A New Empirical Model for Viscosity of Sulfonated Polyacrylamide Polymers

Abstract

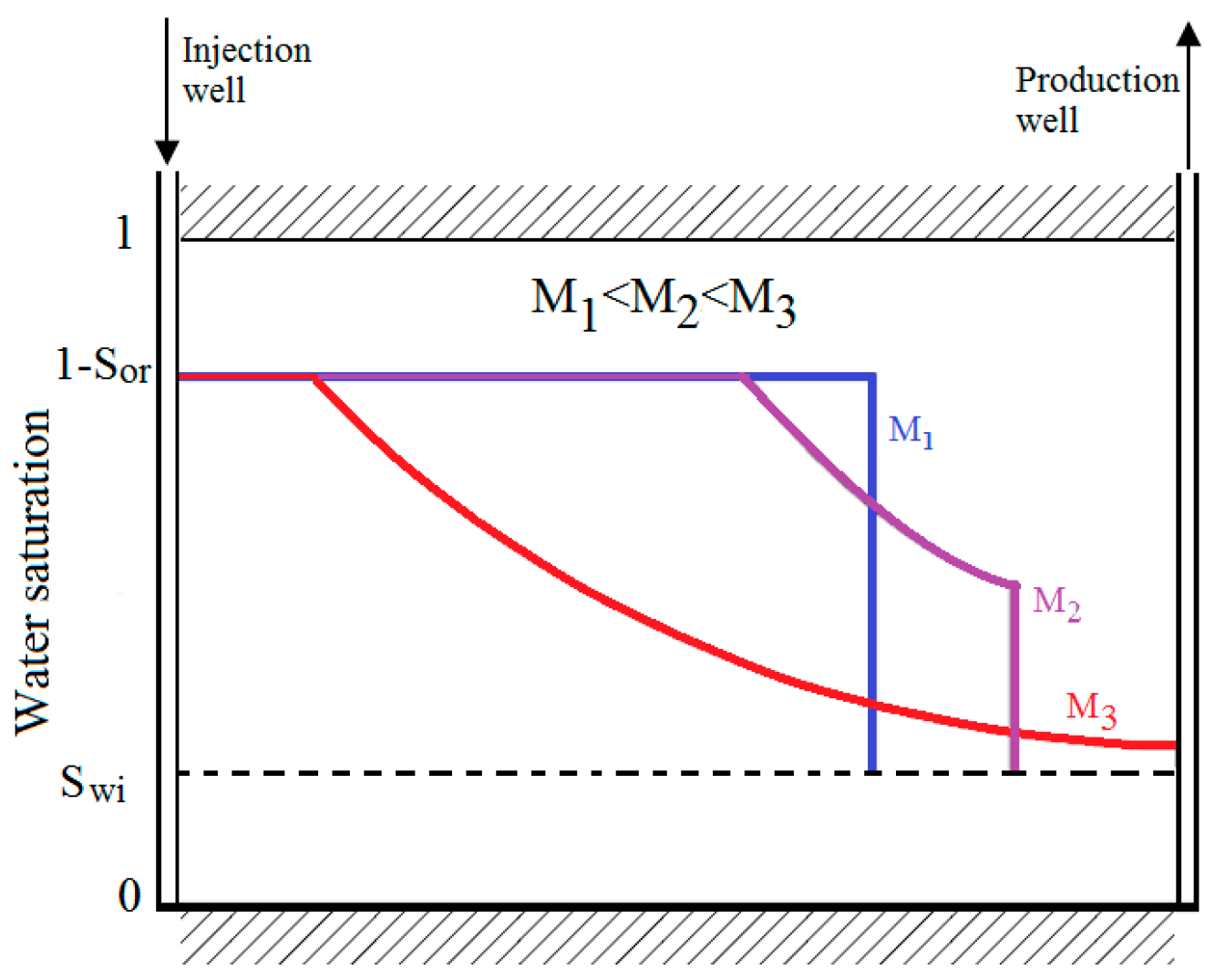

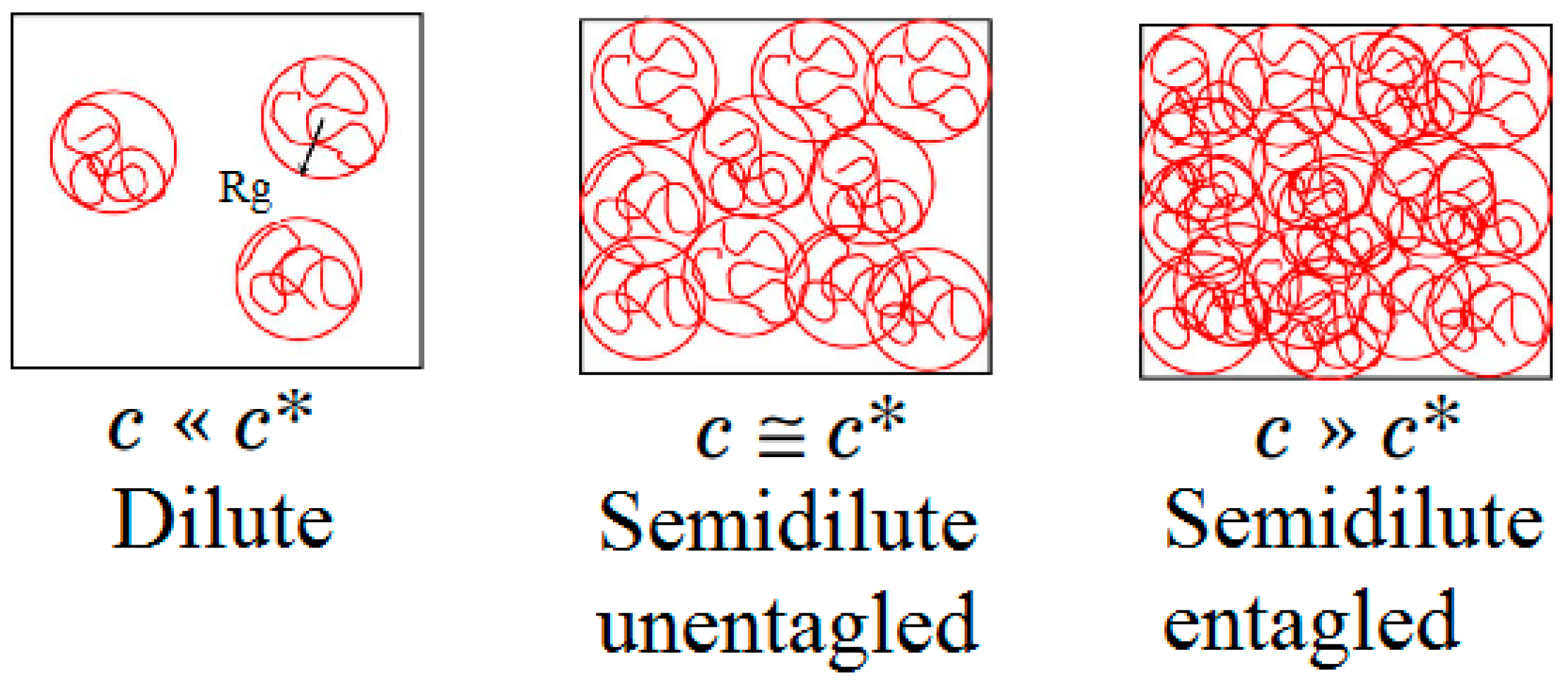

1. Introduction to Polymer Flooding

2. Suitable Viscosity Model for Polymer Flooding Simulation

3. Materials and Methods

3.1. Model Development Procedure Using DOE

3.1.1. Confounding Evaluation

