The Puncture and Water Resistance of Polyurethane- Impregnated Fabrics after UV Weathering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization Techniques

3. Results

3.1. Puncture Strength

3.2. Water Resistance

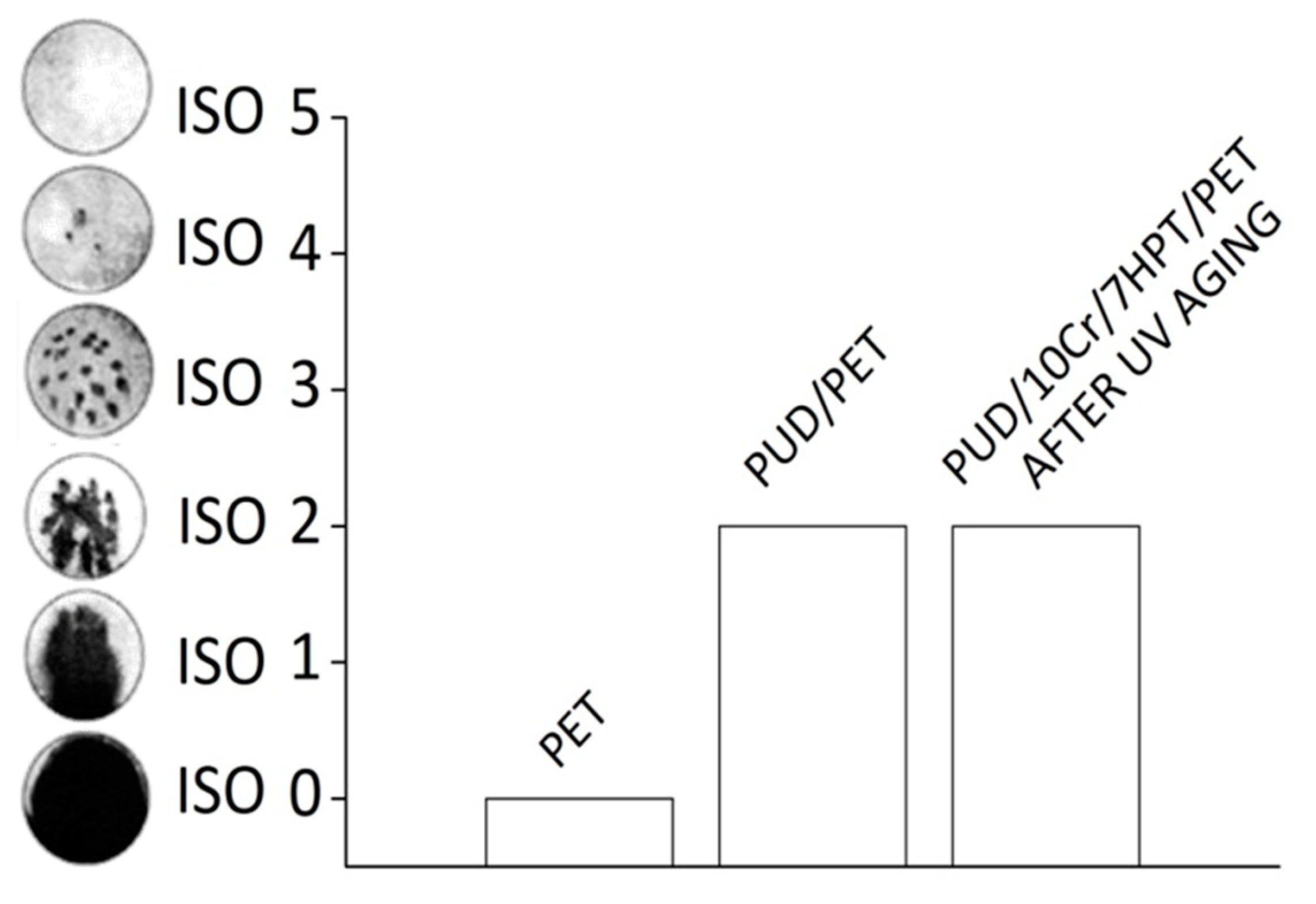

3.3. Microscopic Aspects

3.4. Spectroscopic Analysis

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Engels, H.-W.; Pirkl, H.-G.; Albers, R.; Albach, R.W.; Krause, J.; Hoffmann, A.; Casselmann, H.; Dormish, J. Polyurethanes: Versatile materials and sustainable problem solvers for today’s challenges. Angew. Chem. Int. Ed. 2013, 52, 9422–9441. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef] [Green Version]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Atiqah, A.; Mastura, T.M.; Ahmed Ali, A.; Jawaid, B.M.; Sapuan, M.S. A Review on Polyurethane and its Polymer Composites Current Organic Synthesis. Curr. Org. Synth. 2017, 14, 233–248. [Google Scholar] [CrossRef]

- Golling, F.E.; Pires, R.; Hecking, A.; Weikard, J.; Richter, F.; Danielmeier, K.; Dijkstra, D. Polyurethanes for coatings and adhesives–chemistry and applications. Polym. Int. 2019, 68, 848–855. [Google Scholar] [CrossRef]

- Kovačević, S.; Ujević, D.; Brnada, S. Coated Textile Materials. In Coated Textile Materials, Woven Fabric Engineering; Dubrovski, P.D., Ed.; InTech: London, UK, 2010; ISBN 978-953-307-194-7. Available online: http://www.intechopen.com/books/woven-fabric-engineering/coated-textile-materials (accessed on 18 November 2010).

- Zafara, F.; Ghosal, A.; Sharminc, E.; Chaturvedi, R.; Nishat, N. A review on cleaner production of polymeric and nanocomposite coatings based on waterborne polyurethane dispersions from seed oils. Prog. Org. Coat. 2019, 131, 259–275. [Google Scholar] [CrossRef]

- Tennebroek, R.; van der Hoeven-van Casteren, I.; Swaans, R.; van der Slot, S.; Stals, P.J.M.; Tuijtelaars, B.; Koning, C. Water-based polyurethane dispersions. Polym. Int. 2019, 68, 832–842. [Google Scholar] [CrossRef]

