Thermo-Responsive Nanocomposite Hydrogels Based on PEG-b-PLGA Diblock Copolymer and Laponite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

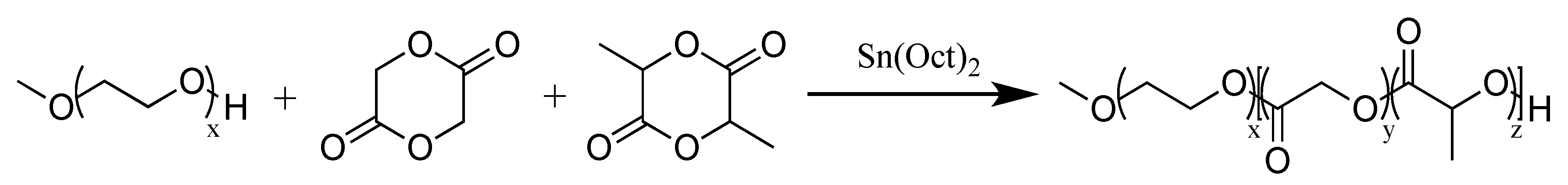

2.2. Synthesis and Characterization of PEG-b-PLGA

2.3. Preparation of the Aqueous Laponite/PEG-b-PLGA Nanocomposite

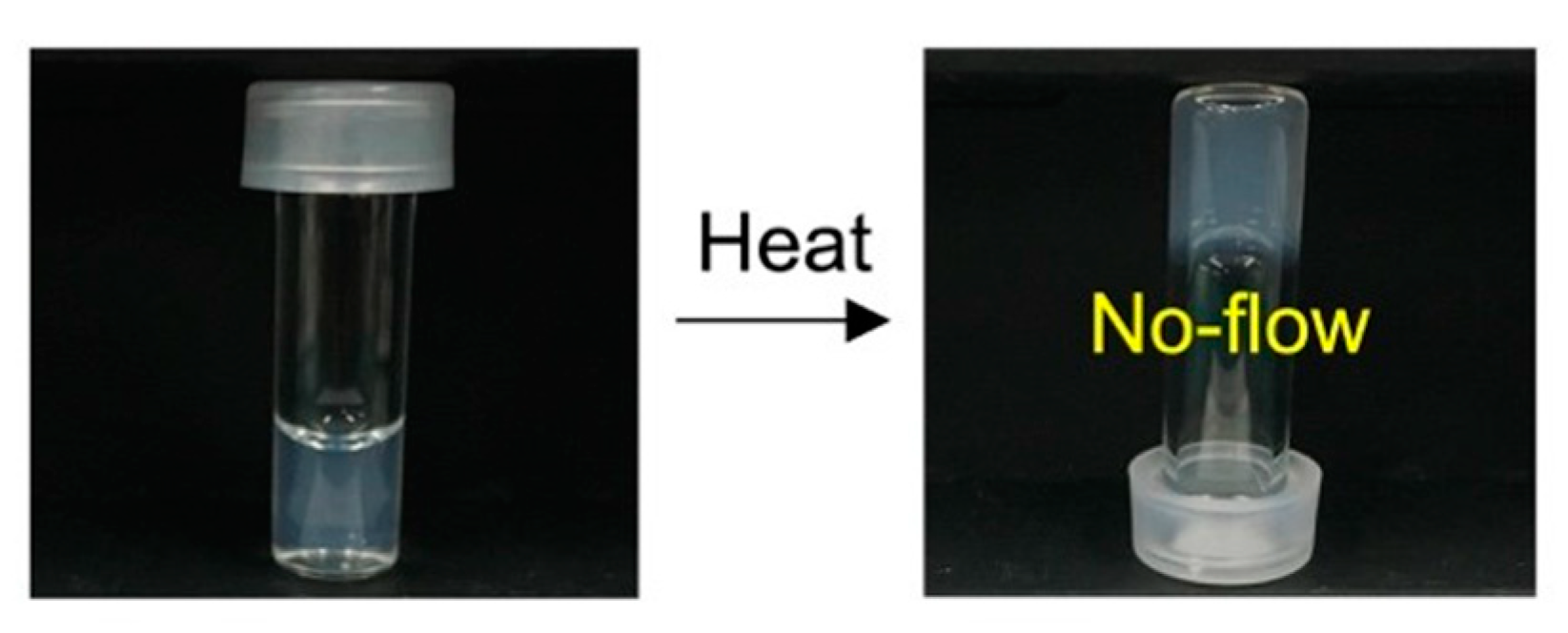

2.4. Analysis of Thermo-Responsive Gelation

2.5. Microstructural Analysis of PEG-b-PLGA Diblock Copolymers in the Nanocomposite

3. Results

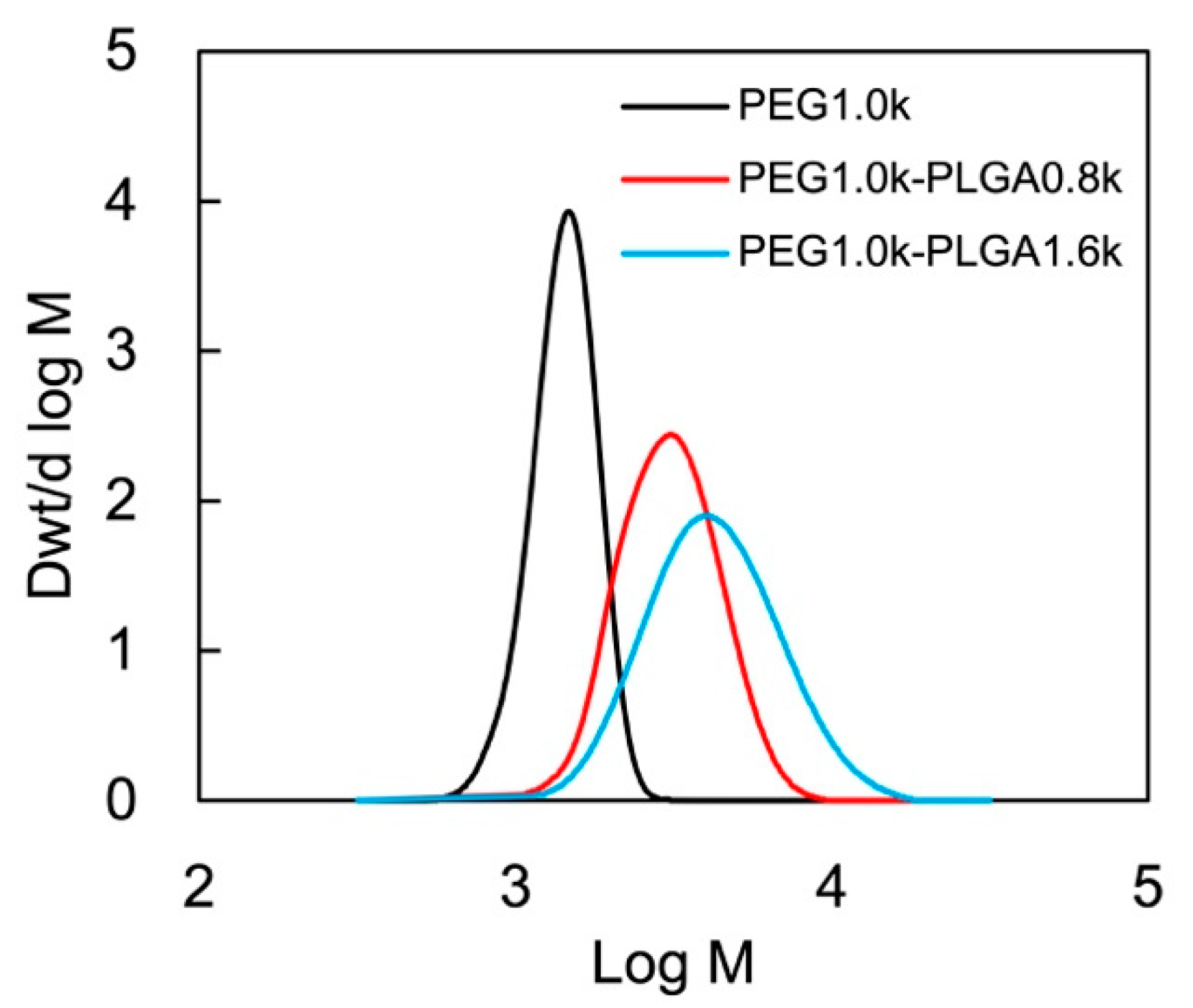

3.1. Characteristics of the Synthesized PEG-b-PLGA Diblock Copolymers

