Poly(arylene ether nitrile) Composites with Surface-Hydroxylated Calcium Copper Titanate Particles for High-Temperature-Resistant Dielectric Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Hydroxylation of CCTO Particles

2.3. Preparation of PAEN/h-CCTO Composite Films

2.4. Characterizations

3. Results and Discussion

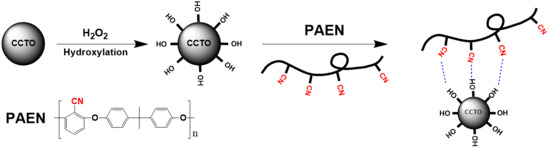

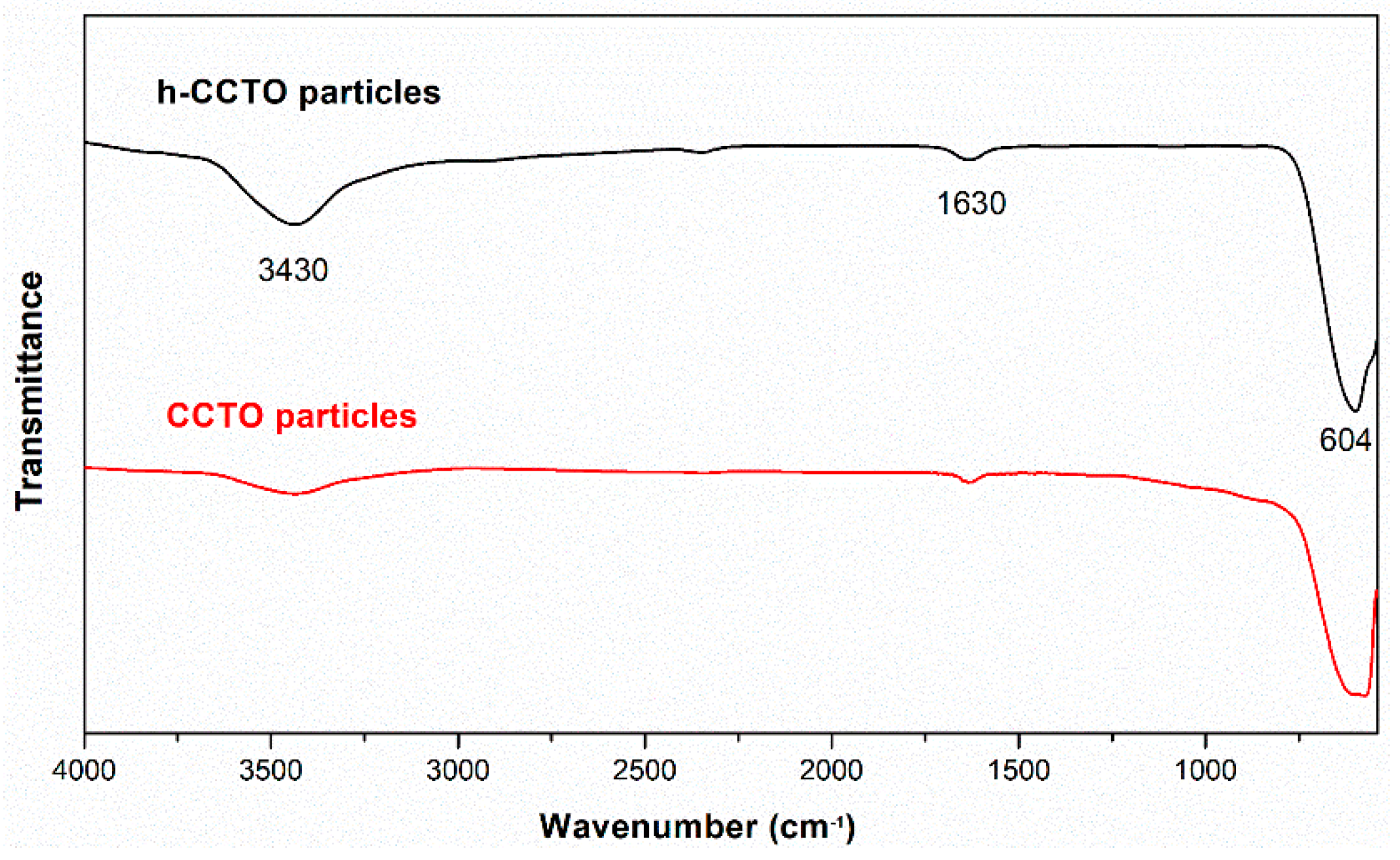

