Molecular Dynamics Study on the Deformation Behaviors of Nanostructures in the Demolding Process of Micro-Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Model Construction

2.2. Force Field

2.3. Adhesion Energy

2.4. Simulation Procedure

3. Results and Discussions

3.1. Simulation of Demolding Process

3.2. Velocity Distributions of Polymers

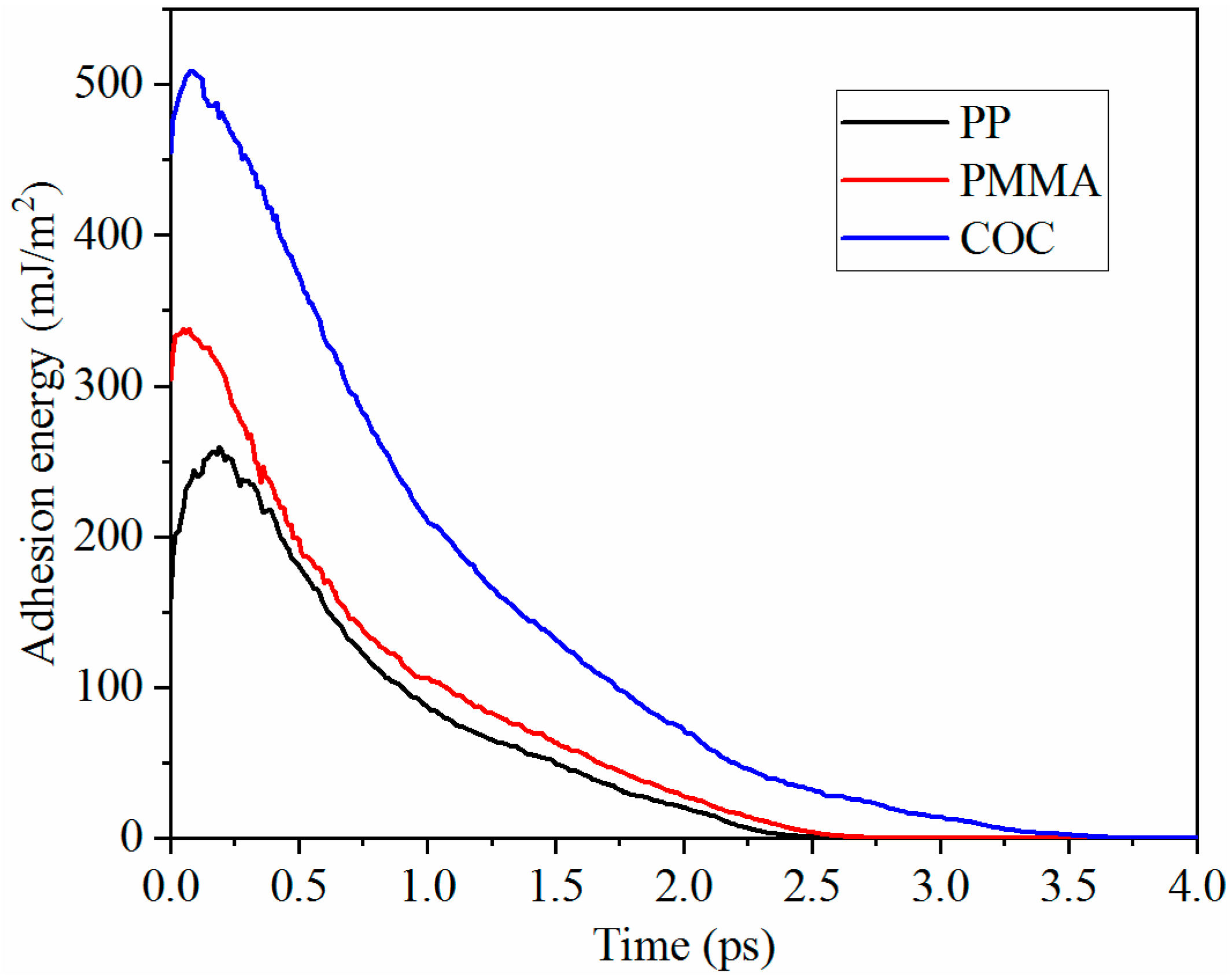

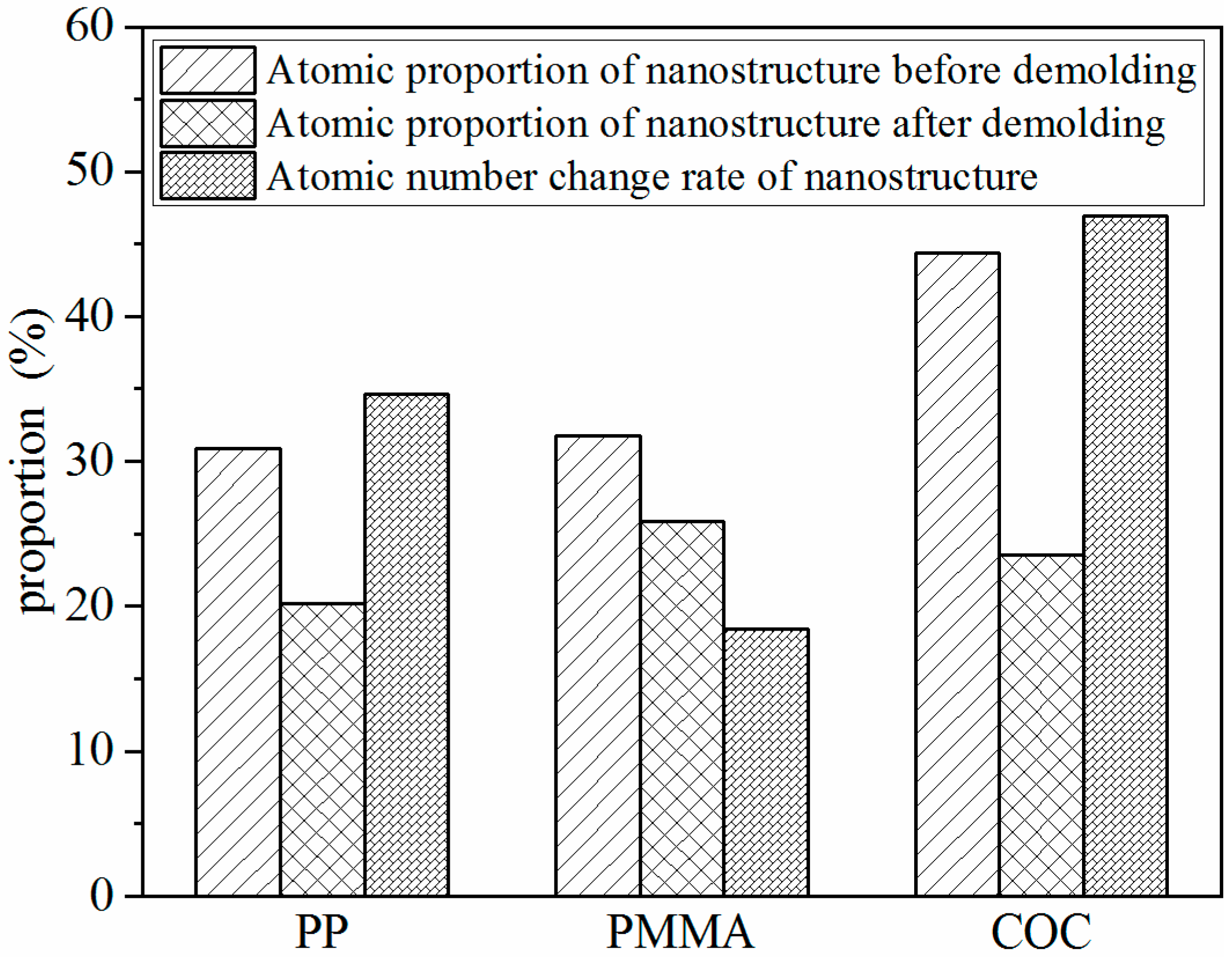

3.3. Adhesion Energies and Demolding Resistances of Polymers

3.4. Density Distributions of Polymers

3.5. Effects of External Demolding Force

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, C. Recent developments in polymer MEMS. Adv. Mater. 2007, 19, 3783–3790. [Google Scholar] [CrossRef]

- Gogolides, E.; Vlachopoulou, M.; Tsougeni, K.; Vourdas, N.; Tserepi, A. Micro and nano structuring and texturing of polymers using plasma processes: Potential manufacturing applications. Int. J. Nanomanuf. 2010, 6, 152–163. [Google Scholar] [CrossRef]

