Permeation Damage of Polymer Liner in Oil and Gas Pipelines: A Review

Abstract

:1. Introduction

1.1. Corrosion in Oil and Gas Pipelines

1.2. Mitigation Practices

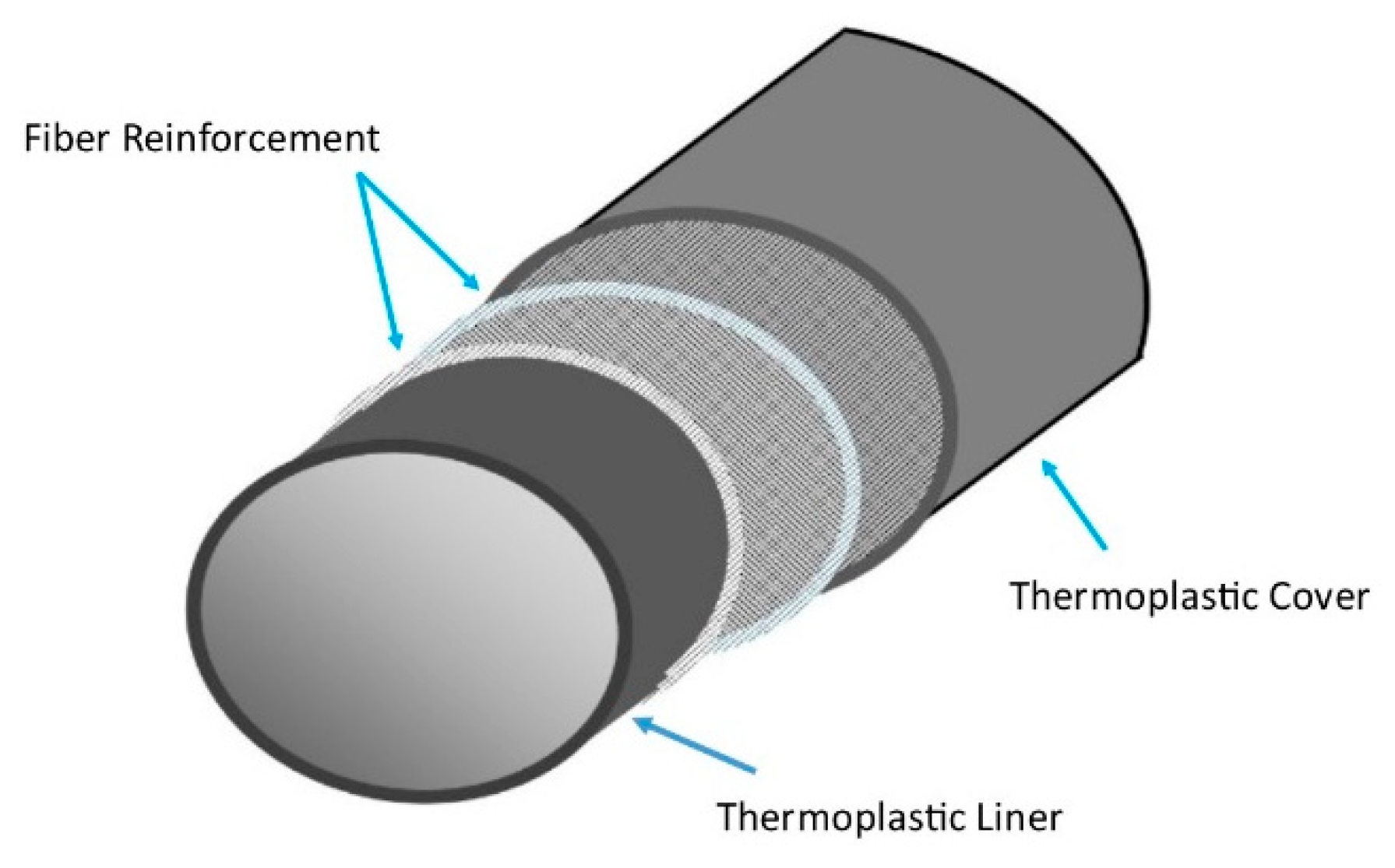

2. Use of Non-Metallic Pipe (NMP)

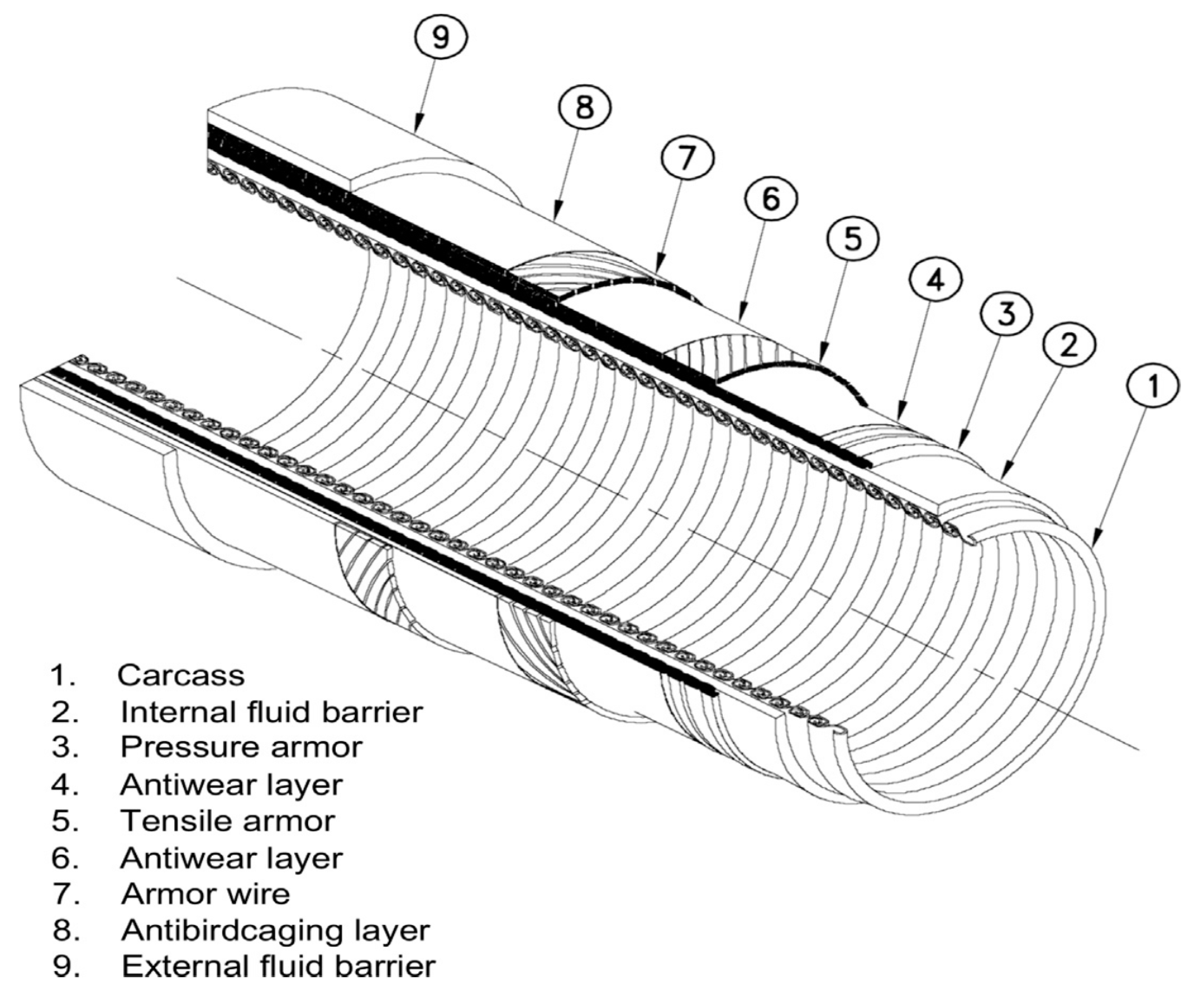

2.1. Flexible Pipes

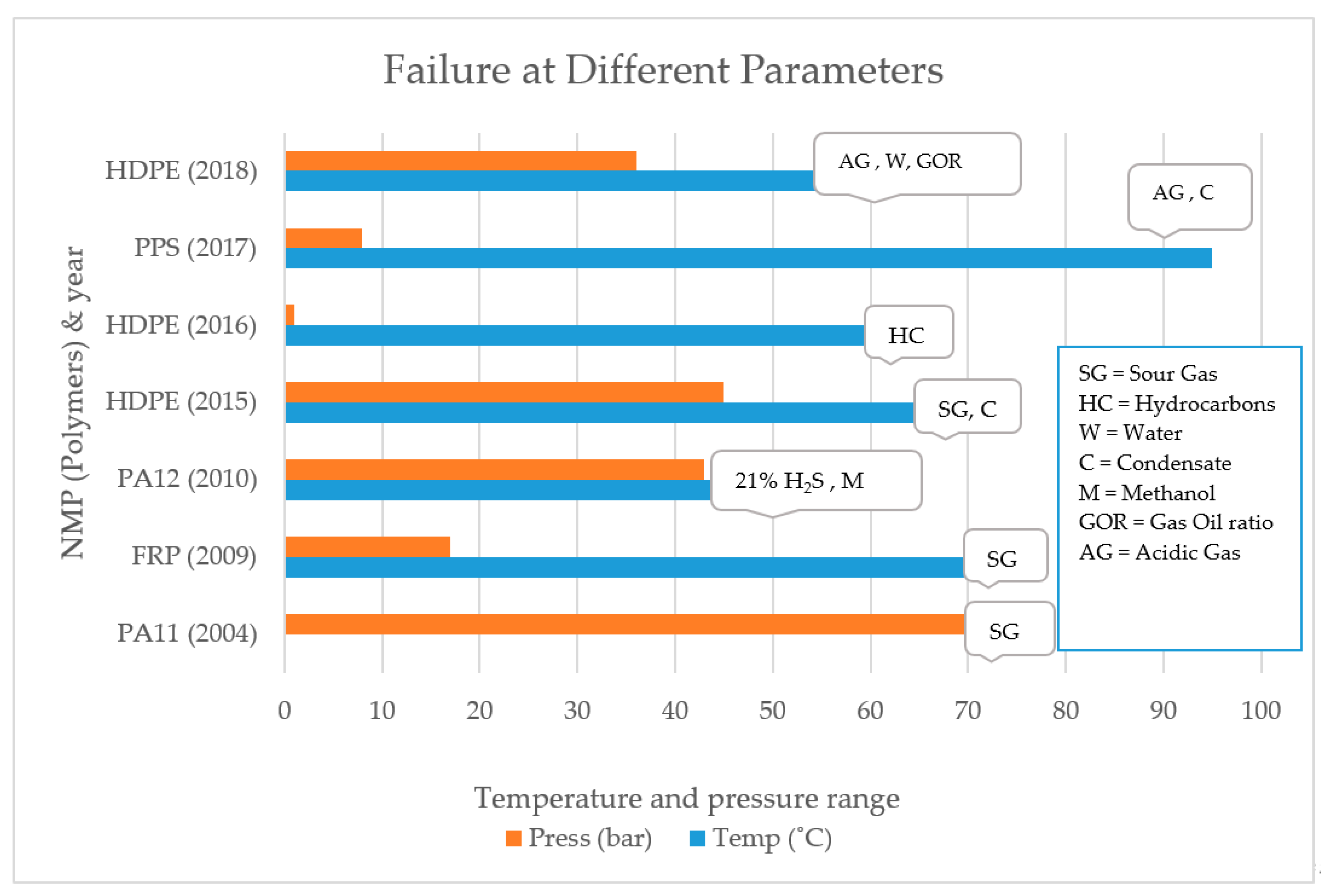

2.2. Degradation of NMP Material

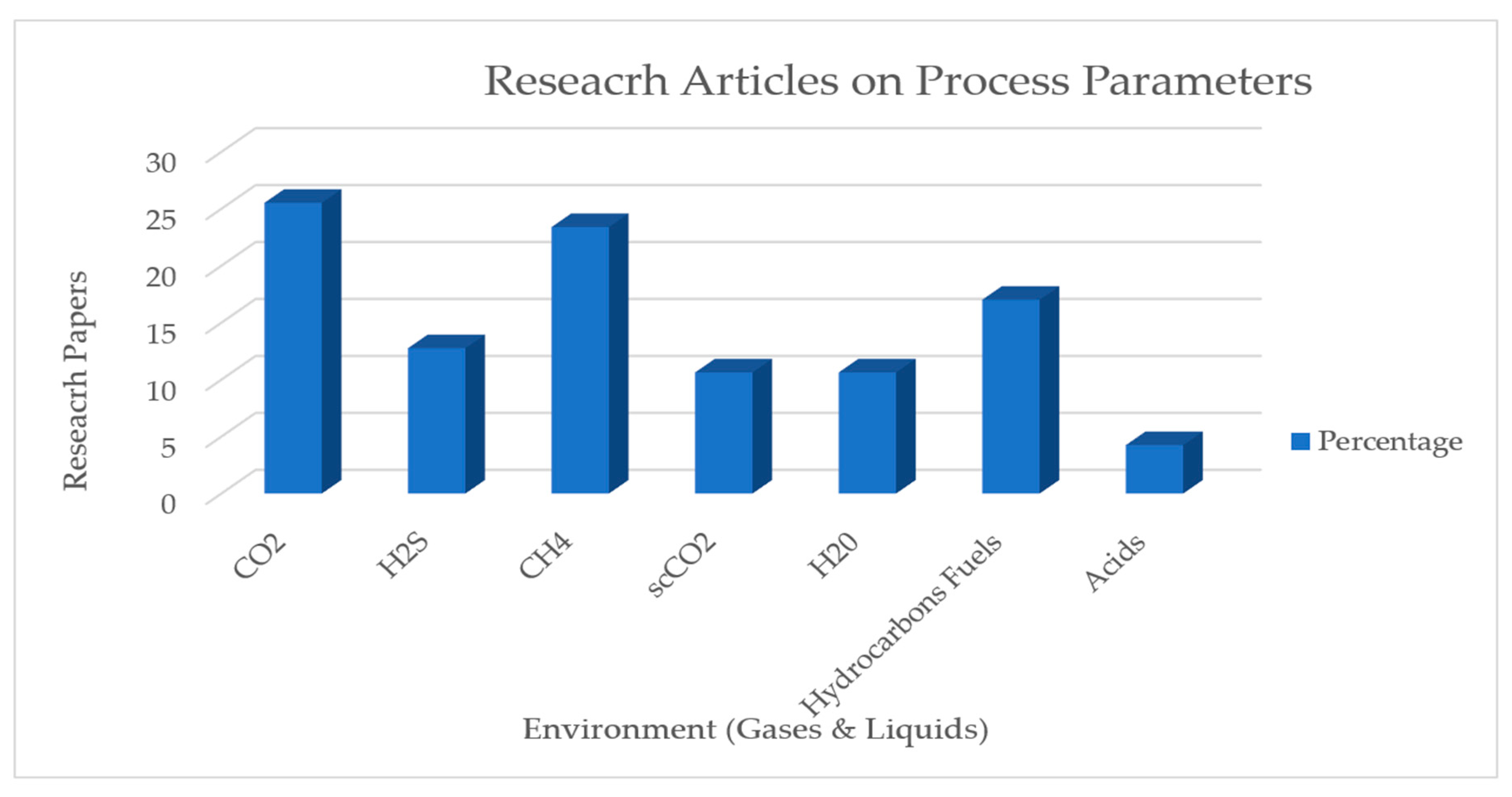

2.2.1. Permeation

- Diffusion (D) between molecular chains

- Solubility (s) of the permeant in the polymer

2.2.2. Flexible Pipelines

2.3. Thermodynamics of scCO2 (Supercritical) in Permeation

3. Inspection and Monitoring Techniques

3.1. Coupons

3.2. Dielectrics

4. Conclusions

5. Future Suggestions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Research Article | Damage | Remarks | Year |

|---|---|---|---|

| Learnings from thermoplastic liner failures in sour gas pipeline service and replacement liner design and installation [108] | Permeation (Exposure) |

| 2004 |

| Analysis of ductile and brittle failures from creep rupture testing of high-density polyethylene (HDPE) pipes [109] | Creep |

| 2005 |

| Supercritical Gas–Polymer Interactions with Applications in the Petroleum Industry. Determination of Thermophysical Properties [110] | Permeation (Diffusion) |

| 2006 |

| Oilfield Engineering with Polymers [111] | Thermal aging, Permeation |

