A Facile Technique to Extract the Cross-Sectional Structure of Brittle Porous Chars from Intumescent Coatings

Abstract

1. Introduction

1.1. Context and Motivation

1.2. Challenge and Scope of Study

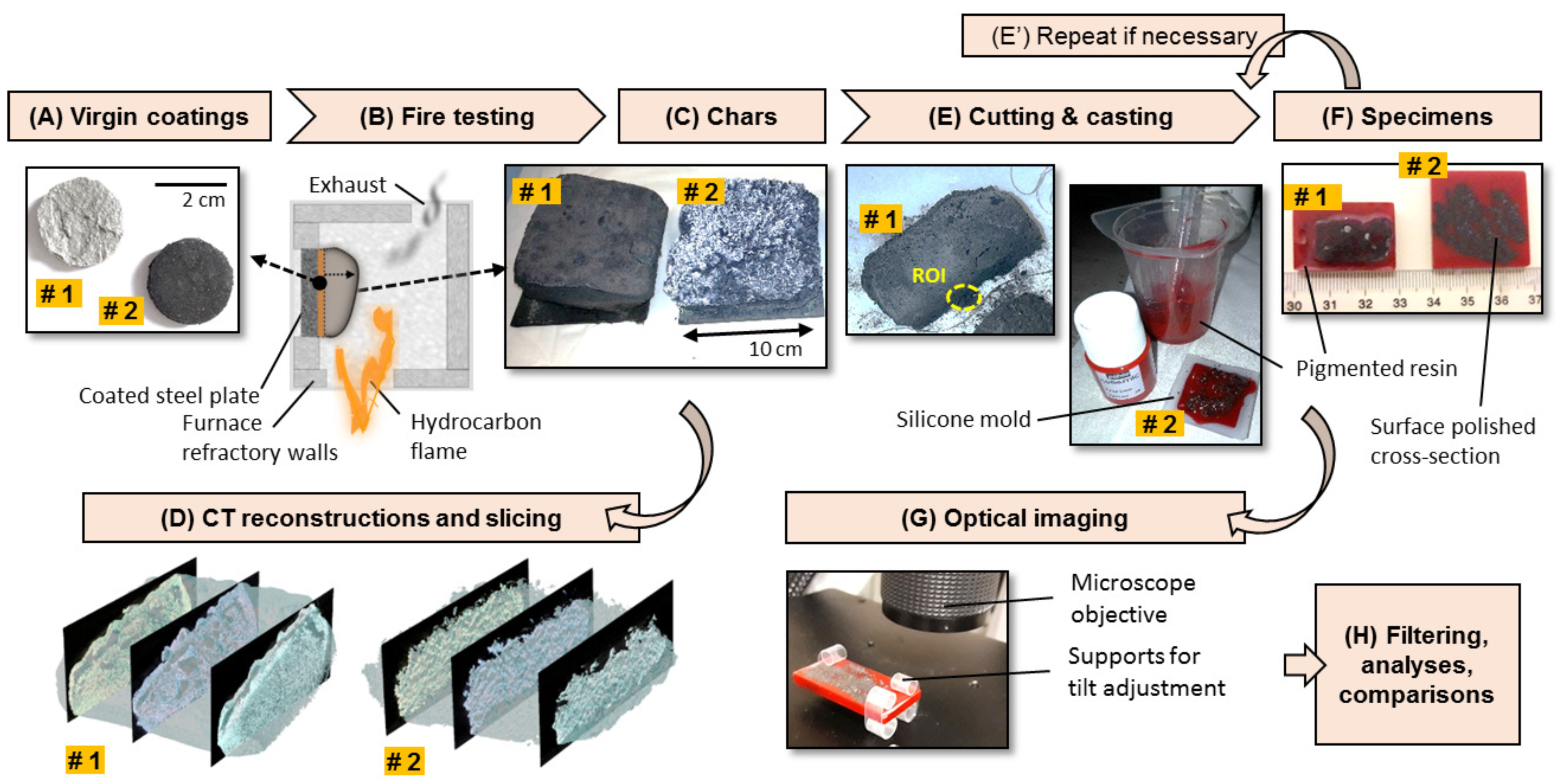

2. Materials and Methods

2.1. Intumescent Coatings

2.2. Fire Exposure

2.3. Specimen Cutting

2.4. Colored Resin Casting

2.5. Surface Preparation

2.6. Image Recordings

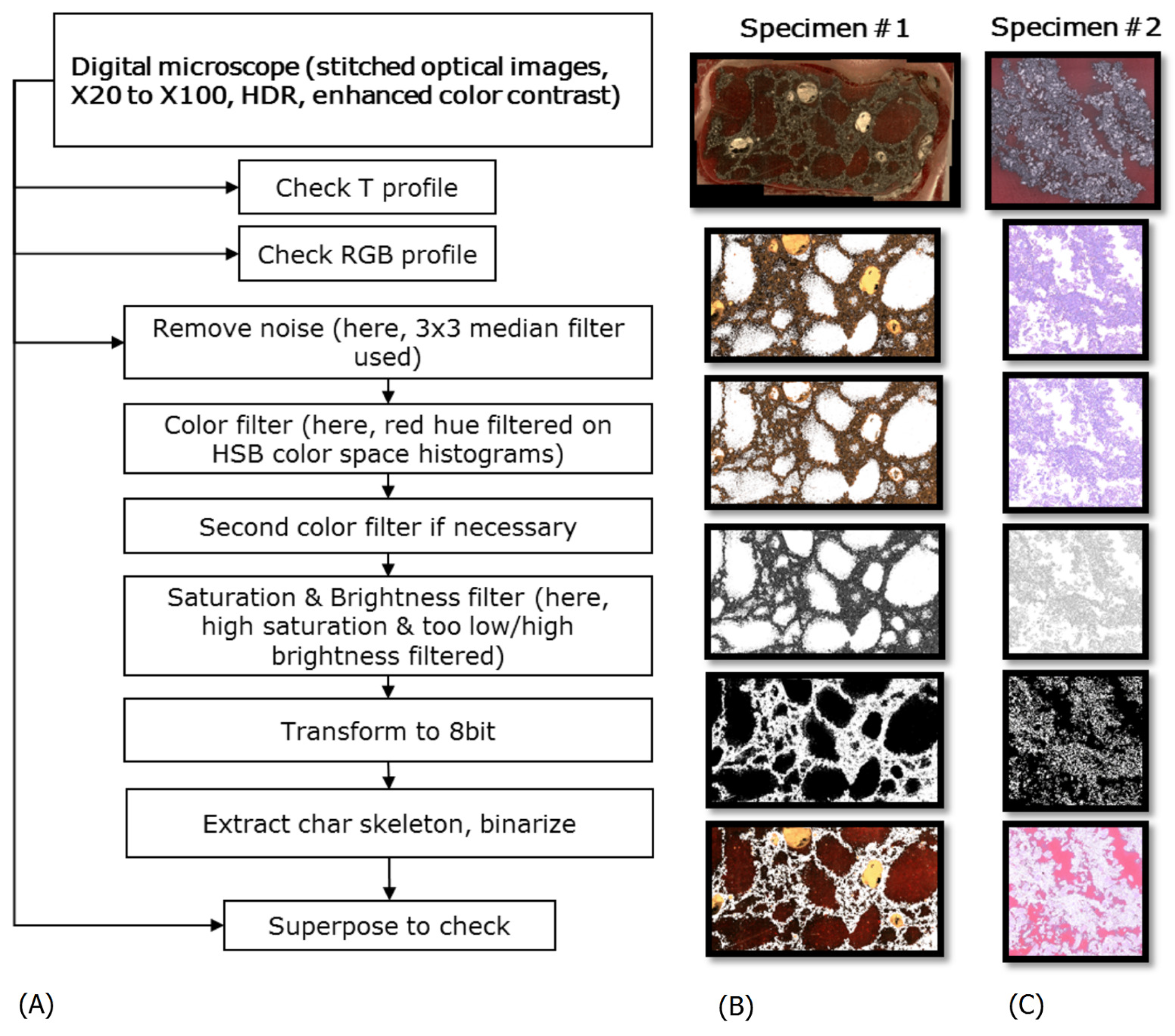

2.7. Image Treatments

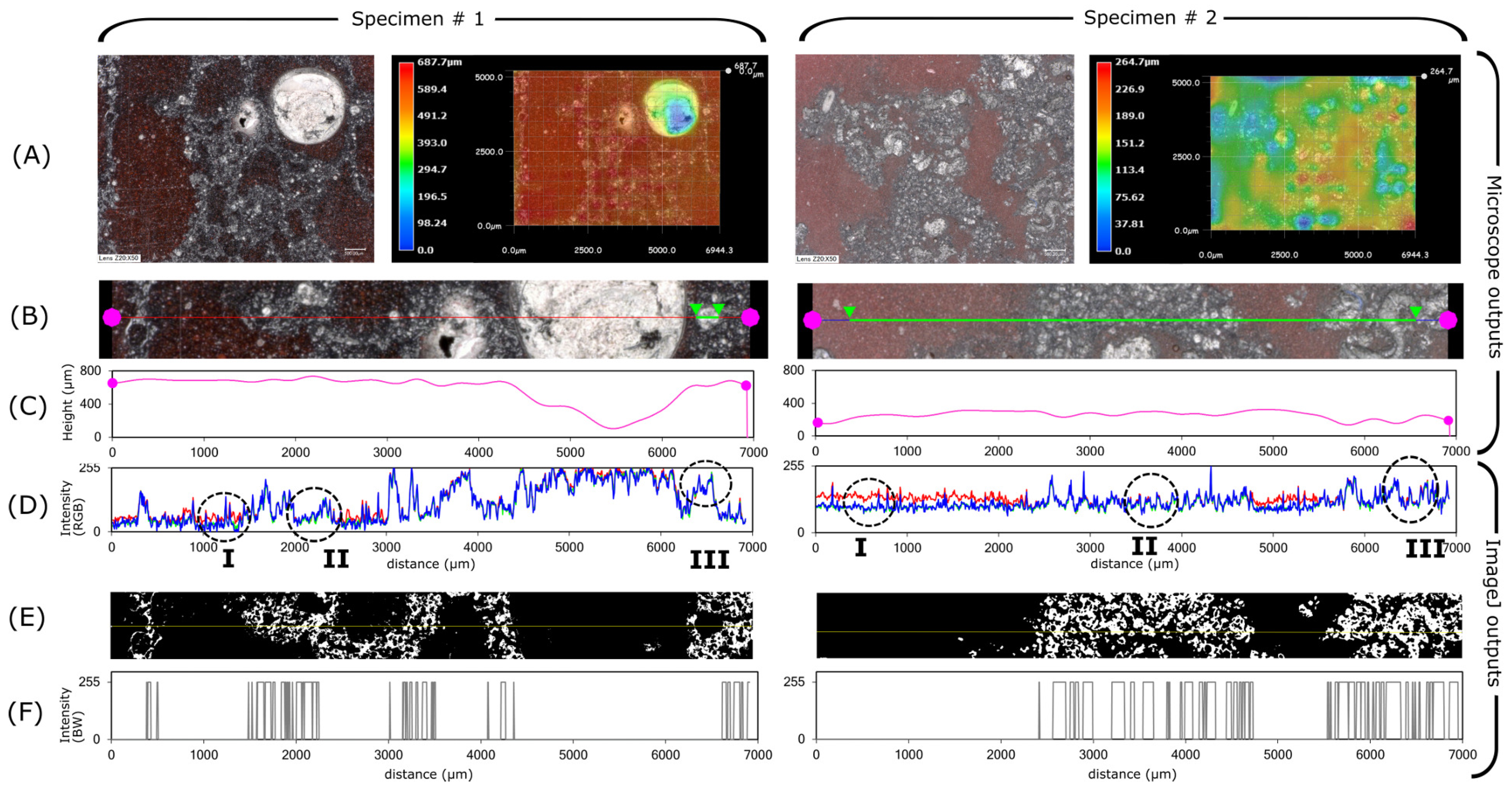

2.8. Image Analyses

3. Results and Discussion

3.1. Understanding the Color Contrast on Resin Casted Specimens

3.2. Optical Image Filtering

3.3. Fractal Analyses and Comparison to CT Results