- Zhimeng, L.; Wu, B.; Jiang, Y.; Lei, J.; Zhou, C.; Zhang, J.; Wang, J. Solvent-free and self-catalysis synthesis and properties of waterborne polyurethane. Polymer 2018, 143, 129–136. [Google Scholar] [CrossRef]

- Ah Hong, K.; Sook Yoo, H.; Kim, E. Effect of waterborne polyurethane coating on the durability and breathable waterproofing of electrospun nanofiber web-laminated fabrics. Text. Res. J. 2015, 85, 160–170. [Google Scholar] [CrossRef]

- Jassal, M.; Khungar, A.; Bajaj, P.; Sinha, T.J.M. Waterproof Breathable Polymeric Coatings Based on Polyurethanes. J. Ind. Text. 2004, 33, 269–280. [Google Scholar] [CrossRef]

- Huang, S.; Liu, G.; Zhang, K.; Hu, H.; Wang, J.; Miao, L.; Tabrizizadeh, T. Water-based polyurethane formulations for robust superhydrophobic fabrics. Chem. Eng. J. 2019, 360, 445–451. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398–430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nguyena, T.V.; Le, X.H.; Dao, P.H.; Decker, C.; Nguyen-Tri, P. Stability of acrylic polyurethane coatings under accelerated aging tests and natural outdoor exposure: The critical role of the used photo-stabilizers. Prog. Org. Coat. 2018, 124, 137–146. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Ahmadi, M.; Mirmohseni, A.; Taseidifar, M.; Naebe, M. The Effects of UV Light on the Chemical and Mechanical Properties of a Transparent Epoxy-Diamine System in the Presence of an Organic UV Absorber. Materials 2017, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Feldman, D. Polymer Weathering: Photo-Oxidation. J. Polym. Environ. 2002, 10, 163–173. [Google Scholar] [CrossRef]

- Yanga, X.F.; Vang, C.; Tallman, D.E.; Bierwagen, G.P.; Croll, S.G.; Rohlik, S. Weathering degradation of a polyurethane coating. Polym. Degrad. Stab. 2001, 74, 341–351. [Google Scholar] [CrossRef]