| 2006 |

| Failure analysis of polyethylene gas pipes [112] | Fatigue |

| 2008 |

| Effect of Fiber-Reinforcement Material on the Leakage Failure In Polymer Composite Pressure Piping [113] | Internal Pressure |

| 2008 |

| Creep damage mechanisms in gas pipes made of high-density polyethylene [114] | Creep, Fatigue |

| 2009 |

| Failure Types of FRP Pipe in Oil and Gas Engineering [115] | Thermal aging, Installation |

| 2009 |

| Corrosion failure in a lined sour gas pipeline—part 1: Case history of incident [116] | Permeation |

| 2010 |

| Effects of thermal aging on mechanical and thermal behaviors of linear low-density polyethylene pipe [117] | Thermal aging |

| 2010 |

| Long-term Behavior of Polyethylene PE 80 Pressurized Pipes, in Presence of Longitudinal Simulated Imperfections [118] | Imperfection |

| 2010 |

| The Alberta experience with composite pipes in production environments [119] | Installation |

| 2010 |

| Effects of ethanol content and temperature on the permeation of fuel through polyamide-12-based pipes [103] | Permeation |

| 2010 |

| Fatigue Analysis Of PE-100 Pipe Under Axial Loading [120] | Fatigue |

| 2011 |

| Non-Metallic Pipe Systems For Use In Oil And Gas [32] | Weepage |

| 2011 |

| Application and Qualification of Reinforced Thermoplastic Pipes in Chinese Oilfields [121] | Installation External damage |

