Multi-Sacrificial Bonds Enhanced Double Network Hydrogel with High Toughness, Resilience, Damping, and Notch-Insensitivity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Hydrogel

2.2. Characterization

3. Result and Discussion

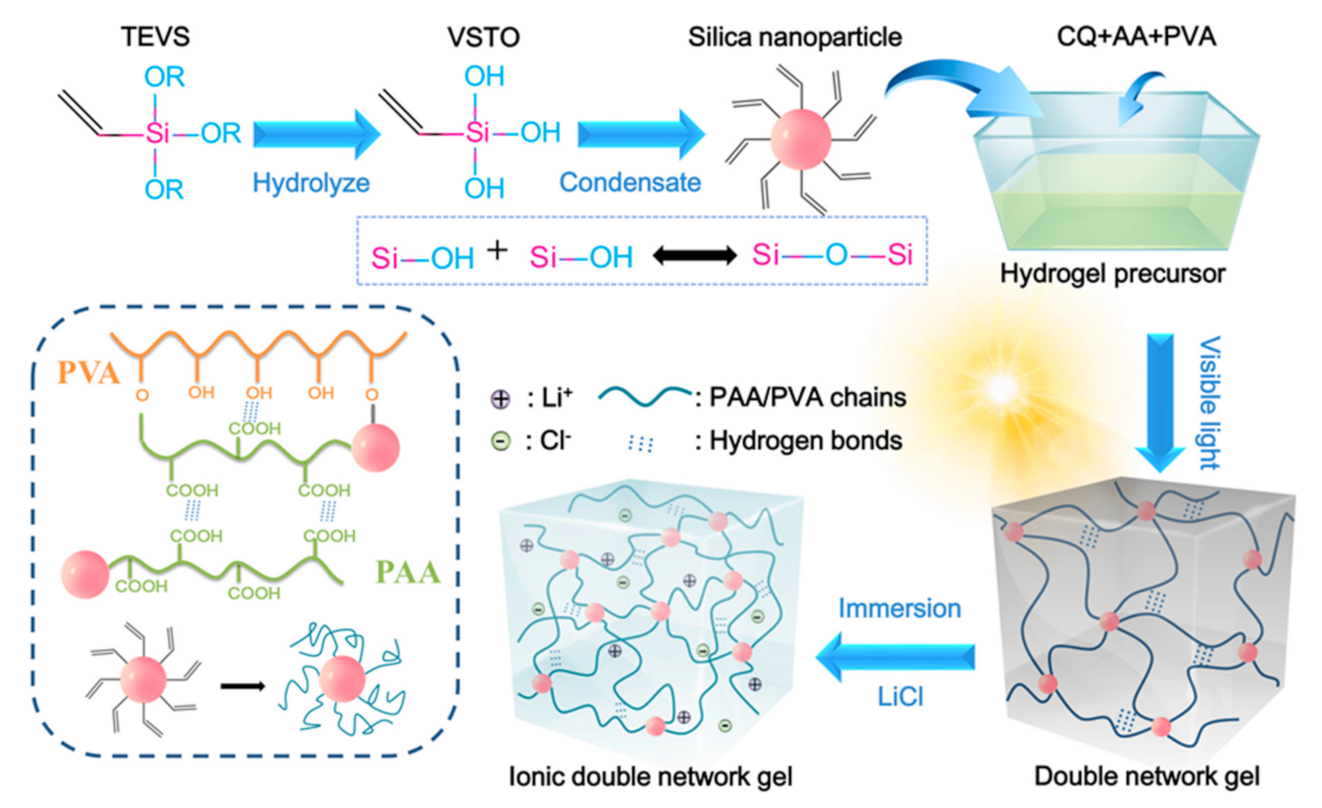

3.1. Synthesis of the CDN-gel

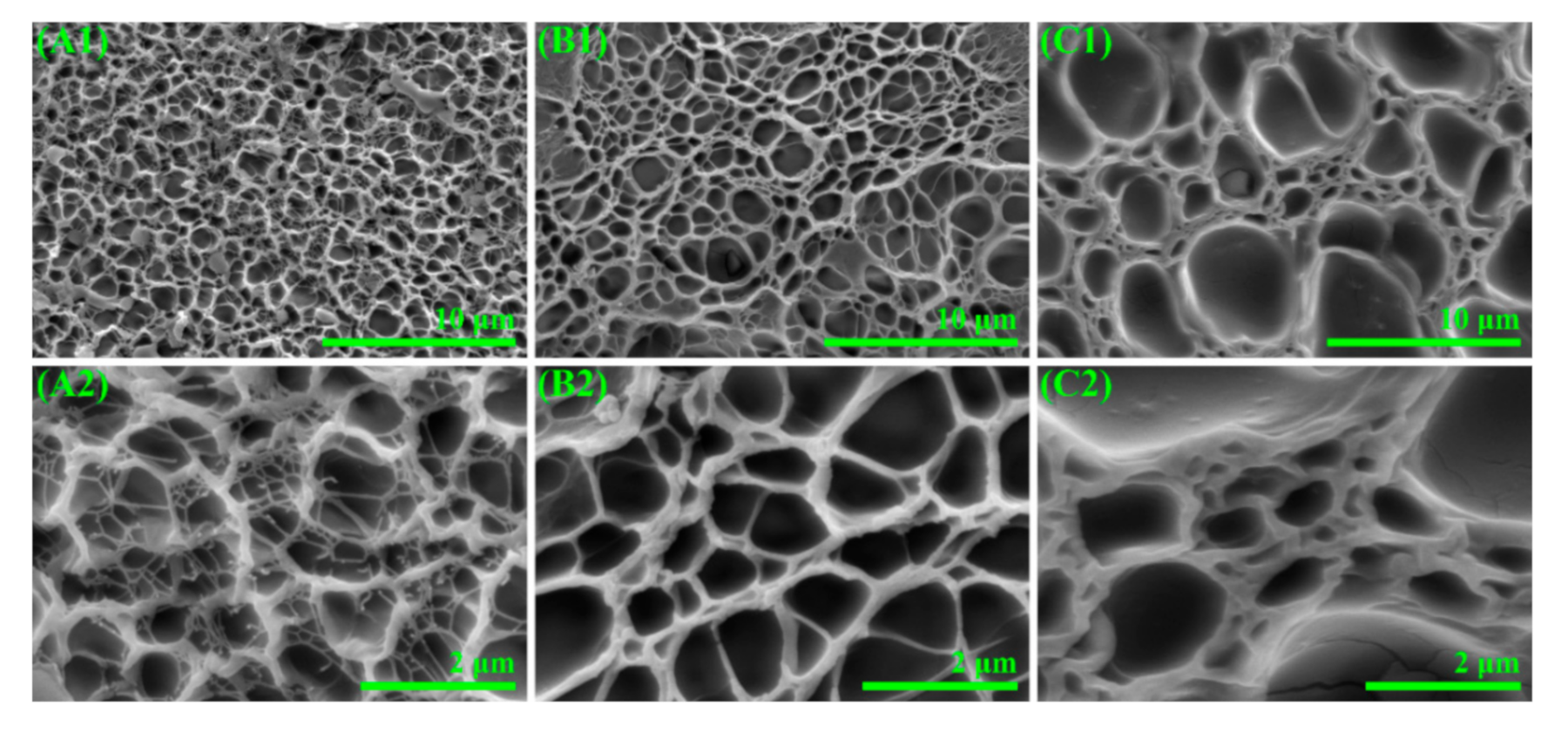