- Sun, J.; Yun, C.; Cui, B.; Li, P.; Liu, G.; Wang, X.; Chu, F. A facile approach for fabricating microstructured surface based on etched template by inkjet printing technology. Polymers 2018, 10, 1209. [Google Scholar] [CrossRef]

- Utko, P.; Persson, F.; Kristensen, A.; Larsen, N.B. Injection molded nanofluidic chips: Fabrication method and functional tests using single-molecule DNA experiments. Lab Chip 2011, 11, 303–308. [Google Scholar] [CrossRef]

- Weng, C.; Wang, F.; Zhou, M.; Yang, D.; Jiang, B. Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl. Surf. Sci. 2018, 436, 224–233. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, X.; Lian, M.; Pan, Y.; Chen, Q.; Liu, H.; Zheng, G.; Guo, Z.; Schubert, D.W.; Shen, C.; et al. Self-reinforcing and toughening isotactic polypropylene via melt sequential injection molding. Polym. Test. 2018, 67, 183–189. [Google Scholar] [CrossRef]

- Baruffi, F.; Calaon, M.; Tosello, G. Effects of micro-injection moulding process parameters on accuracy and precision of thermoplastic elastomer micro rings. Precis. Eng. 2018, 51, 353–361. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Qin, Y.; Voigt, M.; Liu, X.; Zheng, G.; Chen, Q.; Schubert, D.W.; Liu, C.; Shen, C. Creep and recovery behavior of injection-molded isotactic polypropylene with controllable skin-core structure. Polym. Test. 2018, 69, 478–484. [Google Scholar] [CrossRef]

- Jiang, B.; Peng, H.; Wu, W.; Jia, Y.; Zhang, Y. Numerical simulation and experimental investigation of the viscoelastic heating mechanism in ultrasonic plasticizing of amorphous polymers for micro injection molding. Polymers 2016, 8, 199. [Google Scholar] [CrossRef]

- Saha, B.; Toh, W.Q.; Liu, E.; Tor, S.B.; Hardt, D.E.; Lee, J. A review on the importance of surface coating of micro/nano-mold in micro/nano-molding processes. J. Micromech. Microeng. 2015, 26, 013002. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.H.; Kim, K.S.; Kim, K.W. Molecular dynamics study on the effects of stamp shape, adhesive energy, and temperature on the nanoimprint lithography process. Appl. Surf. Sci. 2010, 257, 1562–1572. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Xiong, Y.; Tian, Y. Study of the demolding process—Implications for thermal stress, adhesion and friction control. J. Micromech. Microeng. 2007, 17, 9–19. [Google Scholar] [CrossRef]

- Takeda, M.; Ikeda, M.; Satoh, S.; Dansako, H.; Wakita, T.; Kato, N. Rab13 is involved in the entry step of hepatitis C virus infection. Acta Med. Okayama 2016, 70, 111–118. [Google Scholar] [PubMed]

- Bakharev, A.; Astbury, D. Simulation of ejection of moldings using combination of mold filling and thermo-mechanical analyses. AIP Conf. Proc. 2013, 1532, 555–560. [Google Scholar]

- Yoo, Y.E.; Kim, T.H.; Choi, D.S.; Hyun, S.M.; Lee, H.J.; Lee, K.H.; Kim, S.K.; Kim, B.H.; Seo, Y.H.; Lee, H.G.; et al. Injection molding of a nanostructured plate and measurement of its surface properties. Curr. Appl. Phys. 2009, 9, e12–e18. [Google Scholar] [CrossRef]

- Kamal, M.R.; Lai-Fook, R.A.; Hernandez-Aguilar, J.R. Residual thermal stresses in injection moldings of thermoplastics: A theoretical and experimental study. Polym. Eng. Sci. 2002, 42, 1098–1114. [Google Scholar] [CrossRef]

- Chen, J.Y.; Hwang, S.J. Design and fabrication of an adhesion force tester for the injection moulding process. Polym. Test. 2013, 32, 22–31. [Google Scholar] [CrossRef]

- Stormonth-Darling, J.M.; Pedersen, R.H.; How, C.; Gadegaard, N. Injection moulding of ultra high aspect ratio nanostructures using coated polymer tooling. J. Micromech. Microeng. 2014, 24, 075019. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Liu, G.; Zhu, X.; Tian, Y. Analysis of the demolding forces during hot embossing. Microsyst. Technol. 2007, 13, 411–415. [Google Scholar] [CrossRef]