3.4. Note on the Effect of Threshold Intensities

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Camino, G.; Costa, L.; Martinasso, G. Intumescent fire-retardant systems. Polym. Degrad. Stab. 1989, 23, 359–376. [Google Scholar] [CrossRef]

- Alongi, J.; Han, Z.; Bourbigot, S. Intumescence: Tradition versus novelty. A comprehensive review. Prog. Polym. Sci. 2015, 51, 28–73. [Google Scholar] [CrossRef]

- Muller, M.; Bourbigot, S.; Duquesne, S.; Klein, R.; Giannini, G.; Lindsay, C.; Vlassenbroeck, J. Investigation of the synergy in intumescent polyurethane by 3D computed tomography. Polym. Degrad. Stab. 2013, 98, 1638–1647. [Google Scholar] [CrossRef]

- Morys, M.; Illerhaus, B.; Sturm, H.; Schartel, B. Size is not all that matters: Residue thickness and protection performance of intumescent coatings made from different binders. J. Fire Sci. 2017, 35, 284–302. [Google Scholar] [CrossRef]

- Geoffroy, L.; Samyn, F.; Jimenez, M.; Bourbigot, S. Intumescent polymer metal laminates for fire protection. Polymers 2018, 10, 995. [Google Scholar] [CrossRef]

- Staggs, J. Thermal conductivity estimates of intumescent chars by direct numerical simulation. Fire Saf. J. 2010, 45, 228–237. [Google Scholar] [CrossRef]

- Cirpici, B.; Wang, Y.; Rogers, B. Assessment of the thermal conductivity of intumescent coatings in fire. Fire Saf. J. 2016, 81, 74–84. [Google Scholar] [CrossRef]

