydroxyl (OH−) stretching vibration | Hydroxyl | 0 | 0 | 0 | 17 |

| Polymer Type | IAL/% | IAB/% | IB/% | IS/% |

|---|---|---|---|---|

| SBS | 0.00 | 100.00 | 10.29 | 9.70 |

| POE | 9.69 | 90.31 | 0.00 | 0.00 |

| SPC | 2.07 | 97.93 | 0.00 | 0.00 |

| Polymer Amount | Temperature/℃ | S/MPa | E1/MPa | η1/MPa·s | E2/MPa | η2/MPa·s |

|---|---|---|---|---|---|---|

| SBS3.0% | −12 | 109 | 271 | 29,620 | 235 | 8013 |

| −18 | 194 | 403 | 70,242 | 409 | 17,344 | |

| −24 | 503 | 917 | 233,650 | 1198 | 45,323 | |

| SBS3.0% + POE1% | −12 | 136 | 274 | 30,500 | 166 | 28,490 |

| −18 | 332 | 638 | 117,886 | 749 | 37,051 | |

| −24 | 668 | 1067 | 345,387 | 2131 | 73,917 | |

| SBS3.0% + POE1.5% | −12 | 170 | 283 | 73,152 | 330 | 30,512 |

| −18 | 322 | 578 | 145,182 | 772 | 32,887 | |

| −24 | 704 | 1098 | 376,361 | 2423 | 73,965 | |

| SBS3.0% + POE2% | −12 | 176 | 422 | 57,107 | 349 | 12,463 |

| −18 | 383 | 739 | 154,028 | 945 | 30,511 | |

| −24 | 589 | 1105 | 263,314 | 1719 | 28,297 | |

| SBS3.0% + POE2.5% | −12 | 105 | 235 | 33,689 | 213 | 8756 |

| −18 | 366 | 718 | 153,394 | 838 | 28,452 | |

| −24 | 618 | 1043 | 281,342 | 2029 | 51,642 | |

| SBS3.0% + SCP2% | −12 | 93.5 | 227 | 32,202 | 168 | 6982 |

| −18 | 174 | 392 | 62,099 | 340 | 13,032 | |

| −24 | 446 | 811 | 207,665 | 1203 | 32,917 | |

| SBS3.0% + SCP4% | −12 | 71.5 | 150 | 27,796 | 143 | 6398 |

| −18 | 171 | 353 | 69,116 | 359 | 13,432 | |

| −24 | 560 | 950 | 353,715 | 1387 | 49,496 | |

| SBS3.0% + SCP6% | −12 | 95 | 207 | 38,295 | 184 | 7326 |

| −18 | 179 | 345 | 80,141 | 387 | 15,640 | |

| −24 | 523 | 880 | 310,666 | 1485 | 44,056 |

| Polymer Type and Amount | −12 °C | −18 °C | −24 °C | |||

|---|---|---|---|---|---|---|

| A/Pa | α | A/Pa | α | A/Pa | α | |

| SBS3.0% | 0.00222 | 0.3535 | 0.00148 | 0.3106 | 0.00075 | 0.2448 |

| SBS3.0% + POE1% | 0.00157 | 0.3969 | 0.00092 | 0.2974 | 0.00067 | 0.2008 |

| SBS3.0% + POE1.5% | 0.00168 | 0.3124 | 0.00110 | 0.2594 | 0.00067 | 0.1893 |

| SBS3.0% + POE2% | 0.00152 | 0.3281 | 0.00092 | 0.2597 | 0.00073 | 0.2113 |

| SBS3.0% + POE2.5% | 0.00249 | 0.3342 | 0.00095 | 0.2628 | 0.00070 | 0.2110 |

| SBS3.0% + SCP2% | 0.00265 | 0.3445 | 0.00161 | 0.3168 | 0.00091 | 0.2258 |

| SBS3.0% + SCP4% | 0.00395 | 0.3122 | 0.00185 | 0.286 | 0.00078 | 0.2060 |

| SBS3.0% + SCP6% | 0.00310 | 0.3025 | 0.00187 | 0.2724 | 0.00087 | 0.1955 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Shi, F.-q.; Liu, X.-y.; Ren, R.-b.; Zhu, Y.; Sun, H.; Zheng, G.-s.; Dong, Z.-j.; Wang, L.-z. Role of Aliphatic Chain Characteristics on the Anti-Cracking Properties of Polymer-Modified Asphalt at Low Temperatures. Polymers 2019, 11, 2025. https://doi.org/10.3390/polym11122025

Wang P, Shi F-q, Liu X-y, Ren R-b, Zhu Y, Sun H, Zheng G-s, Dong Z-j, Wang L-z. Role of Aliphatic Chain Characteristics on the Anti-Cracking Properties of Polymer-Modified Asphalt at Low Temperatures. Polymers. 2019; 11(12):2025. https://doi.org/10.3390/polym11122025

Chicago/Turabian StyleWang, Peng, Fu-quan Shi, Xi-yin Liu, Rui-bo Ren, Ying Zhu, Hui Sun, Guang-shun Zheng, Ze-jiao Dong, and Li-zhi Wang. 2019. "Role of Aliphatic Chain Characteristics on the Anti-Cracking Properties of Polymer-Modified Asphalt at Low Temperatures" Polymers 11, no. 12: 2025. https://doi.org/10.3390/polym11122025

APA StyleWang, P., Shi, F.-q., Liu, X.-y., Ren, R.-b., Zhu, Y., Sun, H., Zheng, G.-s., Dong, Z.-j., & Wang, L.-z. (2019). Role of Aliphatic Chain Characteristics on the Anti-Cracking Properties of Polymer-Modified Asphalt at Low Temperatures. Polymers, 11(12), 2025. https://doi.org/10.3390/polym11122025