Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism

Abstract

:1. Introduction

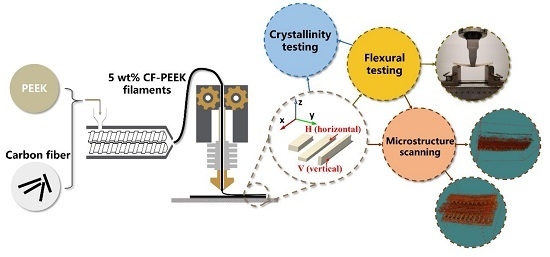

2. Materials and Methods

2.1. Raw Materials and Filaments Preparation

2.2. Fabrication of 3D Printed Specimens

2.3. Fabrication of Injection Molding Specimens

2.4. Flexural Testing of Fabricated Specimens

2.5. Thermal Properties Experiment (DSC)

2.6. Morphological Observation (SEM and X-ray μ-CT)

3. Results and Discussion

3.1. Mechanical Behavior of Orthogonally Orientated Printed Composites

3.2. Multi-Scale Factors Affecting the Flexural Behavior of the Printed Composites

3.2.1. Crystallization Behavior

3.2.2. Layer-to-Layer Bonding Strength

3.2.3. Microstructure

3.2.4. Porosity

3.3. Fracture Modes of the Printed Composites

3.4. Mechanism of CFs Affecting Flexural Behavior of Orthogonal Printed Specimens

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers 2018, 10, 629. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.W.; Tervoort, T.A.; Studart, A.R. Three-dimensional printing of hierarchical liquid-crystal-polymer structures. Nature 2018, 561, 226–230. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the processability, recyclability and crystalline structure of selective laser sintered Polyamide 6 in comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- Arif, M.; Kumar, S.; Varadarajan, K.; Cantwell, W. Performance of biocompatible PEEK processed by fused deposition additive manufacturing. Mater. Des. 2018, 146, 249–259. [Google Scholar] [CrossRef]

- Tian, X.C.; Jin, J.; Yuan, S.Q.; Chua, C.K.; Tor, S.B.; Zhou, K. Emerging 3D-Printed Electrochemical Energy Storage Devices: A Critical Review. Adv. Energy Mater. 2017, 7, 17. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw extrusion-based additive manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Hoskins, T.; Dearn, K.; Kukureka, S. Mechanical performance of PEEK produced by additive manufacturing. Polym. Test. 2018, 70, 511–519. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive layer manufacturing of poly (ether ether ketone) via FDM. Compos. B Eng. 2018, 145, 162–172. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, G.; Wang, D.; Zhao, F.; Wang, T.; Wang, Q. Significance of combined functional nanoparticles for enhancing tribological performance of PEEK reinforced with carbon fibers. Compos. A Appl. Sci. Manuf. 2017, 102, 400–413. [Google Scholar] [CrossRef]

- Chen, J.; Wang, K.; Zhao, Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface. Compos. Sci. Technol. 2018, 154, 175–186. [Google Scholar] [CrossRef]

- Hassan, E.A.; Ge, D.; Yang, L.; Zhou, J.; Liu, M.; Yu, M.; Zhu, S. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF. Compos. A Appl. Sci. Manuf. 2018, 112, 155–160. [Google Scholar] [CrossRef]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical Properties Optimization of Poly-Ether-Ether-Ketone via Fused Deposition Modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef] [PubMed]

- Clancy, G.; Peeters, D.; Oliveri, V.; Jones, D.; O’Higgins, R.M.; Weaver, P.M. A study of the influence of processing parameters on steering of carbon Fibre/PEEK tapes using laser-assisted tape placement. Compos. B Eng. 2019, 163, 243–251. [Google Scholar] [CrossRef]

- Kishore, V.; Ajinjeru, C.; Nycz, A.; Post, B.; Lindahl, J.; Kunc, V.; Duty, C. Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components. Addit. Manuf. 2017, 14, 7–12. [Google Scholar] [CrossRef]

- Luo, M.; Tian, X.; Zhu, W.; Li, D. Controllable interlayer shear strength and crystallinity of PEEK components by laser-assisted material extrusion. J. Mater. Res. 2018, 33, 1632–1641. [Google Scholar] [CrossRef]

- Yan, M.; Tian, X.; Peng, G.; Li, D.; Zhang, X. High temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos. Sci. Technol. 2018, 165, 140–147. [Google Scholar] [CrossRef]