3.2. Morphology of the CDN-Gel

3.3. High Strength and Toughness of CDN-Gels

3.4. Excellent Recoverability of GEL-0.5

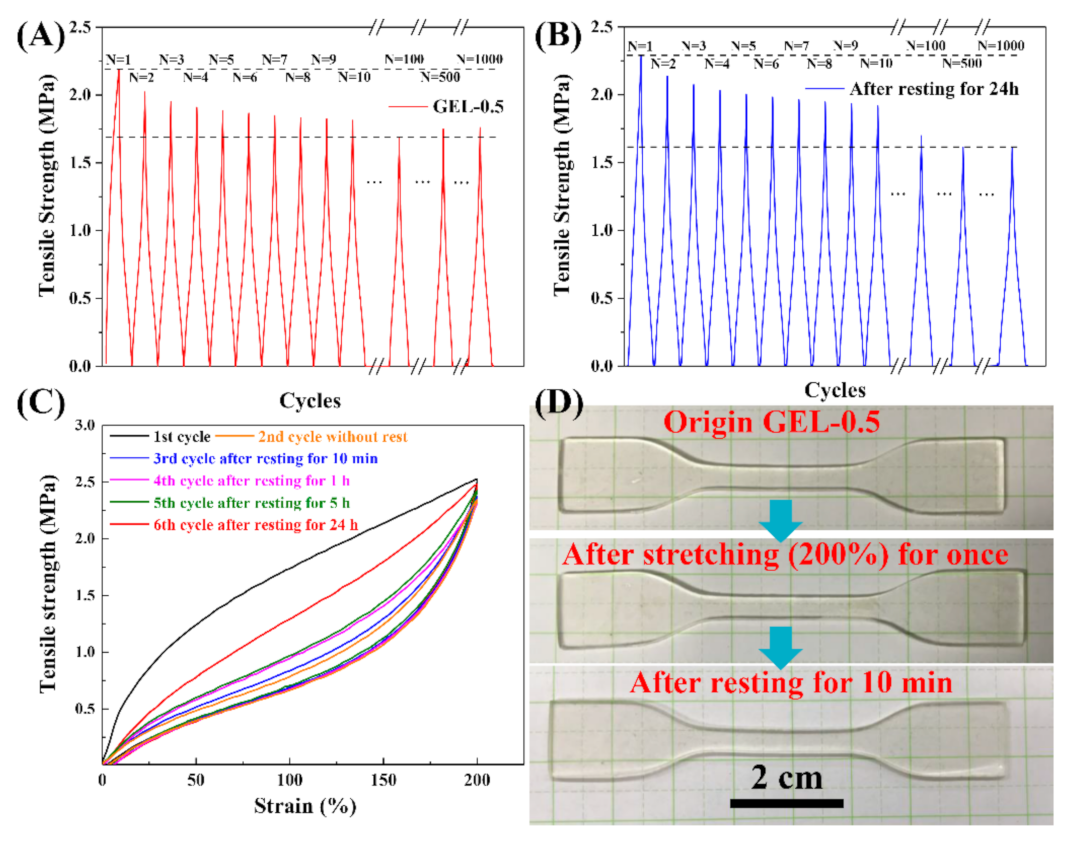

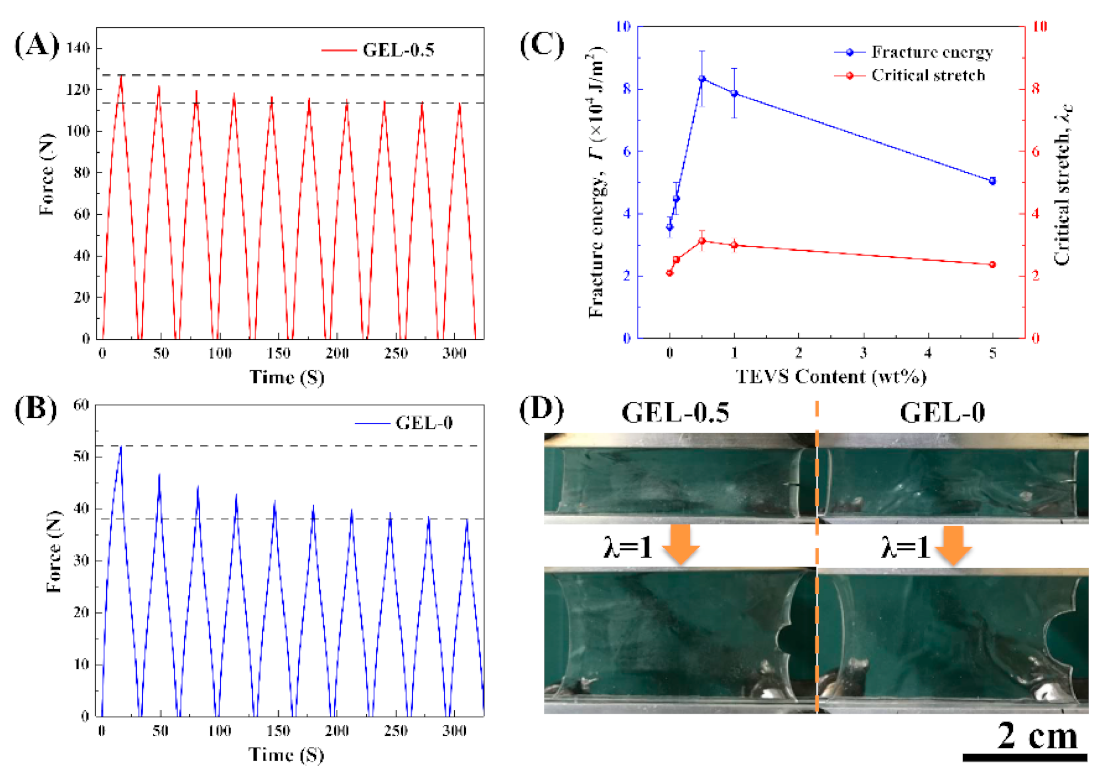

3.4.1. Cyclic Tensile Tests

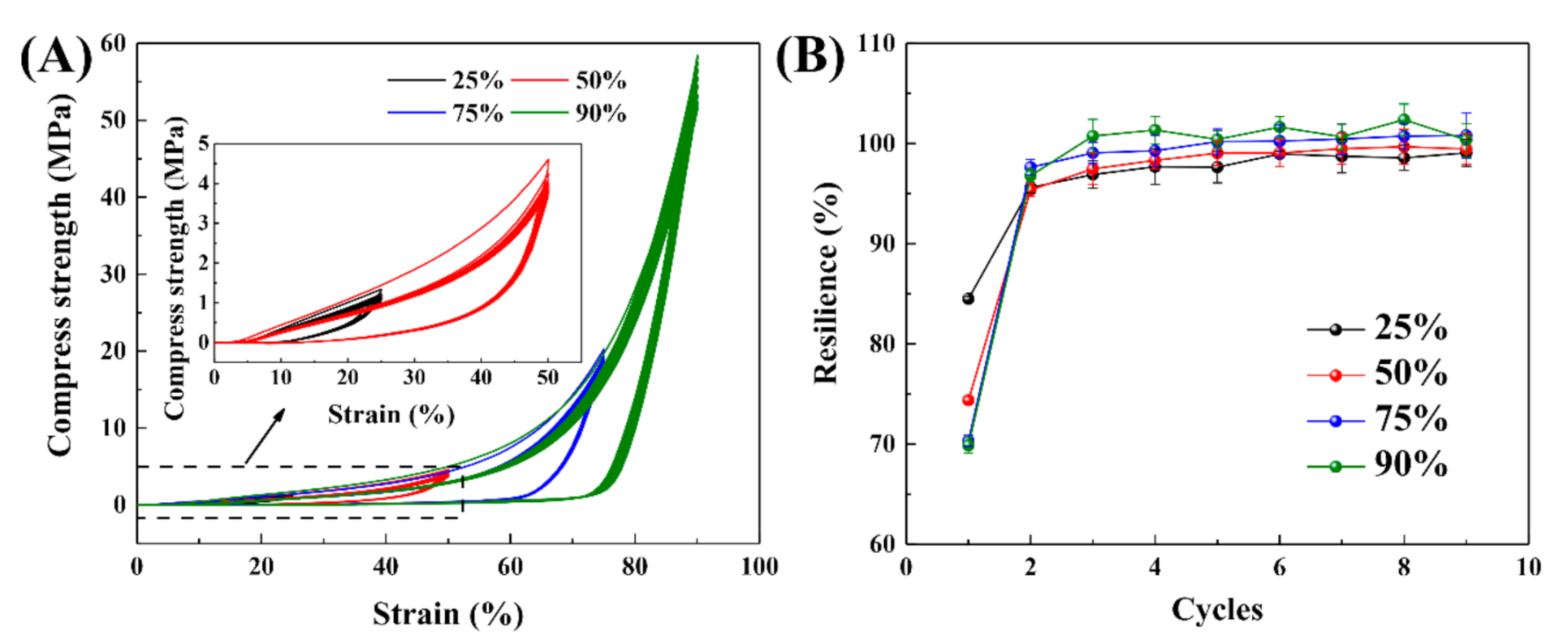

3.4.2. Cyclic Compressive Tests