3.1. Surface Hydroxylation of CCTO Particles

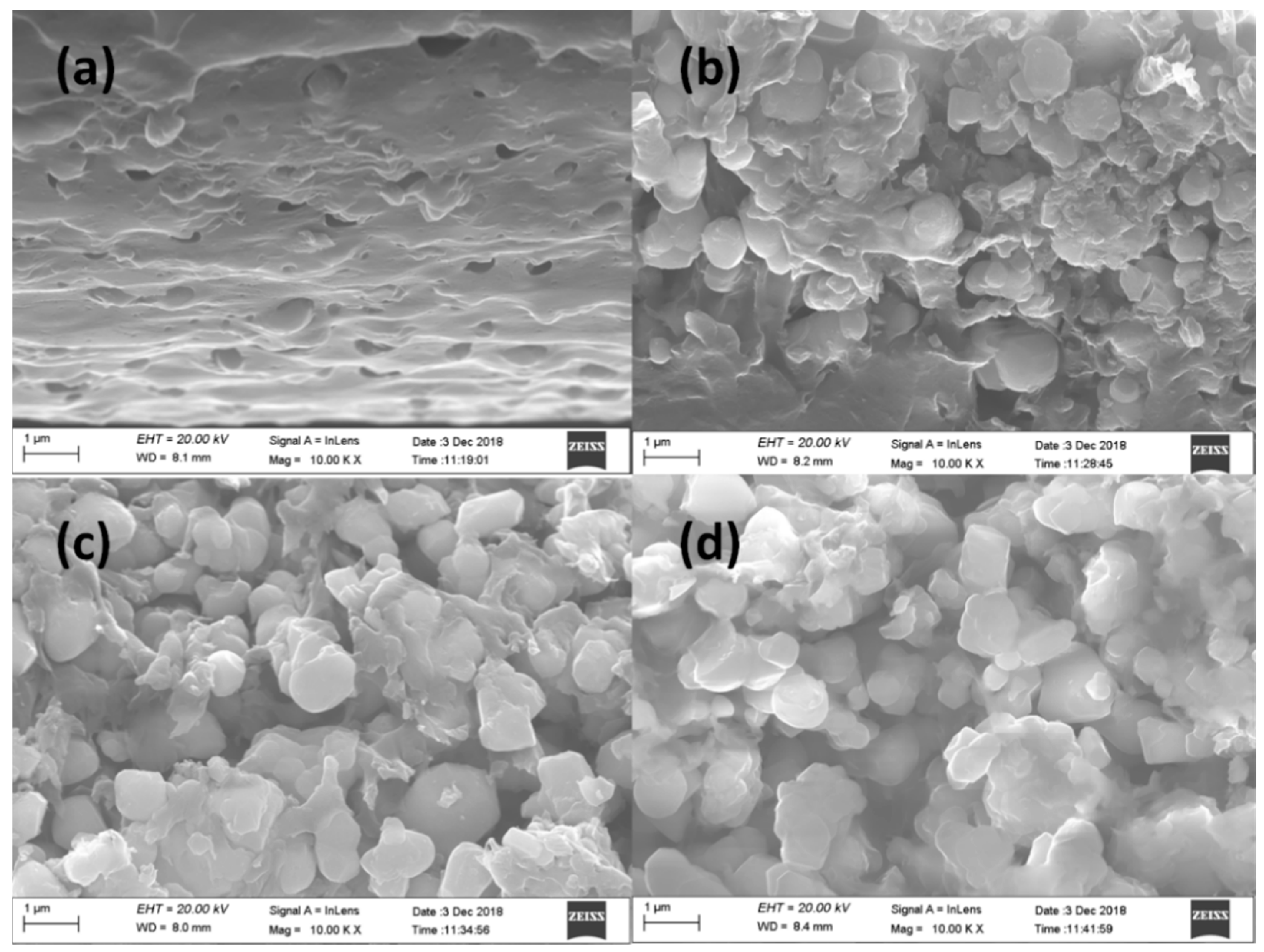

3.2. Morphologies of PAEN/h-CCTO Composites

3.3. Thermal Properties of PAEN/h-CCTO Composites

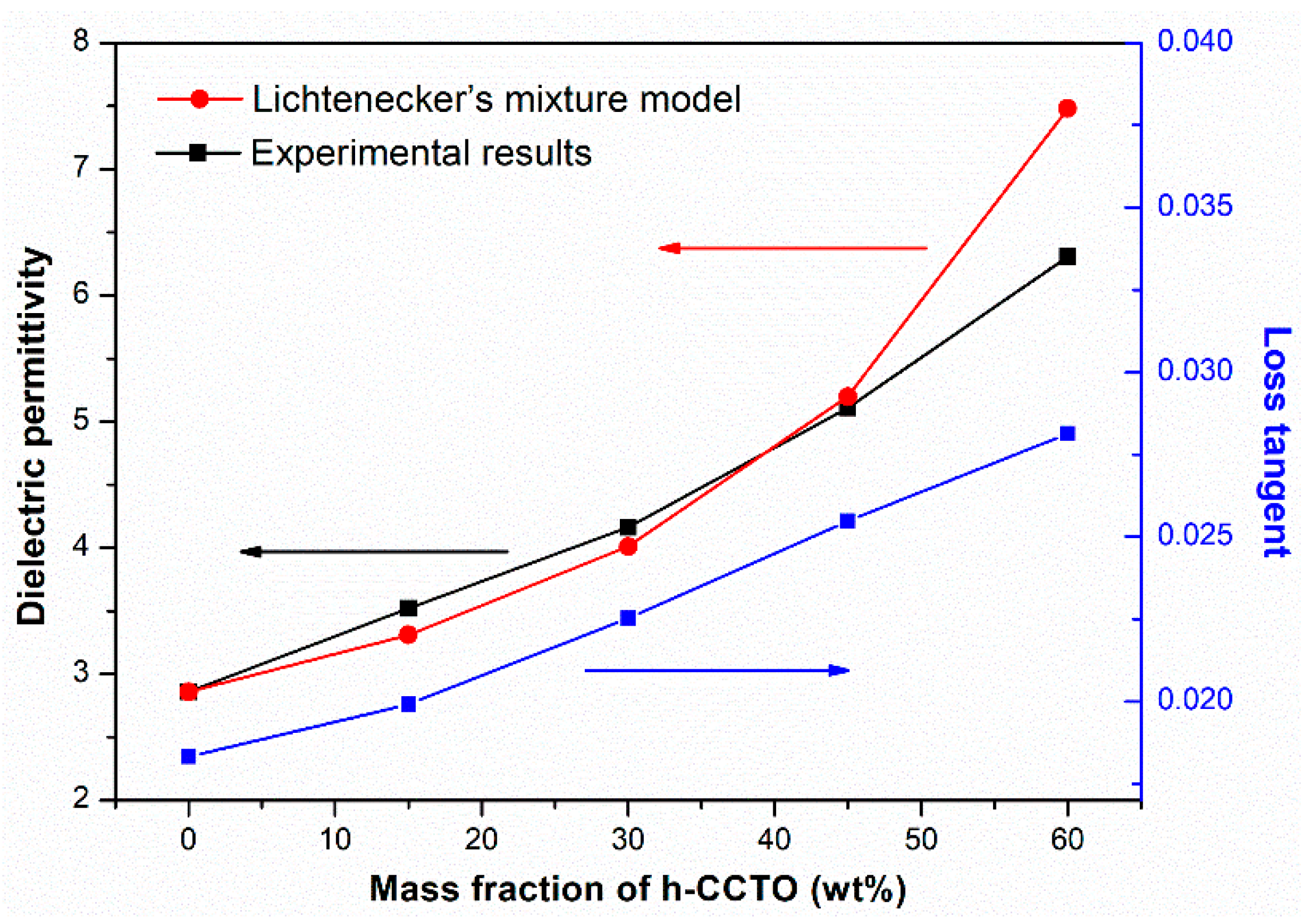

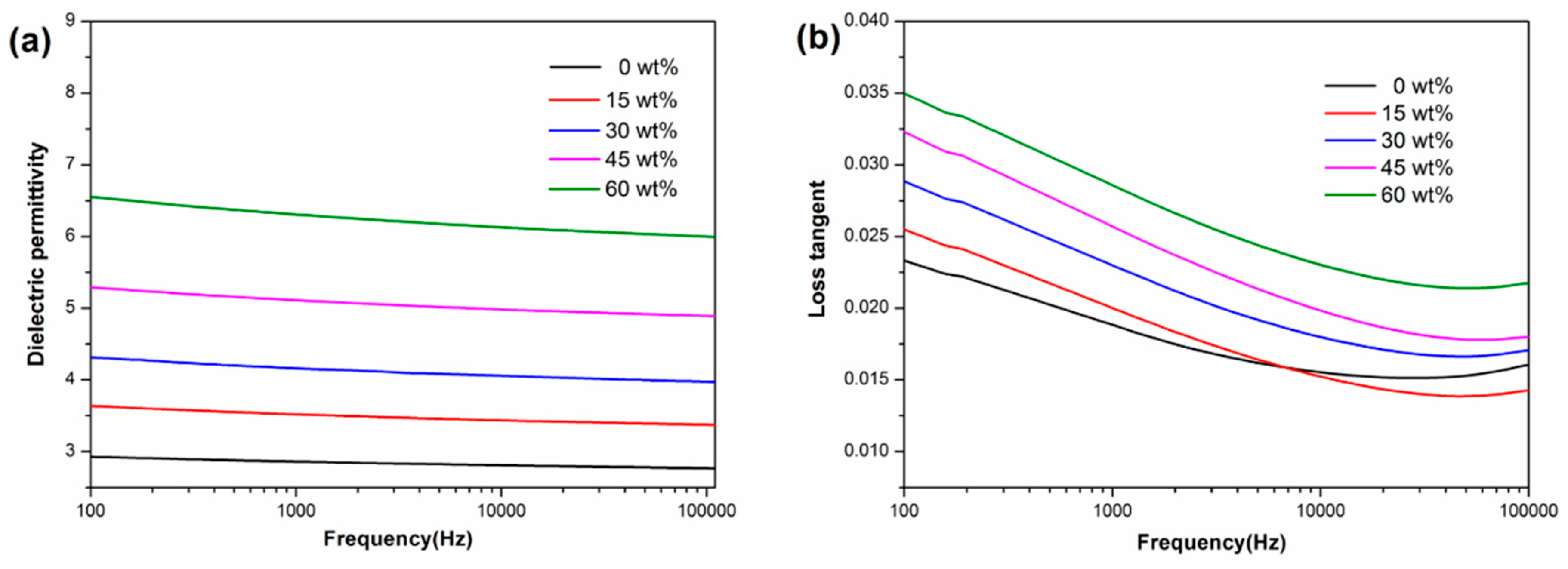

3.4. Dielectric Properties of PAEN/h-CCTO Composites

3.5. Mechanical Properties and Flexibility of PAEN/h-CCTO Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Liu, W.D.; Zhu, B.K.; Jian, Z.; Xu, Y.Y. Preparation and dielectric properties of polyimide/silica nanocomposite films prepared from sol–gel and blending process. Polym. Adv. Technol. 2010, 18, 522–528. [Google Scholar] [CrossRef]

- Hu, E.N.; Chen, X.L.; Fang, H.L.; Xiu, Q.W.; Qiu, G.Z.; Ai, M.Z.; Liu, Q.L. Poly(arylene ether nitrile) anion exchange membranes with dense flexible ionic side chain for fuel cells. J. Membrane Sci. 2018, 550, 254–265. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, S.; Wan, X.; Zhan, Y.; Yi, H. High-performance dielectric poly(arylene ether nitrile)/Ag nanoparticles decorated halloysites nanotube composites through modified bio-inspired method and synergistic effect. Polym. Eng. Sci. 2018, 58, 2227–2236. [Google Scholar]

