Antibacterial Films Based on PVA and PVA–Chitosan Modified with Poly(Hexamethylene Guanidine)

Abstract

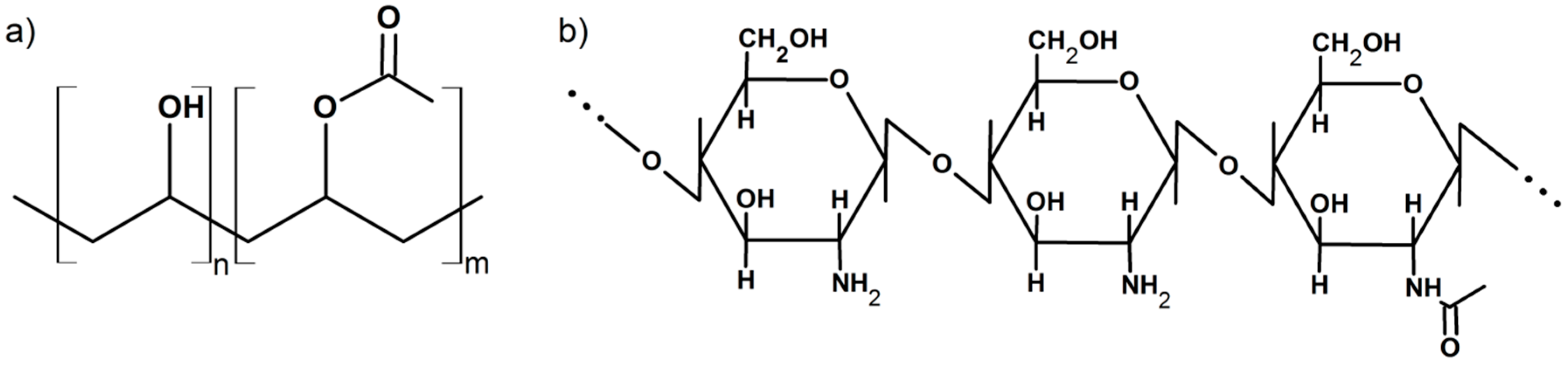

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Poly(Hexamethylene Guanidine)

2.3. The Preparation of Polymeric Films

2.3.1. PVA and Chitosan Solutions

2.3.2. The Formation of Films

2.4. Methods of Analysis

2.4.1. 1H-NMR Analysis

2.4.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.3. Atomic Force Microscopy (AFM)

2.4.4. Contact Angle Measurements

2.4.5. Color Measurement

2.4.6. Thermogravimetric Analysis

2.4.7. Mechanical Properties

2.4.8. Disk Diffusion Method

2.4.9. Dilution and Pour Plate Culture Method

3. Results and Discussions

3.1. Analysis of PHMG Structure by Means of NMR Technique

3.2. Fourier Transform Infrared Spectroscopy

3.3. Atomic Force Microscopy

3.4. Differences in Color of PVA-Based Materials

3.5. Thermal Properties

3.6. Mechanical Testing

3.7. Surface Free Energy Analysis

3.8. Assessment of Antibacterial Potential

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Islam, A.; Yasin, T. Controlled delivery of drug from pH sensitive chitosan/poly (vinyl alcohol) blend. Carbohydr. Polym. 2012, 88, 1055–1060. [Google Scholar] [CrossRef]

- Benhabiles, M.S.; Salah, R.; Lounici, H.; Drouiche, N.; Goosen, M.F.A.; Mameri, N. Antibacterial activity of chitin, chitosan and its oligomers prepared from shrimp shell waste. Food Hydrocoll. 2012, 29, 48–56. [Google Scholar] [CrossRef]

- Chen, J.; Wei, D.; Gong, W.; Zheng, A.; Guan, Y. Hydrogen-Bond Assembly of Poly(vinyl alcohol) and Polyhexamethylene Guanidine for Nonleaching and Transparent Antimicrobial Films. ACS Appl. Mater. Interfaces 2018, 10, 37535–37543. [Google Scholar] [CrossRef]