3.5. High Recovery Properties

3.6. Dynamic Mechanical Analysis

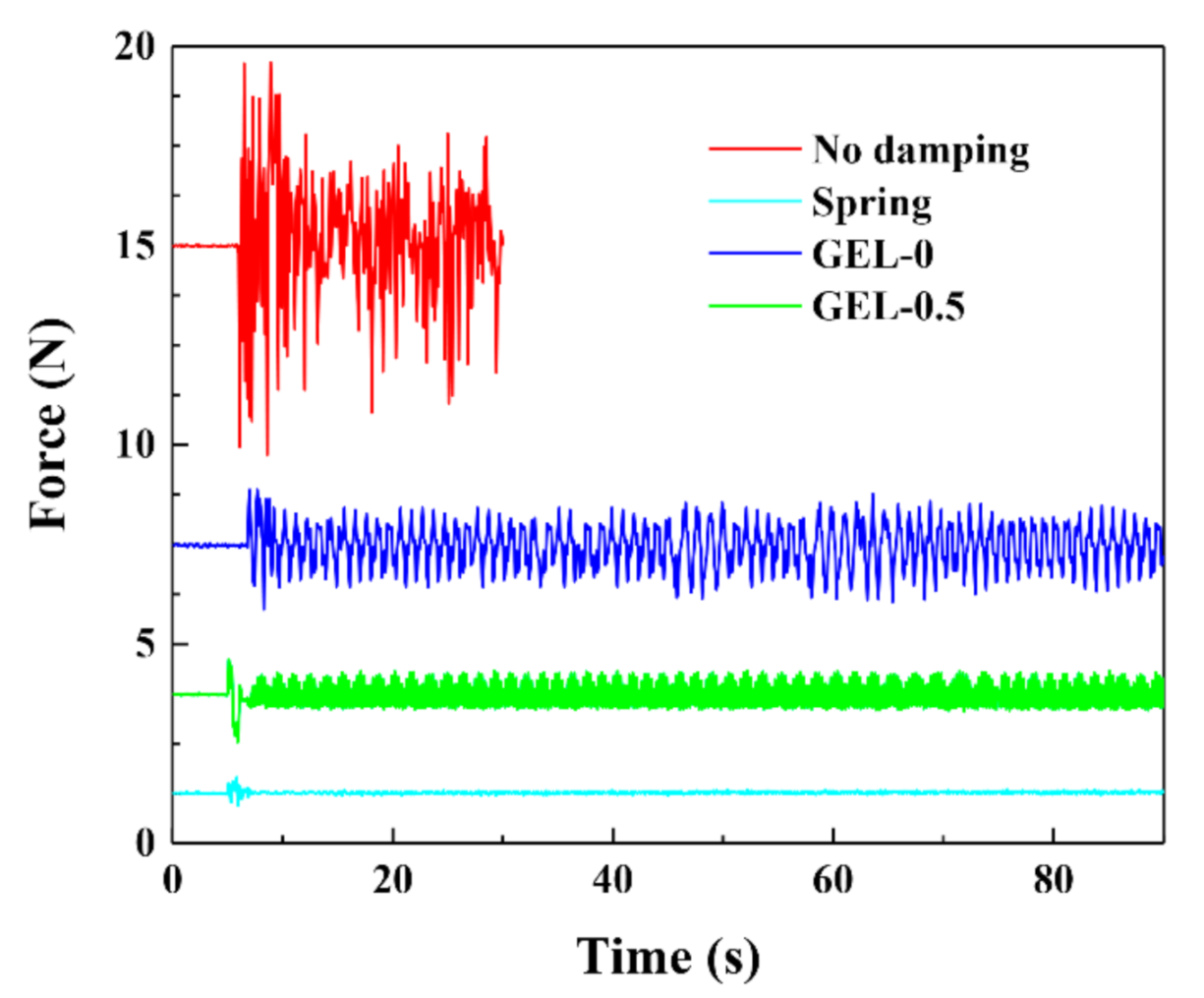

3.7. Damping Ability

3.8. Notch-Insensitive Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, H.D.; Lee, Y.; Kim, Y.; Hwang, Y.; Hwang, N.S. Biomimetically reinforced polyvinyl alcohol-based hybrid scaffolds for cartilage tissue engineering. Polymers 2017, 9, 655. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, F.; Li, X.; Wang, Q.; Liao, L.; Zhang, C. Nanocomposite hydrogels and their applications in drug delivery and tissue engineering. J. Biomed. Nanotechnol. 2015, 11, 40–52. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Ren, B.; Zhang, Y.; Xu, L.; Huang, Q.; He, Y.; Li, X.; Wu, J.; Yang, J.; Chen, Q.; et al. From design to applications of stimuli-responsive hydrogel strain sensors. J. Mater. Chem. B 2020, 8, 3171–3191. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, A.S. Hydrogels for biomedical applications. Adv. Drug Deliv. Rev. 2012, 64, 18–23. [Google Scholar] [CrossRef]