| 2011 |

| Failure Analysis Of Steel Wire Reinforced Thermoplastics Composite Pipe [122] | ESC |

| 2011 |

| Fracture Surface Analysis in HDPE Pipe Material Fatigued at Different Temperatures and Loading Frequencies [123] | Fatigue |

| 2012 |

| Analysis of a Failure in a Polyethylene Gas Pipe Caused by Squeeze off Resulting in an Explosion [124] | Compressive Stress (Brittle Fracture) |

| 2012 |

| Numerical tool to model collapse of polymeric liners in pipelines [125] | Permeation |

| 2012 |

| Application of Non-metallic Composite Pipes in Oilfields in China [126] | Joint Failure, Condensate |

| 2012 |

| The effect of residual stress on polymer pipe lifetime [127] | Imperfection (Residual stresses) |

| 2013 |

| Advanced fiber-reinforced polymer (FRP) composites for the manufacture and rehabilitation of pipes and tanks in the oil and gas industry [128] | Permeation, Moisture |

| 2013 |

| Multilayer polymer pipes failure assessment based on a fracture mechanics approach [129] | Creep |

| 2013 |

| Failure analysis of anticorrosion plastic alloy composite pipe used for oilfield gathering and transportation [126] | Processing |

| 2013 |

| Influence of specimen geometry on the slow crack growth testing of HDPE for pipe applications [130] | Creep |

| 2015 |

| Evaluation of Long-Term Behaviour of Polymers for Offshore Oil and Gas Applications [131] | Thermal aging |

| 2015 |

| Thermoplastic liners for oilfield pipelines [96] | Permeation |

| 2015 |

| Buckling collapse of HDPE liners: Experimental set-up and FEM simulations. Thin-Walled Structures [132] | Permeation |

| 2016 |

| Crack Damage in Polymers and Composites: A Review [133] | Fatigue |

| 2016 |

| HDPE pipes failure analysis and damage modeling [134] | Fatigue |

| 2016 |

| Influence of aging in the failure pressure of a GFRP pipe used in oil industry [135] | Thermal aging |

| 2016 |

| “Failure of glass fiber-reinforced epoxy pipes in oil fields.” Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry [136] | Permeation (diffusion) |

| 2016 |

| Fracture and Mechanical Characteristics Degradation of Glass Fiber-Reinforced Petroleum Epoxy Pipes [137] | Chlorides |

| 2016 |

| Case Study: Engineered Polyamide 12 (PA12) Pipeline Liner for Management of Sour Gas Corrosion at Elevated Temperatures [102] | Permeation |

| 2017 |

| Nonmetallics applications in oil and gas production (pipes, liners, rehabilitations), in Trends in Oil and Gas Corrosion Research and Technologies [5] | CO2 cracking, Thermal aging |

| 2017 |

| Mechanical properties of offshoring polymer composite pipes at various temperatures [138] | Thermomechanical failure |

| 2018 |

| Study of Multilayered Composite Pipe subjected with Metal Interlayer [139] | Poor handling, Stress concentrators |

| 2018 |

| Polymer crystallinity and the ductile to brittle transition [140] | Permeation (Immersion) |

| 2018 |

| Approaches for Safety Analysis of Gas Pipeline Functionality in Terms of Failure Occurrence: A Case Study [141] | Mechanical Damage (outside) |

| 2018 |

| Innovative Field Trial Results of Flangleess Grooved HDPE Liner Application in a Super Gigantic Field for Oil Flow Line Internal Corrosion Management [142] | Permeation |

| 2018 |

| Failure Analysis of Buried Polyethylene Pipe Subjected to Combined Loading of Non-uniform Settlement and Landslide Based on FEM [143] | Outside damage |

| 2018 |

| Sustainable and safe in exploitation of gas networks. Part1. Stress factors of plastic pipelines [144] | Human error |

| 2018 |

| Thermal-oxidative aging performance and life prediction of polyethylene pipe under cyclic and constant internal pressure [145] | Thermal aging |

| 2019 |

| Analysis of cracks in polyvinylidene fluoride lined reinforced thermoplastic pipe used in acidic gas fields [146] | Weld cracks |

| 2019 |

| Creep behavior of in-service flexible flowline polyamide 11 [81] | Permeation |

| 2020 |

| Development of Carbon Fiber Based Structural Health Monitoring System for Glass Fiber-Reinforced Polymer Composite Conduits [147] | Internal Pressure (Creep & Fatigue) |

| 2020 |

| Damage evaluation and protection method of resin pipe for gas conduit subjected to impact load [148] | Third-party damage |

| 2020 |

| Materials | Environment (Gases or Liquids) | Parameters | Permeation Outcomes | Ref |

|---|---|---|---|---|

| MDPE | CO2, CH4, Aromatic hydrocarbon | T: ambient P: 100 psi Thick: 10 mm |

| [149] |

| HDPE | CO2, CH4 | T:40,60,81 °C P: 4 MPa Thick: 2 mm |

| [150] |

| PE80, PE-X, PE-DB (Al-foil) | 33% H2S, 10% CO2, 70% CH4 | T:50 °C P: 40 & 80 bar Thick: 5 mm Duration: 3 months |

| [151] |

| PE-80 | CO2, CH4, CO2/CH4, H2/CH4 | T: 60 °C P: 40 bars Thickness: 1–3 mm |

| [152] |

| PE100 PA11 | H2, CH4 | T: 20,50,80 °C P: 5 & 20 bars Thick: 1 mm Duration: 13 months |

| [97] |

| PA (TP30) | CO2, H2S, CH4, Liquid (H2O) | T: 140 °C |

| [153] |

| PVDF | H2S | T: 100 °C P: 60–70 bars Duration:339 days |

| [42] |

| PE100, PA11, PAHM | H2, CH4 | T: 20,50,80 °C P: 5 & 20 bars Thick: 1 mm Duration: 1 year |

| [154] |

| HDPE, PTFE | H2 | T: ambient P:100 MPa Duration: one week |

| [155] |

| PA12, HDPE | 12.5% H2S, 1.3% CO2, crude oil | T: 45 °C P: 290 psi Thick: 6.7 mm |

| [102] |

| PPS, PEEK | CO2, H2S | T: 80 & 100 °C P: 400 bars Thick: 2.3 mm |

| [156] |

| TFE (PFA) | HCl, NH4 | T: 25 °C Thick: 0.25 mm, round sample with 4.6 cm dia |

| [157] |

| PVDF ECTFE | HCl, HBr | T: 70 °C & 80 °C Thick: 1.35–1.5 & 3–5 mm Duration: 24 h |

| [158] |

| PA12 (PVDF outer layer) | Ethanol | T: 110 °C Duration: 2400 h |

| [159] |

| HDPE with PA barrier | Biofuels (E85, Biodiesel, B10) | T: 20–40 °C Thick: 1.4–1.6 mm Duration: 5 years. |

| [160] |

| HDPE, PVDF | E10(CE10A), 55% butanol (CB55A) 10% Ethanol | Duration: 16 weeks. |

| [161] |

| HDPE | E30 (ethanol-gasoline) B30 (biodiesel) | T: 45 °C Duration: 1608 h |

| [162] |

| HDPE | H2O | T: 23, 70, 90 °C |

| [163] |

| PE100 PE-RT | Brine, NORSOK M-710 (70% heptane, 20% cyclo-hexanes & 10% toluene) | T: 23,50,80 °C |

| [164] |

| PVDF | CO2, CH4 | T: 150 °C P: 300 bars |

| [165] |

| LDPE, PA11 | Gases: CO2, CH4, H2O | T: Ambient P: 24 bars |

| [88] |

| PE-80 | Gases: CO2, CH4, H2S | T: 60 °C P: 2k bars Thick: 1–4 mm |

| [166] |

| PA11 | H2S | T:80 °C P: 200 bars |

| [167] |

| PA11 PA12 | CO2, H2O, Crude oil | T: 80,100,120 °C P: 20 bars |

| [168] |

| HDPE | CO2, water, and sand |

| [169] | |

| HDPE | Aromatic hydrocarbons, Crude oil, diesel |

| [95] | |

| HDPE | Methanol, 1-butanol |

| [170] | |

| HDPE, XLPE | crude oil, toluene, cyclohexane, and n-heptane |

| [171] | |

| PVDF | Amines, esters, Ketones |

| [43] |

References

- Samimi, A. Causes of increased corrosion in oil and gas pipelines in the Middle East. Int. J. Basic Appl. Sci. 2012, 1, 572–577. [Google Scholar]

- Villamizar, W.; Casales, M.; Gonzalez-Rodriguez, J.G.; Martinez, L. CO2 corrosion inhibition by hydroxyethyl, aminoethyl, and amidoethyl imidazolines in water–oil mixtures. J. Solid State Electrochem. 2006, 11, 619–629. [Google Scholar] [CrossRef]