- No, H.K.; Young Park, N.; Ho Lee, S.; Meyers, S.P. Antibacterial activity of chitosans and chitosan oligomers with different molecular weights. Int. J. Food Microbiol. 2002, 74, 65–72. [Google Scholar] [CrossRef]

- Liu, N.; Chen, X.G.; Park, H.J.; Liu, C.G.; Liu, C.S.; Meng, X.H.; Yu, L.J. Effect of MW and concentration of chitosan on antibacterial activity of Escherichia coli. Carbohydr. Polym. 2006, 64, 60–65. [Google Scholar] [CrossRef]

- Casey, L.S.; Wilson, L.D. Investigation of Chitosan-PVA Composite Films and Their Adsorption Properties. J. Geosci. Environ. Prot. 2015, 3, 78–84. [Google Scholar] [CrossRef]

- Yin, M.; Chen, X.; Li, R.; Huang, D.; Fan, X.; Ren, X.; Huang, T.S. Preparation and characterization of antimicrobial PVA hybrid films with N-halamine modified chitosan nanospheres. J. Appl. Polym. Sci. 2016, 133, 1–7. [Google Scholar] [CrossRef]

- Bonilla, J.; Fortunati, E.; Atarés, L.; Chiralt, A.; Kenny, J.M. Physical, structural and antimicrobial properties of poly vinyl alcohol-chitosan biodegradable films. Food Hydrocoll. 2014, 35, 463–470. [Google Scholar] [CrossRef]

- Gutha, Y.; Pathak, J.L.; Zhang, W.; Zhang, Y.; Jiao, X. Antibacterial and wound healing properties of chitosan/poly(vinyl alcohol)/zinc oxide beads (CS/PVA/ZnO). Int. J. Biol. Macromol. 2017, 103, 234–241. [Google Scholar] [CrossRef]

- Costa-Júnior, E.S.; Barbosa-Stancioli, E.F.; Mansur, A.A.P.; Vasconcelos, W.L.; Mansur, H.S. Preparation and characterization of chitosan/poly(vinyl alcohol) chemically crosslinked blends for biomedical applications. Carbohydr. Polym. 2009, 76, 472–481. [Google Scholar] [CrossRef]

- Hajji, S.; Chaker, A.; Jridi, M.; Maalej, H.; Jellouli, K.; Boufi, S.; Nasri, M. Structural analysis, and antioxidant and antibacterial properties of chitosan-poly (vinyl alcohol) biodegradable films. Environ. Sci. Pollut. Res. 2016, 23, 15310–15320. [Google Scholar] [CrossRef] [PubMed]

- Nakano, Y.; Bin, Y.; Bando, M.; Nakashima, T.; Okuno, T.; Kurosu, H.; Matsuo, M. Structure and mechanical properties of chitosan/poly(vinyl alcohol) blend films. Macromol. Symp. 2007, 258, 63–81. [Google Scholar] [CrossRef]

- El-Hefian, E.A.; Nasef, M.M.; Yahaya, A.H.; Khan, R.A. Preparation and characterization of chitosan/agar blends: Rheological and thermal studies. J. Chil. Chem. Soc. 2010, 55, 130–136. [Google Scholar] [CrossRef] [Green Version]

- Falqi, F.H.; Bin-Dahman, O.A.; Hussain, M.; Al-Harthi, M.A. Preparation of miscible PVA/PEG blends and effect of graphene concentration on thermal, crystallization, morphological, and mechanical properties of PVA/PEG (10 wt%) blend. Int. J. Polym. Sci. 2018, 2018, 8527693. [Google Scholar] [CrossRef] [Green Version]

