Determine Mesh Size through Monomer Mean-Square Displacement

Abstract

:1. Introduction

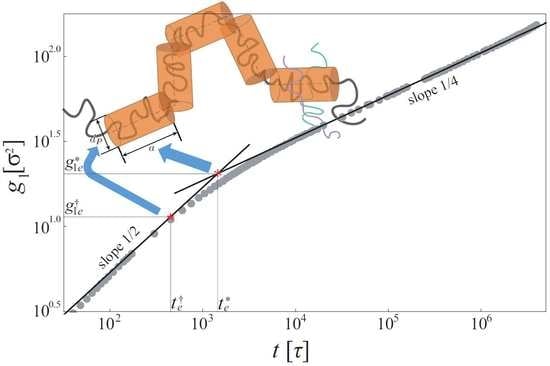

2. Tube Step Length and Tube Diameter

3. Monomer Displacement in Entangled Linear Melts

4. Determination of Mesh Size

5. The Ratio of TSL to TD

6. Summary

Funding

Conflicts of Interest

References and Note

- De Gennes, P. Scaling Concepts in Polymer Physics; Cornell University Press: Ithaca, NY, USA, 1979. [Google Scholar]

- Doi, M.; Edwards, S. The Theory of Polymer Dynamics; Oxford University Press: Oxford, UK, 1986. [Google Scholar]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press: New York, NY, USA, 2003. [Google Scholar]

- Everaers, R.; Sukumaran, S.K.; Grest, G.S.; Svaneborg, C.; Sivasubramanian, A.; Kremer, K. Rheology and microscopic topology of entangled polymeric liquids. Science 2004, 303, 823–826. [Google Scholar] [CrossRef]

- Kröger, M. Shortest multiple disconnected path for the analysis of entanglements in two-and three-dimensional polymeric systems. Comput. Phys. Commun. 2005, 168, 209–232. [Google Scholar] [CrossRef]

- Hoy, R.S.; Foteinopoulou, K.; Kröger, M. Topological analysis of polymeric melts: Chain-length effects and fast-converging estimators for entanglement length. Phys. Rev. E 2009, 80, 031803. [Google Scholar] [CrossRef] [Green Version]

- Hou, J.X.; Svaneborg, C.; Everaers, R.; Grest, G.S. Stress relaxation in entangled polymer melts. Phys. Rev. Lett. 2010, 105, 068301. [Google Scholar] [CrossRef]

- Likhtman, A.E.; McLeish, T.C.B. Quantitative theory for linear dynamics of linear entangled polymers. Macromolecules 2002, 35, 6332–6343. [Google Scholar] [CrossRef]

- De Gennes, P.G. Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 1971, 55, 572–579. [Google Scholar] [CrossRef]

- Yamamoto, U.; Schweizer, K.S. Theory of nanoparticle diffusion in unentangled and entangled polymer melts. J. Chem. Phys. 2011, 135, 224902. [Google Scholar] [CrossRef]

- Cai, L.H.; Panyukov, S.; Rubinstein, M. Mobility of nonsticky nanoparticles in polymer liquids. Macromolecules 2011, 44, 7853–7863. [Google Scholar] [CrossRef]

- Grabowski, C.A.; Mukhopadhyay, A. Size effect of nanoparticle diffusion in a polymer melt. Macromolecules 2014, 47, 7238–7242. [Google Scholar] [CrossRef]

- Cai, L.H.; Panyukov, S.; Rubinstein, M. Hopping diffusion of nanoparticles in polymer matrices. Macromolecules 2015, 48, 847–862. [Google Scholar] [CrossRef]

- Parrish, E.; Caporizzo, M.A.; Composto, R.J. Network confinement and heterogeneity slows nanoparticle diffusion in polymer gels. J. Chem. Phys. 2017, 146, 203318. [Google Scholar] [CrossRef]

- Ge, T.; Kalathi, J.T.; Halverson, J.D.; Grest, G.S.; Rubinstein, M. Nanoparticle motion in entangled melts of linear and nonconcatenated ring polymers. Macromolecules 2017, 50, 1749–1754. [Google Scholar] [CrossRef]

- Rouse, P.E. A theory of the linear viscoelastic properties of dilute solutions of coiling polymers. J. Chem. Phys. 1953, 21, 1272–1280. [Google Scholar] [CrossRef]

- Hou, J.X. Note: Determine entanglement length through monomer mean-square displacement. J. Chem. Phys. 2017, 146, 026101. [Google Scholar] [CrossRef]

- Hsu, H.P.; Kremer, K. Static and dynamic properties of large polymer melts in equilibrium. J. Chem. Phys. 2016, 144, 154907. [Google Scholar] [CrossRef] [Green Version]

- Kremer, K.; Grest, G.S. Dynamics of entangled linear polymer melts: A molecular-dynamics simulation. J. Chem. Phys. 1990, 92, 5057–5086. [Google Scholar] [CrossRef]

- Stephanou, P.S.; Baig, C.; Tsolou, G.; Mavrantzas, V.G.; Kröger, M. Quantifying chain reptation in entangled polymer melts: Topological and dynamical mapping of atomistic simulation results onto the tube model. J. Chem. Phys. 2010, 132, 124904. [Google Scholar] [CrossRef] [Green Version]

