Facile Preparation of Highly Conductive Poly(amide-imide) Composite Films beyond 1000 S m−1 through Ternary Blend Strategy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

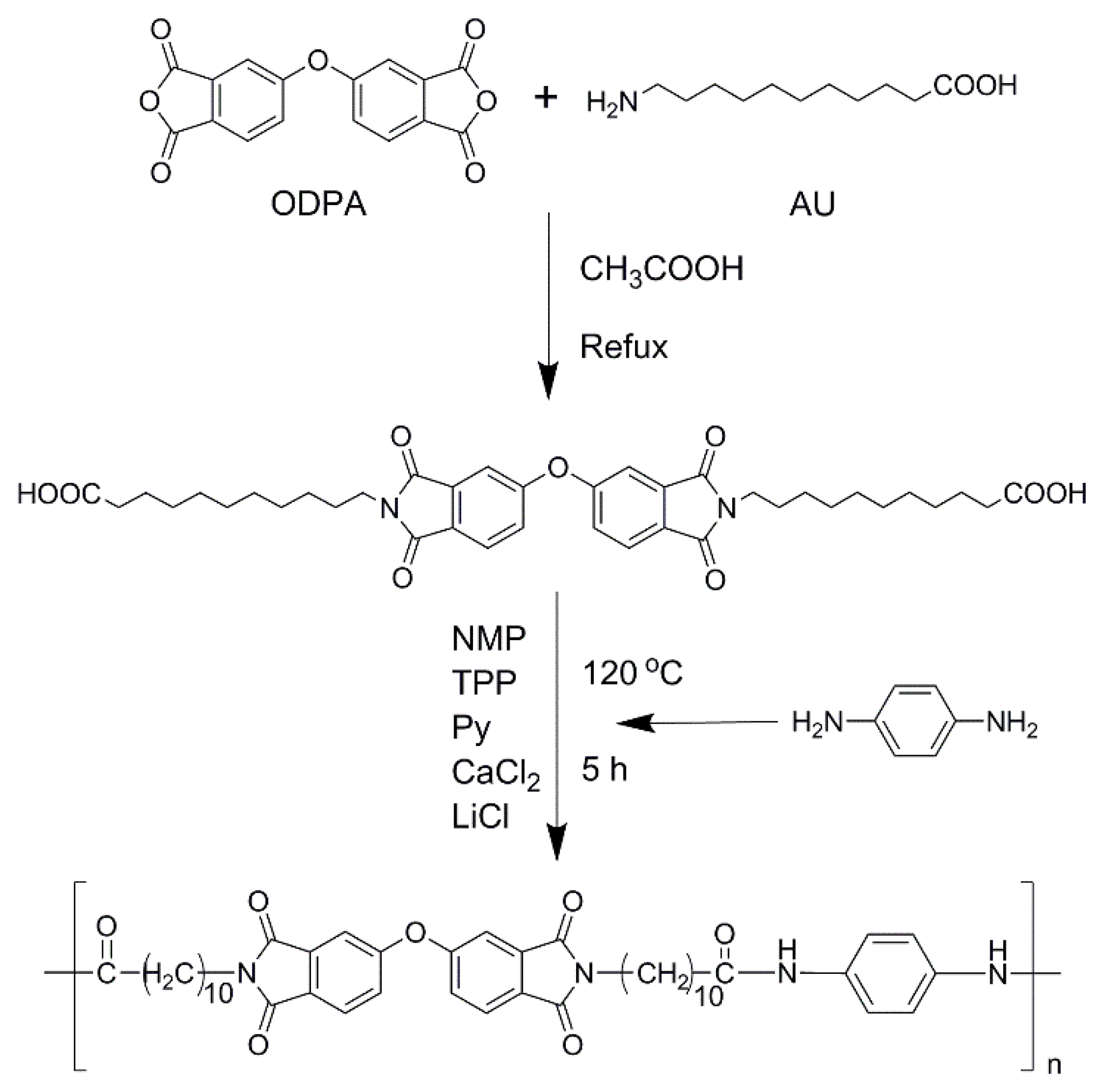

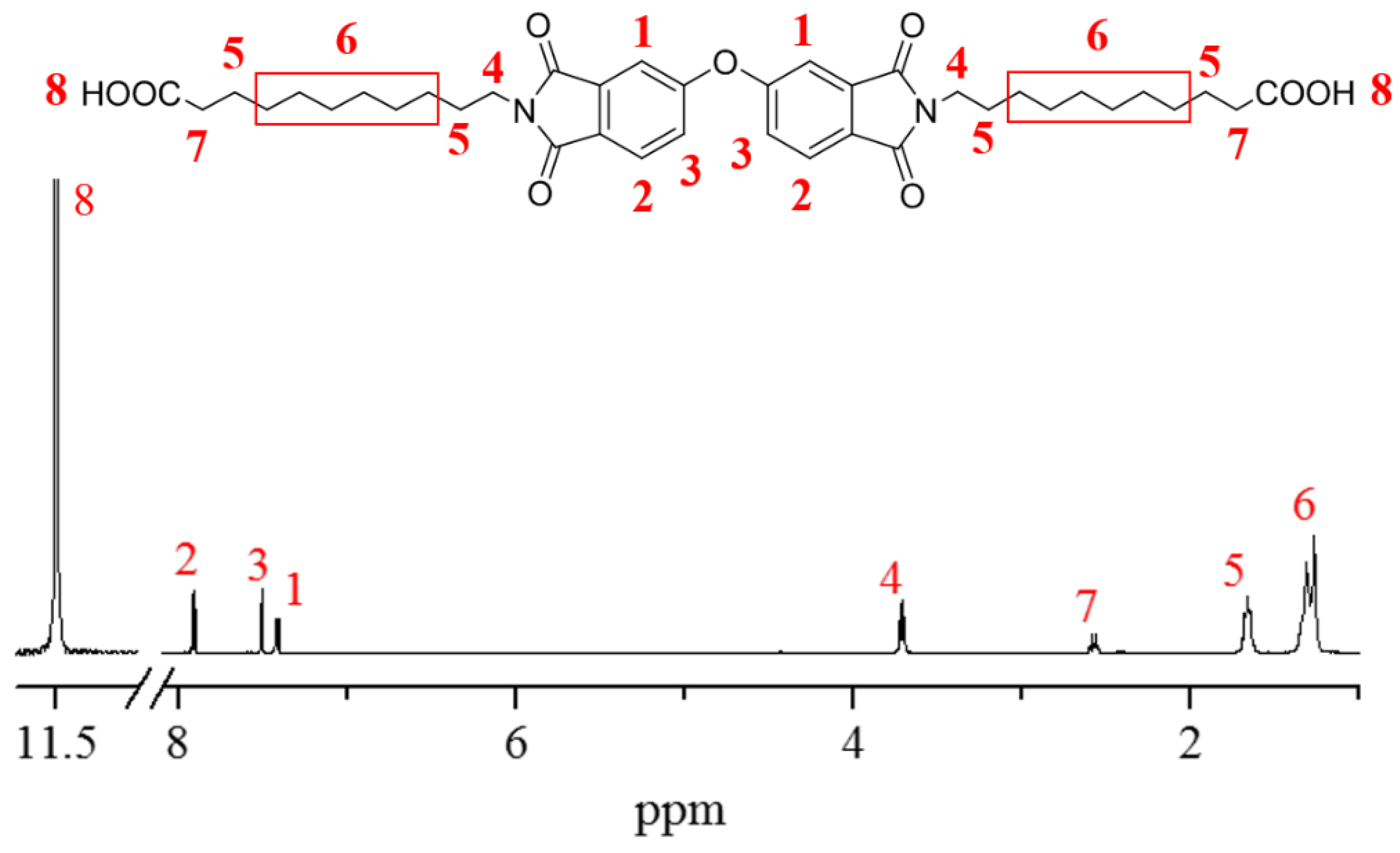

2.2. Synthesis of Aromatic PAI

2.3. Preparation of PANI

2.4. Preparation of PAI/PANI/CB Ternary Conductive Polymer Composites

2.5. Characterization

3. Results

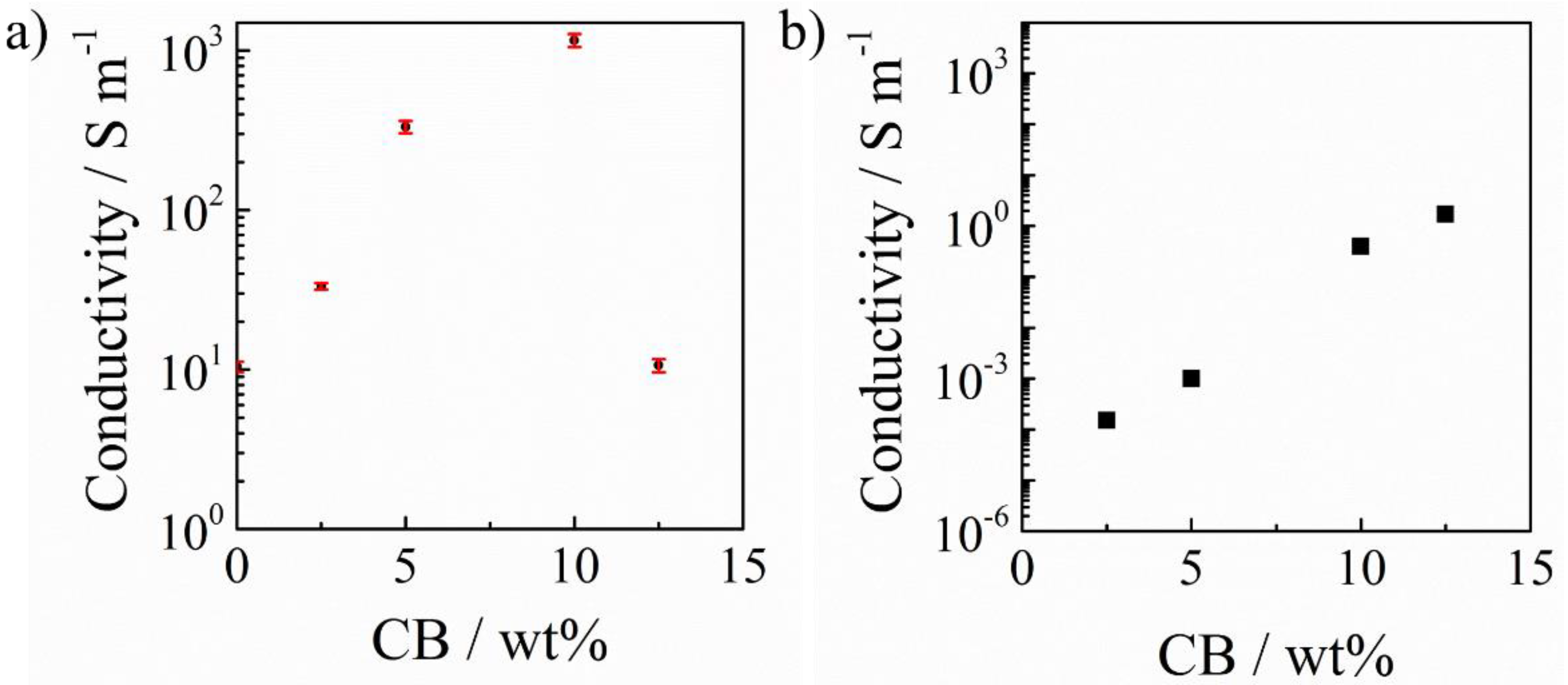

3.1. Electrical Conductivity

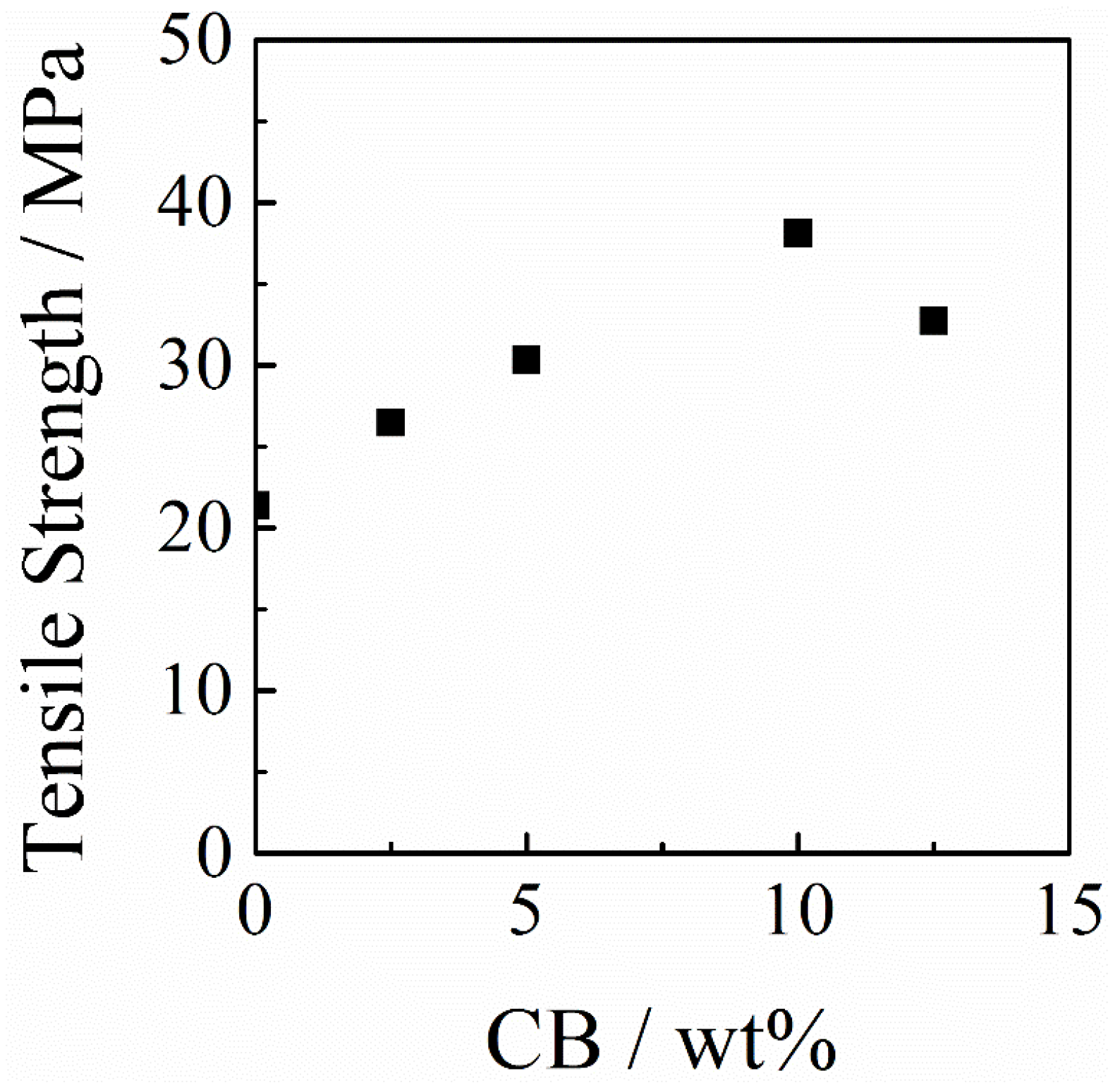

3.2. Tensile Strength

3.3. Thermal Stability

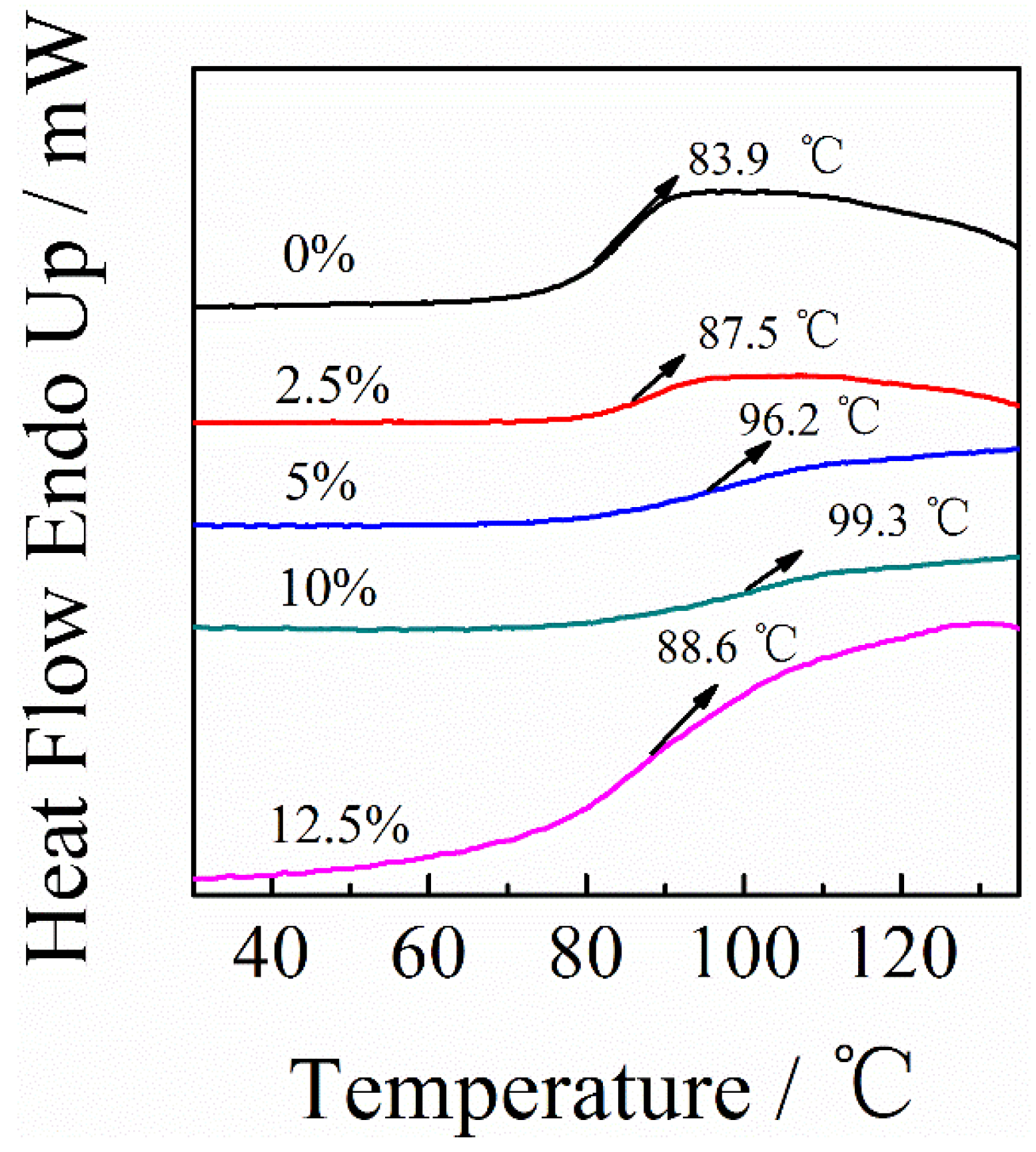

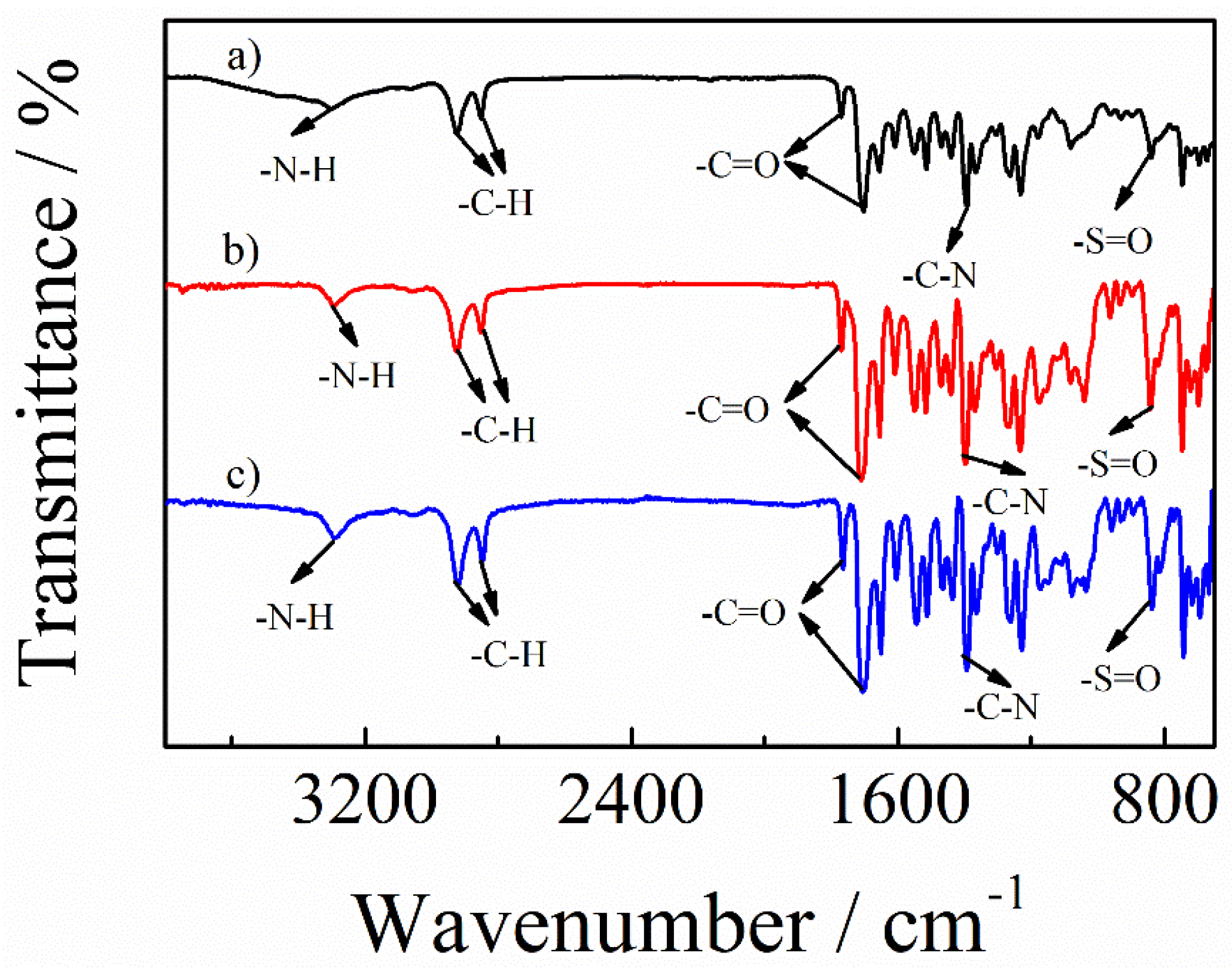

3.4. Phase Transition