- Galya, T.; Sedlařík, V.; Kuřitka, I.; Novotný, R.; Sedlaříková, J.; Sáha, P. Antibacterial poly(vinyl alcohol) film containing silver nanoparticles: Preparation and characterization. J. Appl. Polym. Sci. 2008, 110, 3178–3185. [Google Scholar] [CrossRef]

- Kumar, S.; Deepak, V.; Kumari, M.; Dutta, P.K. Antibacterial activity of diisocyanate-modified chitosan for biomedical applications. Int. J. Biol. Macromol. 2016, 84, 349–353. [Google Scholar] [CrossRef]

- Chien, R.C.; Yen, M.T.; Mau, J.L. Antimicrobial and antitumor activities of chitosan from shiitake stipes, compared to commercial chitosan from crab shells. Carbohydr. Polym. 2016, 138, 259–264. [Google Scholar] [CrossRef]

- Qin, C.; Li, H.; Xiao, Q.; Liu, Y.; Zhu, J.; Du, Y. Water-solubility of chitosan and its antimicrobial activity. Carbohydr. Polym. 2006, 63, 367–374. [Google Scholar] [CrossRef]

- Popelka, A.; Novák, I.; Lehocký, M.; Junkar, I.; Mozetič, M.; Kleinová, A.; Janigová, I.; Šlouf, M.; Bílek, F.; Chodák, I. A new route for chitosan immobilization onto polyethylene surface. Carbohydr. Polym. 2012, 90, 1501–1508. [Google Scholar] [CrossRef]

- Ojagh, S.M.; Rezaei, M.; Razavi, S.H.; Hosseini, S.M.H. Effect of chitosan coatings enriched with cinnamon oil on the quality of refrigerated rainbow trout. Food Chem. 2010, 120, 193–198. [Google Scholar] [CrossRef]

- Georgantelis, D.; Ambrosiadis, I.; Katikou, P.; Blekas, G.; Georgakis, S.A. Effect of rosemary extract, chitosan and α-tocopherol on microbiological parameters and lipid oxidation of fresh pork sausages stored at 4 °C. Meat Sci. 2007, 76, 172–181. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-González, L.; González-Martínez, C.; Chiralt, A.; Cháfer, M. Physical and antimicrobial properties of chitosan-tea tree essential oil composite films. J. Food Eng. 2010, 98, 443–452. [Google Scholar] [CrossRef]

- Avci, H.; Monticello, R.; Kotek, R. Preparation of antibacterial PVA and PEO nanofibers containing Lawsonia Inermis (henna) leaf extracts. J. Biomater. Sci. Polym. Ed. 2013, 24, 1815–1830. [Google Scholar] [CrossRef] [PubMed]

- Sarwar, M.S.; Niazi, M.B.K.; Jahan, Z.; Ahmad, T.; Hussain, A. Preparation and characterization of PVA/nanocellulose/Ag nanocomposite films for antimicrobial food packaging. Carbohydr. Polym. 2018, 184, 453–464. [Google Scholar] [CrossRef] [PubMed]

- Richert, A.; Walczak, M.; Swiontek-Brzezinska, M. The influence of modified polyhexamethylene guanidine PHMG on the biodegradation of polylactide. Int. Biodeterior. Biodegrad. 2013, 84, 97–103. [Google Scholar] [CrossRef]

- Walczak, M.; Richert, A.; Burkowska-But, A. The effect of polyhexamethylene guanidine hydrochloride (PHMG) derivatives introduced into polylactide (PLA) on the activity of bacterial enzymes. J. Ind. Microbiol. Biotechnol. 2014, 41, 1719–1724. [Google Scholar] [CrossRef] [Green Version]

- Solvev, V. Method of Synthesis of Polyhexamethylene-Guanidine Hydrochloride. Patent RU 2191606, 27 October 2002. [Google Scholar]

- Yudanova, T.N.; Skokova, I.F.; Aleshina, E.Y.; Gal’braikh, L.S. Polyvinyl alcohol film materials containing biopolymers: Preparation and properties. Fibre Chem. 2000, 32, 347–352. [Google Scholar] [CrossRef]