- Sastri, V.S.; Ghali, E.; Elboujdaini, M. Corrosion Prevention and Protection; Wiley and Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Papavinasam, S. Corrosion Control in the Oil and Gas Industry; Elsevier BV: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Esaklul, K.A.; Mason, J. Nonmetallics Applications in Oil and Gas Production (Pipes, Liners, Rehabilitations). In Trends in Oil and Gas Corrosion Research and Technologies; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 627–660. [Google Scholar]

- Iannuzzi, M.; Barnoush, A.; Johnsen, R. Materials and corrosion trends in offshore and subsea oil and gas production. npj Mater. Degrad. 2017, 1, 2. [Google Scholar] [CrossRef]

- Prasad, A.R.; Kunyankandy, A.; Joseph, A. Corrosion Inhibition in Oil and Gas Industry. In Corrosion Inhibitors in the Oil and Gas Industry; Wiley and Sons: Hoboken, NJ, USA, 2020; pp. 135–150. [Google Scholar]

- Webster, D. Pipeline Construction Drivers, Corrosion Costs and Engineering Issues; Worley Parsons: North Sydney, Australia, 2010. [Google Scholar]

- Ossai, C.I. Advances in Asset Management Techniques: An Overview of Corrosion Mechanisms and Mitigation Strategies for Oil and Gas Pipelines. ISRN Corros. 2012, 2012, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Nalli, K. Corrosion and its mitigation in the oil and gas industry. In An Overview. PM-Pipeliner Report; John Wiley & Sons, Inc.: Muscat, Oman, 2010. [Google Scholar]

- Kermani, M.B.; Morshed, A. Carbon Dioxide Corrosion in Oil and Gas Production—A Compendium. Corrosion 2003, 59, 659–683. [Google Scholar] [CrossRef]

- Lopez, D.; Perez, T.; Simison, S. The influence of microstructure and chemical composition of carbon and low alloy steels in CO2 corrosion. A state-of-the-art appraisal. Mater. Des. 2003, 24, 561–575. [Google Scholar] [CrossRef]

- Perez, T.E. Corrosion in the Oil and Gas Industry: An Increasing Challenge for Materials. JOM 2013, 65, 1033–1042. [Google Scholar] [CrossRef] [Green Version]

- CAPP. Mitigation of Internal Corrosion in Sour Gas Pipeline Systems; CAPP: Calgary, AB, Canada, 2009. [Google Scholar]

- CAPP. Mitigation of Internal Corrosion in Sweet Gas Gathering Systems; CAPP: Calgary, AB, Canada, 2009. [Google Scholar]

- Groysman, A. Corrosion Problems and Solutions in Oil Refining and Petrochemical Industry; Springer Science and Business Media LLC: Berlin, Germany, 2017. [Google Scholar]

- Popoola, L.T.; Grema, A.; Latinwo, G.K.; Gutti, B.; Balogun, A. Corrosion problems during oil and gas production and its mitigation. Int. J. Ind. Chem. 2013, 4, 35. [Google Scholar] [CrossRef] [Green Version]

- Havlik, W.; Thayer, K.; Oberndorfer, M. Production of Wet Natural Gas Containing Corrosive Components: Four Case Histories. SPE Prod. Oper. 2007, 22, 319–325. [Google Scholar] [CrossRef]

- Smith, L. Control of corrosion in oil and gas production tubing. Br. Corros. J. 1999, 34, 247–253. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Lewis, D.; Münz, W.; Lyon, S.; Tomlinson, M. Combined cathodic arc/unbalanced magnetron grown CrN/NbN superlattice coatings for corrosion resistant applications. Surf. Coat. Technol. 1999, 120, 535–541. [Google Scholar] [CrossRef]

- Ameh, E.; Ikpeseni, S.; Lawal, L. A Review of Field Corrosion Control and Monitoring Techniques of the Upstream Oil and Gas Pipelines. Niger. J. Technol. Dev. 2018, 14, 67. [Google Scholar] [CrossRef] [Green Version]

- Tamalmani, K.; Husin, H. Review on Corrosion Inhibitors for Oil and Gas Corrosion Issues. Appl. Sci. 2020, 10, 3389. [Google Scholar] [CrossRef]

- Engle, E. Pipe Rehabilitation with Polyethylene Pipe Liners; Depterment of Transportation: Ames, IA, USA, 2003. [Google Scholar]

- Brogden, S.; Lu, L.; Dowe, A.; Messina, N.; Robinson, J. The use of Engineering Polymers for Internal Corrosion Protection of Hydrocarbon Pipelines. In Proceedings of the MERL Oilfield Engineering with Polymers Conference, London, UK, 23–25 October 2012. [Google Scholar]

- Davis, R.; Snider, B. Economically Mitigating Downhole Corrosion and Wear Failures with Thermoplastic Liners; NACE International: Houston, TX, USA, 2017. [Google Scholar]

- Badeghaish, W.; Noui-Mehidi, M.; Salazar, O. The Future of Nonmetallic Composite Materials in Upstream Applications; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2019. [Google Scholar]

- Ali, M.M.; Magee, J.C.; Hsieh, P.Y. Corrosion protection of steel pipelines with metal-polymer composite barrier liners. J. Nat. Gas Sci. Eng. 2020, 81, 103407. [Google Scholar] [CrossRef]

- Ngo, G.V. The Use of Polymer Composite Materials in the Manufacturing Technology of the Ship System Pipelines. Key Eng. Mater. 2020, 839, 63–67. [Google Scholar] [CrossRef]

- Petroleum, Petrochemical and Natural Gas Industries—Non-Metallic Materials in Contact with Media Related to Oil and Gas Production—Part 1: Thermoplastics. Available online: https://www.iso.org/obp/ui/#iso:std:iso:23936:-1:ed-1:v1:en (accessed on 11 May 2020).

- Yoon, S.H.; Oh, J.O. Prediction of long term performance for GRP pipes under sustained internal pressure. Compos. Struct. 2015, 134, 185–189. [Google Scholar] [CrossRef]

- Edmund, J.E.; Mustaffa, Z.B. Numerical Analysis of Crack Failure of Reinforced Thermoplastic Pipe (RTP); EDP Sciences: Ulis, France, 2018; Volume 203. [Google Scholar] [CrossRef]

- Gibson, A.G.; Linden, J.M.; Elder, D.; Leong, K.H. Non-metallic pipe systems for use in oil and gas. Plast. Rubber Compos. 2011, 40, 465–480. [Google Scholar] [CrossRef]

- Wolodko, J.; Fotty, B.; Perras, T. Application of Non-Metallic Materials in Oil Sands Operations, 1; NACE International: Houston, TX, USA, 2016. [Google Scholar]

- Comeau, A.; Bar, Y. Significant Reduction of Corrosion Induced Pipe Failures in Oil Sands/SAGD Facilitiesusing PE-Xa Materials; NACE International: Huston, TX, USA, 2016. [Google Scholar]

- Al-Omari, A.S.; Mehdi, M.S.; Al-Marri, A.F.; Schell, J. Revolutionary Non-metallic Liners to Rehabilitate the Aged/Corroded Carbon Steel Water Injection Laterals; NACE International: Houston, TX, USA, 2014. [Google Scholar]

- Yu, K.; Morozov, E.; Ashraf, M.A.; Shankar, K. A review of the design and analysis of reinforced thermoplastic pipes for offshore applications. J. Reinf. Plast. Compos. 2017, 36, 1514–1530. [Google Scholar] [CrossRef]

- Berry, A. Installation of Polyamide-11 Liners for Sour Service Using Loose Fit Technology; NACE International: Houston, TX, USA, 2000. [Google Scholar]

- Vasselin, T.P. Use of Polyamide 11 in Corrosive Applications; NACE International: Houston, TX, USA, 1997. [Google Scholar]

- Farias, C.A.; Demicoli, D. Polyamide 12 Liner for Production Lines–Corrosion Protection, Efficient and Sustainable Revitalization of Mature Onshore Pipeline Infrastructures and New Offshore Pipelines. Available online: https://abraco.org.br/src/uploads/intercorr/2016/INTERCORR2016_301.pdf (accessed on 21 August 2020).