- Lin, S.; Liu, X.; Liu, J.; Yuk, H.; Loh, H.-C.; Parada, G.A.; Settens, C.; Song, J.; Masic, A.; McKinley, G.H.; et al. Anti-fatigue-fracture hydrogels. Sci. Adv. 2019, 5, eaau8528. [Google Scholar] [CrossRef] [Green Version]

- Graham, H.K.; McConnell, J.C.; Limbert, G.; Sherratt, M.J. How stiff is skin? Exp. Dermatol. 2019, 28, 4–9. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Xu, K.; Zhu, P.; Wang, C.; Chi, Q. Smart hydrogels with high tunability of stiffness as a biomimetic cell carrier. Cell Biol. Int. 2019, 43, 84–97. [Google Scholar] [CrossRef]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.; Park, S. Electronic skin: Recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prosthetics. Adv. Mater. 2019, 31, 1904765. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.-W.; Kim, J.E.; Jung, Y.; Sun, J.-Y. Non-swellable, cytocompatible phema-alginate hydrogels with high stiffness and toughness. Mater. Sci. Eng. C 2019, 95, 86–94. [Google Scholar] [CrossRef]

- Sun, J.-Y.; Zhao, X.; Illeperuma, W.R.K.; Chaudhuri, O.; Oh, K.H.; Mooney, D.J.; Vlassak, J.J.; Suo, Z. Highly stretchable and tough hydrogels. Nature 2012, 489, 133–136. [Google Scholar] [CrossRef]

- Fu, J. Strong and tough hydrogels crosslinked by multi-functional polymer colloids. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1336–1350. [Google Scholar] [CrossRef] [Green Version]

- Bai, R.; Yang, Q.; Tang, J.; Morelle, X.P.; Vlassak, J.; Suo, Z. Fatigue fracture of tough hydrogels. Extrem. Mech. Lett. 2017, 15, 91–96. [Google Scholar] [CrossRef]

- Jiang, H.; Duan, L.; Ren, X.; Gao, G. Hydrophobic association hydrogels with excellent mechanical and self-healing properties. Eur. Polym. J. 2019, 112, 660–669. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Deng, Y.; Xiong, J. Porous nano-hydroxyapatite/poly (vinyl alcohol) composite hydrogel as artificial cornea fringe: Characterization and evaluation in vitro. J. Biomater. Sci. Polym. Ed. 2008, 19, 431–439. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, H.; Zhu, L.; Zheng, J. Fundamentals of double network hydrogels. J. Mater. Chem. B 2015, 3, 3654–3676. [Google Scholar] [CrossRef]

- Webber, R.; Creton, C. Large strain hysteresis and mullins effect of tough double-network hydrogels. Macromolecules 2007, 40, 2919–2927. [Google Scholar] [CrossRef]

- Fukao, K.; Tanaka, K.; Kiyama, R.; Nonoyama, T.; Gong, J.P. Hydrogels toughened by biominerals providing energy-dissipative sacrificial bonds. J. Mater. Chem. B 2020, 8, 5184–5188. [Google Scholar] [CrossRef]

- Wang, L.; Lei, K.; Li, Z.; Wang, X.; Xiao, H.; Zheng, Z. Tetra-peg-based nano-enhanced hydrogel with excellent mechanical properties and multi-functions. Macromol. Mater. Eng. 2018, 303, 1800325. [Google Scholar] [CrossRef]

- Xia, S.; Song, S.; Gao, G. Robust and flexible strain sensors based on dual physically cross-linked double network hydrogels for monitoring human-motion. Chem. Eng. J. 2018, 354, 817–824. [Google Scholar] [CrossRef]

- Sun, M.; Qiu, J.; Jin, S.; Liu, W.; Sakai, E. Visible light induced synthesis of high toughness, self-healing ionic hydrogel and its application in strain sensing. Colloids Surf. A Physicochem. Eng. Asp. 2020, 607, 125438. [Google Scholar] [CrossRef]

