In-Situ Polymerization of High-Molecular Weight Nylon 66 Modified Clay Nanocomposites with Low Apparent Viscosity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modification of Clay

2.3. Polymerization of Nanocomposites of Nylon 66 and Mclay

2.4. Melting Spinning of Nanocomposites of Nylon 66 and Mclay

2.5. Characterization

3. Results and Discussion

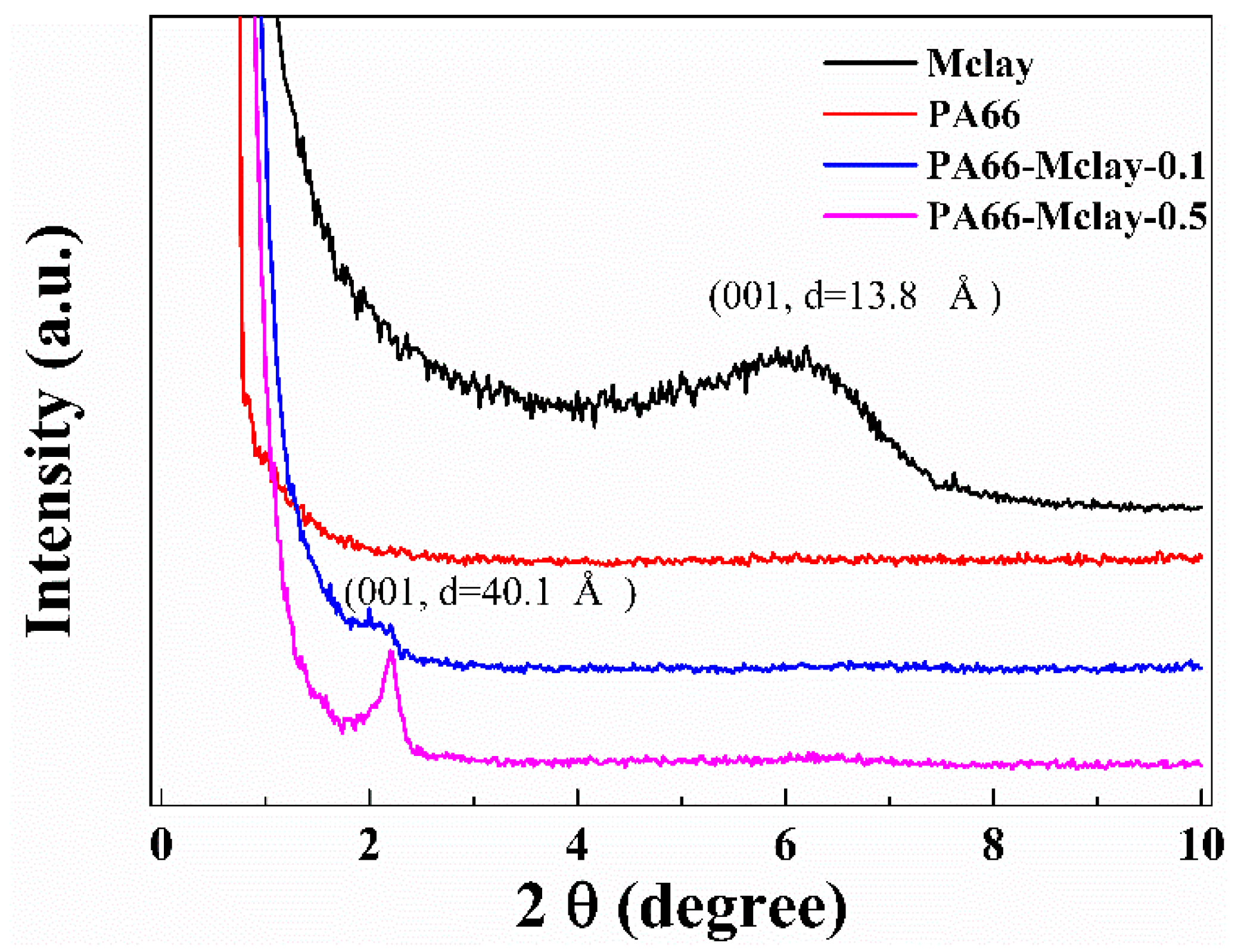

3.1. Characterizations of the Modified Clay

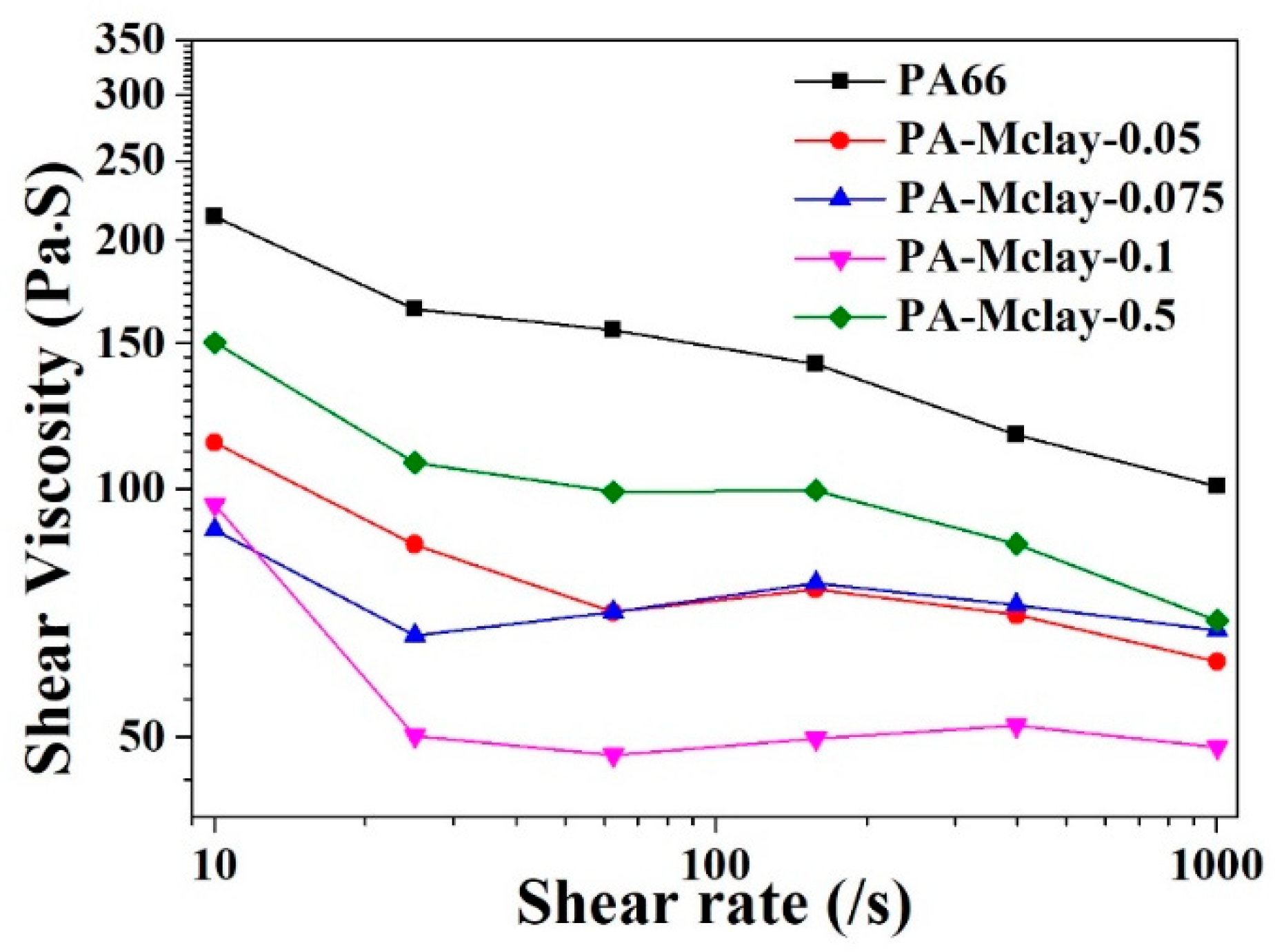

3.2. Characterizations and Properties of Nylon 66 and Nylon 66/Mclay Nanocomposites

3.3. Characterization and Properties of Nylon 66 and Nylon 66/Mclay Fibers

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chavarria, F.; Paul, D.R. Comparison of nanocomposites based on nylon 6 and nylon 66. Polymer 2004, 45, 8501–8515. [Google Scholar] [CrossRef]

- Shah, P.L. Developing critical extrusion parameters for nylon 6, nylon 66, and nylon 46 polyamide from the rheology data. Polym. Eng. Sci. 1994, 34, 759–764. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q.; Berglund, L.A. Polymorphism in polyamide 66/clay nanocomposites. Polymer 2002, 43, 4967–4972. [Google Scholar] [CrossRef]

- Li, Y.; Yang, G. Studies on Molecular Composites of Polyamide 6/Polyamide 66. Macromol. Rapid Commun. 2004, 25, 1714–1718. [Google Scholar] [CrossRef]

- Apichartpattanasiri, S.; Hay, J.N.; Kukureka, S.N. A study of the tribological behaviour of polyamide 66 with varying injection-moulding parameters. Wear 2001, 251, 1557–1566. [Google Scholar] [CrossRef] [Green Version]