- Wei, D.; Ma, Q.; Guan, Y.; Hu, F.; Zheng, A.; Zhang, X.; Teng, Z.; Jiang, H. Structural characterization and antibacterial activity of oligoguanidine (polyhexamethylene guanidine hydrochloride). Mater. Sci. Eng. C 2009, 29, 1776–1780. [Google Scholar] [CrossRef]

- Żenkiewicz, M. Comparative study on the surface free energy of a solid calculated by different methods. Polym. Test. 2007, 26, 14–19. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, J.; Chen, Y. Synthesis and antimicrobial activity of polymeric guanidine and biguanidine salts. Polymer 1999, 40, 6189–6198. [Google Scholar] [CrossRef]

- Rao, C.N.R. Chemical Application of Infrared Spectroscopy; Academic Press: New York, NY, USA, 1963. [Google Scholar]

- Guirguis, O.W.; Moselhey, M.T.H. Optical study of poly(vinyl alcohol)/hydroxypropyl methylcellulose blends. J. Mater. Sci. 2011, 46, 5775–5789. [Google Scholar] [CrossRef]

- Mansur, H.S.; Sadahira, C.M.; Souza, A.N.; Mansur, A.A.P. FTIR spectroscopy characterization of poly (vinyl alcohol) hydrogel with different hydrolysis degree and chemically crosslinked with glutaraldehyde. Mater. Sci. Eng. C 2008, 28, 539–548. [Google Scholar] [CrossRef]

- Yang, J.M.; Su, W.Y.; Leu, T.L.; Yang, M.C. Evaluation of chitosan/PVA blended hydrogel membranes. J. Memb. Sci. 2004, 236, 39–51. [Google Scholar] [CrossRef]

- Pearson, F.G.; Marchessault, R.H.; Liang, C.Y. Infrared spectra of crystalline polysaccharides. J. Polym. Sci. 1960, 43, 101–116. [Google Scholar] [CrossRef]

- Pawlak, A.; Mucha, M. Thermogravimetric and FTIR studies of chitosan blends. Thermochim. Acta 2003, 396, 153–166. [Google Scholar] [CrossRef]

- Zheng, A.; Xue, Y.; Wei, D.; Li, S.; Xiao, H.; Guan, Y. Synthesis and Characterization of Antimicrobial Polyvinyl Pyrrolidone Hydrogel as Wound Dressing. Soft Mater. 2014, 12, 179–187. [Google Scholar] [CrossRef]

- Kukharenko, O.; Bardeau, J.F.; Zaets, I.; Ovcharenko, L.; Tarasyuk, O.; Porhyn, S.; Mischenko, I.; Vovk, A.; Rogalsky, S.; Kozyrovska, N. Promising low cost antimicrobial composite material based on bacterial cellulose and polyhexamethylene guanidine hydrochloride. Eur. Polym. J. 2014, 60, 247–254. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, B.; Liu, Y.; Suo, X.; Li, H. Influence of surface topography on bacterial adhesion: A review (Review). Biointerphases 2018, 13, 060801. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Hays, M.P.; Hardwidge, P.R.; Kim, J. Surface characteristics influencing bacterial adhesion to polymeric substrates. RSC Adv. 2017, 7, 14254–14261. [Google Scholar] [CrossRef] [Green Version]

- Ivanova, E.P.; Truong, V.K.; Webb, H.K.; Baulin, V.A.; Wang, J.Y.; Mohammodi, N.; Wang, F.; Fluke, C.; Crawford, R.J. Differential attraction and repulsion of Staphylococcus aureus and Pseudomonas aeruginosa on molecularly smooth titanium films. Sci. Rep. 2011, 1, 165. [Google Scholar] [CrossRef] [PubMed]