3.1.2. Input Factor Coding and Response Transformation

3.1.3. Model Fitting and Validation

3.1.4. Sensitivity and Uncertainty Analysis

3.2. Experimental Details

3.2.1. Characteristics of the Sulfonated Polyacrylamide Polymers

3.2.2. Polymer Solution Preparation

3.2.3. Viscosity Measurement

3.2.4. Oxygen-Free Environment

4. Results and Discussion

4.1. Confounding Evaluation

4.2. Model Selection

4.3. Model Validation

4.4. Model Sensitivity and Uncertainty Analysis

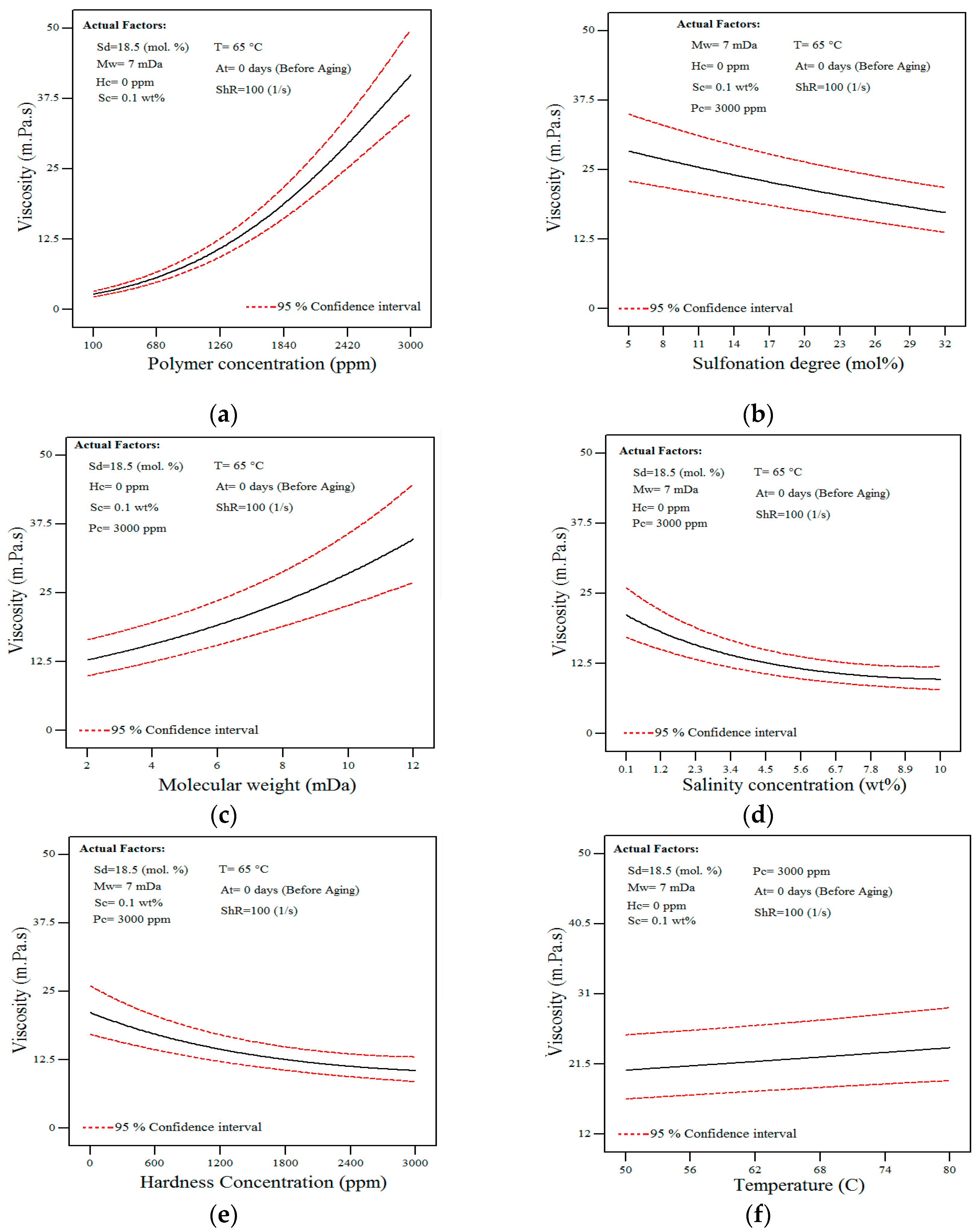

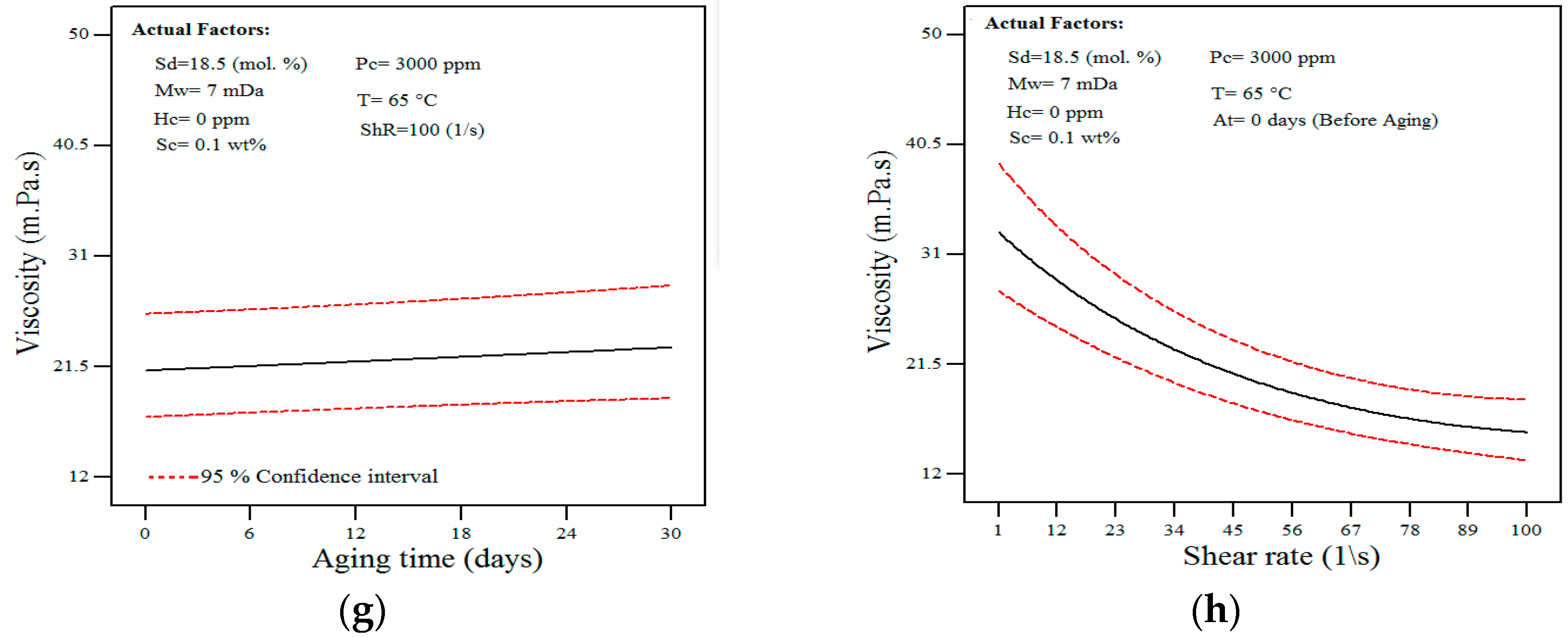

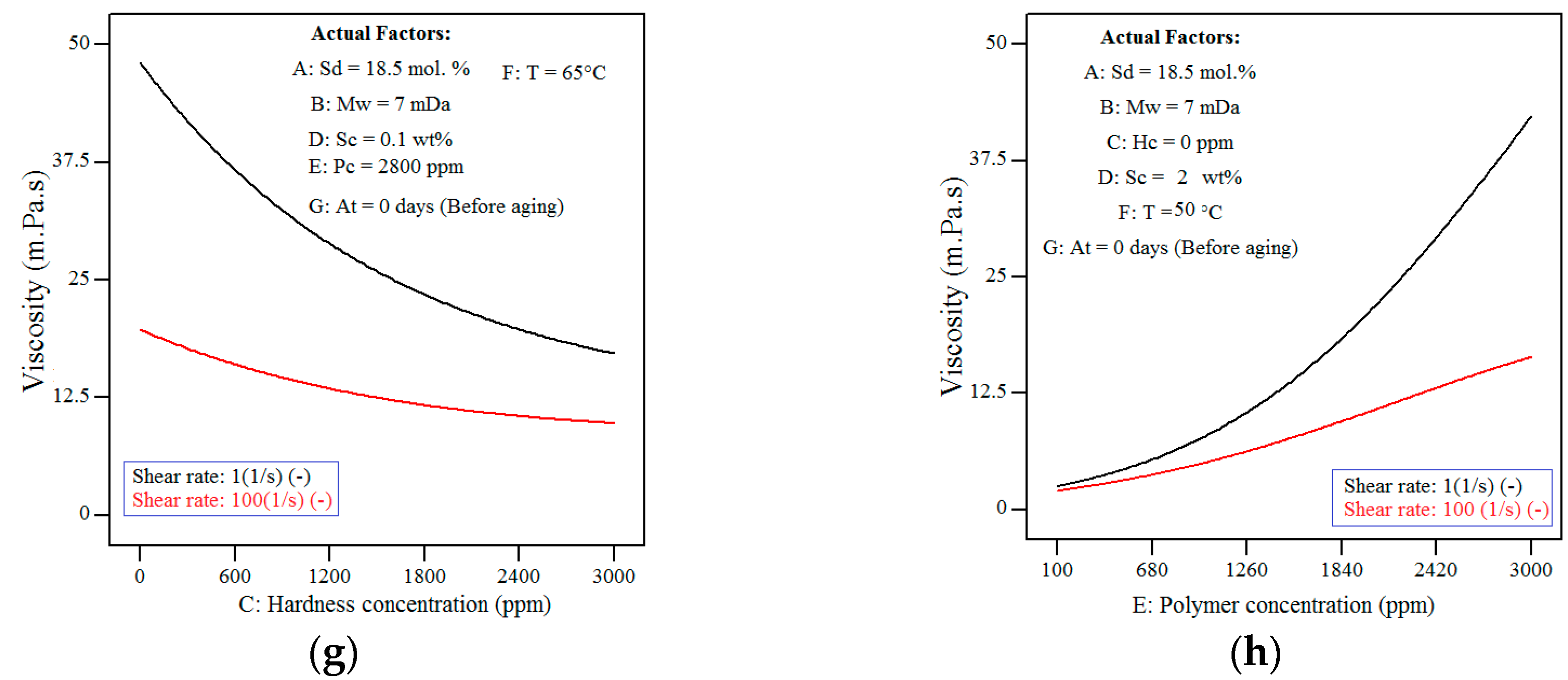

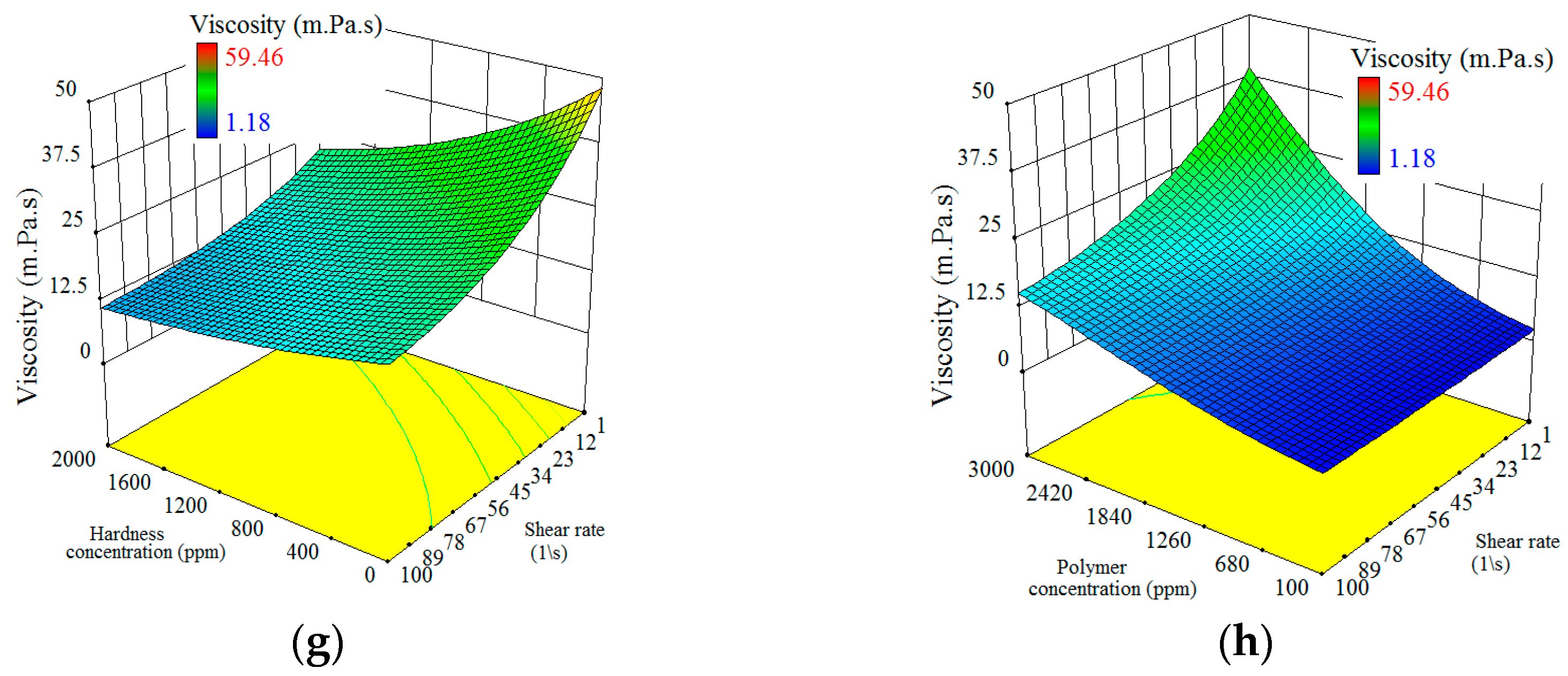

4.5. The Main Effect of Factors on the Viscosity (One-Factor Plot)

4.6. Interaction between Factors

5. Conclusions

- An empirical model was developed for determining the viscosity of polymer solutions that can be used to select a suitable sulfonated polyacrylamide polymer in terms of sulfonation degree and molecular weight, as well as the optimal polymer solution concentration and brine salinity after taking into account the effects of reservoir temperature, formation brine salinity/hardness, aging time and shear rate account.