- Mason, J.F. Pipe Liners for Corrosive High Temperature Oil and Gas Production Applications; NACE International: Houston, TX, USA, 1997. [Google Scholar]

- Yamabe, M. Fluoropolymer Coatings. In Organofluorine Chemistry; Springer: Berlin, Germany, 1994; pp. 397–401. [Google Scholar]

- Messina, N.; Colladon, M.; Fossati, P.; Meynet, C. Internal Lining of Carbon Steel Flowlines with a Plastic Liner Based on a Fluorinated Polymer: Introduction of the Concept and Evidences on CAPEX and OPEX Reductions. OTC Brasil 2015. [Google Scholar] [CrossRef]

- Ebnesajjad, S.; Khaladkar, P.R. Fluoropolymer Applications in The Chemical Processing Industries: The Definitive User’s Guide and Handbook; William Andrew: Norwich, NY, USA, 2017. [Google Scholar]

- Mehdi, M.S.; Al-Dossary, A.K. Thermoplastic Lined Pipework for Corrosive Applications; NACE International: Houston, TX, USA, 2013. [Google Scholar]

- Rahman, M.S.U.; Haryono, A.; Abou-Khousa, M.A. Microwave Non-destructive Evaluation of Glass Reinforced Epoxy and High Density Polyethylene Pipes. J. Nondestruct. Eval. 2020, 39, 1–9. [Google Scholar] [CrossRef]

- Majid, M.S.A.; Assaleh, T.; Gibson, A.G.; Hale, J.; Fahrer, A.; Rookus, C.; Hekman, M. Ultimate elastic wall stress (UEWS) test of glass fibre reinforced epoxy (GRE) pipe. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1500–1508. [Google Scholar] [CrossRef]

- Rique, A.; Machado, A.; Oliveira, D.; Lopes, R.; Lima, I. X-ray imaging inspection of fiberglass reinforced by epoxy composite. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2015, 349, 184–191. [Google Scholar] [CrossRef]

- Beaumont, J. Non-Metallic Piping Systems for Corrosive Fluid Handling; NACE International: Houston, TX, USA, 2017. [Google Scholar]

- Curran, S.D. Fiberglass Pipe Past, Present and Future; Fiber Glass Tank and Pipe Institute: Houston, TX, USA, 2013. [Google Scholar]

- Smith, D.; Frame, B.J.; Anovitz, L.M.; Makselon, C. Feasibility of Using Glass-Fiber-Reinforced Polymer Pipelines for Hydrogen Delivery. In Proceedings of the ASME 2016 Pressure Vessels and Piping Conference, Vancouver, BC, Canada, 17–21 July 2016. [Google Scholar]

- Alsaddah, A.; Almedallah, M.K.; Clark, S.R.; Walsh, S.D.C. A Numerical Model to Assist with the Selection of Non-Metallic Piping Materials for Offshore Developments; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2020. [Google Scholar]

- Adam, S.; Ghosh, S. Application of Flexible Composite Pipe as a Cost Effective Alternative to Carbon Steel—Design Experience; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2016. [Google Scholar]

- Anderson, T.A.; Fang, B.; Attia, M.; Jha, V.; Dodds, N.; Finch, D.; Latto, J. Progress in the Development of Test Methods and Flexible Composite Risers for 3000 m Water Depths; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2016. [Google Scholar]

- Jha, V.; Latto, J.; Dodds, N.; Anderson, T.A.; Finch, D.; Vermilyea, M. Qualification of Flexible Fiber-Reinforced Pipe for 10,000-Foot Water Depths; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2013. [Google Scholar]

- Reis, J.; De Santánna, T.; Coutinho, P.; Monteiro, A.; Teixeira, S.; Chaves, E.; Da Costa-Mattos, H.S. Coupled effect of ageing and temperature in the mechanical behaviour of a polyamide. Polym. Test. 2016, 53, 267–275. [Google Scholar] [CrossRef]

- Fahed, M.; Barsoum, I.; Alfantazi, A.; Islam, M.D. Integrity Assessment of Internally Corroded Pipelines Rehabilitated with a Kevlar-Reinforced Flexible Liner. J. Press. Vessel. Technol. 2020, 142, 041801. [Google Scholar] [CrossRef]

- Romão, W.; Castro, E.V.R.; Filho, E.A.S.; Guimarães, R.C.L.; Silva, A.L.N.; Teixeira, S.C.S.; De Paoli, M.-A.; De Sena, G.L. Ageing of polyamide 11 used in the manufacture of flexible piping. J. Appl. Polym. Sci. 2009, 114, 1777–1783. [Google Scholar] [CrossRef]

- Jacques, B.; Werth, M.; Merdas, I.; Thominette, F.; Verdú, J. Hydrolytic ageing of polyamide 11. 1. Hydrolysis kinetics in water. Polymers 2002, 43, 6439–6447. [Google Scholar] [CrossRef]

- Campbell, T. Polymer Liner & Connector Qualification for Use in Subsea Pipelines; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2009. [Google Scholar]

- Reis, J.; Motta, E.P.; Da Costa-Mattos, H.S. Elasto-viscoplastic behaviour of a polyvinylidene fluoride (PVDF) in tension. Polym. Test. 2015, 46, 9–13. [Google Scholar] [CrossRef]

- Hochstetter, G.; Amouroux, N.; Hugon, L.; Dang, P.; Werth, M. Polyamide 11 in Offshore Conditions: Hydrolytical Ageing, Mechanical Behaviour in Flexible Pipes. In Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference ASME International, Las Vegas, NV, USA, 4–7 September 2007; pp. 561–572. [Google Scholar]

- Hochstetter, G.; Dang, P. Correlation Between Hydrolysis and the Ultimate Mechanical Properties of Polyamides in Offshore Conditions. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition (IMECE2009), Lake Buena Vista, FL, USA, 13–19 November 2009; pp. 797–803. [Google Scholar]

- Dawans, F.A.; Jarrin, J.A.; Lefevre, T.O.; Pelisson, M.A. Improved Thermoplastic Materials for Offshore Flexible Pipes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1986. [Google Scholar]

- Bai, Q.; Bai, Y. Subsea Pipeline Design, Analysis, and Installation; Elsevier BV: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Schweitzer, P.A. Mechanical and Corrosion-Resistant Properties of Plastics and Elastomers; Informa UK Limited: Colchester, UK, 2000. [Google Scholar]

- El-Sherik, A. Trends in Oil and Gas Corrosion Research and Technologies: Production and Transmission; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Flaconneche, B.; Martin, J.; Klopffer, M.H. Transport Properties of Gases in Polymers: Experimental Methods. Oil Gas Sci. Technol. Rev. IFP 2001, 56, 245–259. [Google Scholar] [CrossRef] [Green Version]

- Gleditsch, C.; Jaeger, M.; Lambrych, K.R. Permeation Effects on Fiber Reinforced Thermoset Plastics; NACE International: Houston, TX, USA, 2006. [Google Scholar]

- George, S.C.; Thomas, S. Transport phenomena through polymeric systems. Prog. Polym. Sci. 2001, 26, 985–1017. [Google Scholar] [CrossRef]

- Krishna, R. Describing mixture permeation across polymeric membranes by a combination of Maxwell-Stefan and Flory-Huggins models. Polymers 2016, 103, 124–131. [Google Scholar] [CrossRef]

- Barrer, R.M. Nature of the diffusion process in rubber. Nature 1937, 140, 106–107. [Google Scholar] [CrossRef]

- Schweitzer, P.E. Corrosion-Resistant Linings and Coatings; Informa UK Limited: Colchester, UK, 2001. [Google Scholar]

- Hockin, A. Permeation of PE 100 Pipe Material. Available online: http://api.kwrwater.nl/uploads/2019/08/KWR-2019.043-Permeation-of-PE-100-pipe-material-(OPENBAAR).pdf (accessed on 11 May 2020).

- Hasegawa, Y.; Kusakabe, K.; Morooka, S. Effect of temperature on the gas permeation properties of NaY-type zeolite formed on the inner surface of a porous support tube. Chem. Eng. Sci. 2001, 56, 4273–4281. [Google Scholar] [CrossRef]

- Perez, E.V.; Balkus, K.J., Jr.; Ferraris, J.P.; Musselman, I.H. Instrument for gas permeation measurements at high pressure and high temperature. Rev. Sci. Instrum. 2013, 84, 065107. [Google Scholar] [CrossRef]

- McKeen, L.W. Permeability Properties of Plastics and Elastomers; Elsevier BV: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Felix-Henry, A. Method for Removal of Permeate Gases from a Flexible Tubular Pipe and Pipe Embodied for Carrying out the Same. U.S. Patent 8256469B2, 12 November 2012. [Google Scholar]

- Andersen, T.R.; Skar, J.I. Gas and Water Permeation in Flexible Pipes; ASME International: New York, NY, USA, 2002; pp. 7–14. [Google Scholar]

- Lefebvre, X.; Pasquier, D.; Gonzalez, S.; Epsztein, T.; Chirat, M.; Demanze, F. Development of Reactive Barrier Polymers against Corrosion for the Oil and Gas Industry: From Formulation to Qualification through the Development of Predictive Multiphysics Modeling. Oil Gas Sci. Technol. Rev. IFP 2015, 70, 291–303. [Google Scholar] [CrossRef] [Green Version]

- Kallio, K.; Hedenqvist, M. Effects of ethanol content and temperature on the permeation of fuel through polyamide-12-based pipes. Polym. Test. 2010, 29, 603–608. [Google Scholar] [CrossRef]

- De Lima, H.F.; Vaz, M.A.; Da Costa, M.F.; Gomez, A.A.; De Oliveira, G.L. Creep behavior of in-service flexible flowline polyamide 11. Polym. Test. 2020, 81, 106205. [Google Scholar] [CrossRef]

- Baron, J.J.; Macleod, L.C.; Szklarz, K.E. Non-Metallic Liners for Gas/Condensate Pipelines; NACE International: Houston, TX, USA, 2000. [Google Scholar]