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, H.; Li, Q.; Zhang, S.; Yin, R.; Liu, X.; He, Y.; Dai, K.; Shan, C.; Guo, J.; Liu, C.; et al. Electrically conductive polymer composites for smart flexible strain sensors: A critical review. J. Mater. Chem. C 2018, 6, 12121–12141. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M.; Sanchez, J.A.L.; Capilla, R.P.; Diaz, P.G. Recent developments in graphene/polymer nanocomposites for application in polymer solar cells. Polymers 2018, 10, 217. [Google Scholar] [CrossRef]

- Maity, S.; Chatterjee, A. Conductive polymer-based electro-conductive textile composites for electromagnetic interference shielding: A review. J. Ind. Text. 2018, 47, 2228–2252. [Google Scholar] [CrossRef]

- Agate, S.; Joyce, M.; Lucia, L.; Pal, L. Cellulose and nanocellulose-based flexible-hybrid printed electronics and conductive composites—A review. Carbohydr. Polym. 2018, 198, 249–260. [Google Scholar] [CrossRef]

- Zhan, C.X.; Yu, G.Q.; Lu, Y.; Wang, L.Y.; Wujcik, E.; Wei, S.Y. Conductive polymer nanocomposites: A critical review of modern advanced devices. J. Mater. Chem. C 2017, 5, 1569–1585. [Google Scholar] [CrossRef]

- Kaur, G.; Adhikari, R.; Cass, P.; Bown, M.; Gunatillake, P. Electrically conductive polymers and composites for biomedical applications. RSC Adv. 2015, 5, 37553–37567. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, G.; Wang, W.; Cao, M.; Luo, Z.; Shao, N.; Wang, B. Molecular design and synthesis of thermotropic liquid crystalline poly(amide imide)s with high thermal stability and solubility. e-Polymers 2017, 17, 199–207. [Google Scholar] [CrossRef]