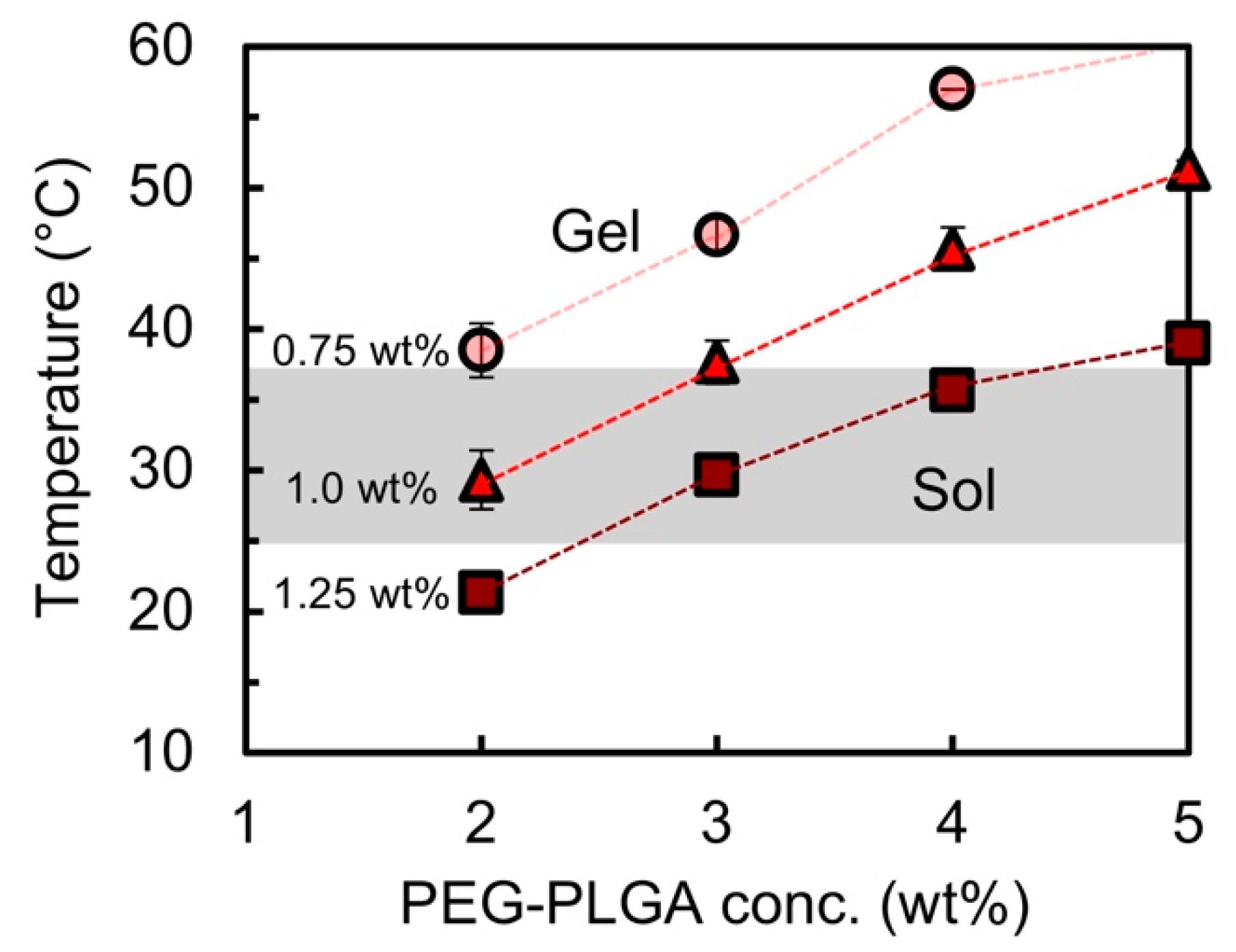

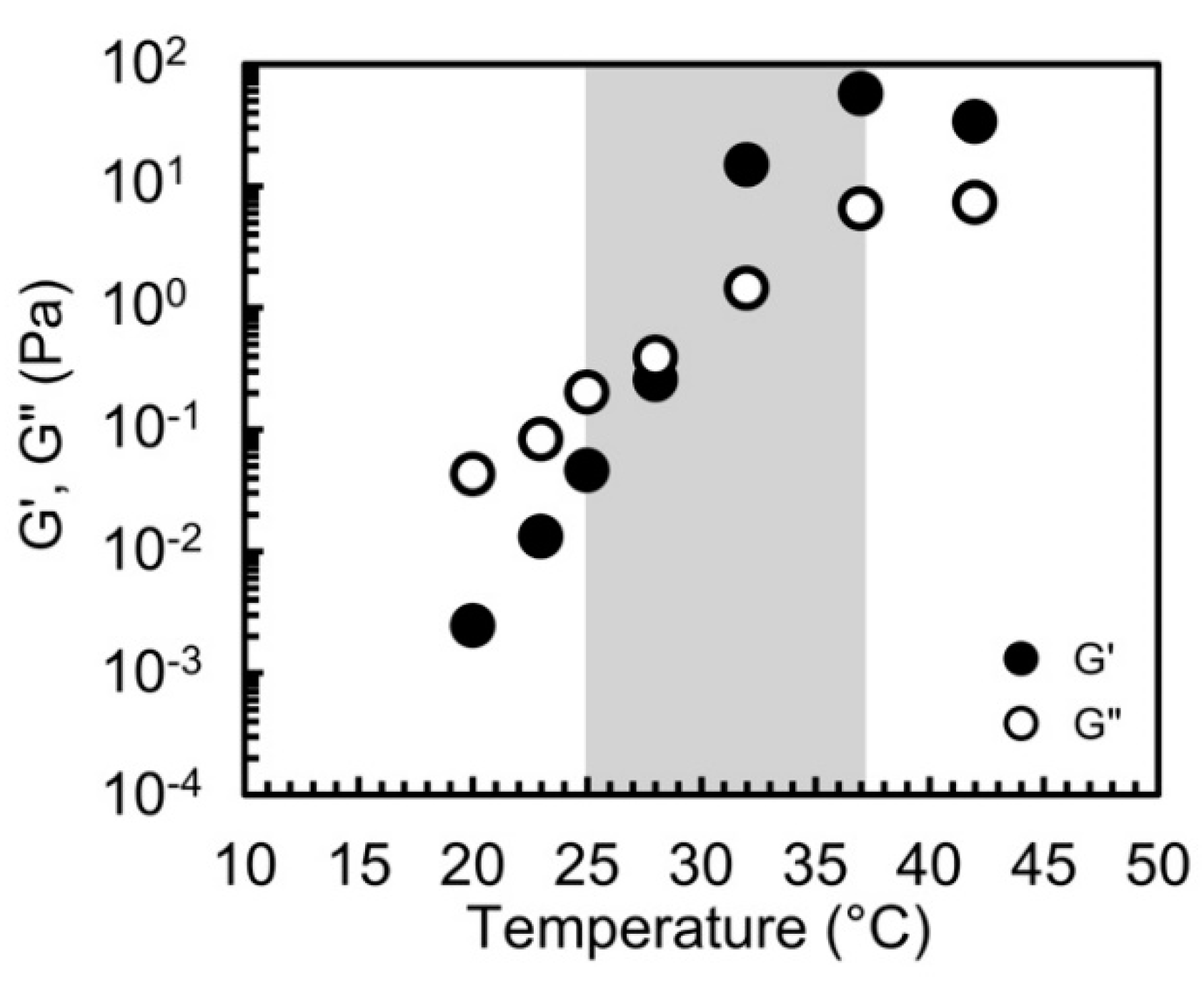

3.2. Thermo-Responsive Gelation of the Laponite/PEG-b-PLGA Nanocomposites

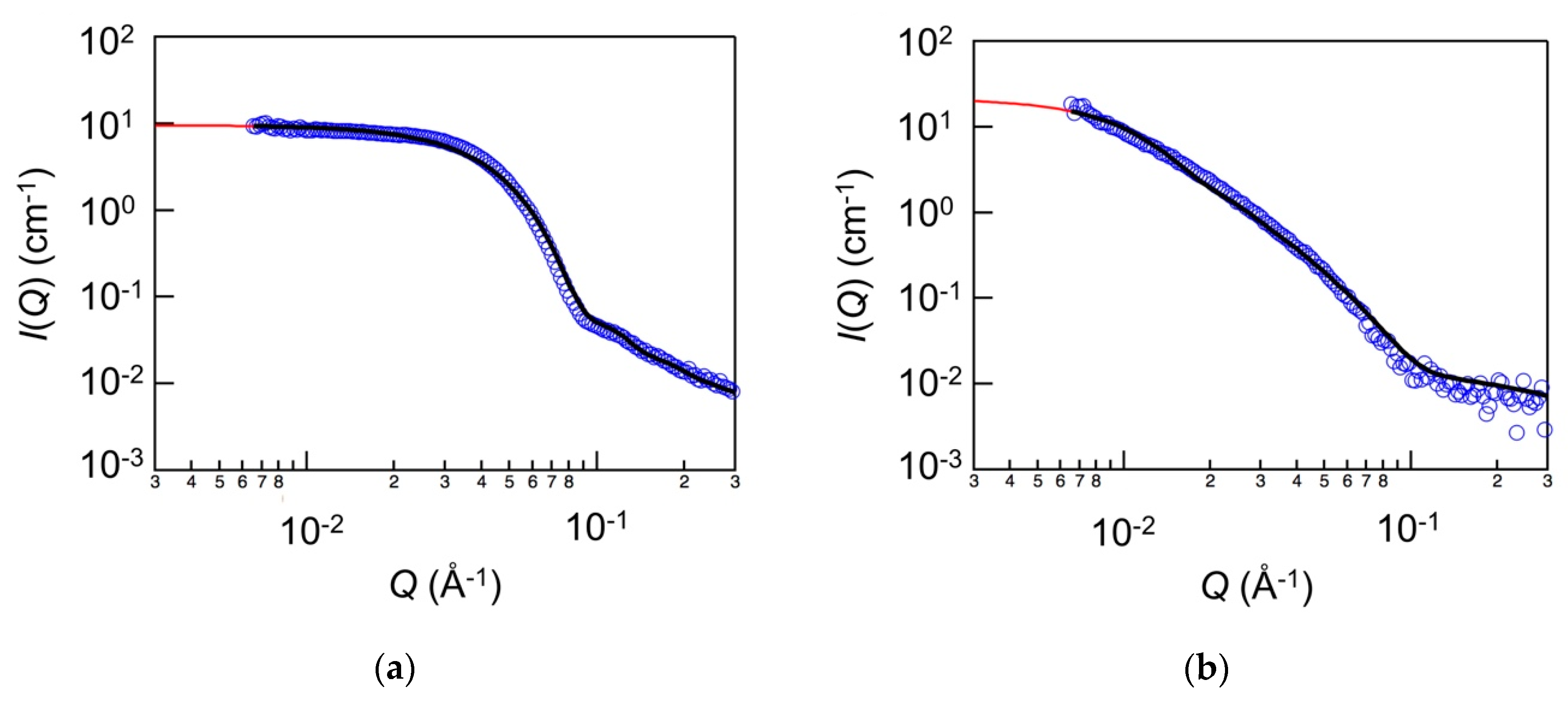

3.3. Microstructure of the Laponite/PEG-b-PLGA Nanocomposites

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zentner, G.M.; Rathi, R.; Shih, C.; McRea, J.C.; Seo, M.H.; Oh, H.; Rhee, B.G.; Mestecky, J.; Moldoveanu, Z.; Morgan, M.; et al. Biodegradable block copolymers for delivery of proteins and water-insoluble drugs. J. Control. Release 2001, 72, 203–215. [Google Scholar] [CrossRef]