- De Almeida, S.R.M. Solubility Measurements for Supercritical CO2 in Polymers for Offshore Applications. Master’s Thesis, University of Porto, Porto, Portugal, July 2012. [Google Scholar]

- Berger, J.; Franosch, J.; Schuett, C.; Dowe, A. The Aging of Offshore Polyamides under Services Conditions in Subsea Applications. OTC Brasil 2011. [Google Scholar] [CrossRef]

- Laurentino, D.A.; Silva, M.D.C.; Costa, C.A.; Pessoa, F.L.P.; Da Costa, M.F. Effect of Supercritical CO2 on PVDF. Ocean Renew. Energy 2014, 9A. [Google Scholar] [CrossRef]

- Wolodko, J.; Petersen, R.; Cor, R.; Taylor, J. Full Scale Testing of Grooved Polymer Liners for Downhole Applications; NACE International: Houston, TX, USA, 2004. [Google Scholar]

- Boyer, S.A.E.; Randzio, S.L.; Grolier, J.-P.E. Thermal expansion of polymers submitted to supercritical CO2 as a function of pressure. J. Polym. Sci. Part B Polym. Phys. 2005, 44, 185–194. [Google Scholar] [CrossRef]

- Boyer, S.A.; Grolier, J.-P.E. Simultaneous measurement of the concentration of a supercritical gas absorbed in a polymer and of the concomitant change in volume of the polymer. The coupled VW-pVT technique revisited. Polymers 2005, 46, 3737–3747. [Google Scholar] [CrossRef]

- Rubin, A.; Wang, C. Qualification of Flexible Dynamic Risers for Supercritical CO2; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2012. [Google Scholar]

- Fu, A.; Zhao, B.; Yuan, J.; Yin, C. Lab Research and Filed Experience of HDPE-Lined Tubing Used in Nitrogen Injection Well; NACE International: Houston, TX, USA, 2019. [Google Scholar]

- Bredács, M.; Frank, A.; Bastero, A.; Stolarz, A.; Pinter, G. Accelerated aging of polyethylene pipe grades in aqueous chlorine dioxide at constant concentration. Polym. Degrad. Stab. 2018, 157, 80–89. [Google Scholar] [CrossRef]

- Grabmann, M.K.; Wallner, G.; Grabmayer, K.; Nitsche, D.; Lang, R.W. Aging behavior and lifetime assessment of polyolefin liner materials for seasonal heat storage using micro-specimen. Sol. Energy 2018, 170, 988–990. [Google Scholar] [CrossRef]

- De Oliveira, G.L.; Costa, C.A.; Da Costa, M.F. Evaluation of Aged PVDF by Instrumented Indentation Technique; ASME International: New York, NY, USA, 2015. [Google Scholar]

- Torres, A.H.U.; D’Almeida, J.R.M.; Habas, J.-P. Aging of HDPE Pipes Exposed to Diesel Lubricant. Polym. Technol. Eng. 2011, 50, 1594–1599. [Google Scholar] [CrossRef] [Green Version]

- Ghabeche, W.; Chaoui, K.; Zeghib, N. Mechanical properties and surface roughness assessment of outer and inner HDPE pipe layers after exposure to toluene methanol mixture. Int. J. Adv. Manuf. Technol. 2019, 103, 2207–2225. [Google Scholar] [CrossRef]

- Grabmayer, K.; Wallner, G.; Beißmann, S.; Braun, U.; Steffen, R.; Nitsche, D.; Röder, B.; Buchberger, W.; Lang, R.W. Accelerated aging of polyethylene materials at high oxygen pressure characterized by photoluminescence spectroscopy and established aging characterization methods. Polym. Degrad. Stab. 2014, 109, 40–49. [Google Scholar] [CrossRef]

- Klopffer, M.-H.; Berne, P.; Castagnet, S.; Weber, M.; Hochstetter, G.; Espuche, E. Polymer Pipes for Distributing Mixtures of Hydrogen and Natural Gas: Evolution of Their Transport and Mechanical Properties After an Ageing Under an Hydrogen Environment. In Proceedings of the Fuel Infrastructures WHEC, Essen, Germany, 16–21 May 2010; p. 78-1. [Google Scholar]

- Force Technology. Flexible Pipe Polymer Monitoring With Coupons. Available online: http://www.kks.com.au/wp-content/uploads/2014/01/Force-Technology-Pipe-Monitoring-flexible-pipe-polymer-monitoring-with-coupons.pdf (accessed on 17 August 2020).

- Dahl, C.S.; Andersen, B.A.M.; Gronne, M. Developments in Managing Flexible Risers and Pipelines, A Suppliers Perspective; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2011. [Google Scholar]

- Siqueira, J.R.; Pedroso, C.A.; Bastos, F.; Alves, H.; Henriques, A.; Wardlaw, S. Atlanta Field: Operational Safety and Integrity Management; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2019. [Google Scholar]

- Kranbuehl, D.E. Method to Predict the Endpoint, Replacement Time and to Monitor Changes in that Time Using Pre Aged Witness Coupons. U.S. Patent 20050247103A1, 10 February 2009. [Google Scholar]

- Mason, J.F.; Stanley, M.; Ponda, A.; Demicoli, D. Case Study: Engineered Polyamide 12 (PA12) Pipeline Liner for Management of Sour Gas Corrosion at Elevated Temperatures; NACE International: Houston, TX, USA, 2017. [Google Scholar]

- Muren, J.; Caveny, K.; Eriksen, M.; Viko, N.G.; MÜLler-Allers, J.; JØRgen, K. Un-Bonded Flexible Risers-Recent Field Experience and Actions for Increased Robustness; 4subsea: Sutton, UK, 2013. [Google Scholar]

- Kranbuehl, D. Multi Point Method and Apparatus for Monitoring the Aging and Changes in Corresponding Tensile Performance Properties of a Polymer. International Patent Application PCT/US2014/040829, 20 February 2018. [Google Scholar]

- Deshmukh, K.; Sankaran, S.; Ahamed, B.; Sadasivuni, K.K.; Pasha, K.S.K.; Ponnamma, D.; Sreekanth, P.S.R.; Chidambaram, K. Dielectric spectroscopy, in Spectroscopic Methods for Nanomaterials Characterization. Micro Nano Technol. 2017, 237–299. [Google Scholar] [CrossRef]

- Hernández, M.; Grande, A.M.; Van Der Zwaag, S.; Garcia, S. Monitoring Network and Interfacial Healing Processes by Broadband Dielectric Spectroscopy: A Case Study on Natural Rubber. ACS Appl. Mater. Interfaces 2016, 8, 10647–10656. [Google Scholar] [CrossRef] [Green Version]

- Drakopoulos, S.X.; Psarras, G.; Forte, G.; Martin-Fabiani, I.; Ronca, S. Entanglement dynamics in ultra-high molecular weight polyethylene as revealed by dielectric spectroscopy. Polymers 2018, 150, 35–43. [Google Scholar] [CrossRef]

- Szklarz, K.E.; Baron, J.J. Learnings from Thermoplastic Liner Failures in Sour Gas Pipeline Service and Replacement Liner Design and Installation; NACE International: Houston, TX, USA, 2004. [Google Scholar]

- Krishnaswamy, R.K. Analysis of ductile and brittle failures from creep rupture testing of high-density polyethylene (HDPE) pipes. Polymers 2005, 46, 11664–11672. [Google Scholar] [CrossRef]

- Boyer, S.A.E.; Klopffer, M.-H.; Martin, J.; Grolier, J.-P.E. Supercritical gas–polymer interactions with applications in the petroleum industry. Determination of thermophysical properties. J. Appl. Polym. Sci. 2006, 103, 1706–1722. [Google Scholar] [CrossRef]

- Bozóki, Z.; Pap, G.; Szabó, G.; Domonkos, I.; Nagy, T. Oilfield Engineering with Polymers 2006. Seal. Technol. 2006, 2006, 7. [Google Scholar]

- Chaoui, K.; Khelif, R.; Zeghib, N.; Chateauneuf, A. Failure Analysis of Polyethylene Gas Pipes, in Safety, Reliability and Risks Associated with Water, Oil and Gas Pipelines; Springer: Berlin, Germany, 2008; pp. 131–163. [Google Scholar]

- Mertiny, P.; Juss, K. Effect of Fiber-Reinforcement Material on the Leakage Failure in Polymer Composite Pressure Piping. In Proceedings of the ASME 2008 Pressure Vessels and Piping Conference, Chicago, IL, USA, 27–31 July 2008; Volume 3, pp. 591–596. [Google Scholar]

- Pusz, A.; Michalik, K. Creep damage mechanisms in gas pipes made of high density polyethylene. Arch. Mater. Sci. Eng. 2009, 36, 89–95. [Google Scholar]

- Liu, Y.; Shao, X.; Han, X.; Zhuang, C.; He, X. Failure Types of FRP Pipe in Oil and Gas Engineering. ICPTT 2009 2009, 2084–2091. [Google Scholar] [CrossRef]