- Kim, S.D.; Lee, B.; Byun, T.; Chung, I.S.; Park, J.; Shin, I.; Ahn, N.Y.; Seo, M.; Lee, Y.; Kim, Y.; et al. Poly(amide-imide) materials for transparent and flexible displays. Sci. Adv. 2018, 4, eaau1956. [Google Scholar] [CrossRef]

- Dodda, J.M.; Belsky, P. Progress in designing poly(amide imide)s (PAI) in terms of chemical structure, preparation methods and processability. Eur. Polym. J. 2016, 84, 514–537. [Google Scholar] [CrossRef]

- Jalalian, E.; Mehdipour-Ataei, S.; Babanzadeh, S.; Khodabakhshi, F. Silicon-containing poly(amide-imide)s: Preparation, characterization, and properties. Des. Monomers Polym. 2015, 18, 714–722. [Google Scholar] [CrossRef]

- Javadi, A.; Shockravi, A.; Rafieimanesh, A.; Malek, A.; Ando, S. Synthesis and structure–property relationships of novel thiazole-containing poly (amide imide) s with high refractive indices and low birefringences. Polym. Int. 2015, 64, 486–495. [Google Scholar] [CrossRef]

- Yao, H.Y.; Fan, Z.; Li, P.C.; Li, B.C.; Guan, X.; Du, D.H.; Ouyang, J.Y. Solution processed intrinsically conductive polymer films with high thermoelectric properties and good air stability. J. Mater. Chem. A 2018, 6, 24496–24502. [Google Scholar] [CrossRef]

- Balint, R.; Cassidy, N.J.; Cartmell, S.H. Conductive polymers: Towards a smart biomaterial for tissue engineering. Acta Biomater. 2014, 10, 2341–2353. [Google Scholar] [CrossRef]