- Wang, Z.; Nelson, J.K.; Hillborg, H.; Zhao, S.; Schadler, L.S. Graphene oxide filled nanocomposite with novel electrical and dielectric properties. Adv. Mater. 2012, 24, 3134–3137. [Google Scholar] [CrossRef]

- Pu, Z.; Zheng, X.; Tian, Y.; Hu, L.; Zhong, J. Flexible ultrahigh-temperature polymer-based dielectrics with high permittivity for film capacitor applications. Polymers 2017, 9, 596. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Wang, Y.; Wang, Q.; Xu, X.; Jiang, M.; Zhou, X.; He, P.; Zhou, Z. High-purity helical carbon nanotubes by trace-water-assisted chemical vapor deposition: Large-scale synthesis and growth mechanism. Nano Res. 2018, 11, 3327–3339. [Google Scholar] [CrossRef]

- Hua, M.; Yong, Y.; Tong, L.; Tang, X.; Wei, R.; Liu, X. Dielectric properties of diblock copolymers containing a polyarylene ether nitrile block and a polyarylene ether ketone block. J. Mater. Sci. Mater. El. 2018, 29, 3127–3134. [Google Scholar]

- Meng, F.; Fei, H.; Guo, Y.; Chen, J.; Chen, X.; Hui, D.; Ping, H.; Zhou, X.; Zhou, Z. In situ intercalation polymerization approach to polyamide-6/graphite nanoflakes for enhanced thermal conductivity. Compos. Part B Eng. 2017, 117, 165–173. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H.; Fei, H.; Guo, Y.; Wang, Z.; Hui, D.; Zhou, Z. Graphene-based microwave absorbing composites: A review and prospective. Compos. Part B Eng. 2017, 137, 260–277. [Google Scholar] [CrossRef]

- Yang, X.; Zhan, Y.; Rui, Z.; Liu, X. Effects of graphene nanosheets on the dielectric, mechanical, thermal properties, and rheological behaviors of poly(arylene ether nitriles). J. Appl. Polym. Sci. 2012, 124, 1723–1730. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Meng, F.; Li, D.; Tian, X.; Wang, Z.; Zhou, Z. Super-high thermal conductivity of polyamide-6/graphene-graphene oxide composites through in situ polymerization. High Perform. Polym. 2017, 29, 585–594. [Google Scholar] [CrossRef]

- Chen, X.; Chen, J.; Meng, F.; Shan, L.; Man, J.; Xu, X.; Lu, J.; Yong, W.; Zhou, Z. Hierarchical composites of polypyrrole/graphene oxide synthesized by in situ intercalation polymerization for high efficiency and broadband responses of electromagnetic absorption. Compos. Sci. Technol. 2016, 127, 71–78. [Google Scholar] [CrossRef]

- Cheng, T.; Zhang, X.; Ma, Y.; Huang, Y.; Liu, X. Constructing continuous proton-conducting highways within sulfonated poly(arylene ether nitrile) composite membrane by incorporating amino-sulfo-bifunctionalized GO. Polymers 2018, 10, 1005. [Google Scholar] [CrossRef] [PubMed]

- Fei, J.; Feng, M.; Xu, H.; Cheng, L.; Liu, X. Effect of SiO2 grafted MWCNTs on the mechanical and dielectric properties of PEN composite films. Appl. Surf. Sci. 2015, 357, 704–711. [Google Scholar]

- Ma, P.C.; Tang, B.Z.; Kim, J.K. Effect of CNT decoration with silver nanoparticles on electrical conductivity of CNT-polymer composites. Carbon 2008, 46, 1497–1505. [Google Scholar] [CrossRef]

- Wei, J.; Li, W.; Min, C.; Wang, F. The relationship between the molecular structure and properties of novel poly(arylene ether nitrile ketone)s with high-temperature and stable dielectric properties. Russ. J. Appl. Chem. 2017, 90, 1320–1325. [Google Scholar] [CrossRef]

- Tian, X.; Meng, F.; Meng, F.; Chen, X.; Guo, Y.; Wang, Y.; Zhu, W.; Zhou, Z. Synergistic enhancement of microwave absorption using hybridized polyaniline@helical-CNTs with dual chirality. ACS Appl. Mater. Inter. 2017, 9, 15711–15718. [Google Scholar] [CrossRef]