- Simon, L.; MacDonald, R.; Goerz, K.; Grigis, M. Corrosion Failure in a Lined Sour Gas Pipeline—Part 1: Case History of Incident. In Proceedings of the NACE NAWC, Regina, SK, Canada, 15–18 February 2010. [Google Scholar]

- Weon, J.-I. Effects of thermal ageing on mechanical and thermal behaviors of linear low density polyethylene pipe. Polym. Degrad. Stab. 2010, 95, 14–20. [Google Scholar] [CrossRef]

- Murariu, A.C.; Safta, V.I.; Mateiu, H.S. Long-term behaviour of polyethylene PE 80 pressurized pipes, in presence of longitudinal simulated imperfections. Mat. Plast. 2010, 47, 263–266. [Google Scholar]

- Grzyb, D.W. The Alberta Experience with Composite Pipes in Production Environments. In Proceedings of the 8th International Pipeline Conference, Calgari, AB, Canada, 27 September–1 October 2010; Volume 1, pp. 1–5. [Google Scholar]

- Gonzalez, M.; Machado, R.; González, J. Fatigue Analysis of PE-100 Pipe Under Axial Loading. In Proceedings of the ASME 2011 Pressure Vessels and Piping Conference, Baltimore, MA, USA, 17–21 July 2011; Volume 3, pp. 905–911. [Google Scholar]

- Qi, D.; Ding, N.; Cai, X.; Houbu, L.; Zhang, S.; Yan, M. Application and Qualification of Reinforced Thermoplastic Pipes in Chinese Oilfields. ICPTT 2011 2011, 267–275. [Google Scholar] [CrossRef]

- Li, H.; Yan, M.; Qi, D.; Ding, N.; Cai, X.; Zhang, S.; Li, Q.; Zhang, X.; Deng, J. Failure analysis of steel wire reinforced thermoplastics composite pipe. Eng. Fail. Anal. 2012, 20, 88–96. [Google Scholar] [CrossRef]

- Khan, Z. Fracture Surface Analysis in HDPE Pipe Material Fatigued at Different Temperatures and Loading Frequencies. J. Mater. Eng. Perform. 2011, 21, 1468–1473. [Google Scholar] [CrossRef]

- Brown, N.; Crate, J.M. Analysis of a Failure in a Polyethylene Gas Pipe Caused by Squeeze off Resulting in an Explosion. J. Fail. Anal. Prev. 2011, 12, 30–36. [Google Scholar] [CrossRef]

- Rueda, F.; Otegui, J.L.; Frontini, P. Numerical tool to model collapse of polymeric liners in pipelines. Eng. Fail. Anal. 2012, 20, 25–34. [Google Scholar] [CrossRef]

- Qi, D.; Houbu, L.; Cai, X.; Ding, N.; Zhang, S. Application of Non-Metallic Composite Pipes in Oilfields in China. ICPTT 2013 2012, 283–291. [Google Scholar] [CrossRef]

- Hutař, P.; Ševčík, M.; Frank, A.; Náhlík, L.; Kučera, J.; Pinter, G. The effect of residual stress on polymer pipe lifetime. Eng. Fract. Mech. 2013, 108, 98–108. [Google Scholar] [CrossRef]

- Taheri, F. Advanced fiber-reinforced polymer (FRP) composites for the manufacture and rehabilitation of pipes and tanks in the oil and gas industry. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier BV: Amsterdam, The Netherlands, 2013; pp. 662–704. [Google Scholar]

- Hutař, P.; Zouhar, M.; Náhlík, L.; Ševčík, M.; Máša, B. Multilayer polymer pipes failure assessment based on a fracture mechanics approach. Eng. Fail. Anal. 2013, 33, 151–162. [Google Scholar] [CrossRef]

- Adib, A.; Dominguez, C.; García, R.A.; Garrido, M.; Rodriguez, J. Influence of specimen geometry on the slow crack growth testing of HDPE for pipe applications. Polym. Test. 2015, 48, 104–110. [Google Scholar] [CrossRef]

- Le Gac, P.-Y.; Davies, P.; Choqueuse, D. Evaluation of Long Term Behaviour of Polymers for Offshore Oil and Gas Applications. Oil Gas Sci. Technol. Rev. IFP 2014, 70, 279–289. [Google Scholar] [CrossRef] [Green Version]

- Rueda, F.; Marquez, A.; Otegui, J.L.; Frontini, P. Buckling collapse of HDPE liners: Experimental set-up and FEM simulations. Thin Walled Struct. 2016, 109, 103–112. [Google Scholar] [CrossRef]

- Naebe, M.; Abolhasani, M.M.; Khayyam, H.; Amini, A.; Fox, B.L. Crack Damage in Polymers and Composites: A Review. Polym. Rev. 2016, 56, 31–69. [Google Scholar] [CrossRef]

- Majid, F.; Elghorba, M. HDPE pipes failure analysis and damage modeling. Eng. Fail. Anal. 2017, 71, 157–165. [Google Scholar] [CrossRef]

- Reis, J.; Martins, F.; Da Costa-Mattos, H.S. Influence of ageing in the failure pressure of a GFRP pipe used in oil industry. Eng. Fail. Anal. 2017, 71, 120–130. [Google Scholar] [CrossRef]

- Capiel, G.; Fayó, P.; Orofino, A.; Montemartini, P.E. Failure of glass fiber-reinforced epoxy pipes in oil fields. In Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry; Elsevier BV: Amsterdam, The Netherlands, 2016; pp. 91–103. [Google Scholar]

- Abdellah, M.Y.; Hassan, M.K.; Alsoufi, M.S. Fracture and Mechanical Characteristics Degradation of Glass Fiber Reinforced Petroleum epoxy Pipes. J. Manuf. Sci. Prod. 2016, 16, 33–40. [Google Scholar] [CrossRef]

- Benyahia, H.; Tarfaoui, M.; El Moumen, A.; Ouinas, D.; Hassoon, O. Mechanical properties of offshoring polymer composite pipes at various temperatures. Compos. Part B Eng. 2018, 152, 231–240. [Google Scholar] [CrossRef]

- Patil, M.J.S.; Ingale, S. Study of multilayered composite pipe subjected with metal interlayer. Int. Res. J. Eng. Technol. 2018, 5, 1465–1467. [Google Scholar]

- Hocker, S.J.; Kim, W.T.; Schniepp, H.C.; Kranbuehl, D. Polymer crystallinity and the ductile to brittle transition. Polymers 2018, 158, 72–76. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B.; Pietrucha-Urbanik, K.; Urbanik, M.; Rak, J. Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study. Energies 2018, 11, 1589. [Google Scholar] [CrossRef] [Green Version]

- Amabipi, A.K.; Salem, M.H.; Grandhe, S.P.; Gupta, T.K.; Awadh, M.A.; Herbig, N.; Schell, J.; Compton, T. Innovative Field Trial Results of Flangeless Grooved HDPE Liner Application in a Super Gigantic Field for Oil Flow Line Internal Corrosion Management; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2018. [Google Scholar]

- Chen, G.; Yan, D.; Zhou, C. Failure Analysis of Buried Polyethylene Pipe Subjected to Combined Loading of Non-uniform Settlement and Landslide Based on FEM. J. Fail. Anal. Prev. 2018, 18, 1278–1285. [Google Scholar] [CrossRef]

- Radermacher, L.; Borş, A.-M.; Lingvay, D.; Voina, A.; Marin, D. Sustainable and Safe in Exploitation of Gas Networks. Part 1. Stress Factors of Plastic Pipelines. Electroteh. Electron. Autom. 2018, 66, 66–72. [Google Scholar]

- Chen, G.; Yang, Y.; Zhou, C.; Zhou, Z.; Yan, D. Thermal-oxidative aging performance and life prediction of polyethylene pipe under cyclic and constant internal pressure. J. Appl. Polym. Sci. 2019, 136, 47766. [Google Scholar] [CrossRef]

- Guoquan, Q.; Yan, H.; Dongtao, Q.; Bin, W.; Houbu, L. Analysis of cracks in polyvinylidene fluoride lined reinforced thermoplastic pipe used in acidic gas fields. Eng. Fail. Anal. 2019, 99, 26–33. [Google Scholar] [CrossRef]

- Pavankumar, A.P.; Channakeshava, K.R.; Rangaswamy, T. Development of Carbon Fiber Based Structural Health Monitoring System for Glass Fiber Reinforced Polymer Composite Conduits. Int. J. Res. Eng. Sci. Manag. 2020, 3, 598–601. [Google Scholar]

- Tamai, H.; Jinkawa, S.; Sonoda, Y. Damage evaluation and protection method of resin pipe for gas conduit subjected to impact load. Int. J. Prot. Struct. 2020, 2041419620902791. [Google Scholar] [CrossRef]

- Hamilton, C.J.; Savidis, J.C. Characterization of Thermoplastic Liners for Steel Pipes; Society of Underwater Technology: London, UK, 1996. [Google Scholar]