- Alemu, D.; Wei, H.Y.; Ho, K.C.; Chu, C.W. Highly conductive PEDOT:PSS electrode by simple film treatment with methanol for ITO-free polymer solar cells. Energy Environ. Sci. 2012, 5, 9662–9671. [Google Scholar] [CrossRef]

- Mccullough, R.D.; Williams, S.P. Toward tuning electrical and optical properties in conjugated polymers using side chains: Highly conductive head-to-tail heteroatom-functionalized polythiophenes. J. Am. Chem. Soc. 1993, 115, 11608–11609. [Google Scholar] [CrossRef]

- Wang, Y.; Sotzing, G.A.; Weiss, R.A. Preparation of conductive polypyrrole/polyurethane composite foams by in situ polymerization of pyrrole. Chem. Mater. 2008, 20, 2574–2582. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, T.; Wang, T.; Zhang, J.; Chen, J.; Yang, R.; Ruan, L.; Wang, B. Facile preparation of multifunctional poly(amide-imide)/polyaniline films: Combining self-cleaning, self-extinguishing, and conductive. Polym. Eng. Sci. 2019, 59, E33–E43. [Google Scholar] [CrossRef]

- Zotti, G.; Schiavon, G.; Zecchin, S.; Morin, J.F.; Leclerc, M. Electrochemical, conductive, and magnetic properties of 2,7-carbazole-based conjugated polymers. Macromolecules 2002, 35, 2122–2128. [Google Scholar] [CrossRef]

- Segal, E.; Tchoudakov, R.; Narkis, M.; Siegmann, A. Thermoplastic polyurethane-carbon black compounds: Structure, electrical conductivity and sensing of liquids. Polym. Eng. Sci. 2002, 42, 2430–2439. [Google Scholar] [CrossRef]

- Arroyo, J.; Ryan, C. Incorporation of carbon nanofillers tunes mechanical and electrical percolation in PHBV:PLA blends. Polymers 2018, 10, 1371. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon 2009, 47, 2–22. [Google Scholar] [CrossRef]

- Cao, M.; Luo, Z.; Yang, Y.; Wang, Y.; Wang, B. In situ polymerized poly(amide imide)/multiwalled carbon nanotube composite: Structural, mechanical, and electrical studies. Polym.-Plast. Technol. 2017, 56, 1391–1400. [Google Scholar] [CrossRef]

- Larin, S.V.; Nazarychev, V.M.; Dobrovskiy, A.Y.; Lyulin, A.V.; Lyulin, S.V. Structural ordering in SWCNT-polyimide nanocomposites and its influence on their mechanical properties. Polymers 2018, 10, 1245. [Google Scholar] [CrossRef]

- Mahmood, N.; Islam, M.; Hameed, A.; Saeed, S. Polyamide 6/multiwalled carbon nanotubes nanocomposites with modified morphology and thermal properties. Polymers 2013, 5, 1380–1391. [Google Scholar] [CrossRef]

- Ramanathan, T.; Abdala, A.A.; Stankovich, S.; Dikin, D.A.; Herrera-Alonso, M.; Piner, R.D.; Adamson, D.H.; Schniepp, H.C.; Chen, X.; Ruoff, R.S.; et al. Functionalized graphene sheets for polymer nanocomposites. Nat. Nanotechnol. 2008, 3, 327–331. [Google Scholar] [CrossRef]

- Kohut-Svelko, N.; Dinant, F.; Magana, S.; Clisson, G.; Francois, J.; Dagron-Lartigau, C.; Reynaud, S. Overview of the preparation of pure polyaniline and conductive composites in dispersed media and by thermal processes: From laboratory to semi-industrial scale. Polym. Int. 2006, 55, 1184–1190. [Google Scholar] [CrossRef]

- Bhadra, S.; Khastgir, D.; Singha, N.K.; Lee, J.H. Progress in preparation, processing and applications of polyaniline. Prog. Polym. Sci. 2009, 34, 783–810. [Google Scholar] [CrossRef]

- Baker, C.O.; Huang, X.W.; Nelson, W.; Kaner, R.B. Polyaniline nanofibers: Broadening applications for conducting polymers. Chem. Soc. Rev. 2017, 46, 1510–1525. [Google Scholar] [CrossRef]

- Sathiyanarayanan, S.; Maruthan, K.; Muthukrishnan, S.; Venkatachari, G. High performance polyaniline containing coating system for wet surfaces. Prog. Org. Coat. 2009, 66, 113–117. [Google Scholar] [CrossRef]

- Wang, K.P.; Xu, L.L.; Li, K.L.; Liu, L.; Zhang, Y.; Wang, J. Development of polyaniline conductive membrane for electrically enhanced membrane fouling mitigation. J. Membr. Sci. 2019, 570, 371–379. [Google Scholar] [CrossRef]

- Zou, J.H.; Chen, H.; Chunder, A.; Yu, Y.X.; Huo, Q.; Zhai, L. Preparation of a superhydrophobic and conductive nanocomposite coating from a carbon-nanotube-conjugated block copolymer dispersion. Adv. Mater. 2008, 20, 3337–3341. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, J.C.; Zheng, Y.M.; Huang, Z.B.; Feng, L.; Jiang, L. Stable, superhydrophobic, and conductive polyaniline/polystyrene films for corrosive environments. Adv. Funct. Mater. 2006, 16, 568–574. [Google Scholar] [CrossRef]