- Truong, V.K.; Lapovok, R.; Estrin, Y.S.; Rundell, S.; Wang, J.Y.; Fluke, C.J.; Crawford, R.J.; Ivanova, E.P. The influence of nano-scale surface roughness on bacterial adhesion to ultrafine-grained titanium. Biomaterials 2010, 31, 3674–3683. [Google Scholar] [CrossRef] [PubMed]

- Preedy, E.; Perni, S.; Nipiĉ, D.; Bohinc, K.; Prokopovich, P. Surface roughness mediated adhesion forces between borosilicate glass and gram-positive bacteria. Langmuir 2014, 30, 9466–9476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, S.; Jaimes-Lizcano, Y.A.; McLay, R.B.; Cirino, P.C.; Conrad, J.C. Subnanometric Roughness Affects the Deposition and Mobile Adhesion of Escherichia coli on Silanized Glass Surfaces. Langmuir 2016, 32, 5422–5433. [Google Scholar] [CrossRef]

- Liu, L.; Ercan, B.; Sun, L.; Ziemer, K.S.; Webster, T.J. Understanding the Role of Polymer Surface Nanoscale Topography on Inhibiting Bacteria Adhesion and Growth. ACS Biomater. Sci. Eng. 2016, 2, 122–130. [Google Scholar] [CrossRef]

- Lüdecke, C.; Roth, M.; Yu, W.; Horn, U.; Bossert, J.; Jandt, K.D. Nanorough titanium surfaces reduce adhesion of Escherichia coli and Staphylococcus aureus via nano adhesion points. Colloids Surf. B Biointerfaces 2016, 145, 617–625. [Google Scholar] [CrossRef]

- Rizzello, L.; Sorce, B.; Sabella, S.; Vecchio, G.; Galeone, A.; Brunetti, V.; Cingolani, R.; Pompa, P.P. Impact of nanoscale topography on genomics and proteomics of adherent bacteria. ACS Nano 2011, 5, 1865–1876. [Google Scholar] [CrossRef]

- Nikkola, J.; Liu, X.; Li, Y.; Raulio, M.; Alakomi, H.L.; Wei, J.; Tang, C.Y. Surface modification of thin film composite RO membrane for enhanced anti-biofouling performance. J. Membr. Sci. 2013, 444, 192–200. [Google Scholar] [CrossRef]

- Guerrero, P.; Garrido, T.; Leceta, I.; De La Caba, K. Films based on proteins and polysaccharides: Preparation and physical-chemical characterization. Eur. Polym. J. 2013, 49, 3713–3721. [Google Scholar] [CrossRef]

- Lewandowska, K.; Sionkowska, A.; Grabska, S.; Kaczmarek, B. Surface and thermal properties of collagen/hyaluronic acid blends containing chitosan. Int. J. Biol. Macromol. 2016, 92, 371–376. [Google Scholar] [CrossRef]

- Lewandowska, K.; Sionkowska, A.; Grabska, S. Chitosan blends containing hyaluronic acid and collagen. Compatibility behaviour. J. Mol. Liq. 2015, 212, 879–884. [Google Scholar] [CrossRef]

- Lewandowska, K. Thermal and atomic force microscopy (AFM) studies of microcrystalline chitosan/poly(vinyl alcohol) mixtures. Prog. Chem. Appl. Chitin Deriv. 2010, XV, 11–16. [Google Scholar]

- Lewandowska, K. Characterization of chitosan composites with synthetic polymers and inorganic additives. Int. J. Biol. Macromol. 2015, 81, 159–164. [Google Scholar] [CrossRef] [PubMed]

- Abraham, A.; Soloman, P.A.; Rejini, V.O. Preparation of Chitosan-Polyvinyl Alcohol Blends and Studies on Thermal and Mechanical Properties. Procedia Technol. 2016, 24, 741–748. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Krishnakumar, B.; Sobral, A.J.F.N.; Koh, J. Bio-based (chitosan/PVA/ZnO) nanocomposites film: Thermally stable and photoluminescence material for removal of organic dye. Carbohydr. Polym. 2019, 205, 559–564. [Google Scholar] [CrossRef]