- Long, R.; Hui, C.-Y. Fracture toughness of hydrogels: Measurement and interpretation. Soft Matter 2016, 12, 8069–8086. [Google Scholar] [CrossRef] [PubMed]

- Kamoun, E.A.; Winkel, A.; Eisenburger, M.; Menzel, H. Carboxylated camphorquinone as visible-light photoinitiator for biomedical application: Synthesis, characterization, and application. Arab. J. Chem. 2016, 9, 745–754. [Google Scholar] [CrossRef] [Green Version]

- Jin, S.; Qiu, J.; Sun, M.; Huang, H.; Sakai, E. Strain-sensitive performance of a tough and ink-writable polyacrylic acid ionic gel crosslinked by carboxymethyl cellulose. Macromol. Rapid Commun. 2019, 40, 1900329. [Google Scholar] [CrossRef]

- Dou, Y.; Wang, Z.-P.; He, W.; Jia, T.; Liu, Z.; Sun, P.; Wen, K.; Gao, E.; Zhou, X.; Hu, X.; et al. Artificial spider silk from ion-doped and twisted core-sheath hydrogel fibres. Nat. Commun. 2019, 10, 5293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, L.; Zhuang, Z.; Li, S.; Ma, X.; Diao, W.; Bu, X.; Fang, Y. Ultrastretchable, super tough, and rapidly recoverable nanocomposite double-network hydrogels by dual physically hydrogen bond and vinyl-functionalized silica nanoparticles macro-crosslinking. Macromol. Mater. Eng. 2019, 304, 1800737. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Brown, H. Jellyfish gel and its hybrid hydrogels with high mechanical strength. Soft Matter 2010, 7, 211–219. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, M.; Fan, Q.; Zhu, M. Designable synthesis of nanocomposite hydrogels with excellent mechanical properties based on chemical cross-linked interactions. Chem. Commun. 2010, 46, 7790–7792. [Google Scholar] [CrossRef]

- Herz, F.A.D.; Nobis, M.; Wendel, D.; Pahl, P.; Altmann, P.J.; Tillmann, J.; Weidner, R.; Inoue, S.; Rieger, B. Application of multifunctional silylenes and siliranes as universal crosslinkers for metal-free curing of silicones. Green Chem. 2020, 22, 4489–4497. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Park, N.; Lim, S.; Ahn, B.; Kim, W.; Moon, H.; Paik, H.-j.; Kim, W. Influence of the silanes on the crosslink density and crosslink structure of silica-filled solution styrene butadiene rubber compounds. Compos. Interfaces 2017, 24, 711–727. [Google Scholar] [CrossRef]

- Kaberova, Z.; Karpushkin, E.; Nevoralová, M.; Vetrík, M.; Šlouf, M.; Dušková-Smrčková, M. Microscopic structure of swollen hydrogels by scanning electron and light microscopies: Artifacts and reality. Polymers 2020, 12, 578. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Lin, G.; Kumar, S.R.; Mark, J.E. Hydrogels prepared from polysiloxane chains by end linking them with trifunctional silanes containing hydrophilic groups. Polymer 2009, 50, 5414–5421. [Google Scholar] [CrossRef]

- Melo, R.P.d.; Aguiar, V.d.O.; Marques, M.d.F.V. Silane crosslinked polyethylene from different commercial pe s: Influence of comonomer, catalyst type and evaluation of hlpb as crosslinking coagent. Mater. Res. 2015, 18, 313–319. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Pu, X.; Liu, M.; Yu, A.; Du, C.; Zhai, J.; Hu, W.; Wang, Z.L. Self-healable, stretchable, transparent triboelectric nanogenerators as soft power sources. ACS Nano 2018, 12, 6147–6155. [Google Scholar] [CrossRef] [PubMed]

- Zhong, M.; Liu, X.-Y.; Shi, F.-K.; Zhang, L.-Q.; Wang, X.-P.; Cheetham, A.G.; Cui, H.; Xie, X.-M. Self-healable, tough and highly stretchable ionic nanocomposite physical hydrogels. Soft Matter 2015, 11, 4235–4241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Jiang, X. Hysteresis loop and energy dissipation of viscoelastic solid models. Mech. Time Depend. Mater. 2007, 11, 1–14. [Google Scholar] [CrossRef]