- Su, Q.; Gilchrist, M.D. Demolding forces for micron-sized features during micro-injection molding. Polym. Eng. Sci. 2016, 56, 810–816. [Google Scholar] [CrossRef]

- Sasaki, T.; Koga, N.; Shirai, K.; Kobayashi, Y.; Toyoshima, A. Experimental study on ejection forces of injection molding. Precis. Eng. 2000, 24, 270–273. [Google Scholar] [CrossRef]

- Delaney, K.D.; Bissacco, G.; Kennedy, D. Demoulding Force Prediction for Micro Polymer Replication: A Review of Relevant Literature. In Proceedings of the 7th International Conference on Multi-Material Micro Manufacture, Oyonnax, France, 17–19 November 2010. [Google Scholar]

- Xiao, K.; Li, D.J.; Wu, C.X. Theoretical studies and molecular dynamics simulations on ion transport properties in nanochannels and nanopores. Chin. Phys. B 2018, 27, 024702. [Google Scholar] [CrossRef]

- Woo, Y.S.; Lee, D.E.; Lee, W.I. Molecular dynamic studies on deformation of polymer resist during thermal nano imprint lithographic process. Tribol. Lett. 2009, 36, 209–222. [Google Scholar] [CrossRef]

- Yang, S.; Yu, S.; Cho, M. Influence of mold and substrate material combinations on nanoimprint lithography process: MD simulation approach. Appl. Surf. Sci. 2014, 301, 189–198. [Google Scholar] [CrossRef]

- Takai, R.; Yasuda, M.; Tochino, T.; Kawata, H.; Hirai, Y. Computational study of the demolding process in nanoimprint lithography. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2014, 32, 06FG02. [Google Scholar] [CrossRef]

- Kang, J.H.; Kim, K.S.; Kim, K.W. Molecular dynamics study of pattern transfer in nanoimprint lithography. Tribol. Lett. 2007, 25, 93–102. [Google Scholar] [CrossRef]

- Zhou, M.; Jiang, B.; Weng, C. Molecular dynamics study on polymer filling into nano-cavity by injection molding. Comput. Mater. Sci. 2016, 120, 36–42. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Molecular dynamics simulation and experimental investigation of the geometrical morphology development of injection-molded nanopillars on polymethylmethacrylate surface. Comput. Mater. Sci. 2018, 149, 208–216. [Google Scholar] [CrossRef]

- Kisin, S.; Vukić, J.B.; Van Der Varst, P.G.T.; De With, G.; Koning, C.E. Estimating the polymer—Metal work of adhesion from molecular dynamics simulations. Chem. Mater. 2007, 19, 903–907. [Google Scholar] [CrossRef]

- Prathab, B.; Subramanian, V.; Aminabhavi, T.M. Molecular dynamics simulations to investigate polymer-polymer and polymer-metal oxide interactions. Polymer 2007, 48, 409–416. [Google Scholar] [CrossRef]

- Li, C.; Strachan, A. Cohesive energy density and solubility parameter evolution during the curing of thermoset. Polymer 2018, 135, 162–170. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, C.; Yang, J.; Yang, D.; Jiang, B. Molecular Dynamics Study on the Deformation Behaviors of Nanostructures in the Demolding Process of Micro-Injection Molding. Polymers 2019, 11, 470. https://doi.org/10.3390/polym11030470

Weng C, Yang J, Yang D, Jiang B. Molecular Dynamics Study on the Deformation Behaviors of Nanostructures in the Demolding Process of Micro-Injection Molding. Polymers. 2019; 11(3):470. https://doi.org/10.3390/polym11030470

Chicago/Turabian StyleWeng, Can, Jin Yang, Dongjiao Yang, and Bingyan Jiang. 2019. "Molecular Dynamics Study on the Deformation Behaviors of Nanostructures in the Demolding Process of Micro-Injection Molding" Polymers 11, no. 3: 470. https://doi.org/10.3390/polym11030470

APA StyleWeng, C., Yang, J., Yang, D., & Jiang, B. (2019). Molecular Dynamics Study on the Deformation Behaviors of Nanostructures in the Demolding Process of Micro-Injection Molding. Polymers, 11(3), 470. https://doi.org/10.3390/polym11030470