- Jeong, B.; Bae, Y.H.; Kim, S.W. Thermoreversible gelation of PEG-PLGA-PEG triblock copolymer aqueous solutions. Macromolecules 1999, 32, 7064–7069. [Google Scholar] [CrossRef]

- Qiao, M.X.; Chen, D.W.; Ma, X.C.; Liu, Y.J. Injectable biodegradable temperature-responsive PLGA-PEG-PLGA copolymers: Synthesis and effect of copolymer composition on the drug release from the copolymer-based hydrogels. Int. J. Pharm. 2005, 294, 103–112. [Google Scholar] [CrossRef]

- Shim, M.S.; Lee, H.T.; Shim, W.S.; Park, I.; Lee, H.; Chang, T.; Kim, S.W.; Lee, D.S. Poly(d,l-lactic acid-co-glycolic acid)-b-poly(ethylene glycol)-b-poly (d,l-lactic acid-co-glycolic acid) triblock copolymer and thermoreversible phase transition in water. J. Biomed. Mater. Res. 2002, 61, 188–196. [Google Scholar] [CrossRef]

- Hunt, J.A.; Chen, R.; van Veen, T.; Bryan, N. Hydrogels for tissue engineering and regenerative medicine. J. Mater. Chem. B 2014, 2, 5319–5338. [Google Scholar] [CrossRef]

- Vashist, A.; Vashist, A.; Gupta, Y.K.; Ahmad, S. Recent advances in hydrogel based drug delivery systems for the human body. J. Mater. Chem. B 2014, 2, 147–166. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Z.; Ding, J.D. In vitro degradation and protein release of transparent