- Koosha, M.; Hamedi, S. Intelligent Chitosan/PVA nanocomposite films containing black carrot anthocyanin and bentonite nanoclays with improved mechanical, thermal and antibacterial properties. Prog. Org. Coat. 2019, 127, 338–347. [Google Scholar] [CrossRef]

- Lewandowska, K. Miscibility and thermal stability of poly(vinyl alcohol)/chitosan mixtures. Thermochim. Acta 2009, 493, 42–48. [Google Scholar] [CrossRef]

- Moshynets, O.; Bardeau, J.-F.; Tarasyuk, O.; Makhno, S.; Cherniavska, T.; Dzhuzha, O.; Potters, G.; Rogalsky, S. Antibiofilm Activity of Polyamide 11 Modified with Thermally Stable Polymeric Biocide Polyhexamethylene Guanidine 2-Naphtalenesulfonate. Int. J. Mol. Sci. 2019, 20, 348. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Ding, S.; Zhou, C. Preparation and degradation of PLA/chitosan composite materials. J. Appl. Polym. Sci. 2004, 91, 274–277. [Google Scholar] [CrossRef]

- Kocijan, A.; Conradi, M.; Hočevar, M. The Influence of Surface Wettability and Topography on the Bioactivity of TiO2/Epoxy Coatings on AISI 316L Stainless Steel. Materials 2019, 12, 1877. [Google Scholar] [CrossRef] [Green Version]

- Lewandowska, K. Effect of an ionic liquid on the physicochemical properties of chitosan/poly(vinyl alcohol) mixtures. Int. J. Biol. Macromol. 2019, in press. [Google Scholar] [CrossRef] [PubMed]

- McAllister, E.W.; Carey, L.C.; Brady, P.G.; Heller, R.; Kovacs, S.G. The role of polymeric surface smoothness of biliary stents in bacterial adherence, biofilm deposition, and stent occlusion. Gastrointest. Endosc. 1993, 39, 422–425. [Google Scholar] [CrossRef]

- An, Y.H.; Friedman, R.J. Concise review of mechanisms of bacterial adhesion to biomaterial surfaces. J. Biomed. Mater. Res. 1998, 43, 338–348. [Google Scholar] [CrossRef]

- Paul, S.; Bag, S.K.; Das, S.; Harvill, E.T.; Dutta, C. Molecular signature of hypersaline adaptation: insights from genome and proteome composition of halophilic prokaryotes. Genome Biol. 2008, 9, R70. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Busscher, H.J.; van der Mei, H.C.; Norde, W. Statistical Analysis of Long- and Short-Range Forces Involved in Bacterial Adhesion to Substratum Surfaces as Measured Using Atomic Force Microscopy. Appl. Environ. Microbiol. 2011, 77, 5065–5070. [Google Scholar] [CrossRef] [Green Version]