- Xiao, Q.; Yang, R.; You, Y.; Zhang, H.; Wei, R.; Liu, X. Crystalline, mechanical and dielectric properties of polyarylene ether nitrile with multi-walled carbon nanotube filled with polyarylene ether nitrile. J. Nanosci. Nanotechno. 2018, 4311–4317. [Google Scholar] [CrossRef]

- Wei, R.; Wang, J.; Zhang, H.; Han, W.; Liu, X. Crosslinked polyarylene ether nitrile interpenetrating with zinc ion bridged graphene sheet and carbon nanotube network. Polymers 2017, 9, 342. [Google Scholar] [CrossRef]

- Yue, Y.; Xu, M.; Hai, P.; Ren, D.; Li, K.; Liu, X. Secondary dispersion of BaTiO3 for the enhanced mechanical properties of the poly(arylene ether nitrile)-based composite laminates. Polym. Test. 2018, 66, 164–171. [Google Scholar]

- Zhou, T.; Zha, J.W.; Cui, R.Y.; Fan, B.H.; Yuan, J.K.; Dang, Z.M. Improving dielectric properties of BaTiO3/ferroelectric polymer composites by employing surface hydroxylated BaTiO3 nanoparticles. ACS Appl. Mater. Inter. 2011, 3, 2184–2188. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Liu, C.; Liu, C.; Tu, L.; You, Y.; Wei, R.; Liu, X. Polyarylene ether nitrile and barium titanate nanocomposite plasticized by carboxylated zinc phthalocyanine buffer. Polymers 2019, 11, 418. [Google Scholar] [CrossRef] [PubMed]

- Alkathy, M.S.; Raju, K.C.J. Enhancement of dielectric properties and energy storage density of bismuth and lithium co-substituted strontium titanate ceramics. Ceram. Int. 2018, 44, 10367–10375. [Google Scholar] [CrossRef]

- Prakash, B.S.; Varma, K.B.R. Dielectric behavior of CCTO/epoxy and Al-CCTO/epoxy composites. Compos. Sci. Technol. 2007, 67, 2363–2368. [Google Scholar] [CrossRef]

- Lee, J.W.; Koh, J.H. Enhanced dielectric properties of Ag-doped CCTO ceramics for energy storage devices. Ceram. Int. 2017, 43, 9493–9497. [Google Scholar] [CrossRef]

- Ren, D.; Chen, L.; Yuan, Y.; Li, K.; Xu, M.; Liu, X. Designing and preparation of fiber-reinforced composites with enhanced interface adhesion. Polymers 2018, 10, 1128. [Google Scholar] [CrossRef] [PubMed]

- You, Y.; Wang, Y.; Tu, L.; Tong, L.; Wei, R.; Liu, X. Interface modulation of core-Shell structured BaTiO3@polyaniline for novel dielectric materials from its nanocomposite with polyarylene ether nitrile. Polymers 2018, 10, 1378. [Google Scholar] [CrossRef]

- Dang, Z.M.; Zhou, T.; Yao, S.H.; Yuan, J.K.; Zha, J.W.; Song, H.T.; Li, J.Y.; Chen, Q.; Yang, W.T.; Bai, J. Advanced calcium copper titanate/polyimide functional hybrid films with high dielectric permittivity. Adv. Mater. 2010, 21, 2077–2082. [Google Scholar] [CrossRef]

- Tang, H.; Pan, W.; Zheng, P.; Liu, X. Core-shell structured BaTiO3@polymer hybrid nanofiller for poly(arylene ether nitrile) nanocomposites with enhanced dielectric properties and high thermal stability. Compos. Sci. Technol. 2016, 123, 134–142. [Google Scholar] [CrossRef]

- Li, C.; Gu, Y.; Liu, X. Synthesis and properties of phenolphthalein-based polyarylene ether nitrile copolymers. Mater. Lett. 2006, 60, 137–141. [Google Scholar] [CrossRef]