- Fukushima, Y.; Inagaki, S. Synthesis of an Intercalated Compound of Montmorillonite and 6-Polyamide. In Inclusion Phenomena in Inorganic, Organic, and Organometallic Hosts; Springer: Dordrecht, The Netherlands, 1987; pp. 365–374. [Google Scholar]

- Song, L.; Hu, Y.; He, Q.; You, F. Study on Crystallization, Thermal and Flame Retardant Properties of Nylon 66/Organoclay Nanocomposites by in situ Polymerization. J. Fire Sci. 2008, 26, 475–492. [Google Scholar] [CrossRef]

- Song, L.; Hu, Y.; He, Q.; You, F. Study of nylon 66–clay nanocomposites via condensation polymerization. Colloid Polym. Sci. 2008, 286, 721–727. [Google Scholar] [CrossRef]

- Gyoo, P.M.; Venkataramani, S.; Kim, S.C. Morphology, thermal, and mechanical properties of polyamide 66/clay nanocomposites with epoxy-modified organoclay. J. Appl. Polym. Sci. 2006, 101, 1711–1722. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q. Polyamide 66/Clay Nanocomposites via Melt Intercalation. Macromol. Mater. Eng. 2002, 287, 180–186. [Google Scholar] [CrossRef]

- Han, B.; Ji, G.; Wu, S.; Shen, J. Preparation and characterization of nylon 66/montmorillonite nanocomposites with co-treated montmorillonites. Eur. Polym. J. 2003, 39, 1641–1646. [Google Scholar] [CrossRef]

- Chae, D.W.; Lim, J.H.; Seo, J.S.; Kim, B.C. Variation of physical properties of nylon-66/clay nanocomposites with preparation conditions. Korea-Aust. Rheol. J. 2012, 24, 45–52. [Google Scholar] [CrossRef]

- Kyu, T.; Zhu, G.C.; Zhou, Z.L.; Tajuddin, Y.; Qutubuddin, S. Novel filled polymer composites prepared from in situ polymerization via a colloidal approach: II. Blends of kaolin/Nylon-6 in situ composites with conventional Nylon-6 and -66. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1769–1775. [Google Scholar] [CrossRef]

- Cho, J.W.; Paul, D.R. Nylon 6 nanocomposites by melt compounding. Polymer 2001, 42, 1083–1094. [Google Scholar] [CrossRef]

- Burke, J.J.; Orofino, T.A. Nylon 66 polymers. I. Molecular weight and compositional distribution. J. Polym. Sci. Part A-2 Polym. Phys. 1969, 7, 1–25. [Google Scholar] [CrossRef]

- Liang, Z.-M.; Yin, J.; Xu, H.-J. Polyimide/montmorillonite nanocomposites based on thermally stable, rigid-rod aromatic amine modifiers. Polymer 2003, 44, 1391–1399. [Google Scholar] [CrossRef]

- Lin, B.; Thümen, A.; Heim, H.-P.; Scheel, G.; Sundararaj, U. Nylon 66/clay nanocomposite structure development in a twin screw extruder. Polym. Eng. Sci. 2009, 49, 824–834. [Google Scholar] [CrossRef] [Green Version]

- Duan, X.; Yu, B.; Yang, T.; Wu, Y.; Yu, H.; Huang, T. In Situ Polymerization of Nylon 66/Reduced Graphene Oxide Nanocomposites. J. Nanomater. 2018, 2018, 1047985. [Google Scholar] [CrossRef]

- Bell, J.P.; Slade, P.E.; Dumbleton, J.H. Multiple melting in nylon 66. J. Polym. Sci. Part A-2 Polym. Phys. 1968, 6, 1773–1781. [Google Scholar] [CrossRef]

- Zhang, Q.-X.; Yu, Z.-Z.; Yang, M.; Ma, J.; Mai, Y.-W. Multiple melting and crystallization of nylon-66/montmorillonite nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 2861–2869. [Google Scholar] [CrossRef]

| Head pressure of extruder (MPa) | 50 |

| Number of spinneret orifice | 36 |

| Diameter of spinneret orifice (mm) | 0.3 |

| L/D of spinneret orifice | 0.25 |

| Barrel temperatures of extruder (°C) | 285, 305, 300, 300 |

| Temperature of spinneret (°C) | 298 |

| Flow rate in volume, Qv (cm3/min) | 50 |

| Temperature of cross air, T (°C) | 25 |

| Take-up velocity, VL (m/min) | 800 |

| Distance from spinneret to the first roller (m) | 4.5 |

| Sample | PA66 | PA66-Mclay-0.05 | PA66-Mclay-0.075 | PA66-Mclay-0.1 | PA66-Mclay-0.5 |