- Del Rey, R.; Serrat, R.; Alba, J.; Perez, I.; Mutje, P.; Espinach, F.X. Effect of Sodium Hydroxide Treatments on the Tensile Strength and the Interphase Quality of Hemp Core Fiber-Reinforced Polypropylene Composites. Polymers 2017, 9, 377. [Google Scholar] [CrossRef] [Green Version]

- Gu, X.; Chen, G.; Zhao, M.; Watson, S.S.; Stutzman, P.E.; Nguyen, T.; Chin, J.W.; Martin, J.W. Role of nanoparticules in life cycle of ZnO/polyurethane nanocomposites. NSTINanotech 2010, 1, 709–712. [Google Scholar]

- Bhargava, S.; Kubota, M.; Lewis, R.D.; Advani, S.G.; Prasad, A.K.; Deitzel, J.M. Ultraviolet, water, and thermal aging studies of a waterborne polyurethane elastomer-based high reflectivity coating. Prog. Org. Coat. 2015, 79, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Maxted, J.; Barber, A.; Lowe, C.; Smith, R. The durability of clear polyurethane coil coatings studied by FTIR peak fitting. Polym. Degrad. Stab. 2013, 98, 527–534. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, D. The effect of silica/polyurethane waterborne dispersion on the perforating features of impregnated polypropylene-based fabric. Text. Res. J. 2019. [Google Scholar] [CrossRef]

- Shesan, O.J.; Stephen, A.C.; Chioma, A.G.; Neerish, R.; Rotimi, S.E. Fiber-Matrix Relationship for Composites Preparation. In Renewable and Sustainable Composites; Pereira, A.B., Fernandes, F.A.O., Eds.; IntechOpen: London, UK, 2019; Available online: https://www.intechopen.com/online-first/fiber-matrix-relationship-for-composites-preparation (accessed on 26 July 2019). [CrossRef] [Green Version]

- Han, Y.; Hu, J.; Xin, Z. Facile preparation of high solid content waterborne polyurethane and its application in leather surface finishing. Prog. Org. Coat. 2019, 130, 8–16. [Google Scholar] [CrossRef]

- Gong, X.; Xu, Y.; Zhu, W.; Xuan, S.; Jiang, W.; Jiang, W. Study of the knife stab and puncture-resistant performance for shear thickening fluid enhanced fabric. J. Compos. Mater. 2014, 48, 641–657. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Schaller, C.; Rogez, D.; Braig, A. Hydroxyphenyl-s-triazines: Advanced multipurpose UV-absorbers for coatings. J. Coat. Technol. Res. 2008, 5, 25–31. [Google Scholar] [CrossRef]