- This approach had provided an overview of the process factors’ impact on the polymer solution viscosity, where the results had shown the polymer concentration to be the main determinant because of its immediate effect on the polymer chain interaction.

- The DOE approach that was used to derive the empirical model was found to be a powerful tool for analysing the main effects (individual effect) and interaction effects (collectively effect) between any sets of two process variables.

6. Recommendations

- The accuracy of the viscosity model of sulfonated polyacrylamide polymer can be improved by increasing the number of levels for each factor. Since this idea may increase the number of required experimental runs, factors with small effects such as temperature levels and aging time can be removed from the design for a temperature range of up to 80 °C.

- By utilizing the conclusions presented, future DOE-based model studies can extend the range of study by excluding the range in which a factor did not show sensitivity or the range in which the factor showed a linear or log-linear behaviour. For example, the polymers have shown to be stable up to 80 °C, which can be extended to a maximum of 90 °C by modifying the range.

- From the conclusions derived in this research, the DOE-based model studies can be extended to a wider range of study that includes the elimination of the factor range that does not exhibit sensitivity or the range in which the factor had shown a linear or log-linear behavioural trait. For example, the sulfonated polymers that were initially shown to be stable of up to 80 °C can be further extended to a maximum of 90 °C after the range modification.

- It is suggested that similar kind of DOE-based studies be conducted on other polymer types such as those of PAM (polyacrylamide), HPAM, thermo-associative and so on.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buckley, S.E.; Leverett, M.C. Mechanism of Fluid Displacement in Sands. Trans. AIME 1942, 146, 107–116. [Google Scholar] [CrossRef]

- Homsy, G.M. Viscous Fingering in Porous Media. Annu. Rev. Fluid Mech. 1987, 19, 271–311. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, M.; Zhao, S. Which One Is More Important in Chemical Flooding for Enhanced Court Heavy Oil Recovery, Lowering Interfacial Tension or Reducing Water Mobility? Energy Fuels 2010, 24, 1829–1836. [Google Scholar] [CrossRef]

- Hashmet, M.R.; Onur, M.; Tan, I.M. Empirical Correlations for Viscosity of Polyacrylamide Solutions with the Effects of Temperature and Shear Rate. II. J. Dispers. Sci. Technol. 2013, 35, 1685–1690. [Google Scholar] [CrossRef]

- Hashmet, M.R.; Onur, M.; Tan, I.M. Empirical Correlations for Viscosity of Polyacrylamide Solutions with the Effects of Salinity and Hardness. J. Dispers. Sci. Technol. 2013, 35, 510–517. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, S.; Tan, I.; Ling, O.; Ghaedi, H. Effect of Aging, Antioxidant and Mono-and Divalent Ions at High Temperature on the Rheology of New Polyacrylamide-Based Co-Polymers. Polymers 2017, 9, 480. [Google Scholar] [CrossRef]

- Green, D.W.; Willhite, G.P. Enhanced Oil Recovery; Henry L. Doherty Memorial Fund of AIME, Society of Petroleum Engineers: Richardson, TX, USA, 1998. [Google Scholar]

- Thomas, A.; Gaillard, N.; Favero, C. Some Key Features to Consider When Studying Acrylamide-Based Polymers for Chemical Enhanced Oil Recovery. Oil Gas Sci. Technol. 2012, 67, 887. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery, 1st ed.; Blackie & Son: Glasgow, UK, 1991. [Google Scholar]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of Polymer-Flooding Technology. J. Can. Pet. Technol. 2015, 74, 116–126. [Google Scholar] [CrossRef]

- Han, M.; Xiang, W.; Zhang, J.; Jiang, W.; Sun, F. Application of EOR Technology by Means of Polymer Flooding in Bohai Oilfields. In Proceedings of the International Oil & Gas Conference and Exhibition in China, Beijing, China, 5–7 December 2006. [Google Scholar]

- Dong, H.; Fang, S.; Wang, D.; Wang, J.; Liu, Z.L.; Hou, W. Review of Practical Experience & Management by Polymer Flooding at Daqing. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Moradi-Araghi, A.; Doe, P.H. Hydrolysis and Precipitation of Polyacrylamides in Hard Brines at Elevated Temperatures. Soc. Pet. Eng. J. 1987, 2, 189–198. [Google Scholar] [CrossRef]

- Seright, R.S.; Campbell, A.; Mozley, P.; Han, P. Stability of Partially Hydrolyzed Polyacrylamides at Elevated Temperatures in the Absence of Divalent Cations. Soc. Pet. Eng. J. 2010, 15, 341–348. [Google Scholar] [CrossRef]

- Moradi-Araghi, A.; Cleveland, D.H.; Westerman, I.J. Development and Evaluation of EOR Polymers Suitable for Hostile Environments: II-Copolymers of Acrylamide and Sodium AMPS. In Proceedings of the SPE International Symposium on Oilfield Chemistry, San Antonio, TX, USA, 4–6 February 1987. [Google Scholar]

- Rashidi, M.; Blokhus, A.M.; Skauge, A. Static and Dynamic Adsorption of Salt Tolerant Polymers. In Proceedings of the 15th European Symposium on Improved oil recovery, European Association of Geoscientists and Engineers, Houten, The Netherlands, 27 April 2009. [Google Scholar]

- Rashidi, M.; Blokhus, A.M.; Skauge, A. Viscosity and retention of sulfonated polyacrylamide polymers at high temperature. J. Appl. Polym. Sci. 2011, 119, 3623–3629. [Google Scholar] [CrossRef]