- Tang, H.; Huang, X.; Yang, X.; Yang, J.; Zhao, R.; Liu, X. An effective approach to enhance temperature independence of dielectric properties for polyarylene ether nitrile films. Mater. Lett. 2012, 75, 218–220. [Google Scholar] [CrossRef]

- Tang, H.; Yang, J.; Zhong, J.; Zhao, R.; Liu, X. Synthesis and dielectric properties of polyarylene ether nitriles with high thermal stability and high mechanical strength. Mater. Lett. 2011, 65, 2758–2761. [Google Scholar] [CrossRef]

- Yong, Y.; Du, X.; Hua, M.; Tang, X.; Liu, X. Synergistic enhancement of mechanical, crystalline and dielectric properties of polyarylene ether nitrile-based nanocomposites by unidirectional hot stretching-quenching. Polym. Int. 2017, 66, 1151–1158. [Google Scholar]

- Tong, L.; Wei, R.; You, Y.; Liu, X. Post self-crosslinking of phthalonitrile-terminated polyarylene ether nitrile crystals. Polymers 2018, 10, 640. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zheng, P.; Wang, L.; Liu, X. Preparation of sulfonated poly(arylene ether nitrile)-based adsorbent as a highly selective and efficient adsorbent for cationic dyes. Polymers 2019, 11, 32. [Google Scholar] [CrossRef]

- Tang, H.; Pu, Z.; Huang, X.; Wei, J.; Liu, X.; Lin, Z. Novel blue-emitting carboxyl-functionalized poly(arylene ether nitrile)s with excellent thermal and mechanical properties. Polym. Chem. 2014, 5, 3673–3679. [Google Scholar] [CrossRef]

- Chang, S.-J.; Liao, W.-S.; Ciou, C.-J.; Lee, J.-T.; Li, C.-C. An efficient approach to derive hydroxyl groups on the surface of barium titanate nanoparticles to improve its chemical modification ability. J. Colloid. Interf. Sci. 2009, 329, 300–305. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, S.; Feng, J.; Ouyang, Z.; Li, X. Measurement of the complex permittivity of dry rocks and minerals: Application of polythene dilution method and Lichtenecker’s mixture formulae. Geophys. J. Int. 2005, 163, 1195–1202. [Google Scholar] [CrossRef]

| Mass Fraction of h-CCTO | 0 wt% | 15 wt% | 30 wt% | 45 wt% | 60 wt% |

|---|---|---|---|---|---|

| Tg (°C) | 172 | 175 | 177 | 178 | 178 |

| T5% (°C) | 516 | 511 | 501 | 510 | 505 |

| Tmax (°C) | 539 | 531 | 529 | 529 | 522 |

| CY (%) | 56.4 | 60.2 | 66.0 | 73.7 | 78.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Tang, Z.; Yin, H.; Liu, Y.; Wang, L.; Tang, H.; Li, Y. Poly(arylene ether nitrile) Composites with Surface-Hydroxylated Calcium Copper Titanate Particles for High-Temperature-Resistant Dielectric Applications. Polymers 2019, 11, 766. https://doi.org/10.3390/polym11050766

Yang J, Tang Z, Yin H, Liu Y, Wang L, Tang H, Li Y. Poly(arylene ether nitrile) Composites with Surface-Hydroxylated Calcium Copper Titanate Particles for High-Temperature-Resistant Dielectric Applications. Polymers. 2019; 11(5):766. https://doi.org/10.3390/polym11050766

Chicago/Turabian StyleYang, Junyi, Zili Tang, Hang Yin, Yan Liu, Ling Wang, Hailong Tang, and Youbing Li. 2019. "Poly(arylene ether nitrile) Composites with Surface-Hydroxylated Calcium Copper Titanate Particles for High-Temperature-Resistant Dielectric Applications" Polymers 11, no. 5: 766. https://doi.org/10.3390/polym11050766

APA StyleYang, J., Tang, Z., Yin, H., Liu, Y., Wang, L., Tang, H., & Li, Y. (2019). Poly(arylene ether nitrile) Composites with Surface-Hydroxylated Calcium Copper Titanate Particles for High-Temperature-Resistant Dielectric Applications. Polymers, 11(5), 766. https://doi.org/10.3390/polym11050766