| Mixing Components | |||||

|---|---|---|---|---|---|

| WPUD | Cr | ZnO | Hals | HPT | |

| PUD | 13 g (100%) | / | / | / | / |

| PUD/10Cr | 13 g (100%) | 0.78 g (10%) 1 | / | / | / |

| PUD/1ZnO | 13 g (100%) | / | 0.08 g (1%) 1 | / | / |

| PUD/4ZnO | 13 g (100%) | / | 0.32 g (4%) 1 | / | / |

| PUD/7ZnO | 13 g (100%) | / | 0.55 g (7%) 1 | / | / |

| PUD/1Hals | 13 g (100%) | / | 0.15 g 2 (1%) 1 | / | |

| PUD/4Hals | 13 g (100%) | / | / | 0.62 g 2 (4%) 1 | / |

| PUD/7Hals | 13 g (100%) | / | / | 1.06 g 2 (7%) 1 | / |

| PUD/1HPT | 13 g (100%) | / | / | / | 0.39 g 2 (1%) 1 |

| PUD/4HPT | 13 g (100%) | / | / | / | 1.60 g 2 (4%) 1 |

| PUD/7HPT | 13 g (100%) | / | / | / | 2.75 g 2 (7%) 1 |

| PUD/10Cr/7ZnO | 13 g (100%) | 0.78 g (10%) 1 | 0.55 g (7%) 1 | / | / |

| PUD/10Cr/7Hals | 13 g (100%) | 0.78 g (10%) 1 | / | 1.06 g 2 (7%) 1 | / |

| PUD/10Cr/7HPT | 13 g (100%) | 0.78 g (10%) 1 | / | / | 2.75 g 2 (7%) 1 |

| BEFORE UV | AFTER UV | |||

|---|---|---|---|---|

| Load (N) | Displacement (mm) | Load (N) | Displacement (mm) | |

| (a) Polyurethane impregnation | ||||

| PET | 160 ± 23 | 29 ± 8 | 138 ± 15 | 19 ± 4 |

| PUD/PET | 204 ± 26 | 26 ± 5 | 105 ± 10 | 22 ± 4 |

| (b) Addition of the crosslinker into WPUD | ||||

| PUD/10Cr/PET | 192 ± 15 | 19 ± 4 | 115 ± 14 | 17 ± 4 |

| (c) Addition of ZnO into WPUD | ||||

| PUD/1ZnO/PET | 187 ± 18 | 22 ± 3 | 107 ± 13 | 19 ± 4 |

| PUD/4ZnO/PET | 203 ± 23 | 23 ± 7 | 118 ± 17 | 17 ± 3 |

| PUD/7ZnO/PET | 212 ± 12 | 24 ± 6 | 116 ± 10 | 19 ± 3 |

| (d) Addition of HALS into WPUD | ||||

| PUD/1HALS/PET | 182 ± 22 | 22 ± 6 | 103 ± 16 | 19 ± 4 |

| PUD/4 HALS/PET | 193 ± 23 | 22 ± 4 | 100 ± 13 | 15 ± 3 |

| PUD/7 HALS/PET | 176 ± 21 | 19 ± 4 | 118 ± 18 | 17 ± 3 |

| (e) Addition of HPT into WPUD | ||||

| PUD/1HPT/PET | 187 ± 25 | 22 ± 4 | 136 ± 18 | 17 ± 3 |

| PUD/4HPT/PET | 176 ± 24 | 25 ± 5 | 126 ± 15 | 19 ± 4 |

| PUD/7HPT/PET | 172 ± 17 | 23 ± 5 | 124 ± 15 | 16 ± 4 |

| (f) Addition of Crosslinker and UV stabilizers into WPUD | ||||

| PUD/10Cr/7ZnO/PET | 200 ± 27 | 17 ± 3 | 142 ± 14 | 19 ± 3 |

| PUD/10Cr/7HALS/PET | 200 ± 17 | 18 ± 4 | 142 ± 17 | 22 ± 3 |

| PUD/10Cr/7HPT/PET | 192 ± 15 | 17 ± 4 | 149 ± 27 | 21 ± 4 |

| Absorbance loss (%) | ||||

|---|---|---|---|---|

| 2928 cm−1 | 1732 cm−1 | 1530 cm−1 | 1250 cm−1 | |

| PUD/PET | 32 | 35 | 22 | 24 |

| PUD/7 HPT/PET | 28 | 33 | 22 | 16 |

| PUD/10Cr/7HPT/PET | 4 | 10 | 0 | 7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patti, A.; Acierno, D. The Puncture and Water Resistance of Polyurethane- Impregnated Fabrics after UV Weathering. Polymers 2020, 12, 15. https://doi.org/10.3390/polym12010015

Patti A, Acierno D. The Puncture and Water Resistance of Polyurethane- Impregnated Fabrics after UV Weathering. Polymers. 2020; 12(1):15. https://doi.org/10.3390/polym12010015

Chicago/Turabian StylePatti, Antonella, and Domenico Acierno. 2020. "The Puncture and Water Resistance of Polyurethane- Impregnated Fabrics after UV Weathering" Polymers 12, no. 1: 15. https://doi.org/10.3390/polym12010015

APA StylePatti, A., & Acierno, D. (2020). The Puncture and Water Resistance of Polyurethane- Impregnated Fabrics after UV Weathering. Polymers, 12(1), 15. https://doi.org/10.3390/polym12010015