- Stephanou, P.S.; Baig, C.; Mavrantzas, V.G. Projection of atomistic simulation data for the dynamics of entangled polymers onto the tube theory: Calculation of the segment survival probability function and comparison with modern tube models. Soft Matter 2011, 7, 380–395. [Google Scholar] [CrossRef]

- Stephanou, P.S.; Baig, C.; Mavrantzas, V.G. Toward an improved description of constraint release and contour length fluctuations in tube models for entangled polymer melts guided by atomistic simulations. Macromol. Theory Simul. 2011, 20, 752–768. [Google Scholar] [CrossRef]

- For a variable r of which the distribution follows a two-dimensional Gaussian distribution , we have . Thus,

- Wang, Z.; Likhtman, A.E.; Larson, R.G. Segmental dynamics in entangled linear polymer melts. Macromolecules 2012, 45, 3557–3570. [Google Scholar] [CrossRef]

- Zhou, Q.; Larson, R.G. Direct calculation of the tube potential confining entangled polymers. Macromolecules 2006, 39, 6737–6743. [Google Scholar] [CrossRef]

- Wang, Z.; Larson, R.G. Constraint release in entangled binary blends of linear polymers: A molecular dynamics study. Macromolecules 2008, 41, 4945–4960. [Google Scholar] [CrossRef]

- Herrmann, A.; Kresse, B.; Wohlfahrt, M.; Bauer, I.; Privalov, A.F.; Kruk, D.; Fatkullin, N.; Fujara, F.; Rossler, E.A. Mean square displacement and reorientational correlation function in entangled polymer melts revealed by field cycling 1H and 2H NMR relaxometry. Macromolecules 2012, 45, 6516–6526. [Google Scholar] [CrossRef]

- Korolkovas, A.; Gutfreund, P.; Barrat, J.L. Simulation of entangled polymer solutions. J. Chem. Phys. 2016, 145, 124113. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-Hernández, A.; Detcheverry, F.A.; Peters, B.L.; Chappa, V.C.; Schweizer, K.S.; Muller, M.; De Pablo, J.J. Dynamical simulations of coarse grain polymeric systems: Rouse and entangled dynamics. Macromolecules 2013, 46, 6287–6299. [Google Scholar] [CrossRef]

- Öttinger, H.C. Coarse-graining of wormlike polymer chains for substantiating reptation. J. Non-Newtonian Fluid Mech. 2004, 120, 207–213. [Google Scholar] [CrossRef]

- Flory, P.J. Statistical Mechanics of Chain Molecules; Hanser: Munich, Germany, 1988. [Google Scholar]

- Tzoumanekas, C.; Theodorou, D.N. Topological analysis of linear polymer melts: A statistical approach. Macromolecules 2006, 39, 4592–4604. [Google Scholar] [CrossRef]

- Foteinopoulou, K.; Karayiannis, N.C.; Mavrantzas, V.G.; Kröger, M. Primitive path identification and entanglement statistics in polymer melts: Results from direct topological analysis on atomistic polyethylene models. Macromolecules 2006, 39, 4207–4216. [Google Scholar] [CrossRef]

- Kamio, K.; Moorthi, K.; Theodorou, D.N. Coarse grained end bridging Monte Carlo simulations of poly(ethylene terephthalate) melt. Macromolecules 2007, 40, 710–722. [Google Scholar] [CrossRef]

- Spyriouni, T.; Tzoumanekas, C.; Theodorou, D.; Müller-Plathe, F.; Milano, G. Coarse-grained and reverse-mapped united-atom simulations of long-chain atactic polystyrene melts: Structure, thermodynamic properties, chain conformation, and entanglements. Macromolecules 2007, 40, 3876–3885. [Google Scholar] [CrossRef]

- Everaers, R. Topological versus rheological entanglement length in primitive-path analysis protocols, tube models, and slip-link models. Phys. Rev. E 2012, 86, 022801. [Google Scholar] [CrossRef] [Green Version]

- Likhtman, A.E.; Talib, M.S.; Vorselaars, B.; Ramirez, J. Determination of tube theory parameters using a simple grid model as an example. Macromolecules 2013, 46, 1187–1200. [Google Scholar] [CrossRef]

| Ref. | Model or Material | ||||

|---|---|---|---|---|---|

| [24] | KGM | 85 | 2.0 | ||

| [18] | KGM | 33 | 2.0 | ||

| [25] | KGM | 28 | 2.0 | ||

| [26] | KGM | 35 | 2.0 | ||

| [24] | KGM | 34 | 2.0 | ||

| [27] | Polybutadiene K | 21,000 | 72,400 | 2.0 | |

| [28] | Continuous Model | 10,000 | 31,500 | 43 | 2.0 |

| [29] | Coarse–Grained Model | 2.0 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.-X. Determine Mesh Size through Monomer Mean-Square Displacement. Polymers 2019, 11, 1405. https://doi.org/10.3390/polym11091405

Hou J-X. Determine Mesh Size through Monomer Mean-Square Displacement. Polymers. 2019; 11(9):1405. https://doi.org/10.3390/polym11091405

Chicago/Turabian StyleHou, Ji-Xuan. 2019. "Determine Mesh Size through Monomer Mean-Square Displacement" Polymers 11, no. 9: 1405. https://doi.org/10.3390/polym11091405

APA StyleHou, J.-X. (2019). Determine Mesh Size through Monomer Mean-Square Displacement. Polymers, 11(9), 1405. https://doi.org/10.3390/polym11091405