| Sample | PVA:Ch Mass Ratio | PHMG Content wt.% |

|---|---|---|

| PVA-0 | 100:0 | 0.0 |

| PVA-0.5 | 0.5 | |

| PVA-1.0 | 1.0 | |

| PVA:Ch-0 | 50:50 | 0.0 |

| PVA:Ch-0.5 | 0.5 | |

| PVA:Ch-1.0 | 1.0 |

| Sample | Color Variables | |||

|---|---|---|---|---|

| L | a | b | ΔE | |

| PVA-0 | 92.4 | 1.2 | −11.6 | − |

| PVA-0.5 | 92.0 | 1.2 | −11.6 | 0.4 |

| PVA-1.0 | 92.7 | 1.2 | −11.7 | 0.3 |

| PVA:Ch-0 | 90.9 | −1.8 | 5.1 | 17.0 |

| PVA:Ch-0.5 | 90.0 | −2.9 | 11.2 | 23.3 |

| PVA:Ch-1.0 | 89.4 | −3.5 | 16.2 | 28.4 |

| Sample | T5% [°C] | T10% [°C] | T50% [°C] |

|---|---|---|---|

| PVA-0 | 272.0 | 296.8 | 361.3 |

| PVA-0.5 | 272.1 | 295.5 | 365.9 |

| PVA-1.0 | 274.1 | 295.0 | 368.1 |

| PVA:Ch-0 | 112.6 | 165.4 | 340.1 |

| PVA:Ch-0.5 | 122.0 | 157.3 | 335.8 |

| PVA:Ch-1.0 | 127.9 | 156.6 | 332.0 |

| Sample | |||

|---|---|---|---|

| PVA-0 | 34.67 ± 0.85 | 4.43 ± 0.27 | 39.10 ± 1.12 |

| PVA-0.5 | 35.27 ± 0.17 | 4.77 ± 0.23 | 40.04 ± 0.39 |

| PVA-1.0 | 37.10 ± 0.20 | 3.95 ± 0.16 | 41.05 ± 0.35 |

| PVA:Ch-0 | 34.67 ± 0.21 | 2.41 ± 0.11 | 37.07 ± 0.32 |

| PVA:Ch-0.5 | 35.11 ± 0.16 | 2.91 ± 0.18 | 38.02 ± 0.15 |

| PVA:Ch-1.0 | 35.90 ± 0.10 | 3.00 ± 0.22 | 38.90 ± 0.21 |

| Sample | Width of the Inhibition Zone [mm] | |

|---|---|---|

| S. aureus | E. coli | |

| PVA-0 | 0 a | 0 a |

| PVA-0.5 | 4 | 2 |

| PVA-1.0 | 3–4 | 3–4 |

| PVA:Ch-0 | 0 b | 0 b |

| PVA:Ch-0.5 | 1–2 | 1 |

| PVA:Ch-1.0 | 1 | 1 |

| Sample | S. aureus | E. coli | ||

|---|---|---|---|---|

| N (CFU/mL) | R | N (CFU/mL) | R | |

| PVA-0 (blank) | 3.7 × 105 | 5.6 ( | 1.0 × 106 | 6.0 ( |

| PVA-0.5 | <1 | ≥5.6 | <1 | ≥6.0 |

| PVA-1.0 | <1 | ≥5.6 | <1 | ≥6.0 |

| PVA:Ch-0 | 2.9 × 103 | 2.1 | 2.8 × 105 | 0.56 |

| PVA:Ch-0.5 | 2.9 × 103 | 2.1 | 5.9 × 104 | 1.2 |

| PVA:Ch-1.0 | 3.7 × 103 | 2.0 | 2.6 × 104 | 1.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olewnik-Kruszkowska, E.; Gierszewska, M.; Jakubowska, E.; Tarach, I.; Sedlarik, V.; Pummerova, M. Antibacterial Films Based on PVA and PVA–Chitosan Modified with Poly(Hexamethylene Guanidine). Polymers 2019, 11, 2093. https://doi.org/10.3390/polym11122093

Olewnik-Kruszkowska E, Gierszewska M, Jakubowska E, Tarach I, Sedlarik V, Pummerova M. Antibacterial Films Based on PVA and PVA–Chitosan Modified with Poly(Hexamethylene Guanidine). Polymers. 2019; 11(12):2093. https://doi.org/10.3390/polym11122093

Chicago/Turabian StyleOlewnik-Kruszkowska, Ewa, Magdalena Gierszewska, Ewelina Jakubowska, Iwona Tarach, Vladimir Sedlarik, and Martina Pummerova. 2019. "Antibacterial Films Based on PVA and PVA–Chitosan Modified with Poly(Hexamethylene Guanidine)" Polymers 11, no. 12: 2093. https://doi.org/10.3390/polym11122093