Bio-Based Epoxy Resins Based on Linseed Oil Cured with Naturally Occurring Acids

Abstract

:1. Introduction

2. Materials and Methods

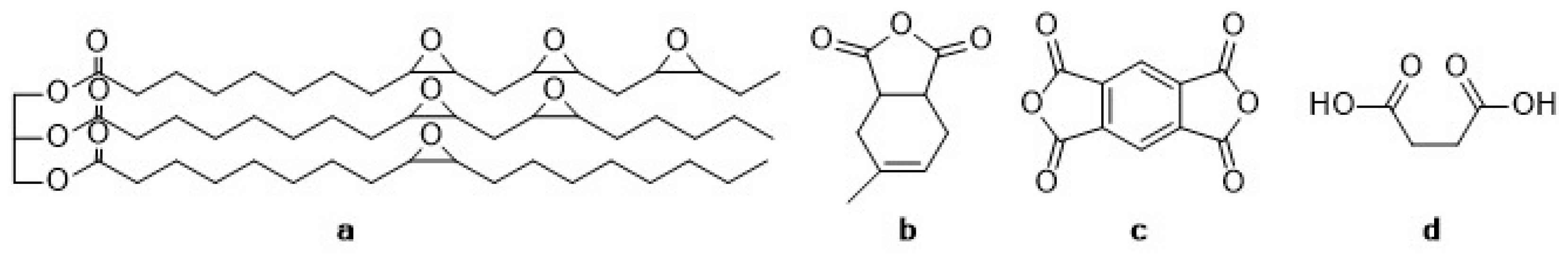

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

3. Results and Discussion

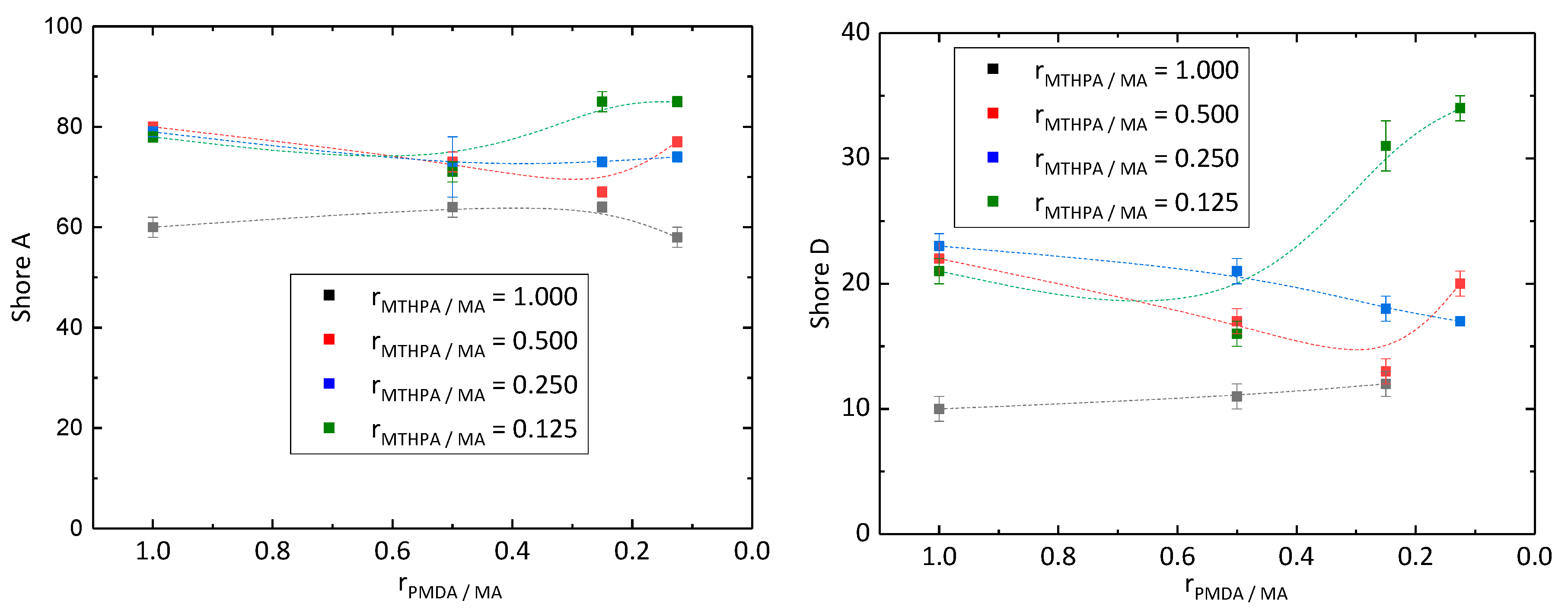

3.1. Prepared Epoxy Resins with Varying Composition of the Hardener System and ELO

3.2. Dependence of the Mass of ELO on the Properties of the Prepared Epoxy Resins

3.3. Substitution of PMDA Using Biogenic Carboxylic Acids

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jin, F.L.; Park, S.J. Thermomechanical behavior of epoxy resins modified with epoxidized vegetable oils. Polym. Int. 2008, 57, 577–583. [Google Scholar] [CrossRef]