- Yavuz, A.G.; Uygun, A.; Bhethanabotla, V.R. Substituted polyaniline/chitosan composites: Synthesis and characterization. Carbohydr. Polym. 2009, 75, 448–453. [Google Scholar] [CrossRef]

- Razak, S.I.A.; Rahman, W.A.W.A.; Yahya, M.Y. Electrically conductive nanocomposites of epoxy/polyaniline nanowires doped with formic acid: Effect of loading on the conduction and mechanical properties. Nano 2012, 7, 1250039. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Huo, P.F.; Liu, X.; Rong, C.R.; Wang, G.B. High dielectric constant polyaniline/sulfonated poly(aryl ether ketone) composite membranes with good thermal and mechanical properties. J. Appl. Polym. Sci. 2013, 130, 1990–1995. [Google Scholar] [CrossRef]

- Krause, B.; Kroschwald, L.; Pötschke, P. The influence of the blend ratio in PA6/PA66/MWCNT blend composites on the electrical and thermal properties. Polymers 2019, 11, 122. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube-polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Byrne, M.T.; Gun’ko, Y.K. Recent advances in research on carbon nanotube-polymer composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef]

- Liu, Y.D.; Kumar, S. Polymer/carbon nanotube nano composite fibers—A review. ACS Appl. Mater. Interfaces 2014, 6, 6069–6087. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Shen, Y.; Wang, T.; Ni, Y.; Zhang, Z.; Sun, L.; Ji, B.; Wang, B. Control of conductive and mechanical performances of poly(amide-imide) composite films utilizing synergistic effect of polyaniline and multi-walled carbon nanotube. Polym. Eng. Sci. 2019, 59, E224–E230. [Google Scholar] [CrossRef]

- Alam, F.E.; Yu, J.H.; Shen, D.Y.; Dai, W.; Li, H.; Zeng, X.L.; Yao, Y.G.; Du, S.Y.; Jiang, N.; Lin, C.T. Highly conductive 3D segregated graphene architecture in polypropylene composite with efficient EMI shielding. Polymers 2017, 9, 662. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Effects of carbon nanotubes/graphene nanoplatelets hybrid systems on the structure and properties of polyetherimide-based foams. Polymers 2018, 10, 348. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.Y.; Li, H.L.; Zhang, Z.Y.; Wang, X.L. Synergistic effect of polyaniline and multiwalled carbon nanotube on the microstructure and the electric property in PP/PANI/MWNT composites. Polym. Eng. Sci. 2012, 52, 979–987. [Google Scholar] [CrossRef]

- Ma, P.C.; Liu, M.Y.; Zhang, H.; Wang, S.Q.; Wang, R.; Wang, K.; Wong, Y.K.; Tang, B.Z.; Hong, S.H.; Paik, K.W.; et al. Enhanced electrical conductivity of nanocomposites containing hybrid fillers of carbon nanotubes and carbon black. ACS Appl. Mater. Interfaces 2009, 1, 1090–1096. [Google Scholar] [CrossRef] [PubMed]

- Wen, M.; Sun, X.J.; Su, L.; Shen, J.B.; Li, J.; Guo, S.Y. The electrical conductivity of carbon nanotube/carbon black/polypropylene composites prepared through multistage stretching extrusion. Polymer 2012, 53, 1602–1610. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Jung, Y.C.; Yoo, H.J.; Cho, J.W. Influence of carbon nanotubes and polypyrrole on the thermal, mechanical and electroactive shape-memory properties of polyurethane nanocomposites. Compos. Sci. Technol. 2007, 67, 1920–1929. [Google Scholar] [CrossRef]

- Radmilovic, V.V.; Carraro, C.; Uskokovic, P.S.; Radmilovic, V.R. Structure and properties of polymer nanocomposite films with carbon nanotubes and graphene. Polym. Compos. 2017, 38, E490–E497. [Google Scholar] [CrossRef]

- Onar, N.; Aksit, A.C.; Ebeoglugil, M.F.; Birlik, I.; Celik, E.; Ozdemir, I. Structural, electrical, and electromagnetic properties of cotton fabrics coated with polyaniline and polypyrrole. J. Appl. Polym. Sci. 2009, 114, 2003–2010. [Google Scholar] [CrossRef]

- Vatani, Z.; Eisazadeh, H. Fabrication and thermal degradation behavior of poly(vinyl chloride) particle coated with polythiophene and polyaniline. Synth. Met. 2012, 162, 1508–1512. [Google Scholar] [CrossRef]

- Marinho, B.; Ghislandi, M.; Tkalya, E.; Koning, C.E.; de With, G. Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black, and graphite powder. Powder Technol. 2012, 221, 351–358. [Google Scholar] [CrossRef]

- De, S.; Lyons, P.E.; Sorel, S.; Doherty, E.M.; King, P.J.; Blau, W.J.; Nirmalraj, P.N.; Boland, J.J.; Scardaci, V.; Joimel, J.; et al. Transparent, flexible, and highly conductive thin films based on polymer—Nanotube composites. ACS Nano 2009, 3, 714–720. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, S.Q.; Li, P.C.; Yuan, D.; Zhou, X.; Sun, J.T.; Lu, X.H.; He, C.B. Interfacial control and carrier tuning of carbon nanotube/polyaniline composites for high thermoelectric performance. Carbon 2018, 136, 292–298. [Google Scholar] [CrossRef]

- Alamer, F.A. Structural and electrical properties of conductive cotton fabrics coated with the composite polyaniline/carbon black. Cellulose 2018, 25, 2075–2082. [Google Scholar] [CrossRef]