and opaque physical hydrogels of block copolymers at body temperature. Macromol. Res. 2012, 20, 234–243. [Google Scholar] [CrossRef]

- Jeong, B.; Bae, Y.H.; Lee, D.S.; Kim, S.W. Biodegradable block copolymers as injectable drug-delivery systems. Nature 1997, 388, 860–862. [Google Scholar] [CrossRef]

- Sun, K.S.; Raghavan, S.R. Thermogelling Aqueous Fluids Containing Low Concentrations of Pluronic F127 and Laponite Nanoparticles. Langmuir 2010, 26, 8015–8020. [Google Scholar] [CrossRef]

- Sun, K.S.; Kumar, R.; Falvey, D.E.; Raghavan, S.R. Photogelling Colloidal Dispersions Based on Light-Activated Assembly of Nanoparticles. JACS 2009, 131, 7135–7141. [Google Scholar] [CrossRef]

- Zu, S.Z.; Han, B.H. Aqueous Dispersion of Graphene Sheets Stabilized by Pluronic Copolymers: Formation of Supramolecular Hydrogel. J. Phys. Chem. C 2009, 113, 13651–13657. [Google Scholar] [CrossRef]

- Motealleh, A.; Kehr, N.S. Nanocomposite Hydrogels and Their Applications in Tissue Engineering. Adv. Healthc. Mater. 2017, 6, 1600938. [Google Scholar] [CrossRef] [PubMed]

- Thompson, D.W.; Butterworth, J.T. The nature of laponite and its aqueous dispersions. J. Colloid Interface Sci. 1992, 151, 236–243. [Google Scholar] [CrossRef]