- Berretta, S.; Davies, R.; Shyng, Y.; Wang, Y.; Ghita, O. Fused Deposition Modelling of high temperature polymers: Exploring CNT PEEK composites. Polym. Test. 2017, 63, 251–262. [Google Scholar] [CrossRef]

- Stepashkin, A.; Chukov, D.; Senatov, F.; Salimon, A.; Korsunsky, A.; Kaloshkin, S. 3D-printed PEEK-carbon fiber (CF) composites: Structure and thermal properties. Compos. Sci. Technol. 2018, 164, 319–326. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C.; Changquan, S. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Liao, G.; Li, Z.; Cheng, Y.; Xu, D.; Zhu, D.; Jiang, S.; Guo, J.; Chen, X.; Xu, G.; Zhu, Y. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling. Mater. Des. 2018, 139, 283–292. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- BS EN ISO 178:2010. Plastics-Determination of Flexural Properties. European Standards; International Organization for Standardization: Vernier, Switzerland, 2010. [Google Scholar]

- ASTM D2344/D2344M-16. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates; ASTM International: West Conshohocken, PA, USA, 2016.

- Regis, M.; Bellare, A.; Pascolini, T.; Bracco, P. Characterization of thermally annealed PEEK and CFR-PEEK composites: Structure-properties relationships. Polym. Degrad. Stab. 2017, 136, 121–130. [Google Scholar] [CrossRef]

- Blundell, D.; Osborn, B. The morphology of poly(aryl-ether-ether-ketone). Polymer 1983, 24, 953–958. [Google Scholar] [CrossRef]

- Germain, L.; Fuentes, C.A.; Van Vuure, A.W.; Rieux, A.D.; Dupont-Gillain, C. 3D-printed biodegradable gyroid scaffolds for tissue engineering applications. Mater. Des. 2018, 151, 113–122. [Google Scholar] [CrossRef]

| Items | Parameters |

|---|---|

| Diameter of nozzle | 0.4 mm |

| Nozzle temperature | 400 °C |

| Ambient temperature | 90 °C |

| Heat platform temperature | 160 °C |

| Nozzle moving speed | 15 mm/s |

| Layer thickness | 0.1 mm |

| Raster angle | +45°/−45° |

| Air gap | 0.18 mm |

| Samples | σmax (MPa) | %R.D. a | E (GPa) | %R.D. | SBS (MPa) | %R.D. |

|---|---|---|---|---|---|---|

| PEEK-M | 148 ± 3.4 | — | 3.49 ± 0.09 | — | — | — |

| CF/PEEK-M | 148 ± 0.8 | — | 3.78 ± 0.05 | +8.31 | — | — |

| PEEK-H | 134 ± 2.8 | −9.46 | 3.39 ± 0.11 | −2.87 | 24.8 ± 0.7 | — |

| PEEK-V | 146 ± 3.3 | −1.35 | 3.44 ± 0.05 | −1.43 | — | — |

| CF/PEEK-H | 124 ± 9.6 | −16.2 | 3.10 ± 0.27 | −11.2 | 19.1 ± 3.2 | −23.1 |

| CF/PEEK-V | 146 ± 4.2 | −1.35 | 3.74 ± 0.09 | +7.16 | — | — |

| Samples | Porosity (%) before Bending | Porosity (%) after Bending | Δ(%) |

|---|---|---|---|

| PEEK-H | 2.60 | 0.72 | −72.3 |

| PEEK-V | 2.62 | 3.00 | +14.5 |

| CF/PEEK-H | 3.00 | 8.06 | +168.7 |

| CF/PEEK-V | 4.38 | 8.22 | +87.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Zhao, W.; Li, Y.; Yang, W.; Wang, G. Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism. Polymers 2019, 11, 656. https://doi.org/10.3390/polym11040656

Li Q, Zhao W, Li Y, Yang W, Wang G. Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism. Polymers. 2019; 11(4):656. https://doi.org/10.3390/polym11040656

Chicago/Turabian StyleLi, Qiushi, Wei Zhao, Yongxiang Li, Weiwei Yang, and Gong Wang. 2019. "Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism" Polymers 11, no. 4: 656. https://doi.org/10.3390/polym11040656

APA StyleLi, Q., Zhao, W., Li, Y., Yang, W., & Wang, G. (2019). Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism. Polymers, 11(4), 656. https://doi.org/10.3390/polym11040656