|---|---|---|---|---|---|

| TmI (°C) | 260.5 | 262.7 | 261.6 | 262.6 | 260.5 |

| TmII (°C) | -- | 251.3 | 250.6 | 251.9 | 250.4 |

| Xc (%) | 20.87 | 21.24 | 22.15 | 24.69 | 21.26 |

| Tc (°C) | 215.0 | 225.3 | 231.1 | 230.2 | 225.7 |

| Sample | PA66 | PA66-Mclay-0.05 | PA66-Mclay-0.075 | PA66-Mclay-0.1 | PA66-Mclay-0.5 | ||

|---|---|---|---|---|---|---|---|

| T1/2 (min) | |||||||

| Rate (°C/min) | |||||||

| 5 | 2.38 | 1.02 | 1.10 | 0.56 | 0.72 | ||

| 10 | 1.57 | 0.72 | 0.53 | 0.39 | 0.48 | ||

| 15 | 1.13 | 0.53 | 0.39 | 0.28 | 0.32 | ||

| 20 | 0.98 | 0.44 | 0.33 | 0.23 | 0.25 | ||

| Sample | PA66 | PA66-Mclay-0.05 | PA66-Mclay-0.075 | PA66-Mclay-0.1 | PA66-Mclay-0.5 |

|---|---|---|---|---|---|

| α1 (o) | 20.1 | 20.2 | 19.9 | 19.8 | 20.1 |

| α2 (o) | 23.3 | 23.5 | 23.1 | 23.0 | 23.1 |

| γ (o) | 22.0 | 21.8 | 21.6 | 21.9 | 21.7 |

| Xc (%) | 33.9 | 34.2 | 34.7 | 33.8 | 25.5 |

| Sample | PA66 | PA66-Mclay-0.05 | PA66-Mclay-0.075 | PA66-Mclay-0.1 | PA66-Mclay-0.5 |

|---|---|---|---|---|---|

| VN (ml/g) | 184.3 | 183.2 | 185.6 | 189.6 | 186.7 |

| RV (JIS) | 3.35 | 3.33 | 3.37 | 3.42 | 3.38 |

| [η] (dL/g) | 1.12 | 1.11 | 1.12 | 1.13 | 1.13 |

| Mva | 28,840 | 28,487 | 28,840 | 29,241 | 29,241 |

| Endgroup content (mmol/kg) | 81.02 | 80.44 | 79.77 | 79.35 | 79.55 |

| Mn | 24,684 | 24,862 | 25,073 | 25,204 | 25,143 |

| MI (g/10 min) | 3.72 ± 0.27 | 5.75 ± 0.31 | 6.05 ± 0.41 | 8.09 ± 0.53 | 4.64 ± 0.14 |

| Sample | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|

| PA66 | 79.5 ± 1.24% | 515.4 ± 2.43% | 434.2 ± 6.73% |

| PA66-Mclay-0.1 | 86.1 ± 0.87% | 517.8 ± 2.78% | 312.8 ± 7.18% |

| PA66-Mclay-0.5 | 88.9 ± 0.92% | 519.5 ± 2.46% | 642.5 ± 7.09% |

| No. | Denier | Fiber Orientation | Tensile Strength (cN/dtex) | Elongation at Break(%) | Modulus (cN/dtex) |

|---|---|---|---|---|---|

| PA66 | 7828.2 | 0.74 | 5.9 ± 3.2% | 63 ± 16.8% | 9.6 |

| PA66-Mclay-0.1 | 7493.4 | 0.74 | 6.3 ± 4.1% | 51.5 ± 14.2% | 13.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, X.; Wu, Y.; Chen, Z.; Yang, T.; Cheng, Y.; Yu, H.; Huang, T. In-Situ Polymerization of High-Molecular Weight Nylon 66 Modified Clay Nanocomposites with Low Apparent Viscosity. Polymers 2019, 11, 510. https://doi.org/10.3390/polym11030510

Duan X, Wu Y, Chen Z, Yang T, Cheng Y, Yu H, Huang T. In-Situ Polymerization of High-Molecular Weight Nylon 66 Modified Clay Nanocomposites with Low Apparent Viscosity. Polymers. 2019; 11(3):510. https://doi.org/10.3390/polym11030510

Chicago/Turabian StyleDuan, Xiaochao, Yanpeng Wu, Zhao Chen, Tonghui Yang, Yongchang Cheng, Hao Yu, and Tao Huang. 2019. "In-Situ Polymerization of High-Molecular Weight Nylon 66 Modified Clay Nanocomposites with Low Apparent Viscosity" Polymers 11, no. 3: 510. https://doi.org/10.3390/polym11030510

APA StyleDuan, X., Wu, Y., Chen, Z., Yang, T., Cheng, Y., Yu, H., & Huang, T. (2019). In-Situ Polymerization of High-Molecular Weight Nylon 66 Modified Clay Nanocomposites with Low Apparent Viscosity. Polymers, 11(3), 510. https://doi.org/10.3390/polym11030510