- Zhu, L.; Qiu, J.; Sakai, E.; Ito, K. Rapid recovery double cross-linking hydrogel with stable mechanical properties and high resilience triggered by visible light. ACS Appl. Mater. Interfaces 2017, 9, 13593–13601. [Google Scholar] [CrossRef]

- Matsuda, T.; Nakajima, T.; Gong, J.P. Fabrication of tough and stretchable hybrid double-network elastomers using ionic dissociation of polyelectrolyte in nonaqueous media. Chem. Mater. 2019, 31, 3766–3776. [Google Scholar] [CrossRef]

- Zhu, L.; Qiu, J.; Sakai, E. A high modulus hydrogel obtained from hydrogen bond reconstruction and its application in vibration damper. RSC Adv. 2017, 7, 43755–43763. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Guo, B.; Zhang, L.; Hu, G.-H. Progress in bio-inspired sacrificial bonds in artificial polymeric materials. Chem. Soc. Rev. 2017, 46, 6301–6329. [Google Scholar] [CrossRef]

- Yan, L.; Dillard, D.A.; West, R.L.; Lower, L.D.; Gordon, G.V. Mullins effect recovery of a nanoparticle-filled polymer. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 2207–2214. [Google Scholar] [CrossRef]

- Liang, Y.; Ye, L.; Sun, X.; Lv, Q.; Liang, H. Tough and stretchable dual ionically cross-linked hydrogel with high conductivity and fast-recovery property for high-performance flexible sensors. ACS Appl. Mater. Interfaces 2020, 12, 1577–1587. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.A.; Kurokawa, T.; Gong, J.P. Super tough double network hydrogels and their application as biomaterials. Polymer 2012, 53, 1805–1822. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Wang, C.; Huang, G. A facile method to fabricate hybrid hydrogels with mechanical toughness using a novel multifunctional cross-linker. RSC Adv. 2017, 7, 35311–35319. [Google Scholar] [CrossRef] [Green Version]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous palmyra palm leaf stalk fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Ye, L.; Lv, Q.; Sun, X.; Liang, Y.; Fang, P.; Yuan, X.; Li, M.; Zhang, X.; Shang, X.; Liang, H. Fully physically cross-linked double network hydrogels with strong mechanical properties, good recovery and self-healing properties. Soft Matter 2020, 16, 1840–1849. [Google Scholar] [CrossRef]

- Kumar, J.S.; Paul, P.S.; Raghunathan, G.; Alex, D.G. A review of challenges and solutions in the preparation and use of magnetorheological fluids. Int. J. Mech. Mater. Eng. 2019, 14, 13. [Google Scholar] [CrossRef]

- Ma, J.; Lee, J.; Han, S.S.; Oh, K.H.; Nam, K.T.; Sun, J.-Y. Highly stretchable and notch-insensitive hydrogel based on polyacrylamide and milk protein. ACS Appl. Mater. Interfaces 2016, 8, 29220–29226. [Google Scholar] [CrossRef]

- Flauzino Neto, W.P.; Mariano, M.; da Silva, I.S.V.; Silvério, H.A.; Putaux, J.-L.; Otaguro, H.; Pasquini, D.; Dufresne, A. Mechanical properties of natural rubber nanocomposites reinforced with high aspect ratio cellulose nanocrystals isolated from soy hulls. Carbohydr. Polym. 2016, 153, 143–152. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Qiu, J.; Lu, C.; Jin, S.; Zhang, G.; Sakai, E. Multi-Sacrificial Bonds Enhanced Double Network Hydrogel with High Toughness, Resilience, Damping, and Notch-Insensitivity. Polymers 2020, 12, 2263. https://doi.org/10.3390/polym12102263

Sun M, Qiu J, Lu C, Jin S, Zhang G, Sakai E. Multi-Sacrificial Bonds Enhanced Double Network Hydrogel with High Toughness, Resilience, Damping, and Notch-Insensitivity. Polymers. 2020; 12(10):2263. https://doi.org/10.3390/polym12102263

Chicago/Turabian StyleSun, Manxi, Jianhui Qiu, Chunyin Lu, Shuping Jin, Guohong Zhang, and Eiichi Sakai. 2020. "Multi-Sacrificial Bonds Enhanced Double Network Hydrogel with High Toughness, Resilience, Damping, and Notch-Insensitivity" Polymers 12, no. 10: 2263. https://doi.org/10.3390/polym12102263