- Hacivelioglu, F.; Kilic, N.; Celebi, E.B.; Yesilot, S. In situ preparation and properties of sulfonic and phosphonic acid substituted polyphosphazene/polyaniline composites. Polymer 2016, 96, 112–120. [Google Scholar] [CrossRef]

- Matchawet, S.; Kaesaman, A.; Bomlai, P.; Nakason, C. Effects of multi-walled carbon nanotubes and conductive carbon black on electrical, dielectric, and mechanical properties of epoxidized natural rubber composites. Polym. Compos. 2017, 38, 1031–1042. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.L.; Li, W.H. Effect of carbon black on the mechanical performances of magnetorheological elastomers. Polym. Test. 2008, 27, 340–345. [Google Scholar] [CrossRef]

- Flandin, L.; Hiltner, A.; Baer, E. Interrelationships between electrical and mechanical properties of a carbon black-filled ethylene–octene elastomer. Polymer 2001, 42, 827–838. [Google Scholar] [CrossRef]

- Van Krevelen, D.W. Some basic aspects of flame resistance of polymeric materials. Polymer 1975, 16, 615–620. [Google Scholar] [CrossRef]

- Kishi, H.; Imai, K.; Iimura, K.; Tanaka, H.; Nagao, A.; Kakibe, T.; Matsuda, S. Interfacial control and mechanical properties of carbon black-reinforced carboxyl-terminated butadiene acrylonitrile rubber/epoxy polymer composites. Polym. Adv. Technol. 2019, 30, 329–335. [Google Scholar] [CrossRef]

- Zhang, R.; Baxendale, M.; Peijs, T. Universal resistivity-strain dependence of carbon nanotube/polymer composites. Phys. Rev. B 2007, 76, 195433. [Google Scholar] [CrossRef]

- Du, F.; Yu, D.S.; Dai, L.M.; Ganguli, S.; Varshney, V.; Roy, A.K. Preparation of tunable 3D pillared carbon nanotube-graphene networks for high-performance capacitance. Chem. Mater. 2011, 23, 4810–4816. [Google Scholar] [CrossRef]

- Kong, Q.; Luo, Z.; Wang, Y.; Wang, B. Fabrication of super-stretchable and electrical conductive membrane of spandex/multi-wall carbon nanotube/reduced graphene oxide composite. J. Polym. Res. 2018, 25, 231. [Google Scholar] [CrossRef]

- Fan, W.; Miao, Y.E.; Huang, Y.P.; Tjiu, W.W.; Liu, T.X. Flexible free-standing 3D porous N-doped graphene-carbon nanotube hybrid paper for high-performance supercapacitors. RSC Adv. 2015, 5, 9228–9236. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, J.H.; Luo, F.B.; Shen, L.; Wang, Y.; Wu, K.; Lu, M.G. Assembly of ordered polyaniline-graphene hybrid nanomaterials based on poly(2-methoxyaniline-5-sulfonic acid) functionalized graphene nanosheets. Synth. Met. 2016, 221, 103–113. [Google Scholar] [CrossRef]

| Composition | First Stage | Second Stage | Third Stage | Tg °C | Yc % | LOI % | |||

|---|---|---|---|---|---|---|---|---|---|

| To/°C | Tmax/°C | To/°C | Tmax/°C | To/°C | Tmax/°C | ||||

| 0% | 119 | 147 | 273 | 300 | 453 | 485 | 83.9 | 27 | 28 |

| 2.5% | 128 | 164 | 295 | 321 | 472 | 499 | 87.5 | 28 | 29 |

| 5% | 136 | 172 | 281 | 324 | 464 | 493 | 96.2 | 28 | 29 |

| 10% | 156 | 175 | 292 | 321 | 463 | 492 | 99.3 | 31 | 30 |

| 12.5% | 154 | 188 | 291 | 321 | 464 | 494 | 88.6 | 32 | 30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yu, H.; Li, Y.; Wang, T.; Xu, T.; Chen, J.; Fan, Z.; Wang, Y.; Wang, B. Facile Preparation of Highly Conductive Poly(amide-imide) Composite Films beyond 1000 S m−1 through Ternary Blend Strategy. Polymers 2019, 11, 546. https://doi.org/10.3390/polym11030546

Wang Y, Yu H, Li Y, Wang T, Xu T, Chen J, Fan Z, Wang Y, Wang B. Facile Preparation of Highly Conductive Poly(amide-imide) Composite Films beyond 1000 S m−1 through Ternary Blend Strategy. Polymers. 2019; 11(3):546. https://doi.org/10.3390/polym11030546

Chicago/Turabian StyleWang, Yanbin, Huang Yu, Yongchao Li, Teng Wang, Tao Xu, Jinxing Chen, Zicheng Fan, Yufeng Wang, and Biaobing Wang. 2019. "Facile Preparation of Highly Conductive Poly(amide-imide) Composite Films beyond 1000 S m−1 through Ternary Blend Strategy" Polymers 11, no. 3: 546. https://doi.org/10.3390/polym11030546

APA StyleWang, Y., Yu, H., Li, Y., Wang, T., Xu, T., Chen, J., Fan, Z., Wang, Y., & Wang, B. (2019). Facile Preparation of Highly Conductive Poly(amide-imide) Composite Films beyond 1000 S m−1 through Ternary Blend Strategy. Polymers, 11(3), 546. https://doi.org/10.3390/polym11030546