- Okyay, G.; Naik, A.; Samyn, F.; Jimenez, M.; Bourbigot, S. Fractal conceptualization of intumescent fire barriers, toward simulations of virtual morphologies. Sci. Rep. 2019, 9, 1872. [Google Scholar] [CrossRef] [PubMed]

- Bourbigot, S.; Sarazin, J.; Samyn, F.; Jimenez, M. Intumescent ethylene-vinyl acetate copolymer: Reaction to fire and mechanistic aspects. Polym. Degrad. Stab. 2019, 161, 235–244. [Google Scholar] [CrossRef]

- Nyazika, T.; Jimenez, M.; Samyn, F.; Bourbigot, S. Modeling heat transfers across a silicone-based intumescent coating. J. Phys. Conf. Ser. 2018, 1107, 032012. [Google Scholar] [CrossRef]

- Gardelle, B.; Duquesne, S.; Vandereecken, P.; Bourbigot, S. Characterization of the carbonization process of expandable graphite/silicone formulations in a simulated fire. Polym. Degrad. Stab. 2013, 98, 1052–1063. [Google Scholar] [CrossRef]

- Naik, A.D.; Duquesne, S.; Bourbigot, S. Hydrocarbon time-temperature curve under airjet perturbation: An in situ method to probe char stability and integrity in reactive fire protection coatings. J. Fire Sci. 2016, 34, 385–397. [Google Scholar] [CrossRef]

- Digital Microscope VHX-1000E User’s Manual; Keyence Corporation: Osaka, Japan, 2009.

- Color Profiler. Available online: https://imagej.nih.gov/ij/plugins/color-profiler.html (accessed on 28 February 2019).

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Sural, S.; Qian, G.; Pramanik, S. Segmentation and histogram generation using the HSV color space for image retrieval. In Proceedings of the International Conference on Image Processing, Rochester, NY, USA, 22–25 September 2002; Volume 2, p. II. [Google Scholar]

- Sarkar, N.; Chaudhuri, B.B. An efficient differential box-counting approach to compute fractal dimension of image. IEEE Trans. Syst. Man Cybern. 1994, 24, 115–120. [Google Scholar] [CrossRef]

- Agocs, E.; Attota, R. Enhancing optical microscopy illumination to enable quantitative imaging. Sci. Rep. 2018, 8, 4782. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, M.W.; Cowan, W.B.; Beatty, J.C. An experimental comparison of RGB, YIQ, LAB, HSV, and opponent color models. ACM Trans. Gr. (TOG) 1987, 6, 123–158. [Google Scholar] [CrossRef]

- Duquesne, S.; Delobel, R.; Bras, M.L.; Camino, G. A comparative study of the mechanism of action of ammonium polyphosphate and expandable graphite in polyurethane. Polym. Degrad. Stab. 2002, 77, 333–344. [Google Scholar] [CrossRef]

- Toldy, A.; Anna, P.; Csontos, I.; Szabó, A.; Marosi, G. Intrinsically flame retardant epoxy resin—Fire performance and background—Part I. Polym. Degrad. Stab. 2007, 92, 2223–2230. [Google Scholar] [CrossRef]

- Gomez-Mares, M.; Tugnoli, A.; Landucci, G.; Barontini, F.; Cozzani, V. Behavior of intumescent epoxy resins in fireproofing applications. J. Anal. Appl. Pyrolysis 2012, 97, 99–108. [Google Scholar] [CrossRef]

- Kang, J.; Takahashi, F.; T’ien, J.S. Computer tomography based structure characterization of expanded intumescent coatings for fire protection. In Fire Technology; Springer: Berlin, Germany, 2018. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okyay, G.; Samyn, F.; Jimenez, M.; Bourbigot, S. A Facile Technique to Extract the Cross-Sectional Structure of Brittle Porous Chars from Intumescent Coatings. Polymers 2019, 11, 640. https://doi.org/10.3390/polym11040640

Okyay G, Samyn F, Jimenez M, Bourbigot S. A Facile Technique to Extract the Cross-Sectional Structure of Brittle Porous Chars from Intumescent Coatings. Polymers. 2019; 11(4):640. https://doi.org/10.3390/polym11040640

Chicago/Turabian StyleOkyay, Gizem, Fabienne Samyn, Maude Jimenez, and Serge Bourbigot. 2019. "A Facile Technique to Extract the Cross-Sectional Structure of Brittle Porous Chars from Intumescent Coatings" Polymers 11, no. 4: 640. https://doi.org/10.3390/polym11040640

APA StyleOkyay, G., Samyn, F., Jimenez, M., & Bourbigot, S. (2019). A Facile Technique to Extract the Cross-Sectional Structure of Brittle Porous Chars from Intumescent Coatings. Polymers, 11(4), 640. https://doi.org/10.3390/polym11040640