- Zhao, L.Z.; Zhou, C.H.; Wang, J.; Tong, D.S.; Yu, W.H.; Wang, H. Recent advances in clay mineral-containing nanocomposite hydrogels. Soft Matter 2015, 11, 9229–9246. [Google Scholar] [CrossRef] [Green Version]

- Oyama, N.; Minami, H.; Kawano, D.; Miyazaki, M.; Maeda, T.; Toma, K.; Hotta, A.; Nagahama, K. A nanocomposite approach to develop biodegradable thermogels exhibiting excellent cell-compatibility for injectable cell delivery. Biomater. Sci. 2014, 2, 1057–1062. [Google Scholar] [CrossRef]

- Lee, S.Y.; Hyun, H.; Youn, J.Y.; Kim, B.S.; Song, I.B.; Kim, M.S.; Lee, B.; Khang, G.; Lee, H.B. Preparation of nano-emulsified paclitaxel using MPEG-PLGA diblock copolymers. Colloids Surf. A-Physicochem. Eng. Asp. 2008, 313, 126–130. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kim, H.J.; Lee, K.E.; Han, S.S.; Sohn, Y.S.; Jeong, B. Reverse thermal gelling PEG-PTMC diblock copolymer aqueous solution. Macromolecules 2007, 40, 5519–5525. [Google Scholar] [CrossRef]

- Mao, H.L.; Pan, P.J.; Shan, G.R.; Bao, Y.Z. In Situ Formation and Gelation Mechanism of Thermoresponsive Stereocomplexed Hydrogels upon Mixing Diblock and Triblock Poly(Lactic Acid)/Poly(Ethylene Glycol) Copolymers. J. Phys. Chem. B 2015, 119, 6471–6480. [Google Scholar] [CrossRef]

- Lucke, A.; Tessmar, J.; Schnell, E.; Schmeer, G.; Gopferich, A. Biodegradable poly(d,l-lactic acid)-poly(ethylene glycol)-monomethyl ether diblock copolymers: Structures and surface properties relevant to their use as biomaterials. Biomaterials 2000, 21, 2361–2370. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y.; Wu, Y.; Hu, Y.L.; Nan, K.H.; Nie, G.J.; Chen, H. Enhanced anti-tumor efficacy by co-delivery of doxorubicin and paclitaxel with amphiphilic methoxy PEG-PLGA copolymer nanoparticles. Biomaterials 2011, 32, 8281–8290. [Google Scholar] [CrossRef]

- Bazile, D.; Prudhomme, C.; Bassoullet, M.T.; Marlard, M.; Spenlehauer, G.; Veillard, M. Stealth me.peg-pla nanoparticles avoid uptake by the mononuclear phagocytes system. J. Pharm. Sci. 1995, 84, 493–498. [Google Scholar] [CrossRef] [PubMed]

- Shibayama, M.; Karino, T.; Miyazaki, S.; Okabe, S.; Takehisa, T.; Haraguchi, K. Small-angle neutron scattering study on uniaxially stretched poly(N-isopropylacrylamide)-clay nanocomposite gels. Macromolecules 2005, 38, 10772–10781. [Google Scholar] [CrossRef]

- Khorshid, N.K.; Zhu, K.Z.; Knudsen, K.D.; Bekhradnia, S.; Sande, S.A.; Nystrom, B. Novel Structural Changes during Temperature-Induced Self-Assembling and Gelation of PLGA-PEG-PLGA Triblock Copolymer in Aqueous Solutions. Macromol. Biosci. 2016, 16, 1838–1852. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, J.E.; Zhu, K.Z.; Sande, S.A.; Kovacik, L.; Cmarko, D.; Knudsen, K.D.; Nystrom, B. Structural and Rheological Properties of Temperature-Responsive Amphiphilic Triblock Copolymers in Aqueous Media. J. Phys. Chem. B 2017, 121, 4885–4899. [Google Scholar] [CrossRef] [PubMed]

- Nelson, A.; Cosgrove, T. A small-angle neutron scattering study of adsorbed poly(ethylene oxide) on laponite. Langmuir 2004, 20, 2298–2304. [Google Scholar] [CrossRef] [PubMed]