- Rashidi, M.; Blokhus, A.M.; Skauge, A. Viscosity study of salt tolerant polymers. J. Appl. Polym. Sci. 2010, 117, 1551–1557. [Google Scholar] [CrossRef]

- Vermolen, E.C.M.; Van Haasterecht, M.J.T.; Masalmeh, S.K.; Faber, M.J.; Boersma, D.M.; Gruenenfelder, M.A. Pushing the envelope for polymer flooding towards high-temperature and high-salinity reservoirs with polyacrylamide based ter-polymers. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 25–28 September 2011. [Google Scholar]

- Luo, J.-H.; Liu, Y.-Z.; Zhu, P. Polymer solution properties and displacement mechanisms. In Enhanced Oil Recovery-Polymer Flooding; Shen, P.-P., Liu, Y.-Z., Liu, H.-R., Eds.; Petroleum Industry Press: Beijing, China, 2006; pp. 1–72. [Google Scholar]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Carreau, P.J. Rheological Equations from Molecular Network Theories. Trans. Soc. Rheol. 1972, 16, 99–127. [Google Scholar] [CrossRef]

- Chauveteau, G. Rodlike Polymer Solution Flow through Fine Pores: Influence of Pore Size on Rheological Behavior. J. Rheol. 1982, 26, 111–142. [Google Scholar] [CrossRef]

- Bingham, E.C. Fluidity and Plasticity; McGraw-Hill: New York, NY, USA, 1922. [Google Scholar]

- Kincaid, J.F.; Eyring, H.; Stearn, A.E. The Theory of Absolute Reaction Rates and its Application to Viscosity and Diffusion in the Liquid State. Chem. Rev. 1941, 28, 301–365. [Google Scholar] [CrossRef]

- Reiner, M. Deformation, Strain and Flow, 1960 ed.; Interscience: New York, NY, USA, 1960. [Google Scholar]

- Stastna, J.; De Kee, D. Dimensionally invariant viscosity function. Can. J. Chem. Eng. 1987, 65, 877–879. [Google Scholar] [CrossRef]

- Bird, R.B.; Hassager, O. Dynamics of Polymeric Liquids: Fluid Mechanics, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1987. [Google Scholar]

- Yerramilli, S.S.; Zitha, P.L.J.; Yerramilli, R.C. Novel Insight into Polymer Injectivity for Polymer Flooding. In Proceedings of the SPE European Formation Damage Conference & Exhibition, Noordwijk, The Netherlands, 5–7 June 2013. [Google Scholar]

- Goudarzi, A.; Delshad, M.; Sepehrnoori, K. A Critical Assessment of Several Reservoir Simulators for Modeling Chemical Enhanced Oil Recovery Processes. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 18–20 February 2013. [Google Scholar]

- Han, B.; Lee, J. Sensitivity Analysis on the Design Parameters of Enhanced Oil Recovery by Polymer Flooding with Low Salinity Waterflooding. In Proceedings of the Twenty-fourth International Ocean and Polar Engineering Conference, Busan, Korea, 15–20 June 2014. [Google Scholar]

- Flory, P.J. Principles of Polymer Chemistry; Cornell University Press: Ithaca, NY, USA, 1953. [Google Scholar]

- Yuan, C.; Delshad, M.; Wheeler, M.F. Modeling multiphase Non-Newtonian polymer flow in IPARS parallel framework. Netw. Heterog. Media 2010, 5, 583–602. [Google Scholar] [CrossRef]

- Sheng, J. Modern Chemical Enhance Oil Recovery: Theory and Practice; Gulf Professional: London, UK; Oxford, UK, 2011. [Google Scholar]

- Meter, D.M.; Bird, R.B. Tube flow of non-Newtonian polymer solutions: PART I. Laminar flow and rheological models. AIChE J. 1964, 10, 878–881. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, S.M.; Tan, I.M.; Adeyemi, B.J. Evaluation of One Factor at a Time (OFAT) Technique in Viscosity Modeling of Polymer Solution. J. Eng. Appl. Sci. 2017, 12, 4313–4319. [Google Scholar] [CrossRef]

- Gao, C. Empirical correlations for viscosity of partially hydrolyzed Polyacrylamide. J. Pet. Explor. Prod. Technol. 2014, 4, 209–213. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, S.M.; Tan, I.M.; Bharadwaj, A.M.; Hematpour, H. Experimental investigation of the effect of different process variables on the viscosity of sulfonated polyacrylamide copolymers. J. Pet. Explor. Prod. Technol. 2016, 7, 87–101. [Google Scholar] [CrossRef]

- Rostami, A.; Kalantari-Meybodi, M.; Karimi, M.; Tatar, A.; Mohammadi, A.H. Efficient estimation of hydrolyzed polyacrylamide (HPAM) solution viscosity for enhanced oil recovery process by polymer flooding. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2018, 73, 22. [Google Scholar] [CrossRef]

- Kang, P.-S.; Lim, J.-S.; Huh, C. Artificial Neural Network Model to Estimate the Viscosity of Polymer Solutions for Enhanced Oil Recovery. Appl. Sci. 2016, 6, 188. [Google Scholar] [CrossRef]