- Flaconneche, B.; Martin, J.; Klopffer, M.H. Permeability, Diffusion and Solubility of Gases in Polyethylene, Polyamide 11 and Poly (Vinylidene Fluoride). Oil Gas Sci. Technol. Rev. IFP 2001, 56, 261–278. [Google Scholar] [CrossRef] [Green Version]

- Siegmund, G.; Schmitt, G.; Sadlowsky, B.; Noga, J. Lining Pipelines with PE-A Solution for Wet Gas Transport? NACE International: Houston, TX, USA, 2002. [Google Scholar]

- Klopffer, M.H.; Flaconneche, B.; Odru, P. Transport properties of gas mixtures through polyethylene. Plast. Rubber Compos. 2007, 36, 184–189. [Google Scholar] [CrossRef]

- Chollet, C.; Do, A.T. Qualification of New Polyamide for Flexible Flowlines and Risers at Elevated Pressure and Temperature; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2013. [Google Scholar]

- Klopffer, M.-H.; Berne, P.; Espuche, E. Development of Innovating Materials for Distributing Mixtures of Hydrogen and Natural Gas. Study of the Barrier Properties and Durability of Polymer Pipes. Oil Gas Sci. Technol. Rev. IFP 2014, 70, 305–315. [Google Scholar] [CrossRef] [Green Version]

- Menon, N.C.; Kruizenga, A.M.; Alvine, K.J.; Marchi, C.S.; Nissen, A.; Brooks, K. Behaviour of Polymers in High Pressure Environments as Applicable to the Hydrogen Infrastructure. In Proceedings of the ASME 2016 Pressure Vessels and Piping Conference, Vancouver, BC, Canada, 17–21 July 2016. [Google Scholar]

- Craster, B.; Jones, T.G. Permeation of a Range of Species through Polymer Layers under Varying Conditions of Temperature and Pressure: In Situ Measurement Methods. Polymers 2019, 11, 1056. [Google Scholar] [CrossRef] [Green Version]

- Moon, S.I.; Caulfield, M.; Extrand, C.W. Measuring Hydrochloric Acid and Ammonium Hydroxide Permeation in Bulk Chemical Distribution; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2012; pp. 181–186. [Google Scholar]

- Jacobson, K.; Bergman, G.; Hedenqvist, M. Diffusion and Permeation of Hydrobromic and Hydrochloric Acids in PVDF and ECTFE at Different Temperatures and Concentrations; NACE International: Houston, TX, USA, 2004. [Google Scholar]

- Kallio, K.; Hedenqvist, M. Ageing properties of polyamide-12 pipes exposed to fuels with and without ethanol. Polym. Degrad. Stab. 2008, 93, 1846–1854. [Google Scholar] [CrossRef]

- Weltschev, M.; Haufe, M.; Kohl, A.; Rehfeldt, R. Resistance of Polyethylene Grades with Permeation Barriers in Biofuels; NACE International: Huston, TX, USA, 2018. [Google Scholar]

- Durbin, T.D.; Karavalakis, G.; Norbeck, J.M.; Park, C.S.; Castillo, J.; Rheem, Y.; Bumiller, K.; Yang, J.; Van, V.; Hunter, K. Material compatibility evaluation for elastomers, plastics, and metals exposed to ethanol and butanol blends. Fuel 2016, 163, 248–259. [Google Scholar] [CrossRef] [Green Version]

- Jiangfang, Z.; Xuehong, C. Compatibility study of high-density polyethylene with ethanol–gasoline and biodiesel. J. Elastomers Plast. 2019, 0095244319891206. [Google Scholar] [CrossRef]

- Zakaria, N.; Merican, Z.; Hamza, M.F. Performance and Critical Issues of Polymer Liners in Pipeline Industry: A review. Mater. Today: Proc. 2019, 16, 2389–2397. [Google Scholar] [CrossRef]

- Venkateswaran, S.P.; Pardey, R.; Thomson, B.; Mirza, S. Expanded Service Temperature of Polymer Liners for Water Injection Pipelines; NACE International: Houston, TX, USA, 2019. [Google Scholar]

- Jaeger, P.; Buchner, S.; Eggers, R. Sorption Kinetics of High Pressure Gases in Polymeric Tubing Materials. Volume 3: Safety and Reliability; Materials Technology. In Proceedings of the 25th International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 July 2006; pp. 581–584. [Google Scholar]

- Sarrasin, F.; Memari, P.; Klopffer, M.; Lachet, V.; Condat, C.T.; Rousseau, B.; Espuche, E. Influence of high pressures on CH4, CO2 and H2S solubility in polyethylene: Experimental and molecular simulation approaches for pure gas and gas mixtures. Modelling of the sorption isotherms. J. Membr. Sci. 2015, 490, 380–388. [Google Scholar] [CrossRef]

- Chirat, M.; Epsztein, T.; Lefebvre, X.; Le Minter, P. Anti-HS Layer for Flexible Pipe: Full Scale Flowline Qualification Tests; Society of Petroleum Engineers (SPE): Dallas, TX, USA, 2015. [Google Scholar]

- Jorge, F.; Dowe, A.; Baron, C. PA12 for Offshore Flexible Pipes and High Pressure Gas Pipes, PPS-23, Salvador. In Proceedings of the 2008 Rio Oil & Gas Expo and Conference, Rio de Janeiro, Brazil, 15–18 September 2008. [Google Scholar]

- Poveda, G.I.D.; Rosales, M.M.V.; Rojas, M.M.; Barragán, M.M. Evaluation and implementation of High Density Polyethylene liner: Alternative of solution to corrosion-wear problems in flowlines. CTF Ciencia Tecnol. Futuro 2019, 9, 65–72. [Google Scholar] [CrossRef]

- Ahart, M.; Gallagher, D.L.; Scardina, P.; Dietrich, A.M. Industrial Spills and Water Distribution: Crude MCHM Sorption and Desorption in Polymer Pipes and Linings. J. Environ. Eng. 2016, 142, 04016045. [Google Scholar] [CrossRef]

- Ritums, J.E.; Mattozzi, A.; Gedde, U.W.; Hedenqvist, M.S.; Bergman, G.; Palmlöf, M. Mechanical properties of high-density polyethylene and crosslinked high-density polyethylene in crude oil and its components. J. Polym. Sci. Part B Polym. Phys. 2005, 44, 641–648. [Google Scholar] [CrossRef]

| Preventive Measures | Selection | Remarks |

|---|---|---|

| Material Selection |

|

|

| Chemical treatment |

|

|

| Coatings |

|

|

| Process Control |

|

|

| Material | Properties |

|---|---|

| HDPE |

|

| PA |

|

| PVDF |

|

| GRE |

|

| FRP (GRP) |

|

| RTP |

|

| Research Article | Materials | Parameters | Time Interval | Characterization Techniques |

|---|---|---|---|---|

| Fu, et al. [90] | HDPE | CO2, H2S, O2 and TH 4XX formation water, 80, 110 and 140 °C 10MPa | 562 days & 30 days | Tensile test |

| Bredács, et al. [91] | PE (2 grades) | ClO2 Immersion, 60 °C 1 ppm 5 & 10 ppm | One Week | SEM, Tensile test, FTIR, Dynamic Oxidation Test |

| Grabmann, et al. [92] | PE-RT PP-R | Hot Air & De-ionized water 115 °C, 50 °C, 95 °C & 135 °C, 115 °C, 95 °C | 77 to 1372 days | Tensile Test, DSC |

| de Oliveira, et al. [93] | PVDF | Crude Oil 80 °C 1 atm | 30, 120, 320 days | Instrument Indentation Technique |

| Torres, et al. [94] | HDPE | Diesel 20 °C & 50 °C | 150 days | Thermogravimetric & FTIR |

| Romão, et al. [57] | PA11 (plasticized) | Deionized water, Oilfield water 110, 120 & 140 °C | 30 & 50 days | DSC, SEM, XRD |

| Ghabeche, et al. [95] | HDPE | Toluene-methanol Ambient | 7 & 1290 days | DSC, tensile test |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalid, H.U.; Ismail, M.C.; Nosbi, N. Permeation Damage of Polymer Liner in Oil and Gas Pipelines: A Review. Polymers 2020, 12, 2307. https://doi.org/10.3390/polym12102307

Khalid HU, Ismail MC, Nosbi N. Permeation Damage of Polymer Liner in Oil and Gas Pipelines: A Review. Polymers. 2020; 12(10):2307. https://doi.org/10.3390/polym12102307

Chicago/Turabian StyleKhalid, Hafiz Usman, Mokhtar Che Ismail, and Norlin Nosbi. 2020. "Permeation Damage of Polymer Liner in Oil and Gas Pipelines: A Review" Polymers 12, no. 10: 2307. https://doi.org/10.3390/polym12102307

APA StyleKhalid, H. U., Ismail, M. C., & Nosbi, N. (2020). Permeation Damage of Polymer Liner in Oil and Gas Pipelines: A Review. Polymers, 12(10), 2307. https://doi.org/10.3390/polym12102307