- Matsuoka, H.; Yamamoto, Y.; Nakano, M.; Endo, H.; Yamaoka, H.; Zorn, R.; Monkenbusch, M.; Richter, D.; Seto, H.; Kawabata, Y.; et al. Neutron spin-echo study of the dynamic behavior of amphiphilic diblock copolymer micelles in aqueous solution. Langmuir 2000, 16, 9177–9185. [Google Scholar] [CrossRef]

- Vashist, A.; Kaushik, A.; Ghosal, A.; Bala, J.; Nikkhah-Moshaie, R.; Wani, W.A.; Manickam, P.; Nair, M. Nanocomposite Hydrogels: Advances in Nanofillers Used for Nanomedicine. Gels 2018, 4, 75. [Google Scholar] [CrossRef]

- Jin, Y.F.; Liu, C.C.; Chai, W.X.; Compaan, A.; Huang, Y. Self-Supporting Nanoclay as Internal Scaffold Material for Direct Printing of Soft Hydrogel Composite Structures in Air. ACS Appl. Mater. Interfaces 2017, 9, 17457–17466. [Google Scholar] [CrossRef]

- Hecht, E.; Hoffmann, H. Adsorption of EOxPOyEOx block copolymers onto saponite. Tenside Surfactants Deterg. 1998, 35, 185–199. [Google Scholar]

- Bongiovanni, R.; Ottewill, R.H.; Rennie, A.R. Small-Angle Neutron-Scattering from Dispersions of Organophilic Clays; Steinkopff: Heidelberg, Germany, 1991; Volume 84, pp. 299–304. [Google Scholar]

- Grillo, I.; Levitz, P.; Zemb, T. SANS structural determination of a nonionic surfactant layer adsorbed on clay particles. Eur. Phys. J. B 1999, 10, 29–34. [Google Scholar] [CrossRef]

- Hanley, H.J.M.; Muzny, C.D.; Butler, B.D. Surface adsorption in a surfactant/clay mineral solution. Int. J. Thermophys. 1998, 19, 1155–1164. [Google Scholar] [CrossRef]

- Hanley, H.J.M.; Muzny, C.D.; Butler, B.D. Surfactant adsorption on a clay mineral: Application of radiation scattering. Langmuir 1997, 13, 5276–5282. [Google Scholar] [CrossRef]

- Hanley, H.J.M.; Muzny, C.D.; Ho, D.L.; Glinka, C.J.; Manias, E. A SANS study of organoclay dispersions. Int. J. Thermophys. 2001, 22, 1435–1448. [Google Scholar] [CrossRef]

| Sample Name | Mn, PEG | Mn, PLGA1 | PEG/PLGA | LA/GA 1 | Mn, total2 | Mw/Mn2 |

|---|---|---|---|---|---|---|

| PEG1.0k | 1000 | - | - | - | 1374 | 1.06 |

| PEG1.0k–PLGA0.8k | 1000 | 785 | 1.27 | 1.6 | 2867 | 1.14 |

| PEG1.0k–PLGA1.6k | 1000 | 1596 | 0.63 | 1.9 | 3768 | 1.24 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maeda, T.; Kitagawa, M.; Hotta, A.; Koizumi, S. Thermo-Responsive Nanocomposite Hydrogels Based on PEG-b-PLGA Diblock Copolymer and Laponite. Polymers 2019, 11, 250. https://doi.org/10.3390/polym11020250

Maeda T, Kitagawa M, Hotta A, Koizumi S. Thermo-Responsive Nanocomposite Hydrogels Based on PEG-b-PLGA Diblock Copolymer and Laponite. Polymers. 2019; 11(2):250. https://doi.org/10.3390/polym11020250

Chicago/Turabian StyleMaeda, Tomoki, Midori Kitagawa, Atsushi Hotta, and Satoshi Koizumi. 2019. "Thermo-Responsive Nanocomposite Hydrogels Based on PEG-b-PLGA Diblock Copolymer and Laponite" Polymers 11, no. 2: 250. https://doi.org/10.3390/polym11020250