- Akbari, S.; Mahmood, S.M.; Tan, I.M.; Ghaedi, H.; Ling, O.L. Assessment of Polyacrylamide Based Co-Polymers Enhanced by Functional Group Modifications with Regards to Salinity and Hardness. Polymers 2017, 9, 647. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Akbari, S.; Mahmood, S.M.; Tan, I.M.; Hematpour, H. Comparison of neuro-fuzzy network and response surface methodology pertaining to the viscosity of polymer solutions. J. Pet. Explor. Prod. Technol. 2017, 8, 887–900. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Zhu, M.-J.; Yao, J.; Wang, W.-B.; Yin, X.-Q.; Chen, W.; Wu, X.-Y. Using response surface methodology to evaluate electrocoagulation in the pretreatment of produced water from polymer-flooding well of Dagang Oilfield with bipolar aluminum electrodes. Desalin. Water Treat. 2016, 57, 15314–15325. [Google Scholar] [CrossRef]

- Xin, Q. Diesel Engine System Design; Illustrated, Reprint Ed.; Elsevier Science: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Farajzadeh, R.; Bedrikovetsky, P.; Lotfollahi, M.; Lake, L.W. Simultaneous sorption and mechanical entrapment during polymer flow through porous media. Water Resour. Res. 2016, 52, 2279–2298. [Google Scholar] [CrossRef]

- Mathews, P.G. Design of Experiments with Minitab; William A. Tony: Milwaukee, MI, USA, 2005. [Google Scholar]

- Rodgers, J.L.; Nicewander, W.A. Thirteen Ways to Look at the Correlation Coefficient. Am. Stat. 1988, 42, 59–66. [Google Scholar] [CrossRef]

- Stat-Ease. Design-Expert. Available online: https://www.statease.com/dx11.html (accessed on 1 May 2019).

- Gaillard, N.; Giovannetti, B.; Leblanc, T.; Thomas, A.; Braun, O.; Favero, C. Selection of Customized Polymers to Enhance Oil Recovery from High Temperature Reservoirs. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015. [Google Scholar]

- Shupe, R.D. Chemical Stability of Polyacrylamide Polymers. J. Pet. Technol. 1981, 33, 1513–1529. [Google Scholar] [CrossRef]

- Wellington, S.L. Biopolymer Solution Viscosity Stabilization-Polymer Degradation and Antioxidant Use. Soc. Pet. Eng. J. 1983, 23, 901–912. [Google Scholar] [CrossRef]

- Gupta, P.; Elkins, C.; Long, T.E.; Wilkes, G.L. Electrospinning of linear homopolymers of poly(methyl methacrylate): Exploring relationships between fiber formation, viscosity, molecular weight and concentration in a good solvent. Polymer 2005, 46, 4799–4810. [Google Scholar] [CrossRef]

- Jamshidi, H.; Rabiee, A. Synthesis and characterization of acrylamide-based anionic copolymer and investigation of solution properties. Adv. Mater. Sci. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Szabo, M.T. An Evaluation of Water-Soluble Polymers for Secondary Oil Recovery-Parts 1 and 2. J. Pet. Technol. 1979, 31, 553–570. [Google Scholar] [CrossRef]

- Huh, C.; Lange, E.A.; Cannella, W.J. Polymer Retention in Porous Media. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–25 April 1990. [Google Scholar]

- Glasbergen, G.; Wever, D.; Keijzer, E.; Farajzadeh, R. Injectivity Loss in Polymer Floods: Causes, Preventions and Mitigations. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, Mishref, Kuwait, 11–14 October 2015. [Google Scholar]

- Tanford, C. Physical Chemistry of Macromolecules; John Wiley & Sons, Inc.: New York, NY, USA, 1961; p. 710. [Google Scholar]

- Ghannam, M.T. Rheological properties of aqueous polyacrylamide/NaCl solutions. J. Appl. Polym. Sci. 1999, 72, 1905–1912. [Google Scholar] [CrossRef]

- Ryles, R.G. Elevated Temperature Testing of Mobility Control Reagents. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Francisco, CA, USA, 5–8 October 1983. [Google Scholar]

- Audibert, A.; Argillier, J.F. Thermal stability of sulfonated polymers. In Proceedings of the SPE International Symposium on Oilfield Chemistry, San Antonio, TX, USA, 14–17 February 1995. [Google Scholar]

- Parker, W.O., Jr.; Lezzi, A. Hydrolysis of sodium-2-acrylamido-2-methylpropanesulfonate copolymers at elevated temperature in aqueous solution via 13C nmr spectroscopy. Polymer 1993, 34, 4913–4918. [Google Scholar] [CrossRef]

- Al-Shammari, B.; Al-Fariss, T.; Al-Sewailm, F.; Elleithy, R. The effect of polymer concentration and temperature on the rheological behavior of metallocene linear low density polyethylene (mLLDPE) solutions. J. King Saud Univ. Eng. Sci. 2011, 23, 9–14. [Google Scholar] [CrossRef]

| Model Inputs (Factors) 1 | Min 2 | Middle 2 | Max 2 | Justification |

|---|---|---|---|---|

| Sulfonation degree (Sd), mol % | 5(−1) | 18.5(0) | 32(1) | Range of available commercial products |

| Molecular weight (Mw), MDa | 2(−1) | 7(0) | 12(1) | Range of available commercial products. |

| Hardness concentration (Hc), ppm | 0(−1) | 1500(0) | 3000(1) | Hard to find a reservoir containing hardness level higher than 3000 ppm |

| Salinity concentration (Sc), Wt % | 0.1(−1) | 5.05(0) | 10(1) | Majority of reservoir oil has salinity concentration in this range |

| Polymer Concentration (Pc), ppm | 100(−1) | 1550(0) | 3000(1) | Apart from injectivity problems, injection of polymer with a concentration higher than 3000ppm is not economical. |

| Temperature (T), °C | 50(−1) | 65(0) | 80(1) | Polymer instability for temperature higher than 80°C. |