- Khandelwal, V.; Sahoo, S.K.; Kumar, A.; Manik, G.J. Study on the effect of carbon nanotube on the properties of electrically conductive epoxy/polyaniline adhesives. Mater. Sci. Mater. Electron. 2017, 28, 14240–14251. [Google Scholar] [CrossRef]

- Vandenberg, L.N.; Maffini, M.V.; Sonnenschein, C.; Rubin, B.S.; Soto, A.M. Bisphenol-A and the great divide: A review of controversies in the field of endocrine disruption. Endocr. Rev. 2009, 30, 75–95. [Google Scholar] [CrossRef] [PubMed]

- Maffini, M.V.; Rubin, B.S.; Sonnenschein, C.; Soto, A.M. Endocrine disruptors and reproductive health: The case of bisphenol-A. Mol. Cell. Endocrinol. 2006, 254–255, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Ratna, D.; Banthia, A.K.J. Epoxidized soybean oil toughened epoxy adhesive. Adhes. Sci. Technol. 2000, 14, 15–25. [Google Scholar] [CrossRef]

- Li, F.; Larock, R.C.J. New soybean oil-styrene-divinylbenzene thermosetting copolymers. III. Tensile stress-strain behavior. J. Polym. Sci. Pol. Phys. 2001, 39, 60–77. [Google Scholar] [CrossRef]

- Khot, S.N.; Lascala, J.J.; Can, E.; Morye, S.S.; Williams, G.I.; Palmese, G.R.; Kusefoglu, S.H.; Wool, R.P.J. Development and application of triglyceride-based polymers and composites. Appl. Polym. Sci. 2001, 82, 703–723. [Google Scholar] [CrossRef]

- Stemmelen, M.; Pessel, F.; Lapinte, V.; Caillol, S.; Habas, J.P.; Robin, J.J. A fully biobased epoxy resin from vegetable oils: From the synthesis of the precursors by thiol-ene reaction to the study of the final material. J. Polym. Sci. Pol. Chem. 2011, 49, 2434–2444. [Google Scholar] [CrossRef] [Green Version]

- Stemmelen, M.; Lapinte, V.; Habas, J.P.; Robin, J.J. Plant oil-based epoxy resins from fatty diamines and epoxidized vegetable oil. Eur. Polym. J. 2015, 68, 536–545. [Google Scholar] [CrossRef] [Green Version]

- Ding, C.; Shuttleworth, P.S.; Makin, S.; Clark, J.H.; Matharu, A.S. New insights into the curing of epoxidized linseed oil with dicarboxylic acids. Green Chem. 2015, 17, 4000–4008. [Google Scholar] [CrossRef]

- Pin, J.M.; Sbirrazzuoli, N.; Mija, A. From epoxidized linseed oil to bioresin: An overall approach of epoxy/anhydride cross-linking. ChemSusChem 2015, 8, 1232–1243. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, J.K.; Vishwakarma, A. Importance of Linseed Crops in Agricultural Sustainability. Int. J. Curr. Microbiol. Appl. Sci. 2018, 12, 1198–1207. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Khandelwal, V.; Manik, G. Development of toughened bio-based epoxy with epoxidized linseed oil as reactive diluent and cured with bio-renewable crosslinker. Polym. Adv. Technol. 2018, 29, 565–574. [Google Scholar] [CrossRef]

- Miyagawa, H.; Mohanty, A.K.; Misra, M.; Drzal, L.T. Thermo-physical and impact properties of epoxy containing epoxidized linseed oil, 1. Macromol. Mater. Eng. 2004, 289, 629–635. [Google Scholar] [CrossRef]

- Kuncho, C.N.; Schmidt, D.F.; Reynaud, E. Effects of Catalyst Content, Anhydride Blending, and Nanofiller Addition on Anhydride-Cured Epoxidized Linseed Oil-Based Thermosets. Ind. Eng. Chem. Res. 2017, 56, 2658–2666. [Google Scholar] [CrossRef]

- Jain, R.; Choudhary, V.; Narula, A.K. Curing and thermal behaviour of epoxy resin in the presence of pyromellitic dianhydride and imidazole. J. Appl. Polym. Sci. 2007, 106, 2593–2598. [Google Scholar] [CrossRef]