| Aging Time (At), days | 0(−1) | 15(0) | 30(1) | Experimental limitation |

| Shear Rate (ShR), 1/s | 1(−1) | 50.5(0) | 100(1) | Expected shear rate in the reservoir is in the range of 1 to 20 1/s |

| Polymer Product (Trade Name) | Molecular Weight (Million Daltons) | Sulfonation Degree (mol. %) | Data Source |

|---|---|---|---|

| AN105 | 6 | 5 | [17,18] |

| AN105 VHM | 12 | 5 | Company Data |

| AN113 VLM | 2 | 13 | Company Data |

| AN113 | 8 | 13 | [17,18] |

| AN113 VHM | 12 | 13 | Company Data |

| AN125 VLM | 2 | 25 | [17,18] |

| AN132 | 8 | 32 | [17,18] |

| AN132 VHM | 12 | 32 | [51] |

| Sd 1 | Mw 2 | Hc 3 | Sc 4 | Pc 5 | T 6 | At 7 | ShR 8 | |

|---|---|---|---|---|---|---|---|---|

| Sd | 1.000 | |||||||

| Mw | 0.091 | 1.000 | ||||||

| Hc | 0.000 | 0.000 | 1.000 | |||||

| Sc | 0.000 | 0.000 | 0.000 | 1.000 | ||||

| Pc | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 | |||

| T | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 | ||

| At | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 | |

| ShR | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 110.58 | 20 | 5.53 | 153.42 | <0.0001 |

| Sd a | 1.38 | 1 | 1.38 | 38.30 | <0.0001 |

| Mw b | 8.40 | 1 | 8.40 | 233.00 | <0.0001 |

| Hc c | 1.58 | 1 | 1.58 | 43.86 | <0.0001 |

| Sc d | 0.15 | 1 | 0.15 | 4.14 | 0.0446 |

| Pc e | 67.98 | 1 | 67.98 | 1886.26 | <0.0001 |

| T f | 0.27 | 1 | 0.27 | 7.61 | 0.0069 |

| At g | 0.12 | 1 | 0.12 | 3.29 | 0.0729 |

| ShR h | 2.39 | 1 | 2.39 | 66.22 | <0.0001 |

| Sd*Pc | 0.21 | 1 | 0.21 | 5.91 | 0.0168 |

| Mw*Sc | 0.20 | 1 | 0.20 | 5.67 | 0.0192 |

| Mw*Pc | 0.77 | 1 | 0.77 | 21.50 | <0.0001 |

| Mw*ShR | 0.79 | 1 | 0.79 | 21.83 | <0.0001 |

| Hc*Sc | 1.81 | 1 | 1.81 | 50.20 | <0.0001 |

| Hc*ShR | 0.17 | 1 | 0.17 | 4.58 | 0.0348 |

| Sc*Pc | 0.12 | 1 | 0.12 | 3.33 | 0.0712 |

| Pc*ShR | 0.87 | 1 | 0.87 | 24.03 | <0.0001 |

| Hc2 | 0.36 | 1 | 0.36 | 10.08 | 0.0020 |

| Sc2 | 0.89 | 1 | 0.89 | 24.76 | <0.0001 |

| P2 | 2.63 | 1 | 2.63 | 73.05 | <0.0001 |

| ShR 2 | 0.57 | 1 | 0.57 | 15.84 | 0.0001 |

| Residual | 3.57 | 99 | 0.036 | ||

| Lack of Fit | 3.48 | 92 | 0.038 | 2.90 | 0.0689 |

| Pure Error | 0.091 | 7 | 0.013 | ||

| Cor Total | 114.15 | 119 |

| Mean Value * | Lower * | Upper * | Variance * | |

|---|---|---|---|---|

| Sulfonation degree (mol %) | 13(−0.41) | 12(−0.48 **) | 14(−0.33) | 0.07 |

| Molecular weight (MDa) | 8(0.2) | 7(0) | 9(0.4) | 0.2 |

| Hardness concentration (ppm) | 1500(0) | 1470(−0.02) | 1530(0.02) | 0.03 |

| Salinity concentration (wt %) | 5.05(0) | 5.04(−0.001) | 5.055(0.001) | 0.001 |

| Polymer concentration (ppm) | 1550(0) | 1520(−0.021) | 1580(0.021) | 0.034 |

| Temperature (°C) | 65(0) | 64.5(−0.03) | 65.5(0.03) | 0.066 |

| Aging time (days) | 15(0) | 14.75(−0.016) | 15.25(0.016) | 0.016 |

| Shear rate (1/s) | 50.5(0) | 50(−0.01) | 51(0.01) | 0.019 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbari, S.; Mahmood, S.M.; Ghaedi, H.; Al-Hajri, S. A New Empirical Model for Viscosity of Sulfonated Polyacrylamide Polymers. Polymers 2019, 11, 1046. https://doi.org/10.3390/polym11061046

Akbari S, Mahmood SM, Ghaedi H, Al-Hajri S. A New Empirical Model for Viscosity of Sulfonated Polyacrylamide Polymers. Polymers. 2019; 11(6):1046. https://doi.org/10.3390/polym11061046

Chicago/Turabian StyleAkbari, Saeed, Syed Mohammad Mahmood, Hosein Ghaedi, and Sameer Al-Hajri. 2019. "A New Empirical Model for Viscosity of Sulfonated Polyacrylamide Polymers" Polymers 11, no. 6: 1046. https://doi.org/10.3390/polym11061046

APA StyleAkbari, S., Mahmood, S. M., Ghaedi, H., & Al-Hajri, S. (2019). A New Empirical Model for Viscosity of Sulfonated Polyacrylamide Polymers. Polymers, 11(6), 1046. https://doi.org/10.3390/polym11061046