- DIN EN ISO 8987:2005-12. Kunststoffe—Phenolharze—Bestimmung der Reaktivität Auf Einer B-Zeit-Prüfplatte; Beuth Publishing Din: Berlin, Gemany, 2005. [Google Scholar]

- DIN ISO 7619-1:2012-02. Elastomere Oder Thermoplastische Elastomere—Bestimmung der Eindringhärte—Teil 1: Durometer-Verfahren (Shore-Härte); Beuth Publishing Din: Berlin, Gemany, 2012. [Google Scholar]

- Boquillon, N.; Fringant, C. Polymer networks derived from curing of epoxidised linseed oil: Influence of different catalysts and anhydride hardeners. Polymer 2000, 41, 8603–8613. [Google Scholar] [CrossRef]

- Silicone Moulding Compounds—2 Components. Available online: http://shop1.r-g.de/en/list/Silicone-moulding-compounds/2-Components--RTV-2-/Addition-curing/Epoxy-resins--EP- (accessed on 28 February 2018).

- Compare Epoxy Physical Properties. Available online: https://www.westsystem.com/products/compare-epoxy-physical-properties/ (accessed on 28 February 2018).

- Zhao, C.; Zhang, G.; Zhao, L. Effect of curing agent and temperature on the rheological behavior of epoxy resin systems. Molecules 2012, 17, 8587–8594. [Google Scholar] [CrossRef] [PubMed]

| Sample Name | nMTHPA/mmol | nPMDA/mmol | nMA/mmol | mELO/g |

|---|---|---|---|---|

| PD111 | 8.0 | 8.0 | 8.0 | 12 |

| PD212 | 10.2 | 5.1 | 10.3 | 12 |

| PD414 | 11.9 | 3.0 | 11.9 | 12 |

| PD818 | 12.9 | 1.6 | 12.9 | 12 |

| PD122 | 4.8 | 9.6 | 9.6 | 12 |

| PD112 | 6.5 | 6.5 | 13.0 | 12 |

| PD214 | 7.9 | 3.9 | 15.8 | 12 |

| PD418 | 8.9 | 2.2 | 17.7 | 12 |

| PD144 | 2.7 | 10.6 | 10.7 | 12 |

| PD124 | 3.7 | 7.5 | 15.0 | 12 |

| PD114 | 4.7 | 4.7 | 18.9 | 12 |

| PD218 | 5.4 | 2.7 | 21.6 | 12 |

| PD188 | 1.4 | 11.3 | 11.3 | 12 |

| PD148 | 2.1 | 8.1 | 16.3 | 12 |

| PD128 | 2.6 | 5.2 | 20.9 | 12 |

| PD118 | 3.1 | 3.0 | 24.4 | 12 |

| PD418-ELO8 | 8.9 | 2.2 | 17.7 | 8 |

| PD418-ELO10 | 8.9 | 2.2 | 17.7 | 10 |

| PD418-ELO14 | 8.9 | 2.2 | 17.7 | 14 |

| PD418-ELO16 | 8.9 | 2.2 | 17.7 | 16 |

| Sample Name | nMTHPA/mmol | nX1/mmol | nMA/mmol | mELO/g |

|---|---|---|---|---|

| OA418 | 9.3 | 2.3 | 18.6 | 12 |

| FA418 | 9.4 | 2.3 | 18.7 | 12 |

| SA418 | 9.3 | 2.4 | 18.7 | 12 |

| HSA418 | 9.3 | 2.3 | 18.5 | 12 |

| TA418 | 9.2 | 2.3 | 18.4 | 12 |

| IA418 | 9.3 | 2.3 | 18.6 | 12 |

| CA418 | 8.9 | 2.2 | 17.8 | 12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thiele, K.; Eversmann, N.; Krombholz, A.; Pufky-Heinrich, D. Bio-Based Epoxy Resins Based on Linseed Oil Cured with Naturally Occurring Acids. Polymers 2019, 11, 1409. https://doi.org/10.3390/polym11091409

Thiele K, Eversmann N, Krombholz A, Pufky-Heinrich D. Bio-Based Epoxy Resins Based on Linseed Oil Cured with Naturally Occurring Acids. Polymers. 2019; 11(9):1409. https://doi.org/10.3390/polym11091409

Chicago/Turabian StyleThiele, Kerstin, Nicole Eversmann, Andreas Krombholz, and Daniela Pufky-Heinrich. 2019. "Bio-Based Epoxy Resins Based on Linseed Oil Cured with Naturally Occurring Acids" Polymers 11, no. 9: 1409. https://doi.org/10.3390/polym11091409